Traulsen KROGER RBC200 User manual

Project Quantity Item #

Model Specified: CSI Section 11400

SECTION

6-3

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

Listed by Underwriters Laboratories Inc.

and CSA certified by Underwriters

Laboratories Inc. and classified by

Underwriters Laboratories in accor-

dance with ANSI/NSF7.

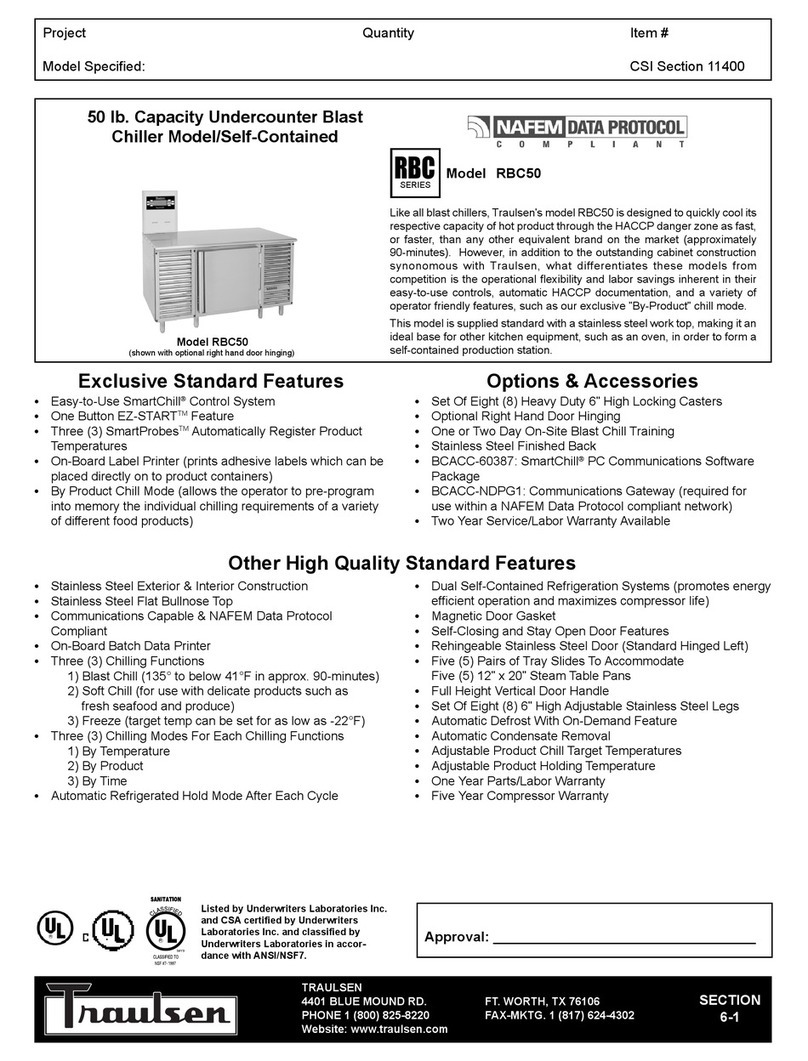

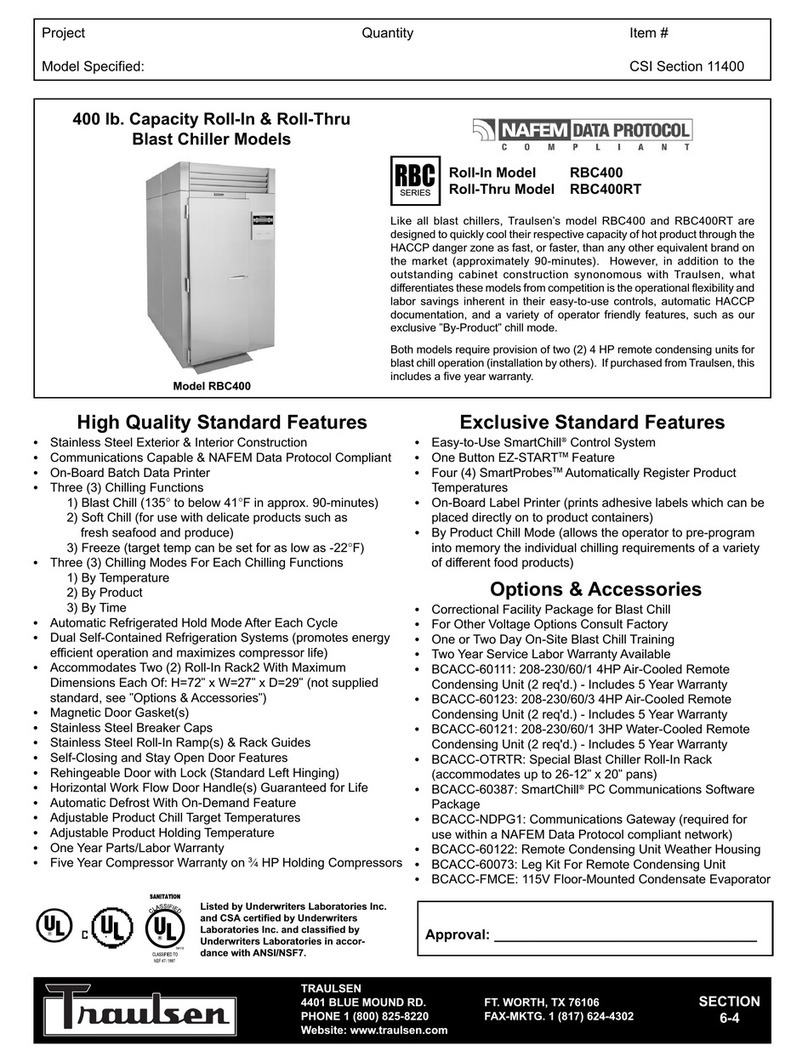

200 lb. Capacity Roll-In & Roll-Thru

Blast Chiller Models

Model RBC200

(shown with optional roll-in rack)

Approval: __________________________________

R

RBC

SERIES

Roll-In Model RBC200

Roll-Thru Model RBC200RT

Like all blast chillers, Traulsen's model RBC200 and RBC200RT are

designed to quickly cool their respective capacity of hot product through the

HACCP danger zone as fast, or faster, than any other equivalent brand on

the market (approximately 90-minutes). However, in addition to the

outstanding cabinet construction synonomous with Traulsen, what

differentiates these models from competition is the operational flexibility and

labor savings inherent in their easy-to-use controls, automatic HACCP

documentation, and a variety of operator friendly features, such as our

exclusive "By-Product"chill mode.

Both models require provision of one (1) 4 HP remote condensing unit for

blast chill operation (installation by others). If purchased from Traulsen, this

includes a five year warranty.

Model RBC200RT

Exclusive Standard Features

•Easy-to-Use SmartChill®Control System

•One Button EZ-STARTTM Feature

•Three (3) SmartProbesTM Automatically Register Product

