TRAXX BG5 User manual

Unit 4/1 Rocklea Drive

Port Melbourne Vic 3207

1300 109 108

www.traxxcp.com.au

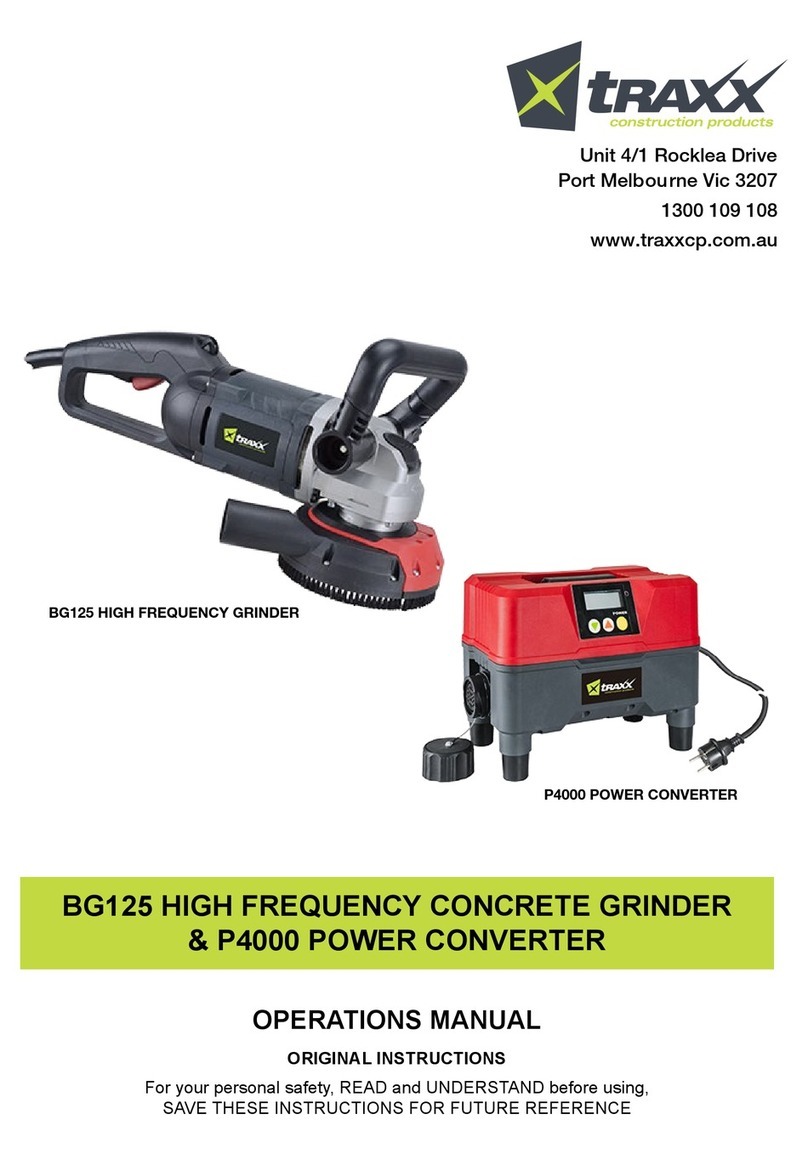

BG5 HIGH FREQUENCY CONCRETE GRINDER

& P4000 POWER CONVERTER

OPERATIONS MANUAL

ORIGINAL INSTRUCTIONS

For your personal safety, READ and UNDERSTAND before using,

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

BG5 HIGH FREQUENCY GRINDER

P4000 POWER CONVERTER

2

1. Motor

2. Load Warning Lamp

3. Trigger Switch

4. Handles

5. Lugs (for Trolley)

6. Dust Port

7. Skirt

8. Tab

9. Half-Moon Door

10. Coupling Cable

11. Motor Coupling Socket

12. Handle

13. Screen

14. Power Button

15. Selection Buttons

16. Power Supply Cable

1.

Concrete Grinder:

Power Converter:

Model Concrete Grinder

Power Input 3~ 2200W

No Load/min

-1

3850 - 5800

Wheel Diameter 125mm (5")

Arbor 22.23mm (7/8") & 25.4 (1") (Double-Sided)

Spindle M14 or 5/8-11 ( Specify when ordering)

Ingress Protection IP55

Dimensions (LxWxH) 235mm x 290mm x 235mm

Weight 5.1kg (11.3 Lbs)

Model Power Converter

Voltage 100V - 240V ~ 50-60Hz

Max. Power Input 1~ 4500W

Max. Power Output 3~ 4000W

Ingress Protection IP55

Weight 3.1kg (6.9 Lbs)

2.

3.

5.

6. 7.

4.

10.

11.

12.

16.

15.

13.

14.

9.

8.

3

General Safety Rules

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

d. Never leave the electric power tool unattended. Only leave the machine when the tool in use has come

to a complete standstill.

2. ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter

plugs with earthed (grounded) power tools. Unmodi ed plugs and matching outlets will reduce risk of

electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk

of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk

of electric shock.

e. When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

f. If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

3. PERSONAL SAFETY

a. Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the in uence of drugs, alcohol or medication. A

4

moment of inattention while operating power tools may result in serious personal injury.

b. Use personal protective equipment. Always wear eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce

personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the o-position before connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your nger on

the switch or energising power tools that have the switch on invites accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better control of the

power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g. If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dustrelated hazards.

h. Do not let familiarity gained from freuquent use of tools allow you to become complacent and

ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

4. POWER TOOL USE AND CARE

a. Do not force the power tool. Use the correct power tool for your application. The correct power tool

will do the job better and safer at the rate for which it was designed.

b. Do not use the power tool if the switch does not turn it on and o. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c. Disconnect the plug from the power source and/or battery pack from the power tool before making

any adjustments, changing accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of

untrained users.

e. Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may aect the power tool‘s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

g. Use the power tool, accessories and tool bits etc. in accordance with these instructions taking into

account the working conditions and the work to be performed. Use of the power tool for operations

dierent from those intended could result in a hazardous situation.

h. Keep handles and grasping surfaces dry, clean and free of oil and grease. Slippery handles do not

allow for safe handling and control of the tool in unexpected situations.

5

5. SERVICE

a. Have your power tool serviced by a quali ed repair person using only identical replacement parts.

