treesse Muse GP User manual

Installation manual

Muse GP

minipool

The installation of this minipool is simple and immediate, however we advise you to read

this manual carefully before installing it.

The Treesse team is always available for any information or request for assistance that

may be required during installation.

GRUPPO TRE S s.p.a.

Telephone +39 0761 527242

Fax +39 0761 527223

Email [email protected]

Good luck with your work!

Contents

Safety instructions __________________________________________4

EXPLANATION OF PICTOGRAMS _________________________________________________4

Preliminary operations ______________________________________5

1PREPARATIONS AND CHOICE OF POSITION _________________________________________ 5

2CHECKING MINIPOOL INTEGRITY __________________________________________________ 5

OUTDOOR INSTALLATION__________________________________________________________________5

INDOOR INSTALLATION ____________________________________________________________________5

Transport and position ______________________________________6

1MOVING _________________________________________________________________________ 6

2POSITIONING_____________________________________________________________________ 7

TEMPORARY POSITIONING _________________________________________________________________7

POSITIONING IN THE PLANNED LOCATION__________________________________________________7

Installation _________________________________________________8

1DESCRIPTION OF COMPONENTS___________________________________________________ 8

2QUALIFICATIONS OF THE INSTALLER _______________________________________________ 8

3CONNECTIONS REQUIRED_________________________________________________________ 9

4WATER SUPPLY ____________________________________________________________________ 12

CHARACTERISTICS OF THE WATER SUPPLY___________________________________________________12

TAP WATER AND WELL WATER ______________________________________________________________12

WATER HARDNESS_________________________________________________________________________12

WATER ALKALINITY ________________________________________________________________________12

5CLEANING THE PAPER FILTER ______________________________________________________ 13

6EMPTYING THE MINIPOOL _________________________________________________________ 13

7ELECTRICAL CONNECTIONS _______________________________________________________ 14

SAFETY ZONE _____________________________________________________________________________15

TESTING AFTER INSTALLATION _____________________________________________________________15

First run____________________________________________________16

1FILLING THE MINIPOOL ______________________________________________ 16

2FIRST RUN ________________________________________________________________________ 17

Alarms _____________________________________________________18

Decorative panels___________________________________________22

Covering ___________________________________________________23

4

EN

Muse GP

minipool

Safety instructions

Read this guide carefully before install-

ing the appliance, and conserve this

booklet with care for any future consultation

of users.

If you do not understand something, contact

the manufacturer for an explanation.

Installation must be carried out by

qualied personnel in compliance with

local regulations and national provisions re-

garding civil and industrial systems.

Before making electrical connection to the

equipment, the installer must receive the

declaration of conformity of the building's sys-

tems from the user. Without such document,

the Manufacturer cannot be held responsible

for damage to the systems or premises where

the minipool will be installed.

Comply with regulations, instructions

and measurements on the “Pre-instal-

lation technical sheet”.

Unauthorised actions, tampering or

modications that do not follow the

information provided in this manual can cause

damages, injuries or fatal accidents and null

and void the warranty.

During the installation of the minipool,

do not place objects inside it, even

temporarily: they may fall down the drain

When installing the minipool, always

use personal protective equipment

(e.g., gloves, safety shoes, etc.)

Persons not involved with appliance

installation may not pass through or

occupy the work area during appliance

assembly.

EXPLANATION OF PICTOGRAMS

Danger! Situation presenting immediate danger, or a hazardous situation that could cause injury or

death.

More info: helps the installer understand a topic better

The pictogram refers to text in another document

Ecological notes for respecting the environment

Ecological notes

Given their potential danger, the packaging

materials must be kept out of reach of chil-

dren and animals, and correctly disposed of

in compliance with local regulations.

Treesse invites you to protect the environ-

ment by disposing of the material in special

separate collection bins.

5

EN

Muse GP

minipool

2CHECKING MINIPOOL INTEGRITY

After having removed the minipool from the packing, check its integrity.

Check:

• That there is no visible structural damage;

• That there are no cracks in the surface of the minipool or in the outer covering (cracks due to incorrect transport

or support are not covered by the warranty);

• The correct position of the sleeves and pipes;

• That any ties are not loosened.

If you notice any anomalies, do not proceed with the installation but rather promptly contact the Manufacturer.

Preliminary operations

1PREPARATIONS AND CHOICE

OF POSITION

The pre-installation sheet supplied at the time

of purchase provides all the information neces-

sary for a correct preparation of the installation

environments.

Before installing the minipool, check that everything

has been prepared. Find below a quick checklist, for

complete information always refer to the pre-installation

sheet.

Check that:

• A platform or a recess (in the case of recessed installa-

tions) of reinforced concrete, with a minimum thickness

of10cm,hasbeencreated,perfectlyatandsuitable

for supporting the weight of the minipool and the

people within.

• Ø15 cm vents have been installed to ensure proper

ventilation of the technical compartment.

• Drainage grating around the perimeter has been

installed to help preserve the equipment and the

structure (even for indoor installations);

• Non-slipooringhasbeeninstalledintheareaaround

the minipool;

• For a recessed installation, a technical inspection port

measuring at least 50 cm wide has been prepared on

all sides of the minipool;

• The connections to the electrical grid have been made

in compliance with current regulations in force in the

country of installation;

• A water softener has been installed for the water used

tolltheminipoolifthewaterhasahighdegreeof

hardness;

• For outdoor recessed versions, the walls have been

insulated to protect against the cold.

More information

OUTDOOR INSTALLATION

Preparations:

To run the electric cables from the main electrical panel

to the minipool underground ducts must be used and

adequately protected against freezing by using insula-

tion. It is also recommended to add drainage points in

them to prevent standing water.

Choice of position: take into account the proximity of

trees or hedges, and note that debris (e.g., leaves) can

cause damage to the equipment over time that is not

covered by warranty and make maintenance more ex-

pensive and frequent. It is also recommended to always

installooringaroundtheminipool,possiblyanti-slip.

INDOOR INSTALLATION

Preparations: in the area used to access the minipool

itisrecommendedtoinstallanti-slipooring.

The evaporation of water in the minipool in the pres-

ence of high internal temperatures can generate very

high levels of humidity in the environment.

To avoid this problem, provide good natural or forced

ventilation in the installation environment and, if nec-

essary,adehumidicationsystem.Damagecausedby

this phenomenon is not covered by the manufacturer

warranty.

Choice of position: Always take into account the size

of the minipool: narrow passages, doors and steps can

be an obstacle to its transport to the desired place.

6

EN

Muse GP

minipool

8x

Transport and position

1MOVING

To move the minipool to the place of installation a suit-

able lifting device (e.g., pallet jack) is required.

As an alternative, provide for the availability of eight

people.

If the installation is indoor, before moving the minipool

make sure that it can easily pass through the doors and

hallways to reach the desired place of installation.

Movement must be carried out using personal

protective equipment (e.g., gloves, safety shoes,

etc.) and taking all the necessary safety precau-

tions for those involved and to not damage the minipool.

During transport, lift the minipool by holding it

exclusively by the edge and NEVER by holding the

plumbing lines or operational parts (e.g., pumps, etc.).

During movement, the surrounding area must be

kept free of persons not involved in the operation,

animals or objects (e.g., packaging, etc.) that

could get in the way.

7

EN

Muse GP

minipool

Transport and position

2POSITIONING

TEMPORARY POSITIONING

The installation of the minipool should be done

immediately upon receipt.

In any case, once unpacked, if it is necessary to

temporarily place it on a surface awaiting the installation,

it will be necessary to place level concrete slabs having

a minimum thickness of 5 cm under the entire bottom

of the minipool.

Since the temporary base may shift, it is recommended

to leave the minipool in that position for the shortest

possible time.