Temperatures

•On-Board Label Printer (prints adhesive labels which can be

placed right directly on to product containers)

•By Product Chill Mode (allows the operator to pre-program

into memory the individual chilling requirements of a variety

of different food products)

Options & Accessories

•Correctional Facility Package for Blast Chill

•For Other Voltage Options Consult Factory

•One or Two Day On-Site Blast Chill Training

•Two Year Service Labor Warranty Available

•BCACC-60111: 208-230/60/1 4HP Air-Cooled Remote

Condensing Unit - Includes 5 Year Warranty

•BCACC-60123: 208-230/60/3 4HP Air-Cooled Remote

Condensing Unit - Includes 5 Year Warranty

•BCACC-60121: 208-230/60/1 3HP Water-Cooled Remote

Condensing Unit - Includes 5 Year Warranty

•BCACC-OTRTR: Special Blast Chiller Roll-In Rack

(accommodates up to 26-12"x 20"pans)

•BCACC-60387: SmartChill®PC Communications Software

Package

•BCACC-NDPG1: Communications Gateway (required for

use within a NAFEM Data Protocol compliant network)

•BCACC-60122: Remote Condensing Unit Weather Housing

•BCACC-60073: Leg Kit For Remote Condensing Unit

•BCACC-FMCE: 115V Floor-Mounted Condensate Evaporator

•Modification For Use With Hobart CE20 Combi Oven Racks

(for use with other brands please contact factory)

High Quality Standard Features

•Stainless Steel Exterior & Interior Construction

•Communications Capable & NAFEM Data Protocol Compliant

•On-Board Batch Data Printer

•Three (3) Chilling Functions

1) Blast Chill (135°to below 41°F in approx. 90-minutes)

2) Soft Chill (for use with delicate products such as

fresh seafood and produce)

