TABLE OF CONTENTS

THANK YOU…. .........................................................................................................................................................2

WARRANTY .............................................................................................................................................................. 2

GENERAL SAFETY ..................................................................................................................................................3

1.0 –COMPLETE ASSEMBLY OVERVIEW.............................................................................................................4

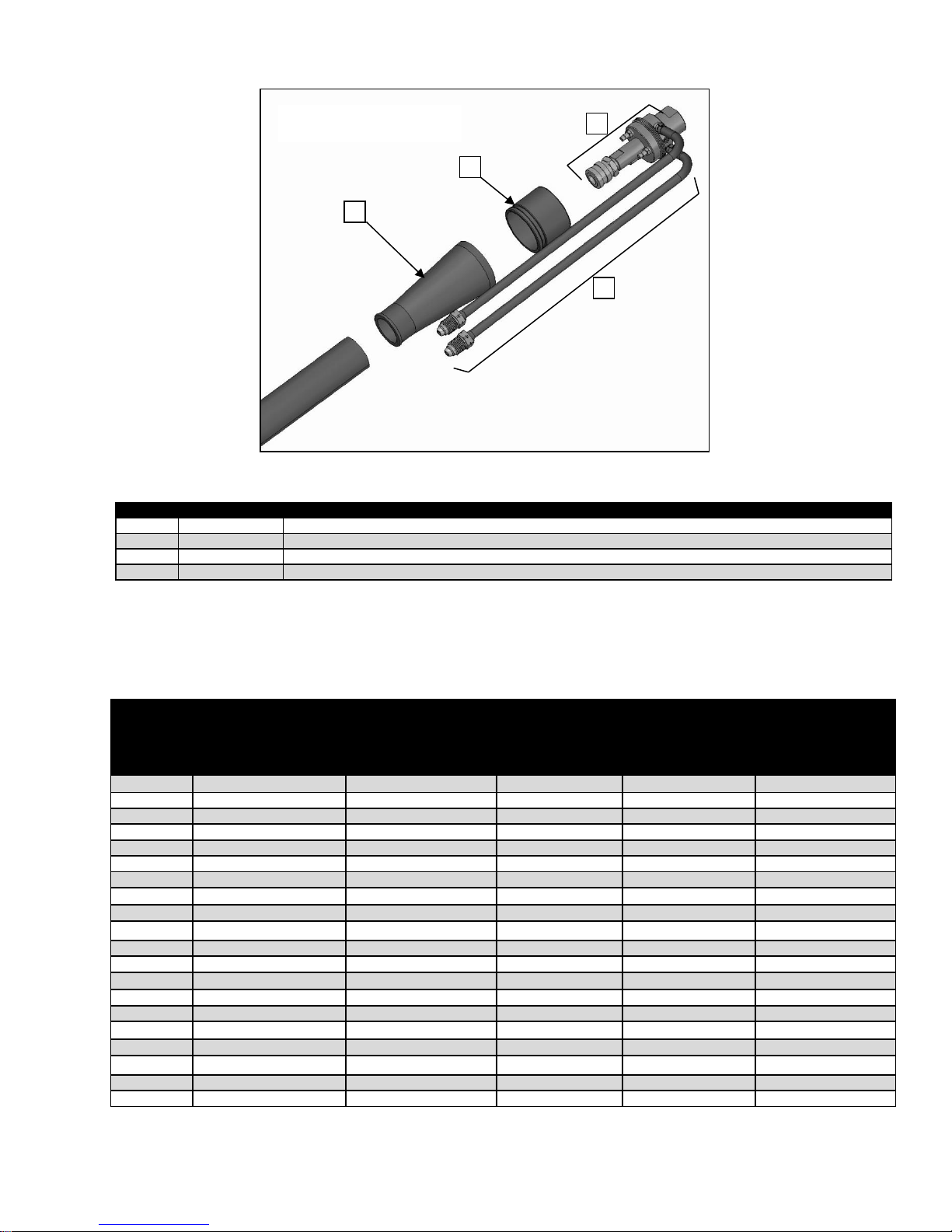

2.0 –EXPLODED VIEW AND PARTS LIST .............................................................................................................5

2.1 FRONT-END COMPONENTS ........................................................................................................................5

2.2 CABLE BUNDLE COMPONENTS ..................................................................................................................6

2.2.1 CABLE BUNDLE COMPONENTS –FRONT...............................................................................................6

2.2.2 CABLE BUNDLE COMPONENTS –REAR.................................................................................................7

2.2.3 CABLE BUNDLES........................................................................................................................................7

