Trejon 1800HD Specification sheet

TREJON FÖRSÄLJNINGS AB

Företagsvägen 9

SE-911 35 VÄNNÄSBY

SWEDEN

Tel: + 46 (0)935 39 900

Webb: trejon.se

Instructions for Use and

Maintenance

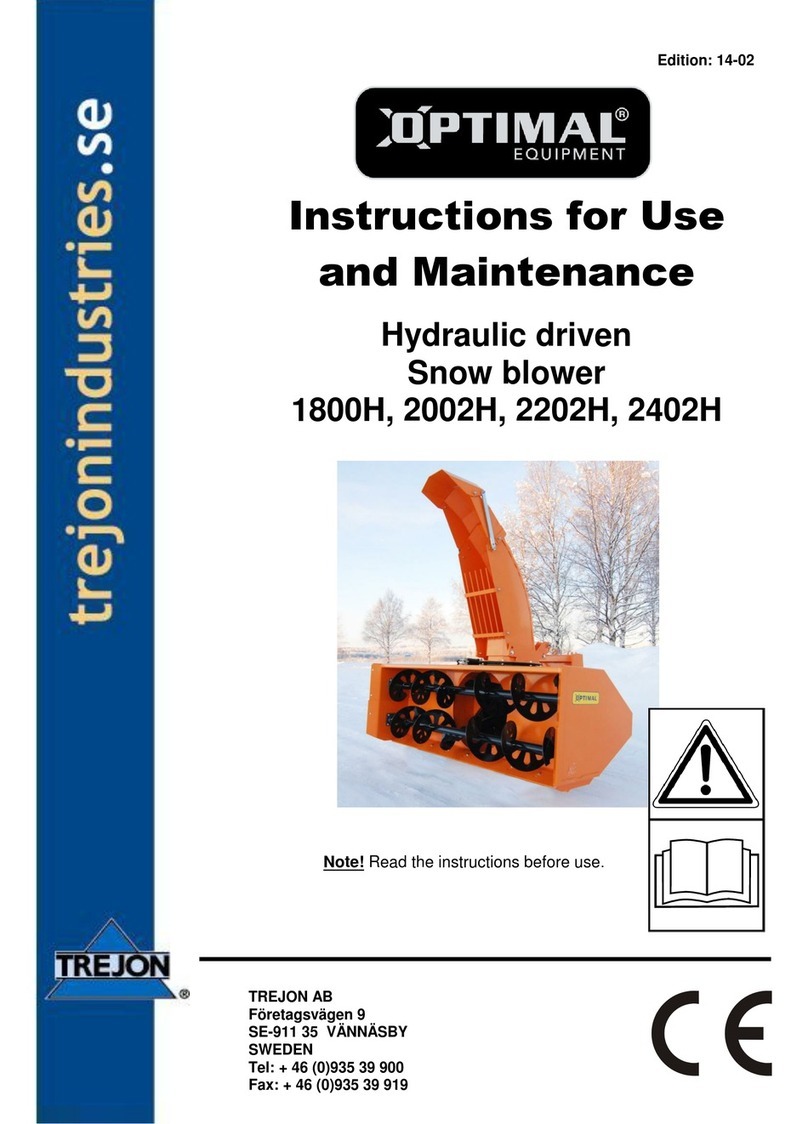

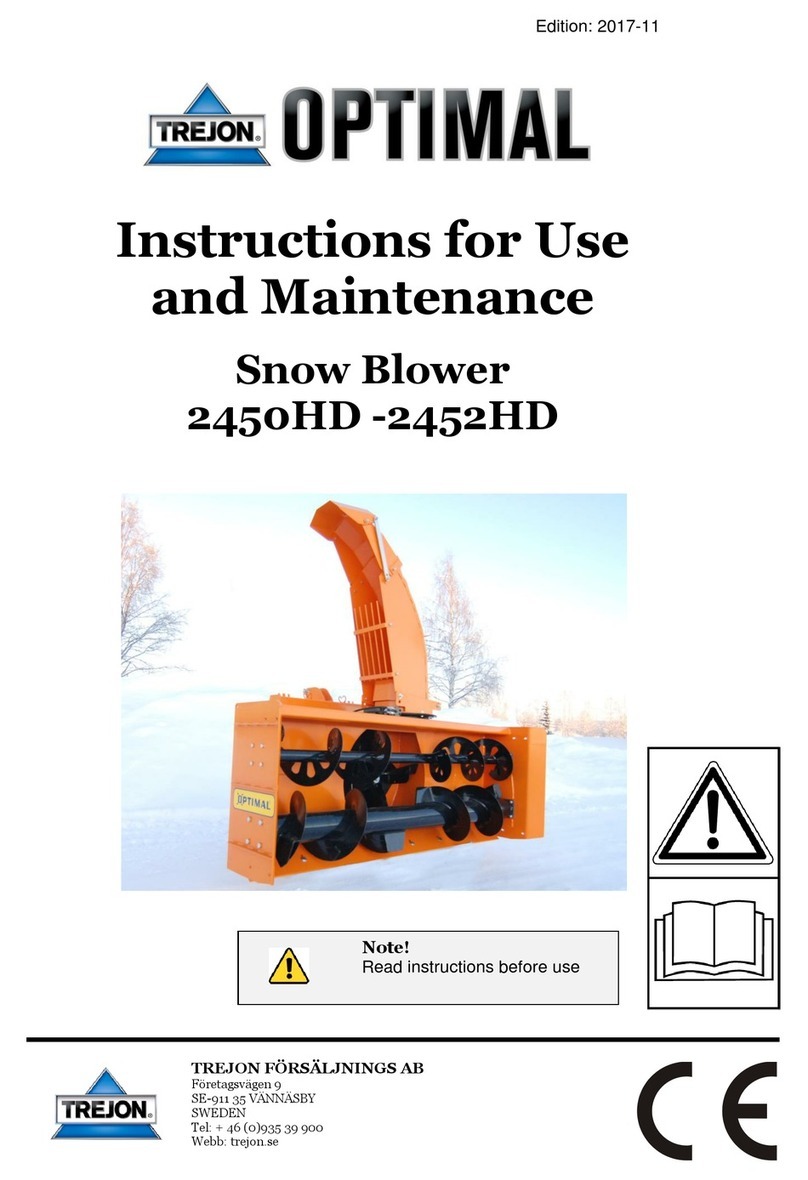

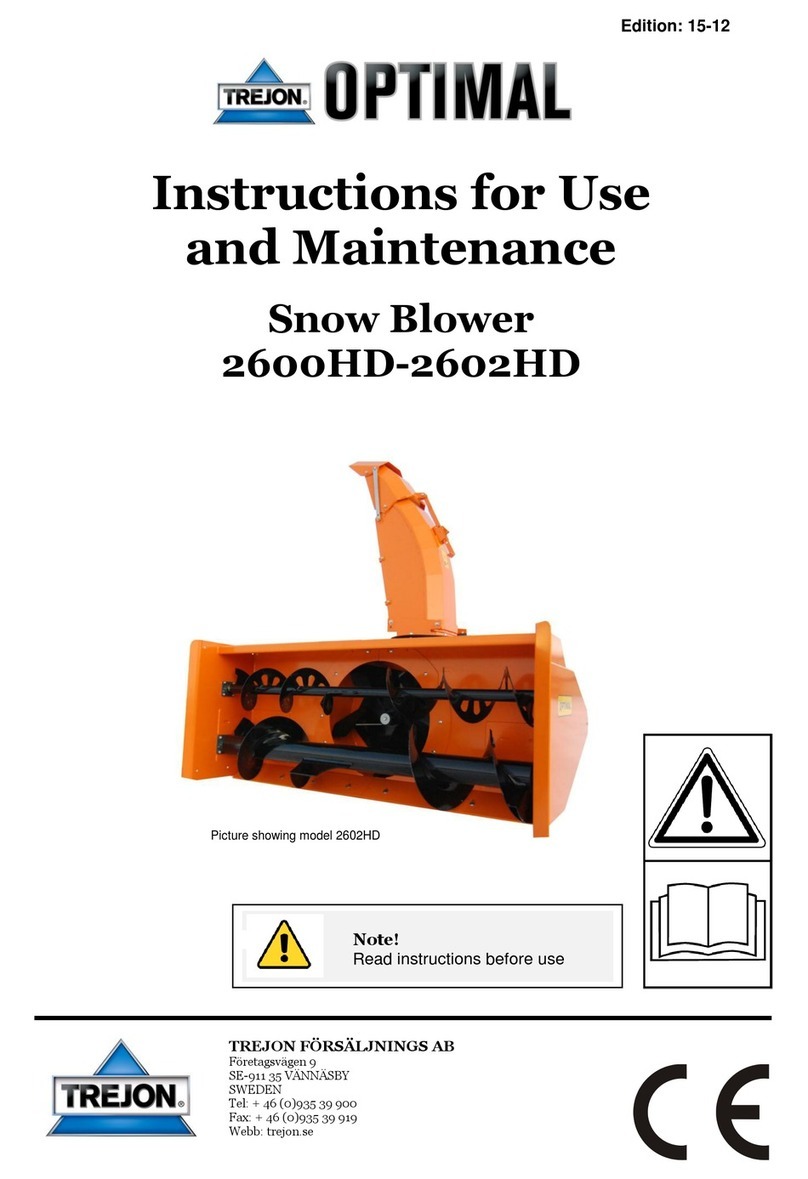

Snow Blower

1800HD-2402HD

Edition: 2018-10

Note!

Read instructions before use

Instructions for Use and maintenance 1800HD-2402HD (1810)

2

Breddningsvinge

n monteras på

insidan av

maskinen

Instructions for Use and maintenance 1800HD-2402HD (1810)

3

Breddningsvinge

n monteras på

insidan av

maskinen

TABLE OF CONTENT

1Introduction....................................................................................................7

1.1 Foreword ...................................................................................................7

1.2 Description.................................................................................................7

1.3 Working stages..........................................................................................7

1.4 Detailed description...................................................................................8

1.5 Technical data...........................................................................................9

2Safety instructions ......................................................................................10

2.1 Safety precautions...................................................................................10

2.2 Explanation of the symbols......................................................................13