This will ensure that the safety of the power tool is maintained.

b. Only use original Festool parts for repair and maintenance. The use of incompatible accessories or

spare parts can result in electric shocks or other injuries.

Safety Warnings for Concrete Grinders

Safety Warnings Common for Grinding

• This power tool is intended to function as a grinder. Read all safety warnings, instructions,

illustrations and specications provided with this power tool. Failure to follow all instructions listed

below may result in electric shock, re and/or serious injury.

• Operations such as sanding, wire brushing, polishing or cutting-o are not recommended to be

performed with this power tool. Operations for which the power tool was not designed may create a

hazard and cause personal injury.

• Do not use accessories which are not specifically designed and recommended by the tool

manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe

operation.

• The rated speed of the accessory must be at least equal to the maximum speed marked on the

power tool. Accessories running faster than their rated speed can break and y apart.

• The outside diameter and the thickness of your accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories cannot be adequately guarded or controlled.

• Threaded mounting of accessories must match the grinder spindle thread. For accessories mounted

by anges, the arbour hole of the accessory must t the locating diameter of the ange. Accessories

that do not match the mounting hardware of the power tool will run out of balance, vibrate excessively

Symbols used in this manual

V…….........volts

A…….........amperes

Hz…….......hertz

W……........watt

~………....alternating current

n

………...rated speed

min-1….......revolutions or reciprocation

per minute

.........warning of general danger

.…..class II tool

.......read these instructions

......always wear eye protection

......always wear a dust mask.

.....always wear hearing protection

.....wear safety-approved hard hat

do not dispose of electric tools,

accessories and packaging together

with household waste material

6

and may cause loss of control.

• Do not use a damaged accessory. Before each use inspect the accessory such as abrasive wheels for

chips and cracks, backing pad for cracks, tear or excess wear, wire brush for loose or cracked wires.

If power tool or accessory is dropped, inspect for damage or install an undamaged accessory. After

inspecting and installing an accessory, position yourself and bystanders away from the plane of

the rotating accessory and run the power tool at maximum no-load speed for one minute. Damaged

accessories will normally break apart during this test time.

• Wear personal protective equipment. Depending on application, use face shield, safety goggles

or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of

stopping ying debris generated by various operations. The dust mask or respirator must be capable of

ltrating particles generated by your operation. Prolonged exposure to high intensity noise may cause

hearing loss.

• Keep bystanders a safe distance away from work area. Anyone entering the work area must wear

personal protective equipment. Fragments of workpiece or of a broken accessory may y away and

cause injury beyond immediate area of operation.

• Hold the power tool by insulated gripping surfaces only, when performing an operation where the

cutting accessory may contact hidden wiring or its own cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live” and could give the operator an electric shock.

• Position the cord clear of the spinning accessory. If you lose control, the cord may be cut or snagged

and your hand or arm may be pulled into the spinning wheel.

• Never lay the power tool down until the accessory has come to a complete stop. The spinning wheel

may grab the surface and pull the power tool out of your control.

• Do not run the power tool while carrying it at your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the accessory into your body.

• Regularly clean the power tool’s air vents. The motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may cause electrical hazards.

• Do not operate the power tool near ammable materials. Sparks could ignite these materials.

• Do not use accessories that require liquid coolants. Using water or other liquid coolants may result in

electrocution or shock.

Kickback and related warnings

• Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad, brush or any other

accessory. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction opposite of the accessory’s rotation at the point

of the binding. For example, if an abrasive wheel is snagged or pinched by the workpiece, the edge of

the wheel that is entering into the pinch point can dig into the surface of the material causing the wheel

to climb out or kick out. The wheel may either jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of pinching. Abrasive wheels may also break under

these conditions. Kickback is the result of power tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below.

• Maintain a firm grip on the power tool and position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if provided, for maximum control over kickback or

torque reaction during start-up. The operator can control torque reactions or kickback forces, if proper

precautions are taken.

7

• Never place your hand near the rotating accessory. Accessory may kickback over your hand.

• Do not position your body in the area where power tool will move if kickback occurs. Kickback will

propel the tool in direction opposite to the wheel’s movement at the point of snagging.

• Use special care when working corners, sharp edges, etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have a tendency to snag the rotating accessory and cause

loss of control or kickback.

• Do not attach a saw chain woodcarving blade or toothed saw blade. Such blades create frequent

kickback and loss of control.

Additional safety instructions for grinding

• Use only wheel types that are recommended for your power tool and the specic guard designed

for the selected wheel. Wheels for which the power tool was not designed cannot be adequately

guarded and are unsafe.

• The grinding surface of the centre depressed wheels must be mounted below the plane of the

guard lip. An improperly mounted wheel that projects through the plane of the guard lip cannot be

adequately protected.

• The guard must be securely attached to the power tool and positioned for maximum safety, so the

least amount of wheel is exposed towards the operator. The guard helps to protect operator from

broken wheel fragments, accidental contact with wheel and sparks that could ignite clothing.

• Wheels must be used only for recommended applications. For example: do not grind with the side

of the cut-o wheel. Abrasive cut-o wheels are intended for peripheral grinding; side forces applied to

these wheels may cause them to shatter.

• Always use undamaged wheel anges that are of correct size and shape for your selected wheel.

Proper wheel anges support the wheel thus reducing the possibility of wheel breakage. Flanges for cut-

o wheels may be dierent from grinding wheel anges.

• Do not use worn down reinforced wheels from larger power tools. Wheels intended for larger power

tools are not suitable for the higher speed of a smaller tool and may burst.

ELECTRICAL CONNECTION

The network voltage must conform to the voltage indicated on the tool name plate. Under no

circumstances should the tool be used when the power supply cable is damaged. A damaged cable

must be replaced immediately by an authorized Customer Service Center. Do not try to repair the

damaged cable yourself. The use of damaged power cables can lead to an electric shock.

WARNING: Never operate a damaged machine. Always tag a damaged machine and take it out of

service until repairs can be made.

SAFETY SYMBOLS

CAUTION: Indicates a potentially hazardous situation, which, if not avoided may result in minor or

moderate injury. It may also be used to alert against unsafe practices that may cause property damage.

DANGER: Indicates an imminently hazardous situation which if not avoided will result in death or

serious injury.