3.0 –SECURING THE NECK....................................................................................................................................8

4.0 –WIRE BRAKE OPTION ....................................................................................................................................9

4.1 WIRE BRAKE REPLACEMENT......................................................................................................................9

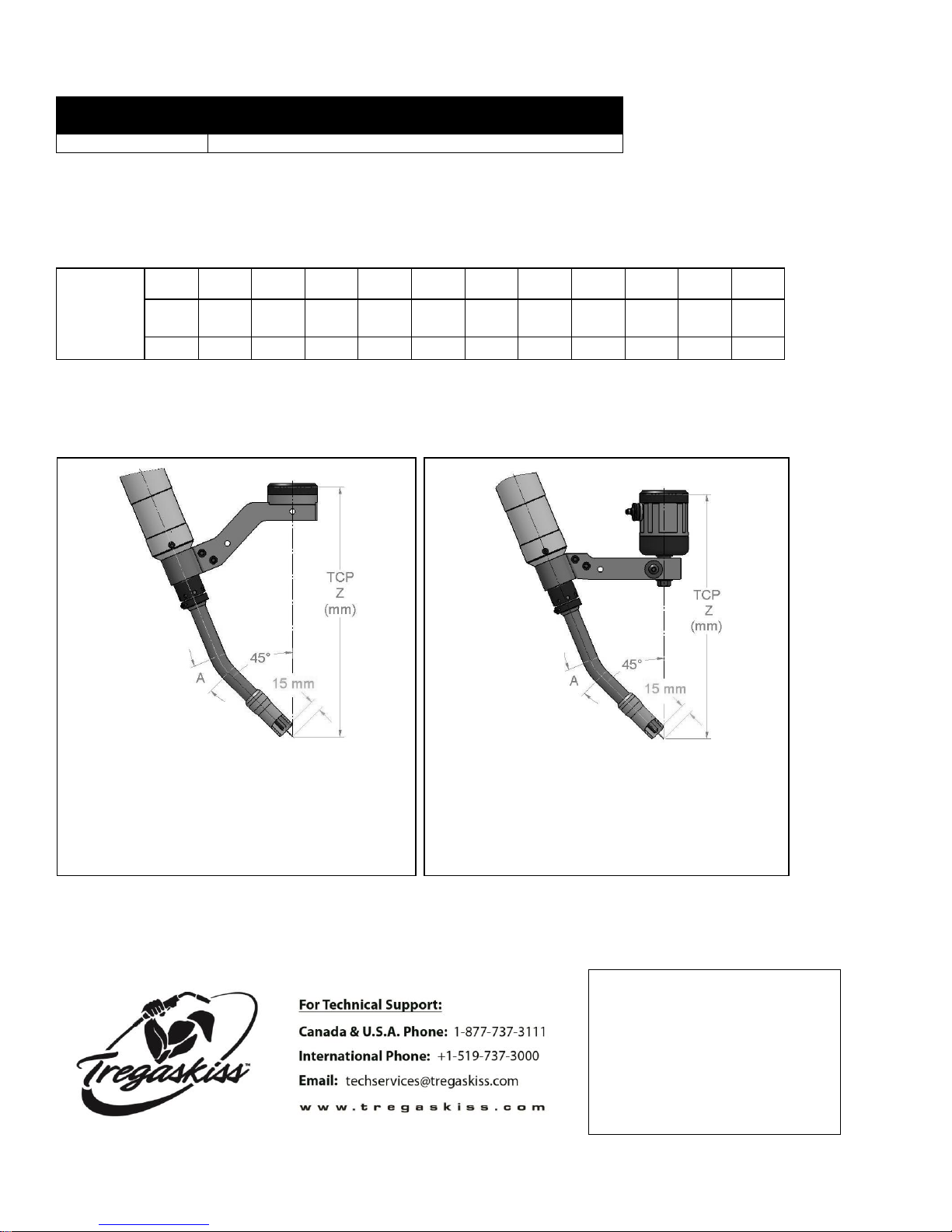

5.0 –AMPERAGE RATINGS ..................................................................................................................................10

6.0 –ORDERING INFORMATION ..........................................................................................................................10

THANK YOU….