3Using the equipment...................................................................................15

3.1 Assembly.................................................................................................15

3.2 Attaching machine to the tractor..............................................................16

3.3 Before starting up....................................................................................18

3.4 Adjustments.............................................................................................18

3.5 Operating the machine............................................................................20

4Service and maintenance ...........................................................................22

4.1 General....................................................................................................22

4.2 Maintenance schedule.............................................................................23

4.3 Before the snowy season........................................................................23

4.4 After the snowy season ...........................................................................24

4.5 Gear box oil check and change...............................................................24

5Troubleshooting..........................................................................................25

6Options.........................................................................................................26

6.1 Mounting of extension wing (accessories)...............................................26

7Spare Parts ..................................................................................................28

EC-Certificate of Conformity ............................................................................31

Instructions for Use and maintenance 1800HD-2402HD (1810)

4

Breddningsvinge

n monteras på

insidan av

maskinen

SAFETY SYMBOLS

Note! This warning symbol is used throughout this instruction manual to call attention to safety

precautions that you, your employees or any other people that may come near the implement

must read and understand. Failure to follow these instructions may result in serious injury or

even death.

This symbol means:

WARNING!

CAUTION!

YOUR SAFETY IS

ENDANGERED!

A word of advice

Pay special attention to the words WARNING!, CAUTION! and NOTE! in the safety instructions.

The words have been chosen from of the following:

WARNING! This safety sign is used to identify potential hazards that can lead to serious injury

or even death. These hazards include situations that may occur when the safety equipment

and/or the safety shields are removed. Signal words can also be used to alert about dangerous

use.

CAUTION! Failure to observe this warning sign could result in light personal injuries. The sign is

also used to indicate that the disregarding of these instructions may cause damage to the

implement.

Instructions for Use and maintenance 1800HD-2402HD (1810)

5

Breddningsvinge

n monteras på

insidan av

maskinen

Dear Customer,

You have made a good choice. We congratulate you to your selection of a TREJON OPTIMAL

product that offers quality and performance with reliable service.