3) Freeze (target temp can be set for as low as -22°F)

•Three (3) Chilling Modes For Each Chilling Functions

1) By Temperature

2) By Product

3) By Time

•Automatic Refrigerated Hold Mode After Each Cycle

•Dual Self-Contained Refrigeration Systems (promotes energy

efficient operation and maximizes compressor life)

•Accommodates One (1) Roll-In Rack With Maximum

Dimensions Of: H=72"x W=27"x D=29" (not supplied

standard, see "Options & Accessories")

•Magnetic Door Gasket(s)

•Stainless Steel Breaker Caps

•Stainless Steel Roll-In Ramp(s) & Rack Guides

•Self-Closing and Stay Open Door Features

•Rehingeable Door with Lock (Standard Left Hinging)

•Horizontal Work Flow Door Handle(s) Guaranteed for Life

•Automatic Defrost With On-Demand Feature

•Adjustable Product Chill Target Temperatures

•Adjustable Product Holding Temperature

•One Year Parts/Labor Warranty

•Five Year Compressor Warranty on 3⁄4HP Holding Compressor

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

SECTION

6-3

SECTION

6-3

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

Project Quantity Item #

Model Specified: CSI Section 11400

TRAULSEN

4401 BLUE MOUND RD. FT. WORTH, TX 76106

PHONE 1 (800) 825-8220 FAX-MKTG. 1 (817) 624-4302

Website: www.traulsen.com

SECTION

6-3

Construction, Hardware and Insulation

Exterior sides, front, rear, door and interior are constructed of heavy gauge

stainless steel. The exterior top and bottom are constructed of heavy gauge

galvanized steel. The interior floor is constructed of stainless steel and insulated with

3⁄4"of resilient cork. Door(s) are equipped with guaranteed for life cam lift hinges with

stay open feature at 120°. Guaranteed for life, work flow handle is mounted

horizontally over recess in door which limits protrusion from door face into aisle ways.

Door is standard with cylinder lock. Easily removable for cleaning, vinyl magnetic

gasket assures tight door seal. Anti- condensate heater is located behind door

opening. Door is hinged left as supplied standard. Both cabinet and door are

insulated with high density, non-CFC foamed in place polyurethane.

Refrigeration System

Dual refrigeration systems are utilized in order to prevent short cycling, providing for

energy efficient operation and maximizing compressor life. These combine their

efforts through a unique air circulation system within the food zone. During Blast

Chill cycles both systems are in full operation. At the completion of any chill or freeze

cycle, one refrigeration system remains in use to maintain proper refrigerated

storage temperatures. Each unit requires a separate 4 HP remote condensing unit

for blast chill operation, and a floor drain or optional condensate evaporator for

condensate removal.

Blast Chill Operation

In Blast Chill mode both refrigeration systems, as well as four blowers are in

operation. Cabinet air temperature can be as low as 0°F. The control closely

monitors both the air and product temperatures to assure rapid chilling without

freezing. The operator is notified upon completion of each chill cycle, and the unit

automatically begins to maintain proper refrigerated storage temperatures. All chill

cycle data is then stored in memory and can either be printed or downloaded to a PC

on demand.

Controller

The SmartChill®microprocessor system operates using a familiar "ATM"type

interface, providing for ease of training and use. The control allows the chiller to be

operated in any one of three different chilling functions, and in any one of three

modes. HACCP documentation is facilitated by two on-board printers which record

all required product chill cycle information. This same data can also be downloaded

to a PC using optional SmartChill®communications software (available from Traulsen)

or via optional NAFEM Data Protocol Compliant hardware and software (by others).

An instructional DVD is included.

Roll-In Racks

Readily removable, interior mounted stainless steel guides for rack are provided.

Maximum rack size with wheels inboard of frame is 27"wide by 29"deep by 72"high.

Racks are typically supplied by others, however these may be purchased directly

from Traulsen as an option.

Warranties

The standard warranty is a one year parts and labor warranty on all components and

the cabinet, and an additional four year parts only warranty on the 3⁄4HP maintenance

compressor. Additional warranties are available at extra cost.

An on-site service validation is provided by an authorized agent at no-charge upon

installation in order to insure proper operation.

Specifications

Continued product development may necessitate specification changes without notice.