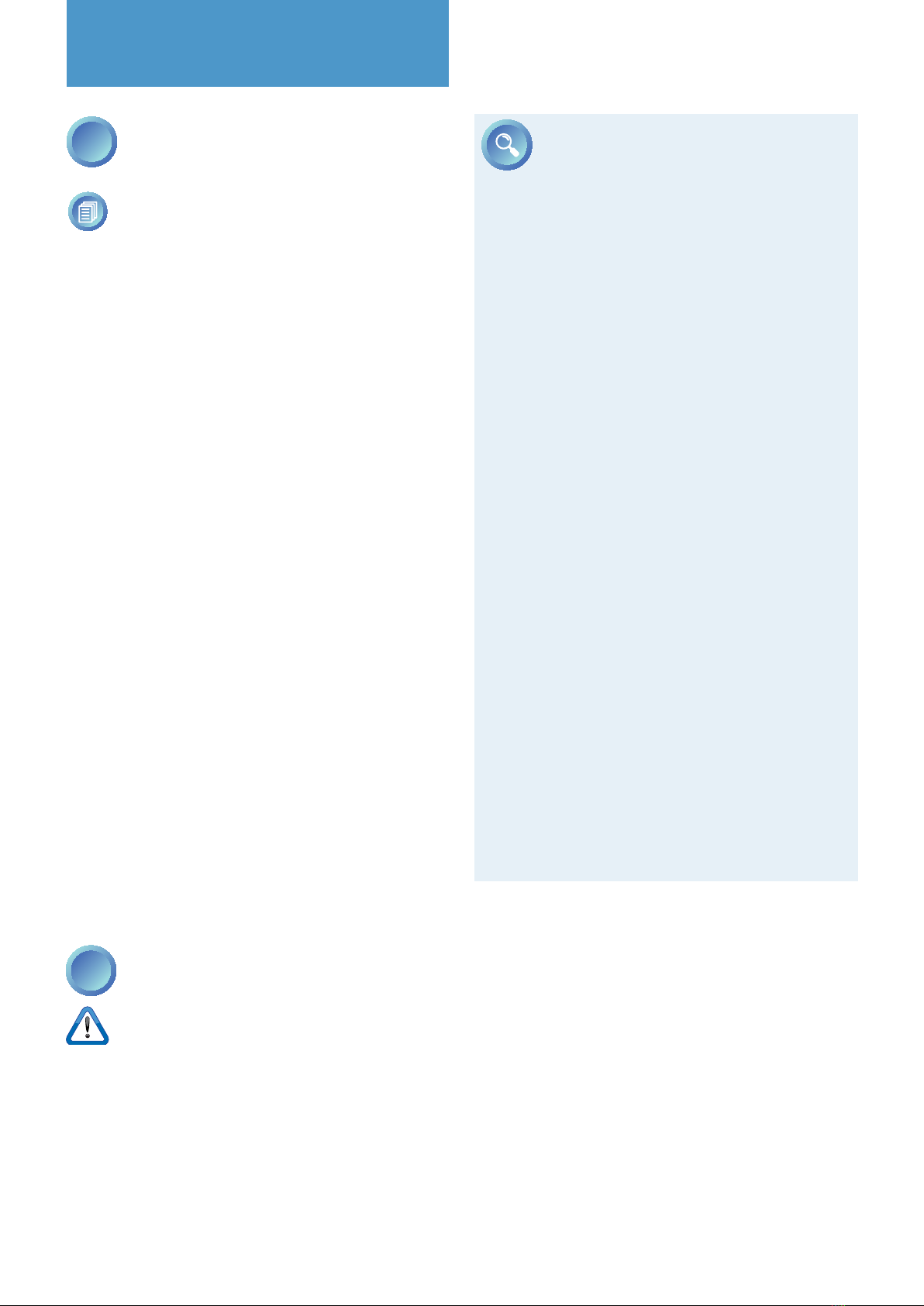

POSITIONING IN THE PLANNED LOCATION

In case of installation above ground (freestanding),

place the minipool in the installation environment (out-

doororindoor)andverifyitsperfectatness,essential

for proper operation.

For a recessed installation, lower the minipool into the

prepared space.

If it was not possible to provide a technical inspec-

tion port on all sides of the minipool, a pneu-

matic lift is available (OPTIONAL - to be request-

ed from the Manufacturer) in order to simplify future

maintenance operations. It is recommended to provide

a removable inspection hatch “A” positioned on the side

where the minipool components are situated.

After positioning the minipool in its prepared space and

after having connected the lift, test it.

Do not leave the empty minipool in DIRECT

SUNLIGHT. The surface temperature could rise

above 80°C resulting in serious damage, including

cavitation and the deformation of the surface and com-

ponents. Damage caused by direct exposure to sunlight

is not covered by the warranty.

In such conditions place a cover (xed or mobile) to

protect the minipool.

80°C

176°F

80°C

176°F

OPTIONAL

A

Optional lift with removable inspection hatch “A”

positioned on the side where the components of the

minipool are situated.

8

EN

Muse GP

minipool

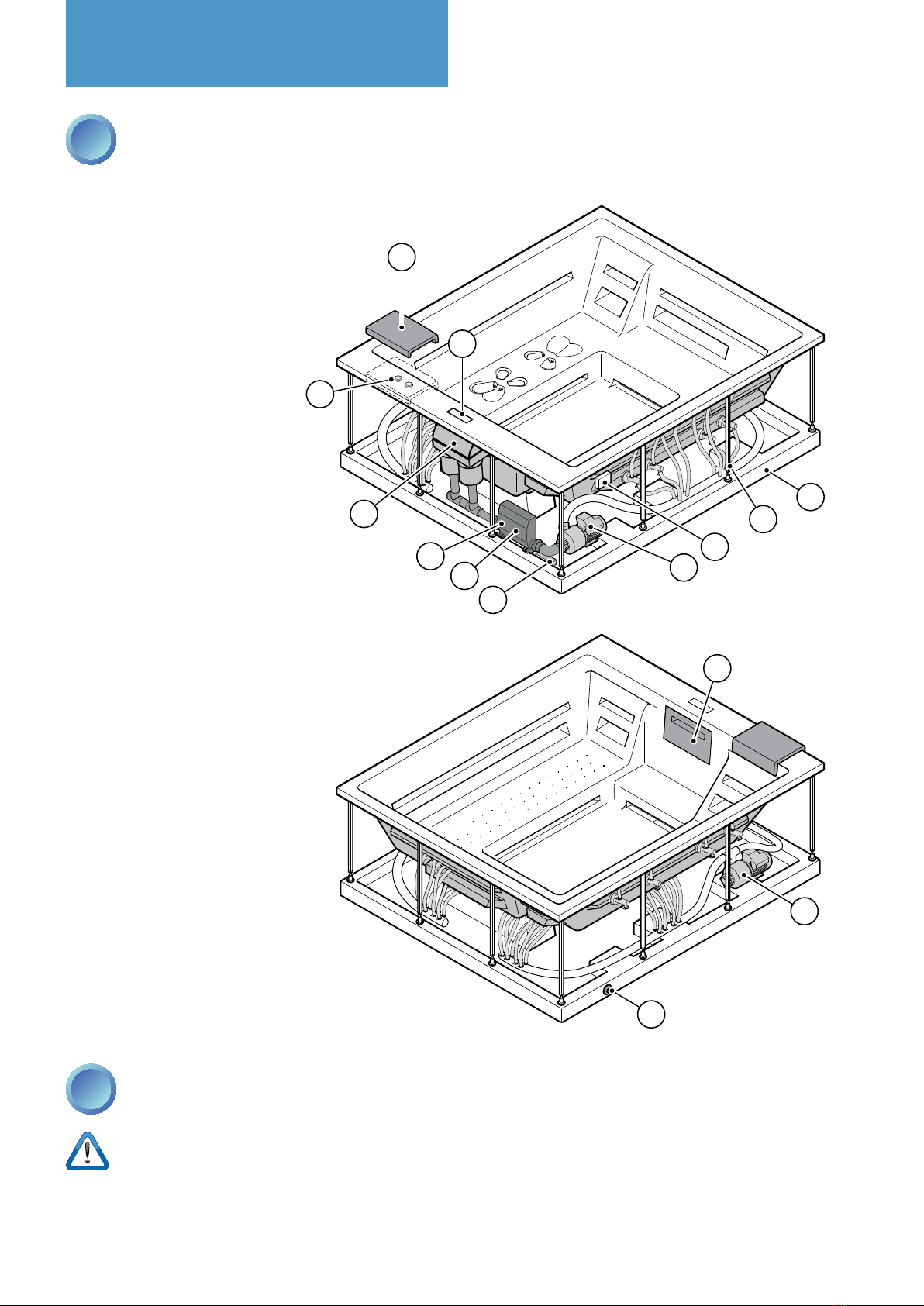

1DESCRIPTION OF COMPONENTS

1 Control Panel

2 2-speed pump (water + recirculation)