8

WARNING: Indicates a potentially hazardous situation which if not avoided will result in death or serious

injury.

BEFORE USING THIS TOOL

WARNING: Some dust created by the power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-bases paints

• Crystalline silica from bricks, cement and other masonry products

• Arsenic and chromium from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety equipment such as

dust masks specially designed to filter out microscopic particles.

UNPACKING

Remove the tool and all loose parts from the carton. Place all parts on a secure, stationary work surface and

look the machine over carefully.

LIST OF PARTS

List of Contents

Basic Assembly....................................1

Operator’s Manual.............................1

Lock Nut Wrench................................1

Face Spanner Wrench.......................1

L-Hex Wrench.......................................1

Flanges...................................................2

INTRODUCTION

This machine is a special, high-frequency, PMSM power tool (permanent magnet synchronous motor). It must

be only be used with its special power converter, which acts as a motor controller.

The converter also provides variable speed control.

Connection between the converter and motor is made by a motor coupling cable with special plug.

The power converter has overload, thermal, under voltage and over voltage protection.

RECOMMENDED ACCESSORIES

This machine may only be used with diamond cup wheels of 125mm diameter with 25.4mm (1") or 22.23mm

(7/8") arbor hole or with M14 female thread.All other uses are prohibited.

Bonded abrasive accessories are not allowed to be used with this machine.

9

BASIC OPERATION

NOTE: Make sure that the power circuit voltage is the same as that shown on the specification plate of

the machine and that switch is“OFF” before connecting the tool to the power circuit.

Connect the motor to the converter before turning the converter on.

The connection between the power converter and the motor is by a special motor coupling cable. To connect,

unscrew the cap, align the tangs, push in, and screw on the collar. Take care to avoid bending the pins. Keep

the cap on when not in use. Do not alter this plug in any way.

THE SWITCH

The machine has a lockable trigger switch. Squeeze the trigger to

start the machine. To lock the switch on, press the lock button while

holding the trigger switch on.

To release, squeeze the trigger and release.

CAUTION: After the machine has been switched off, the spindle

will continue rotating. Take care that parts of your body do not

come into contact with the rotating parts or set the machine

down while it is still rotating!

HOW TO USE THE TOOL

Effective control of this machine requires two-handed operation for maximum protection and resistance to

the start-up and operating torque. Place the work properly and hold the machine firmly WITH BOTH HANDS

to prevent loss of control, which could cause personal injury. Protect your eyes from injury with safety glasses

or goggles.

OVERLOAD PROTECTION, OVERHEAT PROTECTION

Overload & Load Warning Lamp

When operating within the normal load range, the load warning lamp will glow green.

When full load is reached, the load warning lamp will flash red. If full load is exceeded and sustained for too

long, the motor will shut down and the load warning lamp will glow solid red. In this case, the motor must be

first shut off and then restarted. When this happens, the motor will very likely be near overheating, so it is

also a good idea to run the motor at no load for a few minutes to cool it before continuing.

Overheat Thermal Protection

If the temperature of the motor gets too high, the thermal protection will shut the motor down. The switch

must be first shut off and then restarted. When this happens, do not immediately start working after restarting

the motor. Always run the machine at no load for a few minutes to return to a normal operating temperature

before continuing. (Also see below the section: "POWER CONVERTER LCD SCREEN CODES")

Trigger Switch

10

SPEED STABILIZATION

This machine is equipped with an electronic speed stabilization system which maintains constant speed under

load.

VARIABLE SPEED FUNCTION

The motor's speed can be varied to suit the needs of different work situations. Press the UP and DOWN arrow

buttons on the converter to change the speed.

NOTE: The motor must first be turned OFF before the speed can be adjusted.

The available speeds are as below:

5800 min-1

5500 min-1

5150 min-1

4850 min-1

4500 min-1

4200 min-1

3850 min-1

VACUUM CONNECTION

WARNING: Dust developing while working can be harmful to one’s health.

This machine is designed specifically for dry grinding of concrete and similar materials. It uses dry diamond cup

wheels and must be used with a suitable vacuum cleaner. Never exhaust the dust directly into the

atmosphere.

To attach vacuum hose to Dust Port, hold machine firmly with one hand. Then with a twisting motion push the

vacuum hose onto the Dust Port.

SAFETY GUARD

The Safety Guard (ie. the Skirt) must be used at all times when operating this machine. It is not adjustable. The

Half-Moon Door may be temporarily removed to expose the Edge Cut-Out. See below.

THE EDGE CUT-OUT

When working against a wall or into a corner, the Skirt will prevent

the grinding head from reaching all the way to the edge.

Press the Tab, slide the Half-Moon Door outward to

unlock, then rotate the Half-Moon Door to the side until it clicks.