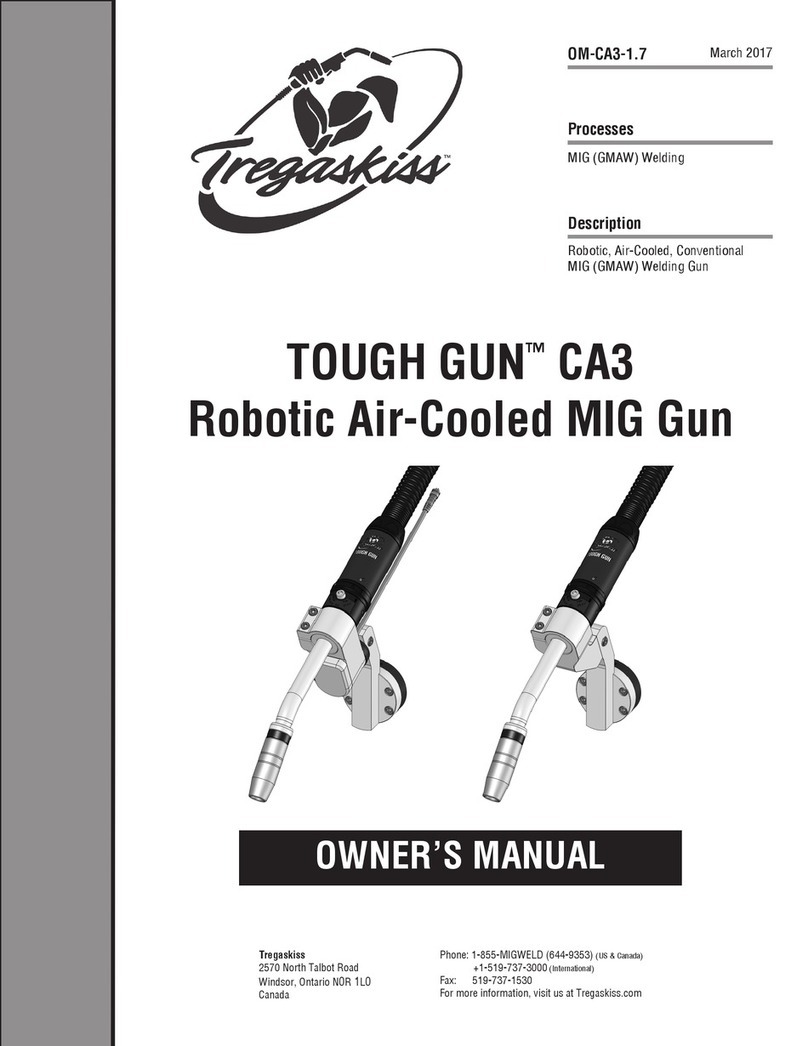

…for selecting a Tregaskiss TOUGH GUN™Robotic MIG Gun. Manufacturing operations demand extremely

dependable robotic equipment. With this in mind, the TOUGH GUNMIG Gun was designed and engineered to be

a reliable tool to support high production within a robotic cell. As the name implies, the TOUGH GUN MIGGun is

made from durable materials and components engineered to perform in a rugged welding environment. Your

TOUGH GUN MIG Gun is completely assembled and ready to weld, and has undergone numerous quality checks

to ensure high performance.

The instructions and illustrations in this technical guide make it easy for you to maintain your TOUGH GUN MIG

Gun. Please read, understand, and follow all safety procedures. Keep this Technical Guide booklet as a

handy reference when ordering complete guns, parts and special options. For technical support and special

applications, call the Tregaskiss Technical Service Department at 1-855-MIGWELD (644-9353) or fax

1-877-737-2111. Our trained technicians are available Monday through Friday from 8:00 am and 5:00 pm EST

and will answer your application or repair questions.

Tregaskiss employees build TOUGH GUN MIG Guns for the world’s welding professionals. We are always

striving to improve our products and services, and would appreciate receiving your suggestions or comments.

Please contact us immediately if you experience any safety or operating problems.

WARRANTY

Product is warranted to be free from defects in material and workmanship for the period specified below after the

sale by an authorized Buyer. Should there be a defect please refer to our Return Merchandise Policy.

TOUGH GUN™ Robotic MIG Guns and Components

TOUGH GUN™TT3 Reamer with Lubricator

TOUGH GARD™Spatter Cleaner

TOUGH GUN Robotic Peripherals (Clutch, Sprayer, Wire Cutter, Mounting Arms)

Low-Stress Robotic Unicables (LSR Unicables)

Tregaskiss reserves the right to repair, replace or refund the purchase price of non-conforming product. Product

found not defective will be returned to the Buyer after notification by Customer Service.

Tregaskiss makes no other warranty of any kind, expressed or implied, including, but not limited to the warranties

of merchantability or fitness for any purpose. Tregaskiss shall not be liable under any circumstances to Buyer, or

to any person who shall purchase from Buyer, for damages of any kind, including, but not limited to any, direct,