2a Hydromassage pump

3 Skimmerwithpaperlters

4 Skimmer cover panel

5 Electronic control unit

6 Heater (integrated with the control unit)

7 Chromotherapy control unit

8 Drain tap

9 Air regulators (under the pillow)

10 Ozone (option)

11 Frame

12 Base

13 Pillows

2QUALIFICATIONS OF THE INSTALLER

Before installation, it is recommended to carefully read the safety warnings at the beginning of this manual

and to always operate in perfect physical and mental condition.

Theinstaller,qualiedandauthorisedbytheManufacturer,mustcarryouttheoperationsbasedonhisorherpro-

fessionalqualications.Anyactivitiesforwhichheorsheisnotqualied(e.g.,plumbingorelectricalconnections)

mustbeperformedbyspecicandqualiedprofessionalssoasnottorisktheirownsafetyandthatofotherswho

interact with the equipment.

1

4

8

12

11

2a

2

10

5

6

7

3

13

9

Installation

9

EN

Muse GP

minipool

Installation

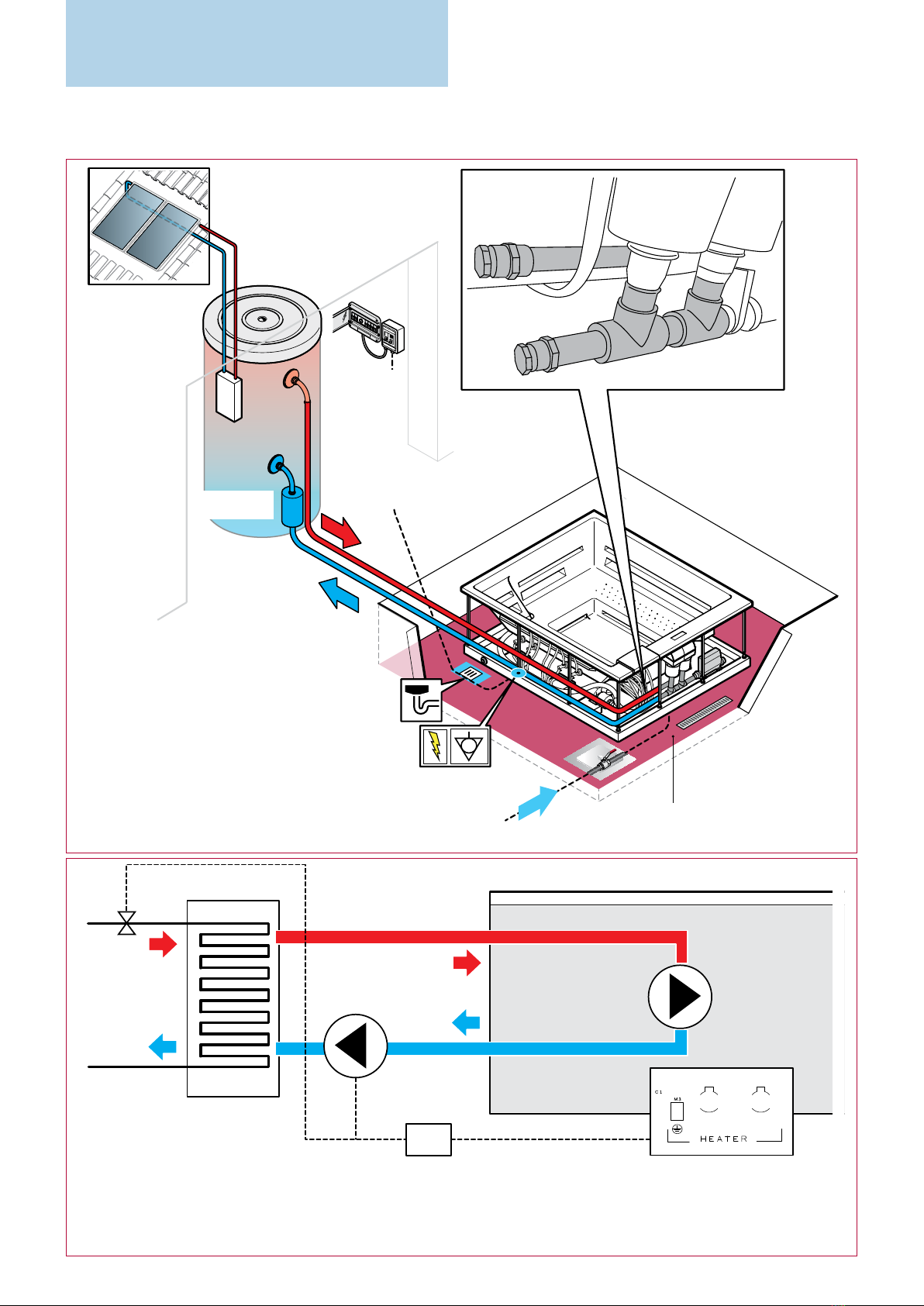

3CONNECTIONS REQUIRED

To be used, the minipool only requires

an electrical connection (power supply).

Also prepare an electrical and plumbing

connection to an exchanger (optional - if

provided) - see following page.

The following pages will provide detailed

explanations of how to perform these

preparations.

EXAMPLES OF OUTDOOR/INDOOR

MINIPOOL INSTALLATION

Electrical connection

Electrical connection

Room for

the electrical

connections

Room for

the electrical

connections

Drain

Drain

Technical

inspection port

10

EN

Muse GP

minipool

Installation

PREPARATION OF CONNECTION TO AN OPTIONAL EXTERNAL EXCHANGER (NOT SUPPLIED)

IN

OUT

IN

IN

OUT

Electrical connection

Exchanger

(not supplied)

Circulator

(not supplied)

Room for

the electrical

connections

Drain

Water

supply

Technical

inspection port

IN: incoming

hot domestic

water

OUT: outgoing cold

water

230V

C

S

P

in

out

PR

EV

P2

BL 1

BL2

HTR

Cromo

230V~

EVc

EVs

EVclv

+

-

J49J48

230V: heater/exchanger control cable

C: switch (recommended)

OUT: outgoing cold water

P: circulator (not supplied)

PR: recirculation pump

S: exchanger (not supplied)

The exchanger

means the

device that

heats water (in

this manual, it is

represented by a

boiler connected

to the solar

panels)

Inlet connection:

1”1/4 female

If no heater is required,

disconnect pin J44

The circulator must be

installed according to

the characteristics of the

domestic system (head,

length, etc...) and the water

content (in litres)

Outlet connection:

1”1/4 female

11

EN

Muse GP

minipool

Installation

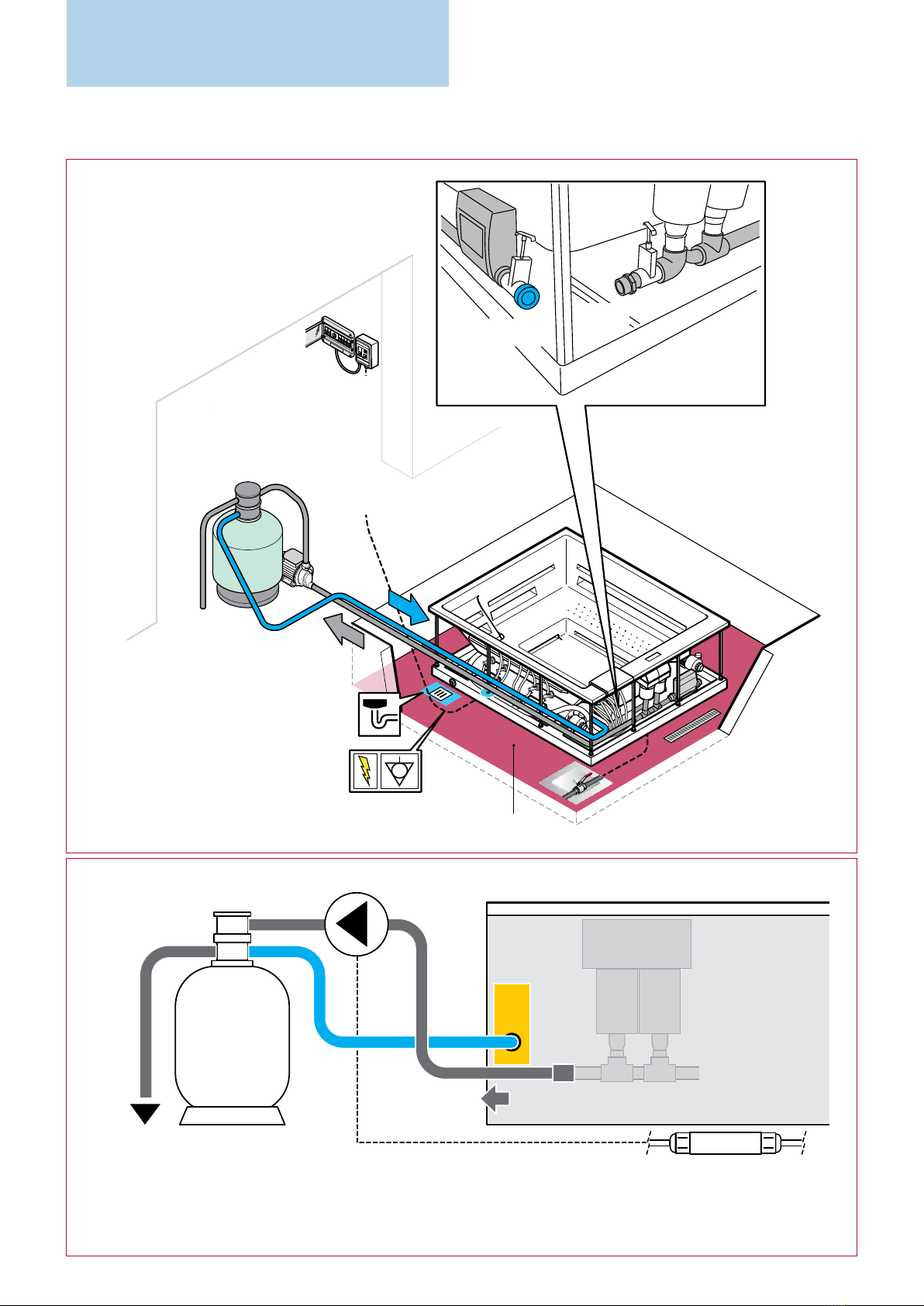

ARRANGEMENT FOR CONNECTION TO AN OPTIONAL OUTDOOR SPA PACK

IN

OUT IN

OUT

Electrical connection

Room for

the electrical

connections

Drain

Technical

inspection port

IN: water

inlet

OUT: water

outlet

230V

IN

PR

F

C

CP

230V: circulator control cable

OUT: water outlet

IN: water inlet

PR: recirculation pump

F: lter

C: control unit

Inlet connection:

1”1/4 female

The circulator must be

installed according to

the characteristics of the

domestic system (head,

length, etc...) and the water

content (in litres)

Outlet connection:

1”1/4 female

12

EN

Muse GP

minipool

4WATER SUPPLY

It is recommended to use ONLY tap water.

If this is not possible refer to the “more informa-

tion” section to the side.

CHARACTERISTICS OF THE WATER SUPPLY

The optimal values for the water supply are as follows:

• hardness between 7ºf and 14ºF (fresh water) - 200 to

400 mg/l (ppm);

• total alkalinity (TA) between 80 and 125 mg/l (8-12.5°F)

• pH between 7.4 and 7.8;

• minimum inlet pressure: 150,000 Pa (1.5 bar)

• minimum inlet pressure: 300,000 Pa (3 bar)

• Water suitable for human consumption.

More information

WATER HARDNESS

Water hardness (TH) is determined by the total content

of calcium and magnesium present in the water, coming

from their soluble salts.

Water classication:

............up to 7ºf = Very soft water

From 7ºf to 14ºf = Soft water

From 14ºf to 22ºf = Slightly hard water

From 22ºf to 32ºf = Fairly hard water

From 32ºf to 54ºf = Hard water

....more than 54ºf = Very hard water

(1°f = 10 mg calcium carbonate per litre of water)

WATER ALKALINITY

Alkalinity (CAT) represents the concentration of bicar-

bonate ions present in the water. It is expressed as

mg/L of calcium carbonate or in French degrees (°F).

Ideal values of alkalinity range between 80 mg/L and

125 mg/L (8°F-12.5°F). Valuesoutside of this range can

more easily cause variations of the pH. Instead, alkalin-

ity within the range noted makes it possible to “buffer”

the pH value, resulting in fewer abrupt variations.

WATER PH

What is pH?

The pH is a chemical parameter that gives an idea of

the acidity or basicity of the water. It can assume values

between0and14.Bydenitionwaterisconsidered

neutral if its pH is equal to 7. It is acidic if the pH is lower

than 7 and basic if the pH is greater than 7. Disinfect-

ants have an ideal pH at which they are most effective.

In the case of heated water treated with bromine

products it is recommended to keep the pH value in

the range from 7.4 to 7.8 using chemical correctors as

needed if the pH is higher or lower to bring the pH

value back to the recommended interval.

acid water alkaline water

acid pH neutral pH basic pH

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

More information

TAP WATER AND WELL WATER

To ensure maximum hygiene and durability of the min-

ipool it is essential to pay close attention to the quality

ofthe waterthatwill beused toll it.Itis important

that the water used be drinkable. It is always advisable

not to use well water because it may be very hard, rich

in metals like iron and manganese, and have bacterial

loads. Tap water is recommended. In the case of very

hard or ferrous water it is always recommended to in-

stall softening and iron removal systems upstream. The

company cannot be held responsible for issues related

to the use of non-drinkable water or lack of installation

of such systems. The plumber is responsible for choosing

the type of components to be used and the verication

of compliance with the purity and potability parameters

of the water supply.

Installation

13

EN

Muse GP

minipool

Installation

5CLEANING THE PAPER FILTER

Cleaning/replacing the paper lter depends on how often the

minipool is used.

In general, rinse the cartridge every 2-3 weeks with clean water

to remove hair and other foreign substances. Be careful to clean

wellbetweenthefoldsofthelter.

Ateachchangeofwater,theltercartridgemustbeimmersed

inasolutionsuitableforcleaningthistypeoflter,possiblyover-

night, or replaced.

In any case refer to the instructions provided by the manufacturer

of the cleaning product used.

Paper lters should be mounted when they are com-

pletely dry.

5

2

1

4

3

6EMPTYING THE MINIPOOL

CLICK!

1

2

4

3

Emptying takes place by carrying out the

operationsindicatedinthegureontheside.