Edge Cut-Out in Skirt Half-Moon Door

3

2

1

Selection Buttons

Power Button

LED indicator

LCD screeen

11

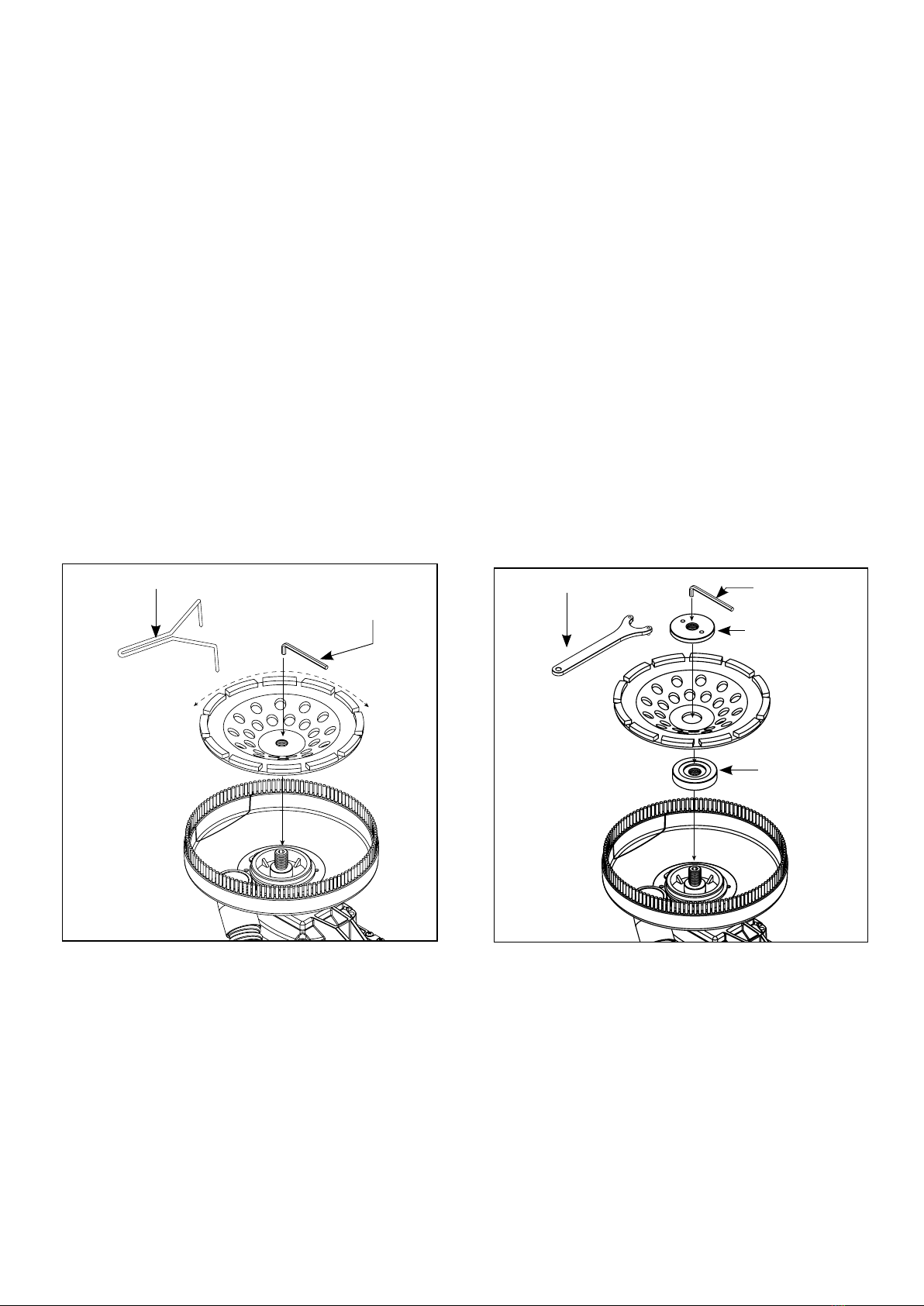

TOOL CHANGE – Removing and Replacing Diamond Cup Wheel

CAUTION: Before Working on or adjusting the machine, switch the machine “OFF”and UNPLUG machine

from the socket.

CAUTION: The wheel can become very hot during the working process. Before replacing, allow the

wheel to cool down

1. Place the machine on a level and sturdy workspace.

2. If using a diamond cup wheel with M14 female thread, do not use the flanges. Simply thread the wheel

onto the spindle. Use the L-Hex Wrench to keep the spindle from turning and tighten the wheel using

the Face Spanner Wrench.

3. If using a diamond cup wheel with arbor hole, first mount the inner flange onto the spindle.

It is 22.23mm on one side and 25.4mm on the other. Mount the wheel onto the shoulder of the Inner

Flange, then thread on the Arbor Nut. Use the L-Hex Wrench to keep the spindle from turning and

tighten the Arbor Nut with the Lock Nut Wrench.

4. Replacement is the opposite of removal.

INSTALLING DIAMOND CUP

WHEELS W/ M14 FEMALE THREAD.

STORAGE

CAUTION: Do not store machine resting on its bristles – Store on its side.

CAUTION: Do not store machine with its power supply cable pinched. This will result in damage to the

cable.

L-Hex Wrench

Arbor Nut

Inner Flange

Lock Nut Wrench

INSTALLING DIAMOND CUP

WHEELS WITH ARBOR HOLE.

Face Spanner Wrench

L-Hex Wrench

12

REPLACING DUST SKIRT BRUSHES

The dust skirt brushes may be replaced when worn. To replace, remove the 3 screws to replace the small brush

on the half moon door and remove the 6 screws to replace the large brush on the dust skirt.

MAINTENANCE

WARNING: To reduce the risk of injury from unexpected starting or electrical shock, unplug the power

cord before working on the machine.

Keep the tool clean. Remove accumulated dust from working parts. Make sure that the tool operates properly.

Periodically check screws and bolts for tightness.

KEEPING TOOL CLEAN

Keep the machine and its air inlet slots clean to ensure correct and safe operation. To clean, blow compressed

air through the air inlet slots with the motor running at no load.

WARNING: If the replacement of the power supply cord is necessary, this has to be done by the

manufacturer or their agent in order to avoid a safety hazard.

Do not throw electric power tools into the household waste! In accordance with the European Directive

2002/96/EG on Waste Electrical and Electronic Equipment and transposition into national law, used

electricpower tools must be collected separately and recycled in an environmentally friendly manner.

OPTIONAL FLOOR GRINDING TROLLEY

This machine has built-in mounting tabs in its handle for mounting to the optional floor

grinding trolley for fatique free grinding of floors. The trolley's 4 spring-loaded

mounting plungers thread into the tabs to suspend the machine.

NOTE: This tool does not use the floor trolley's remote switching function.

CAUTION:

Do not attempt edge grinding with the machine mounted to the floor grinding trolley. The extra

leverage of the trolley will easily damage the dust shroud or turbine housing when it inevitably

contacts the wall. In addition, the range of motion allowed by the floor grinding trolley is not suitable

for edge grinding. Always perform edge grinding in hand-held mode only. Only use the floor grinding

trolley for open areas.

13

POWER CONVERTER LCD SCREEN CODES:

8888

Loss of communication between

the motor electronics board, the

converter electronics board and

the LCD module when powering

up

Check the connection of the coupling cable

E1 Overload of the converter. At the tool, turn the switch OFF and then ON again

E2

Overheat of the converter

As soon as temperature returns to normal, at the tool, turn

the switch OFF and then ON again

E3 Under voltage As soon as supply voltage returns to normal, at the tool,

turn the switch OFF and then ON again

E4 Over voltage As soon as supply voltage returns to normal, at the tool,

turn the switch OFF and then ON

E5 Excessive back voltage from the

motor brake to the converter

At the converter, press the POWER button to turn the power

OFF and then back ON again

(If the problem persists, bring the unit to an authorized

service center for repair)

E6

RCD current leak detection

between the converter and the

voltage supply

Check connections and then, at the converter, press the

POWER button to turn the power OFF and then back ON

again

(If the problem persists, bring the unit to an authorized

service center for repair)

E7 Hall eect sensor error

At the converter, press the POWER button to turn the power

OFF and then back ON again

(If the problem persists, bring the unit to an authorized

service center for repair)

E8

Motor overheat

Allow the motor to cool.