Part No. TR35799 (revised 1/07)

RBC200 RBC200RT

DIMENSIONAL DATA Roll-In Roll-Thru

Net Capacity cu. ft. 35 (990.5 l) 35 (990.5 l)

Number of Pans 12"x 20"x 2

1

⁄

2

"26 26

# of Pans Depends Upon Rack Purchased

Rack Capacity (see "Roll-In Racks")1 1

Length Overall in. 48

1

⁄

2

(123.2 cm) 48

1

⁄

2

(123.2 cm)

Depth - Cabinet Only in. / Over Body in. 34 (86.4 cm) 34 (86.4 cm)

Depth - with Door Open 90°in. 65

1

⁄

8

(165.4 cm) 96

1

⁄

4

(244.5 cm)

Depth - Overall in. 37

1

⁄

2

(95.3 cm) 41

1

⁄

8

(104.5 cm)

Clear Door Width in. 27

1

⁄

4

(69.2 cm) 27

1

⁄

4

(69.2 cm)

Clear Door Height in. 72

5

⁄

8

(184.5 cm) 72

5

⁄

8

(184.5 cm)

Height - Overall in. 89

1

⁄

2

(227.3 cm) 89

1

⁄

2

(227.3 cm)

ELECTRICAL DATA

Voltage 115/60/1 115/60/1

Feed Wires with Ground 3 3

Full Load Amperes 15.2 15.2

Minimum Circuit Ampacity 20 20

Wattage 1725 1725

REFRIGERATION DATA Holding System Only

Refrigerant R404a R404a

BTU/HR - HP -

3

⁄

4

HP Holding Compressor 3880 3880

Heat Load - BTU/HR 7000 7000

Suction Line in.

3

⁄

8

(.95 cm)

3

⁄

8

(.95 cm)

Liquid Line in.

1

⁄

4

(.63 cm)

1

⁄

4

(.63 cm)

REMOTE CONDENSER

(Note: all models require a remote condenser unit. For additional

technical support on optional remote condenser units consult factory.

REFRIGERATION DATA RBC200 RBC200RT

Refrigerant R404a R404a

Voltage 208-230/60/1 208-230/60/1

Recommended BTU/HR - HP 18,700 - 4 HP 18,700 - 4 HP

BTU’s are rated at 90°F ambient and a -10°F evaporator temp.

Suction Line in.

7

⁄

8

(2.2 cm)

7

⁄

8

(2.2 cm)

Ref. Lines at Blast Chill Unit

Liquid Line in.

1

⁄

2

(1.3 cm)

1

⁄

2

(1.3 cm)

Ref. Lines at Blast Chill Unit

Suction Line in. 1

1

⁄

8

(2.9 cm) 1

1

⁄

8

(2.9 cm)

Ref. Line on Remote Condenser

Liquid Line in.

1

⁄

2

(1.3 cm)

1

⁄

2

(1.3 cm)

Ref. Line on Remote Condenser

NOTE

Figures in parentheses reflect metric equivalents

Equipped With One NEMA 5-20 P Plug

NOTE: Full load amps and plug style may vary depending

on electrical options chosen and condensing unit employed.

*REMOTE COMPRESSOR NOTES:

1 - See spec sheet 6-5 for remote compressor specifications.

2 - Remote compressor installation required by others. Traulsen provides an

service agent validation upon completion of remote system installation at no-

charge (call 800-825-8220 in order to arrange this).

3 - Remote compressor includes a five year warranty if purchased from Traulsen.

Other manuals for KROGER RBC200

1

This manual suits for next models

1

Table of contents

Other Traulsen Chiller manuals

Traulsen

Traulsen TBC5 Setup guide

Traulsen

Traulsen KROGER RBC100 User manual

Traulsen

Traulsen KROGER RBC50 User manual

Traulsen

Traulsen RBC400 User manual

Traulsen

Traulsen KROGER RBC100 Setup guide

Traulsen

Traulsen KROGER RBC100 User manual

Traulsen

Traulsen TBC5 User manual

Traulsen

Traulsen TBC13 User manual

Popular Chiller manuals by other brands

Carrier

Carrier HERMETIC CENTRIFUGAL LIQUID CHILLERS 19XR installation instructions

AERMEC

AERMEC WRL 200 Installation & maintenance manual

Nordcap

Nordcap 433000006 user manual

Carrier

Carrier 17 Start up & operation manual

Accorroni

Accorroni ACFR MICRO E 25H manual

Parker Hiross

Parker Hiross Hyperchill HLS076 user manual