Ifitisnecessarytorelltheminipool,seethe

pertinent chapter on page 16.

The water can be drained at any time,

without people inside the minipool.

It is advisable to always empty the

minipool during maintenance and at

the end of the season.

Before emptying the minipool, especially

if a shock treatment has just been

performed, make sure that the values of

disinfectants and additives are at normal values.

14

EN

Muse GP

minipool

Installation

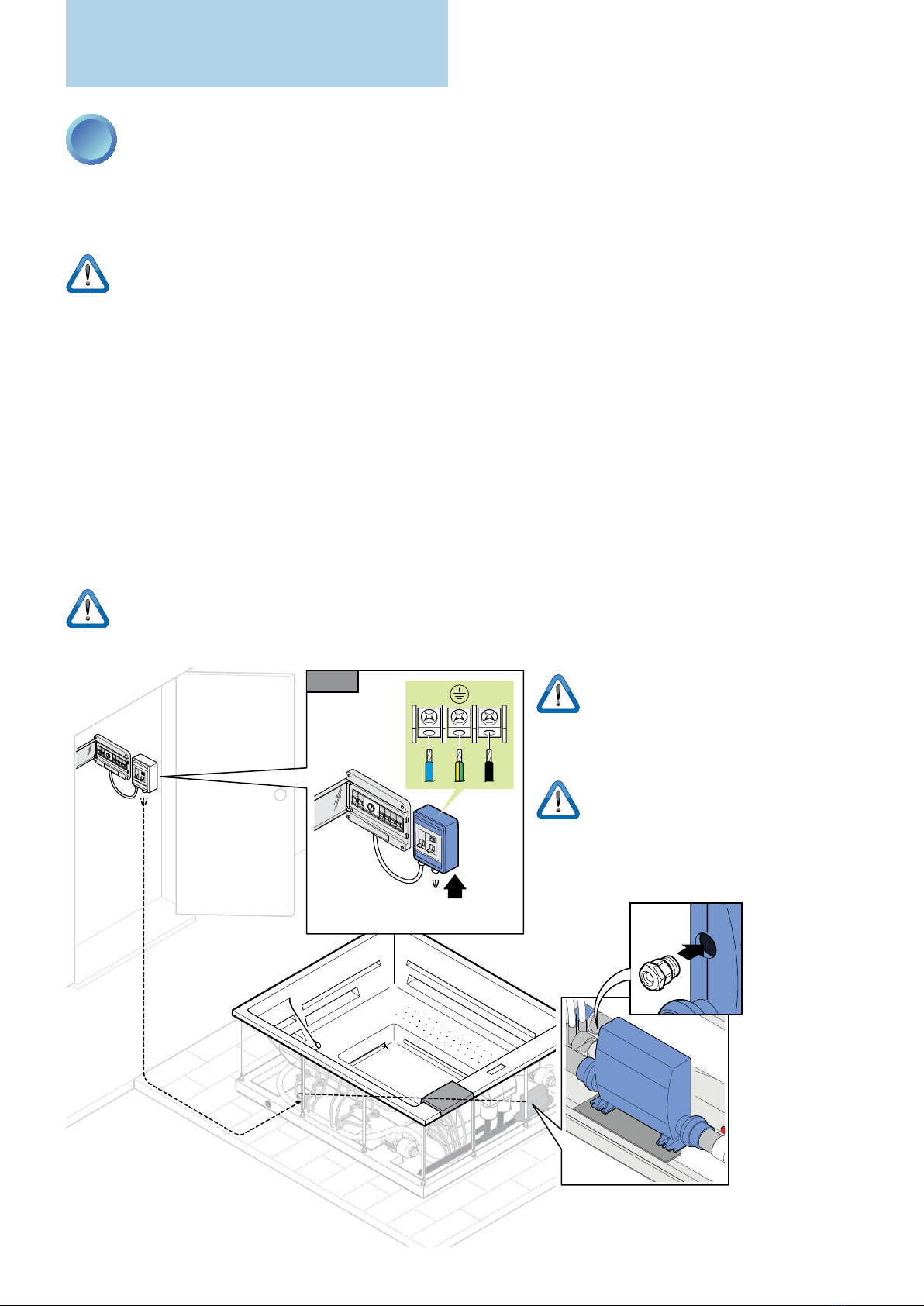

7ELECTRICAL CONNECTIONS

The Treesse minipools are built in compliance with European laws (EN 60 335-2-60) and are tested during production

to ensure the safety of the installer and user.

The connection must be made by an experienced, qualied electrician.

All electrical connections must be made only after disconnecting the electricity in the work area.

The electrical connection must be:

• Performed in a xed and permanent manner, without intermediate splices, in accordance with regulations of the

country of installation.

• Sufcient for the current absorbed by the bathtub (see technical specications).

• Provided with a functioning ground as per current regulations.

• Protected against splashing water, then placed in a dedicated room, closed and sheltered from the weather.

• Controlled by a multi-pole switch with a contact gap of at least 3 mm and a breaking capacity equal to 60A (or in

any case adequate for the absorption of the bathtub).

• Controlled by a differential switch no larger than 30mA.

The control unit's power supply cable must be of the H05 type with three wires (single-phase 230V) whose gauges

are adequate for the absorption of the minipool (see “Pre-installation sheet”). Its size depends on the absorbed

current and the distance of the minipool from the main electrical cabinet.

In addition, if the minipool is installed outdoors, the power cord from the main electrical panel to the minipool must

pass through an underground duct, without splices and adequately protected against freezing.

The Manufacturer is not responsible for connections made in a way that does not comply with local codes, the

specicationsinthismanualortamperingwithanyelectricalcomponentoftheminipool.

NL

230V~ When the connections have been made,

verify the proper operation of the differen-

tial switch by pressing the TEST key.

NB: to correctly connect the power cable, use

a cable gland (not supplied), suitable for the

diameter of the hole and the diameter of the

cable.