Then, at the tool, turn the switch OFF and then ON again

(If the temperature has sill not dropped suciently, wait

longer for the temperature to drop to the acceptable range)

E91

Loss of communication between

the converter electronics

board and LCD module during

operation

At the converter, try pressing the POWER button to turn

the power OFF and then back ON again. (If the problem

persists, bring the unit to an authorized

service center for repair)

OFF: When the converter is plugged in, the screen will display the supply voltage. The voltage displayed will

depend on the voltage of the supply

ON: When the converter power button is pressed, the tool will be energized and the screen will display

the speed setting. Press the UP or DOWN buttons to adjust the speed setting as required.

ERROR CODES

14

E92

Loss of communication between

the motor electronics board

and the LCD module during

operation

Check the connection of the coupling cable. Then, at the

tool, try turning the switch OFF and then ON again (If the

problem persists, bring the unit to an authorized

service center for repair)

E16

No signal from the motor

temperature sensor

At the tool, try turning the switch OFF and then ON again (If

the problem persists, bring the unit to an authorized service

center for repair)

E17

Motor temperature sensor short

circuited

At the tool, try turning the switch OFF and then ON again (If

the problem persists, bring the unit to an authorized service

center for repair)

15

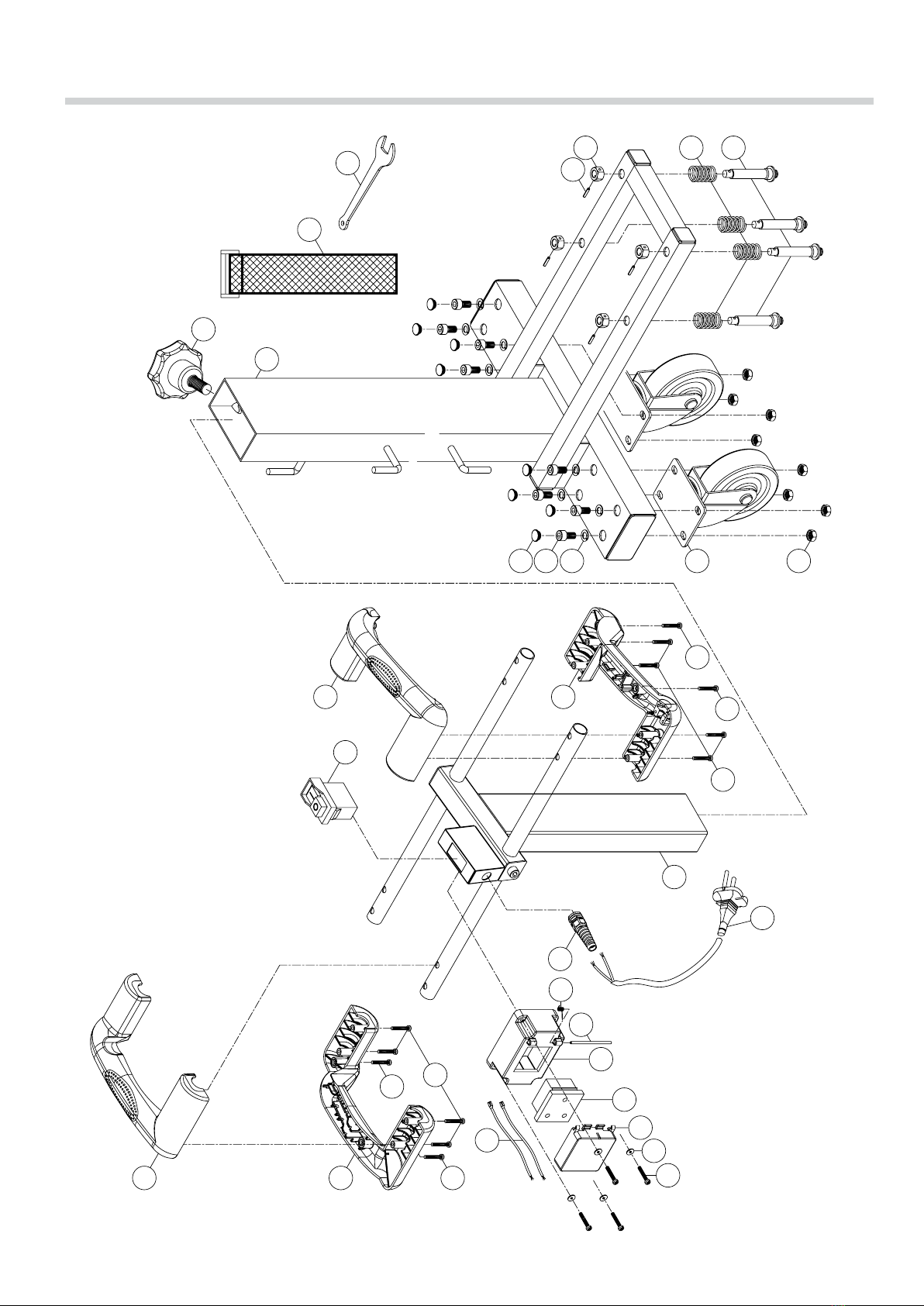

WIRING

LED

MOTOR

Temperature Sensor

BLACK

BLUE

Brown

BLACK

BLUE

Brown

WIRE

CONNECTOR

BLOCK

ELECTRONICS UNIT

SWITCH

UVW

LCD

DISPLAY

AC

AC N2

AC L2

BRAKING

RESISTOR

BLUE

BROWN

ELECTRONICS UNIT

BLUE

BROWN

BLACK

FAN

LCT

Concrete Grinder:

Power Converter:

16

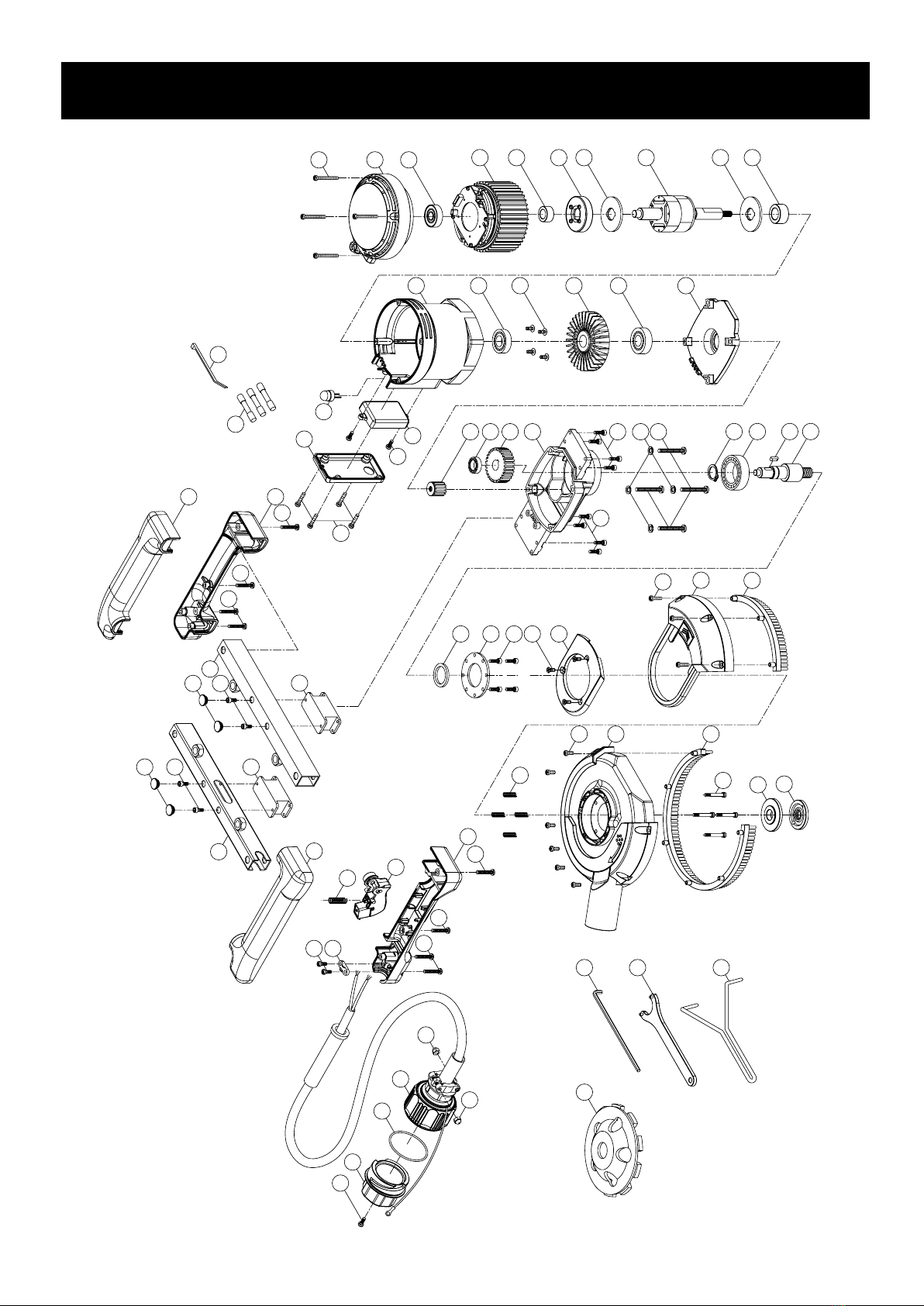

EXPLODED VIEW

06

07

16

15

11

12

12

17

18

19

21

21

13

13

14

14 69

09

42

43

45

47

48

49

50

51

31

35

32

01

30

34

06

57

58

52

59

64

63

62

12

22

23

26

27

29

36

37

38

39

40

41

44

46

45

53

54

55

56

65

66

67

NO.01~69 A1 Version 1.2

20

25

33

60

61

A1

01 02

03

04

05

68

05

17

18

28

28

24

08

10

17

NO. Parts Name Q'ty

1 PANHEAD TAPPING SCREW (M4x12) 5

2 PLUG CAP 1

3 O-RING (AS-137) 1

4 MOTOR COUPLING CABLE SET 1

5 CAP NUT 2

6 PANHEAD TAPPING SCREW (M4x14) 5

7 CABLE CLIP 1

8 HANDLE HALF-RIGHT 1

9 SPRING (Ø1.0 x Ø6.4 x Ø8.4 x 8.5T x 35L) 1

10 SWITCH ACTUATOR (BLACK)(LOCK-ON) 1

11 HANDLE HALF-RIGHT 1

12 PANHEAD TAPPING SCREW (M4x35) 6

13 PANHEAD TAPPING SCREW (M4x20) 5

14 PANHEAD TAPPING SCREW (M4x25) 4

15 HANDLE HALF-LEFT 1

16 HANDLE HALF-LEFT 1

17 RUBBER PLUG 4

18 SOCKET CAP SCREW (M4x6xP0.7) 4

19 CROSS BAR LOWER 1

20 CROSS BAR UPPER 1

21 ANTI-VIBRATION MOUNT 2

22 TAIL COVER 1

23 BALL BEARING (6200-ZZ ) 1

24 STATOR 1

25 SPACER 1

26 MAGNET HOLDER 1

27 ROTOR 1

28 ROTOR END PLATE 2

29 SPACER 1

30 PANHEAD TAPPING SCREW (M4x16) 4