15

EN

Muse GP

minipool

Installation

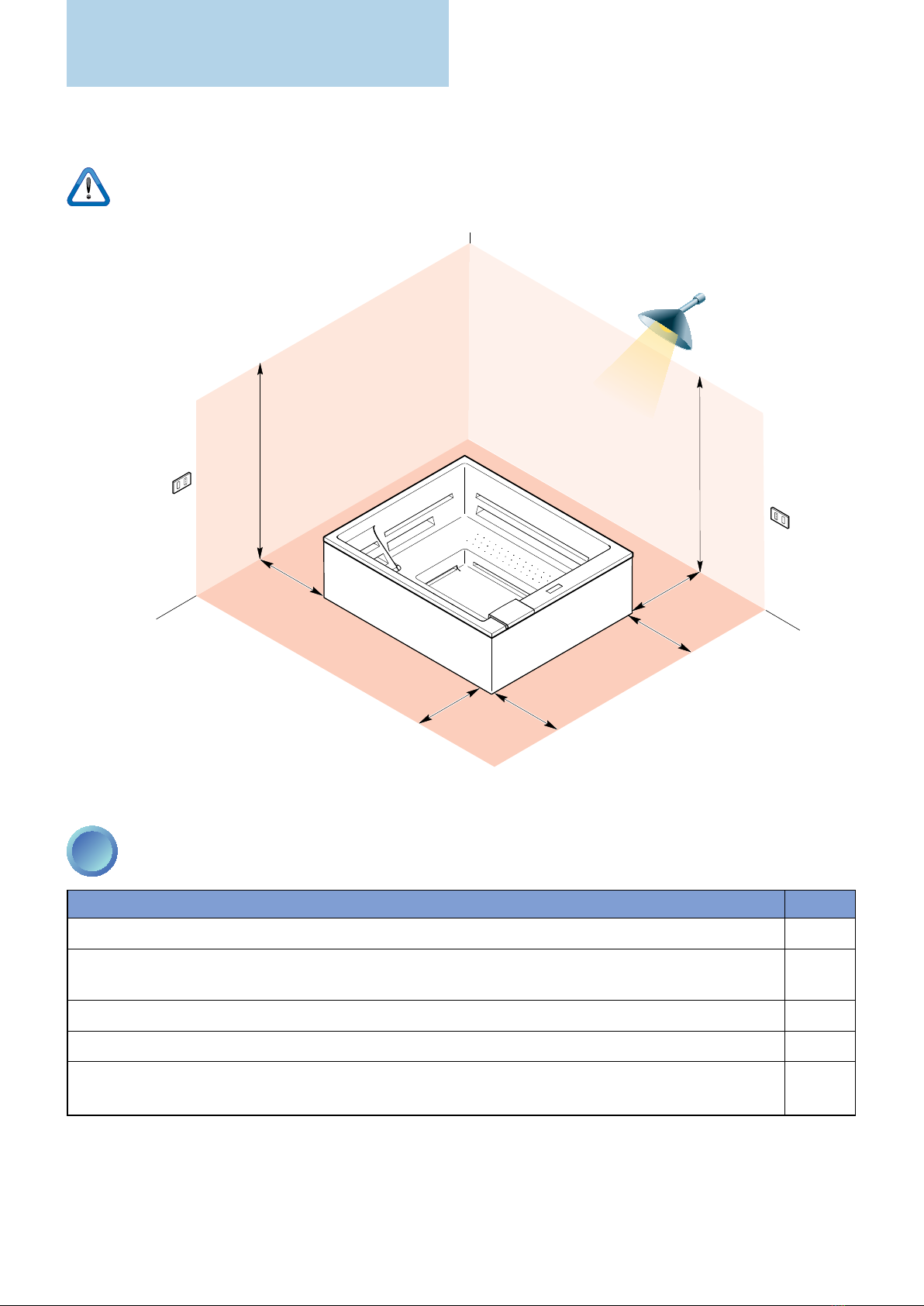

SAFETY ZONE

min.

60 cm

min.

60 cm

min.

60 cm

min.

60 cm min.

60 cm

MIN. 230 cm

MIN. 230 cm

Local regulations prohibit any electrical installation (plug sockets, switches, lamps, etc.) in the area surround-

ing the minipool for a distance of at least 60 cm and a height of 230 cm.

MAKE SURE THAT... √

The minipool is level and stable.

Electrical connections are made correctly in accordance with local and national codes and that the cables

are not damaged, crushed or abnormally bent.

The minipool's drainage valve is closed.

The minipool is not leaking.

Tools, documents or other items were not left under the minipool or in the recess.

TESTING AFTER INSTALLATION

8

16

EN

Muse GP

minipool

First run

1FILLING THE MINIPOOL

Perform a preliminary cleaning of the minipool using a

bit of water and a mild detergent.

Do not use cloths or cleaners that are abrasive, aggressive

or that contain solvents because they could irreparably

damage the surface of the minipool.

Do not start any operation until the minipool has

beencompletelylled,otherwisetheminipool

could be damaged.

Before lling, once again check the quality of the water

supply. This is very important for the well-being of the

users and for the long life of the minipool.

For more information see chapter “Characteristics

of the water supply” on page 12

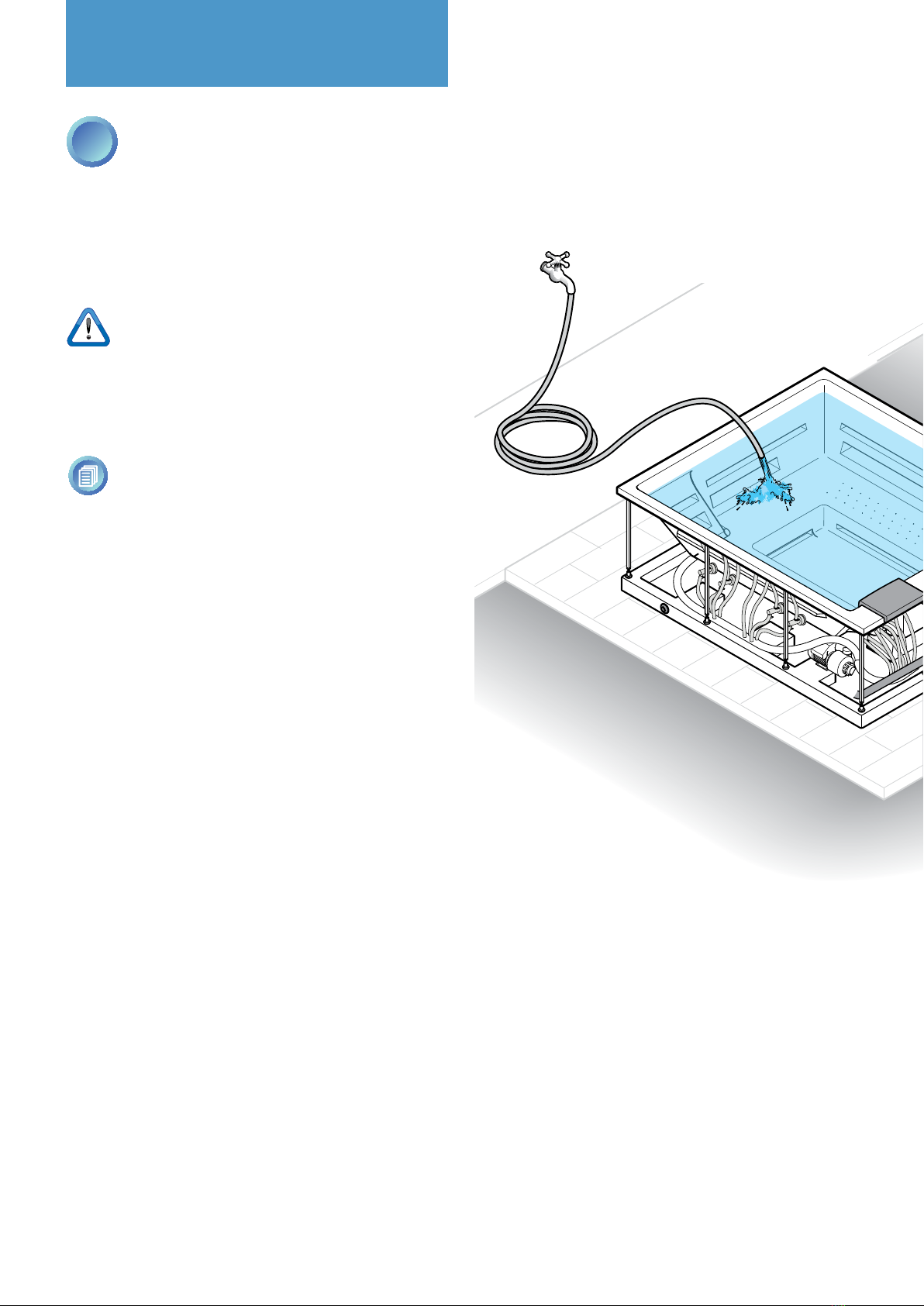

FILLING

Forlling,usearubberhoseasshowninthegure.

The water used must meet the requirements detailed in

the previous pages and summarised here:

Potability

Hardness (TH): between 10°F and 25°F

(100 mg/l-250 mg/l)

pH: between 7.4 and 7.8

Alkalinity: 80 and 125 mg/l (8-12.5°F)

Fill the minipool until the water reaches about 6-7 cm from

the upper edge and in any case until the “LL” indication

disappears.

Manual lling with a garden hose

17

EN

Muse GP

minipool

JETS 1

JETS 2

BLOWER

WARM

COOL

LIGHT

First run

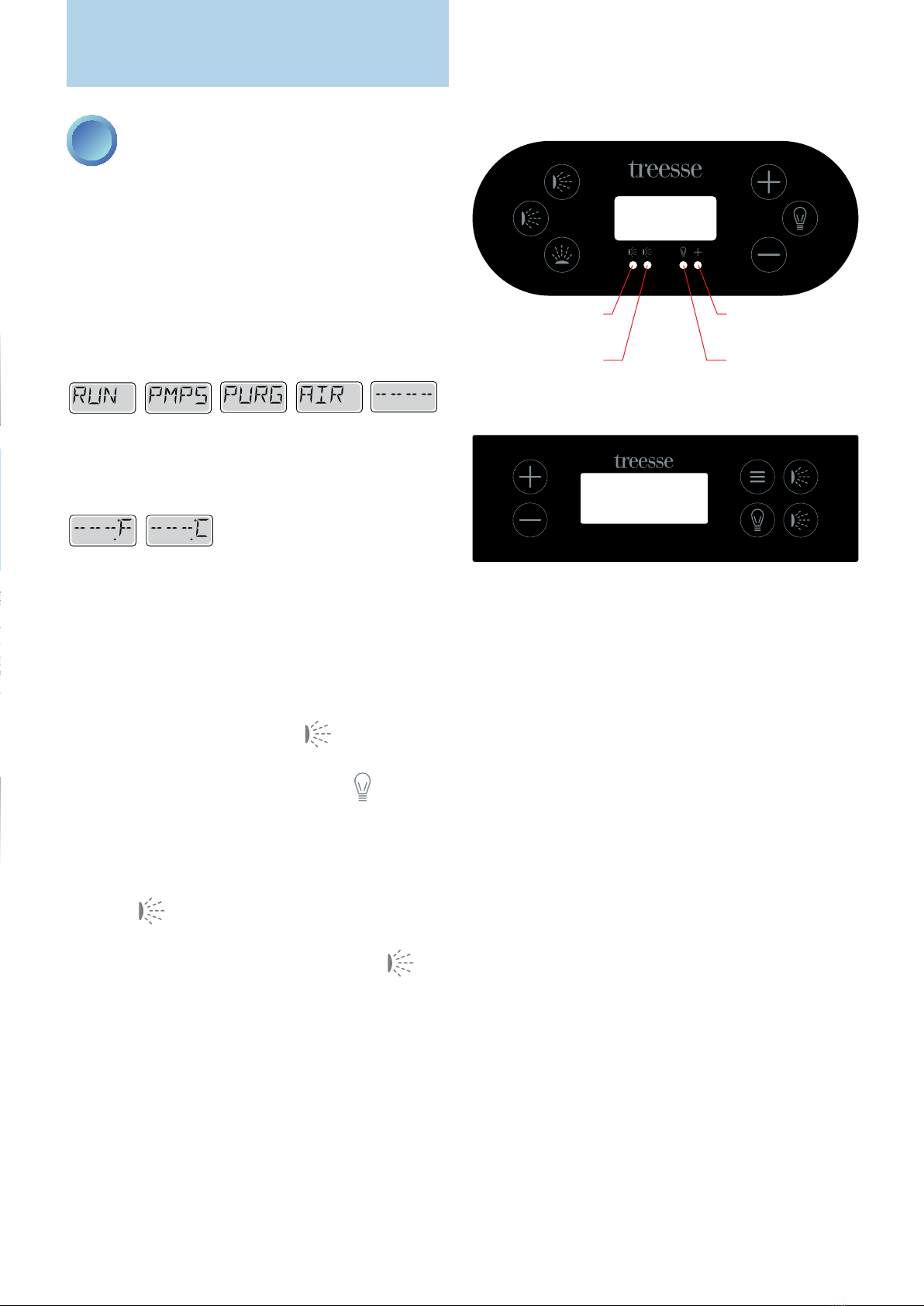

2FIRST RUN

After turning the power on at the main power panel, the

top-sidepaneldisplaywillgothroughspecicsequences.

This sequence displays a variety of information regarding

thecongurationoftheminipool.

PRIMING MODE

This procedure lasts 4-5 minutes, during which the heat-

ing is deactivated to prevent any overheating in case of

lowornon-existentow.

You can exit the mode manually even before the end of

the 4-5 minutes by pressing one of the temperature keys

+ or -. In this case the display will show:

READY RANGE

o

READY RANGE

Regardlessofwhetheryouwaitfortheprimingtonish

or exit manually before it is completed, the system will

automaticallyreturntoheatingandlteringnormallyonly

when the process has completed.

During the priming procedure it is possible to activate

the pumps pressing the “Jet” key .

If your minipool has a recirculation pump, it is possible

to activate it by pressing the “Light” key during the

priming process.

PRIMING THE PUMPS

As soon as the control panel display lights up, press the

“Jet” key once to activate pump 1 at low speed

and press it a second time to increase the speed.

If you have a second pump, press the “Jet2” key

to activate it. The pumps work at high speed to facilitate

priming.

If the pumps are not primed after two minutes and the

water does not come out, turn off the pumps and repeat

the process. Switching off and restarting will start a new

pump priming process. Sometimes momentarily turning

the pump off and on will help it to prime. Do not repeat

the operation more than 5 times. If the pumps cannot be

primed, switch off completely and call a Service Centre.

Main page

heater LED on

LED - chromotherapy on

LED - pump 1 on

(jets 1)

LED - pump 2 on

(jets 2)

Important: It is not allowed to operate a pump without the

priming process being completed. Doing so may cause

damage to the pump and cause the system to energize

the heater and go into an overheat condition.

Exiting Priming Mode

It is possible to manually exit the priming mode by press-

ing one of the temperature keys, otherwise the priming

process ends automatically after 4-5 minutes. Be sure that

the pump(s) have been primed by this time.

When the system exits priming mode, the display shows

the following.

Warm Jets(1)

Jets(2)