31 ELECTRONICS COVER 1

32 LED INDICATOR LIGHT 1

33 PANHEAD TAPPING SCREW (M4x10) 6

34 ELECTRONICS UNIT 1

35 MOTOR HOUSING 1

PARTS LIST

NO. Parts Name Q'ty

36 BALL BEARING (6002 ) 1

37 TRUSS HEAD TAPPING SCREW M4x8) 4

38 FAN 1

39 BALL BEARING (6202 ) 1

40 GEAR PLATE 1

41 BEVEL PINION GEAR (M1.5x10T) 1

42 BALL BEARING (608) 1

43 OUTPUT GEAR (M1.5x31T) 1

44 GEAR HOUSING 1

45 SOCKET CAP SCREW (M4x12xP0.7) 8

46 SPRING WASHER (M5) 4

47 PANHEAD TAPPING SCREW (M5x40) 4

48 EXTERNAL CIRCLIP (S-17) 1

49 BALL BEARING (6303) 1

50 PARALLEL KEY (5x5x12) 1

51 M14xP2.0-88mm 1

52 OIL SEAL (Ø24xØ32x4) 1

53 BEARING PLATE 1

54 SOCKET CAP SCREW (M4x10xP0.7) 4

55 FLAT HEAD TAPPING SCREW (M4x10) 3

56 COVER PANEL 1

57 HALF-MOON DOOR 1

58 SKIRT BRUSH - SMALL 1

59 SPRING (Ø0.55xØ4.9xØ6x15Lx6T) 4

60 DUST SKIRT 1

61 SKIRT BRUSH - LARGE 1

62 SHOULDER BOLT (M4xP0.7x32L) 4

63 INNER FLANGE (Ø22.2 / Ø25.4) 1

64 OUTER FLANGE (M14) 1

65 SOCKET HEX KEY (M6) 1

66 LOCK NUT WRENCH (30MM) 1

67 FACE SPANNER WRENCH (78MM) 1

68 HEAT SHRINK BUTT CONNECTOR 3

69 ZIP TIE (2.5x100MM) 1

A1 DIAMOND GRINDING HEAD (60/80) 1

18

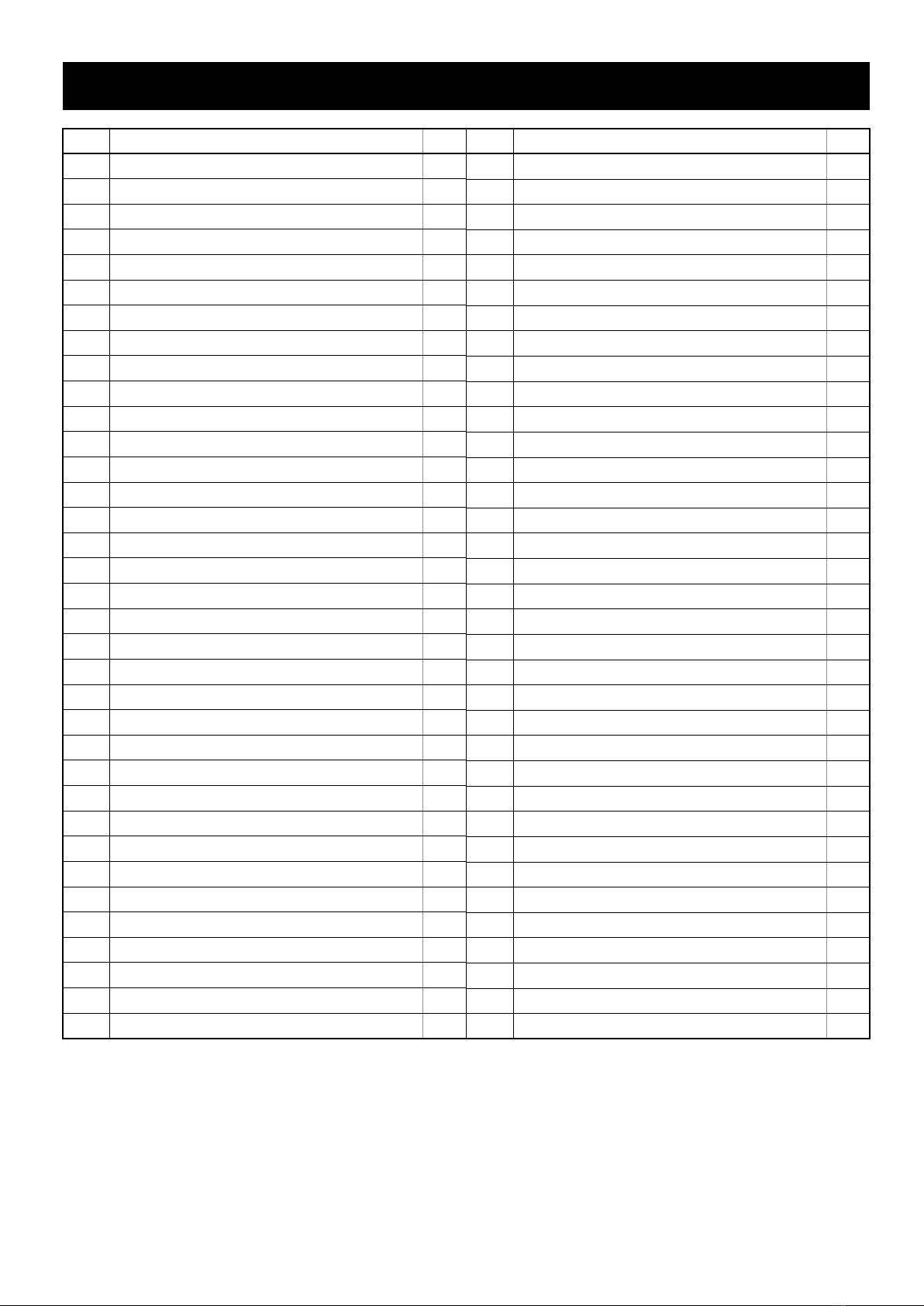

EXPLODED VIEW (Power Converter)