menu/

select

Cool Light

18

EN

Muse GP

minipool

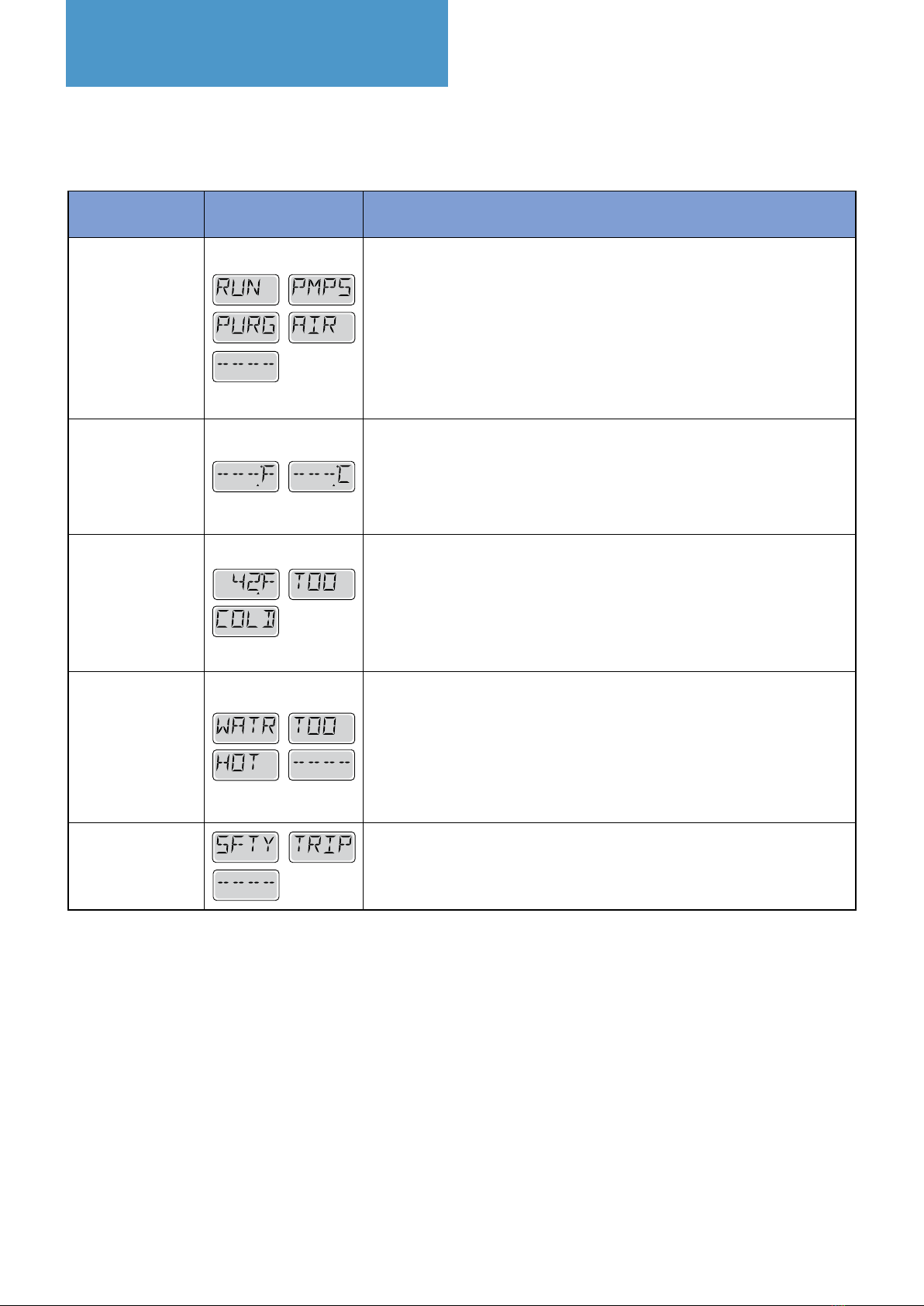

Alarms

If any alarms appear during initial startup, read the instructions provided in the following table. If the solution is not

possible, immediately contact the Manufacturer to request technical support. In the meantime, do not try to repair

or use the minipool but rather disconnect it from the electricity and water supplies.

GENERAL

MESSAGES

DISPLAY

SCREEN DESCRIPTION OF SIGNALS AND POSSIBLE SOLUTIONS

Initialization

(Priming mode)

M019

Problem description: Every time the system is activated it automatically

enters initialization mode to allow the user to operate each pump sepa-

rately and to manually check that the air has been eliminated from the

circuit and the water is owing, operations not possible during normal

operation. Initialization mode lasts 4 minutes but it is possible to exit

the function before by pressing any Temperature key.

Heating is not allowed during the initialization mode.

Note: If the pool has a recirculation pump, it turns on with “Jets 1”

during the initialization process and activates autonomously when the

process is nished.

Water

Temperature is

Unknown

(notication)

READY RANGE READY RANGE

or

Problem description: The message indicates that it is necessary to wait

before knowing the water temperature: in order for it to be detected

correctly, in fact, the pump dedicated to water circulation must have

been in operation for at least one minute.

S

olutions: wait a minute to view the water temperature.

Frost protection

(notication)

READY RANGE FLTR1

Problem description: The system has detected that conditions exist

for the water to freeze. Therefore, to avoid this, all the pumps are au-

tomatically activated and remain active for at least 4 minutes after the

freezing danger has passed.

Solutions:

The starting and stopping of the pumps is automatic but

further utilities (e.g. heater) can be switched on or off to better protect

against freezing.

Water too hot

(OHS) – M029

Problem description: The sensors have detected a potential danger

due to the water temperature being too high, above 43.3°C (110°F).

The minipool functions are disabled.

Solutions:

When a temperature lower than 42.2°C (108°F) is restored,

the message disappears and normal operation resumes. Check for a

possible pump malfunction or high temperature.

Suction pump

block* M033

Problem description: The error message “Safety trip” indicates that

the suction pump is blocked due to a suction problem or an obstruction.

(Note: not all minipools have this function).

Solutions:

Contact Technical Service

* this message can be deleted from the top of the panel by pressing any key.

19

EN

Muse GP

minipool

Alarms

MESSAGES

CONNECTED

TO WATER

HEATING

DISPLAY

SCREEN DESCRIPTION OF SIGNALS AND POSSIBLE SOLUTIONS

The water

heating is too low

(HFL) - M016

Problem description: There may be an insufcient water ow into the

heater. Water heating is blocked for about a minute, until a new heating

attempt is made.

See the “Water ow problems” section.

Water heating

is too low (LF)* -

M017

Problem description: The system has detected an insufcient passage

of water in the heater.

See the “Water ow problems” section.

When the problem is solved, simply press any key on the control panel

to re-enable the operation of the

heater and reset the error.

The heater may

be dry (dr)* -

M028

Problem description: Possible lack of water in the heater.

Each pool function is disabled for 15 minutes.

Press any key on the control panel to re-enable the heater operation

and reset the error.

See the “Water ow problems” section.

The heater is

dry* - M027

Problem description: No water in the heater. All minipool functions are

disabled. After solving the problem, remove and restore the power to

initialize the water heating procedure.

See the “Water ow problems” section.

The heater is

too hot (OHH)* -

M030

Problem description: The water temperature sensors have detected

too high temperatures, above 47.8°C (118°F). All minipool functions are

disabled. Press any key on the control panel to re-enable the heater

operation when the water temperature is below 42.2°C (108°F).

See the “Water ow problems” section.

A reset message

can accompany

other messages

Problem description: Some errors may require the interruption of the

electric current and the subsequent restoration of the same.

* this message can be deleted from the top of the panel by pressing any key.

More information

PROBLEMS CONNECTED TO THE WATER FLOW

Check that the water level is not too low, the suction ow is not blocked, the valves are working, the air is not

trapped, the jets and pumps are ready.

In some systems, even when the pool is switched off, some functions occasionally activate to continue monitoring

the temperature or the need to activate frost protection.

20

EN

Muse GP

minipool

Alarms

SENSOR-RELATED

MESSAGES

DISPLAY

SCREEN DESCRIPTION OF SIGNALS AND POSSIBLE SOLUTIONS

Temperature

sensor not

accurate - M015

READY RANGE FLTR1

Problem description: The sensors connected to the water temperature

survey provide inaccurate indications (error margin of 2°C or 3°F).

Solutions:

If the problem persists, contact Technical Service.

Temperature

sensor not

accurate - M026

Problem description: The sensors connected to the water temperature

survey give incorrect indications. The malfunction continues for at least

1 hour.

Solutions:

Contact Technical Service.

Sensor fault -

Sensor A: M031,

Sensor B: M032

Problem description: The sensor connected to the temperature survey

or the circuit sensor do not work.

Solutions:

Contact Technical Service.

VARIOUS TYPES

OF MESSAGES

DISPLAY

SCREEN DESCRIPTION OF SIGNALS AND POSSIBLE SOLUTIONS

No signal

Problem description: The control panel does not communicate with

the electronic control unit.

Solutions:

If the problem persists, contact Technical Service.

Development

software (beta)

Problem description: The control system is operating with a non-nal

software version.

Solutions:

Contact Technical Service.

°F or °C are

replaced by °T

READY RANGE FLTR1

Problem description: The minipool is working with an incorrect con-

guration.

Solutions:

Contact Technical Service.

* this message can be deleted from the top of the panel by pressing any key.

* this message can be deleted from the top of the panel by pressing any key.

Table of contents

Other treesse Swimming Pool manuals

Popular Swimming Pool manuals by other brands

Outside Living Industries

Outside Living Industries Ubbink OCEA Note of assembly

CARVIN

CARVIN 975282 Series user manual

Outside Living Industries

Outside Living Industries ubbink Azura 400x750 - H130 cm Note of assembly

Bestway

Bestway 56709 manual

avenli

avenli SPA4 user manual

Bestway

Bestway PLATINUM SWIM VISTA 1425469 owner's manual