27

26

30

31

33

23

20

32

10

09

06

17

19

20

11

16

03

02

04

15

21

24

25

11

29

28

04

18

22

05

08

07

01

11

14

NO.01~33 Version 1.3

12

13

19

NO. Parts Name Q'ty

1 POWER SUPPLY CABLE 1

2 CABLE GLAND 1

3 HOUSING - LOWER 1

4 SOCKET CAP SCREW (M4-0.7 x 10) 8

5SPRING WASHER (M4) 4

6 MIL-SPEC SOCKET RECEPTACLE 1

7 TETHER 1

8 BAYONET COLLAR 1

9 O-RING (Ø52.07 x 2.62) 1

10 CAP 1

11 PANHEAD TAPPING SCREW (M4 x 12) 6

12 PANHEAD MACHINE SCREW (M5-0.8 x 8) 1

13 NYLOCK NUT (M5-0.8) 1

14 FAN UNIT 1

15 FAN GRILL 1

16 PANHEAD TAPPING SCREW (M5 x 10) 4

17 FOOT 4

18 FLAT WASHER (Ø6.5 x Ø13 x 1) 4

19 PANHEAD SCREW 4

20 PANHEND TAPPING SCREW (5/32" x 1 1/2") 12

21 BRAKING RESISTOR 1

22 MOLDED GASKET (Ø2 x 37cm) 1

23 ELECTRONICS UNIT 1

24 TRUSS HEAD TAPPING SCREW (M4 x 12) 6

25 MOLDED GASKET (Ø2 x 87cm) 1

26 HOUSING - UPPER 1

27 TOP HANDLE 1

28 FLAT WASHER (Ø5 x Ø12 x 1) 2

29 PANHEAD TAPPING SCREW (M5 x 25) 2

30 HEX NUT (M4-0.7) 4

31 LCD DISPLAY 1

32 PANHEAD MACHINE SCREW (M4-0.7 x 12) 4

33 WINDOW (65 x 35 x 1) 1

PARTS LIST (Power Converter)

20

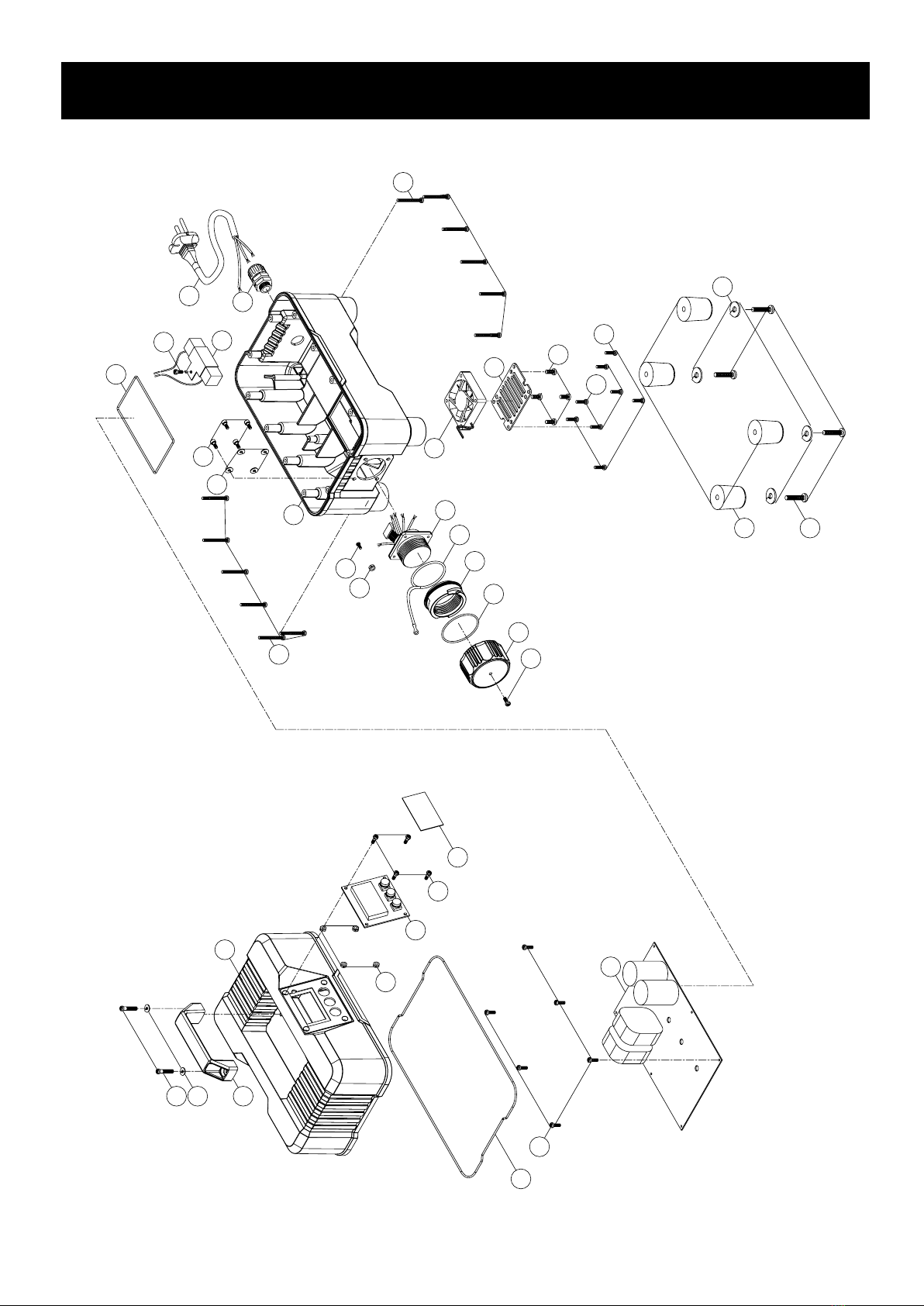

FLOOR GRINDING TROLLEY EXPLODED VIEW

NO.01~33 Version 1.3

05

02

01

03

04

25

26

29

30

28

27

09

10

06

07

06

07

05

08

23

24

22

32

33

21

19

18

17

15 14

13

16

20

11

12

This manual suits for next models

1

Table of contents

Other TRAXX Grinder manuals

Popular Grinder manuals by other brands

Inelco

Inelco AutoGrind Digital user manual

Lincoln Electric

Lincoln Electric K5447-1 instruction manual

EWM

EWM TGM 40230 Handy operating instructions

Rikon Power Tools

Rikon Power Tools 80-800VS Operator's manual

EINHELL

EINHELL AXXIO 18/115 operating instructions

Hilti

Hilti AG 100-8 (S/D) Original operating instructions

Black & Decker

Black & Decker Linea Pro KG915 instruction manual

Trumpf

Trumpf quicksharp Operator's manual

Atlas Copco

Atlas Copco LSF12 S400-2 Original product instructions

Worx

Worx WU736 Original instructions

EINHELL

EINHELL Bavaria BAG 230 Original operating instructions

Scheppach

Scheppach PWS-115 Translation of original instruction manual