By reading the manual and following its recommendations you will ensure the long and effective

use of the equipment.

We have produced this manual for you to get a good understanding of the functioning of the

machine and what safety and maintenance instructions to follow when working with it.

If any question should arise when using the machine or when reading this manual, you are

welcome to contact us for further information.

TREJON AB

Företagsvägen 9

SE-911 35 Vännäsby

Sweden

Tel: + 46 (0)935 399 00

Email: [email protected]

Website: www.trejonindustries.se

Instructions for Use and maintenance 1800HD-2402HD (1810)

6

Breddningsvinge

n monteras på

insidan av

maskinen

Honoured retailer,

in order for the guarantee to be valid and to forfill all legal requirements, we ask you to fill out

the guarantee form together with the customer and register at trejon.se

The guarantee is valid from the day the equipment is handed over to the customer.

Delivery checklist:

Check for damages caused in transporting. Inform the transporting company.

Check that all packing material has been taken away. Dispose packing material in an

environmentally friendly way

Check if the PTO-shaft with shear bolt 2920Nm is included.

Check that the machine is lubricated, see section “Service and maintenance”.

Check that all screws are properly tightened, see section “Service and

maintenance”.

Check that all guards and safety shields are properly fastened.

Check the oil level in the gearbox. See section “Service and maintenance”.

Check chain tension, see section “Service and maintenance”

Make a funtion test.

Having gone through and explained to the customer, with the help of the manual, the

startup, use and maintenance of the equipment and it’s accessories.

Fill out the guarantee form with the customer and register at trejon.se

Instruction manual given to the customer.

Enter the serialnumber of the machine to the

right.

S/N:

Instructions for Use and maintenance 1800HD-2402HD (1810)

7

Breddningsvinge

n monteras på

insidan av

maskinen

1 Introduction

1.1 Foreword

Thank you for choosing this TREJON OPTIMAL machine. We have concentrated our efforts in

order to develop a sturdy machine that will operate trouble-free for many years. The working life

of the machine, however, depends not only on us but also on you. We have compiled this

instruction manual in order to facilitate the use of the implement and describe proper

maintenance procedures. Read these instructions carefully. Contact the retailer from whom you

purchased the machine whenever you want to order repair parts or need any other assistance.

When you are ordering repair parts, make sure that you know the right model, type and serial

number. See the identification plate on the chassis.

1.2 Description

The equipment is designed to clear snow from level ground such as roads and parking lots. The

snow blower is to be mounted at the front or at the rear on the three point lift of the tractor. Cat.

II/III. A double acting hydraulic connection is needed to turn the ejector tube. If the equipment is

fitted with an hydraulic flap regulator, an added double acting connection is needed. The

equipment is powered by the PTO of the tractor. When mounted to the rear of an pulling tractor:

540 rpm (just 2000HD). When mounted on a reversing tractor: 1000 rpm. When mounted to the

front of a tractor: 1000 rpm.

1.3 Working stages

The equipment works in three stages:

1. Break-up and feeding in with self-cleaning feed screws with cutting action.

2. Transport to the ejecting rotor.

3. The ejecting rotor will powerfully throw out the snow through the ejector tube. The

ejector tube is adjustable as to the direction and the distance of the thrown snow.

Instructions for Use and maintenance 1800HD-2402HD (1810)

8

Breddningsvinge

n monteras på

insidan av

maskinen

1.4 Detailed description

1

Chassie

2

Ejector tube (long or short tube)

3

Twinflap

4

Ejecting rotor

5

Feeding augers (1pcs at 1800 and 2000HD)

6

Flap control

7

Turntable gear

8

Reversible wearing edge

9

Gearbox

10

Drive shaft for frontal mounting, 1000 rpm

11

Drive shaft for rear mounting, 540 rpm

12

Shear bolt clutch for the feeder screw

13

Tool box with holders for spare shear bolts

14

3-point/A-frame, adjustable, bolted pulling frame

4.

1.

3.

2.

5.

6.

7.

12.

9.

8.

11.

10.

14.

13.

Instructions for Use and maintenance 1800HD-2402HD (1810)

9

Breddningsvinge

n monteras på

insidan av

maskinen

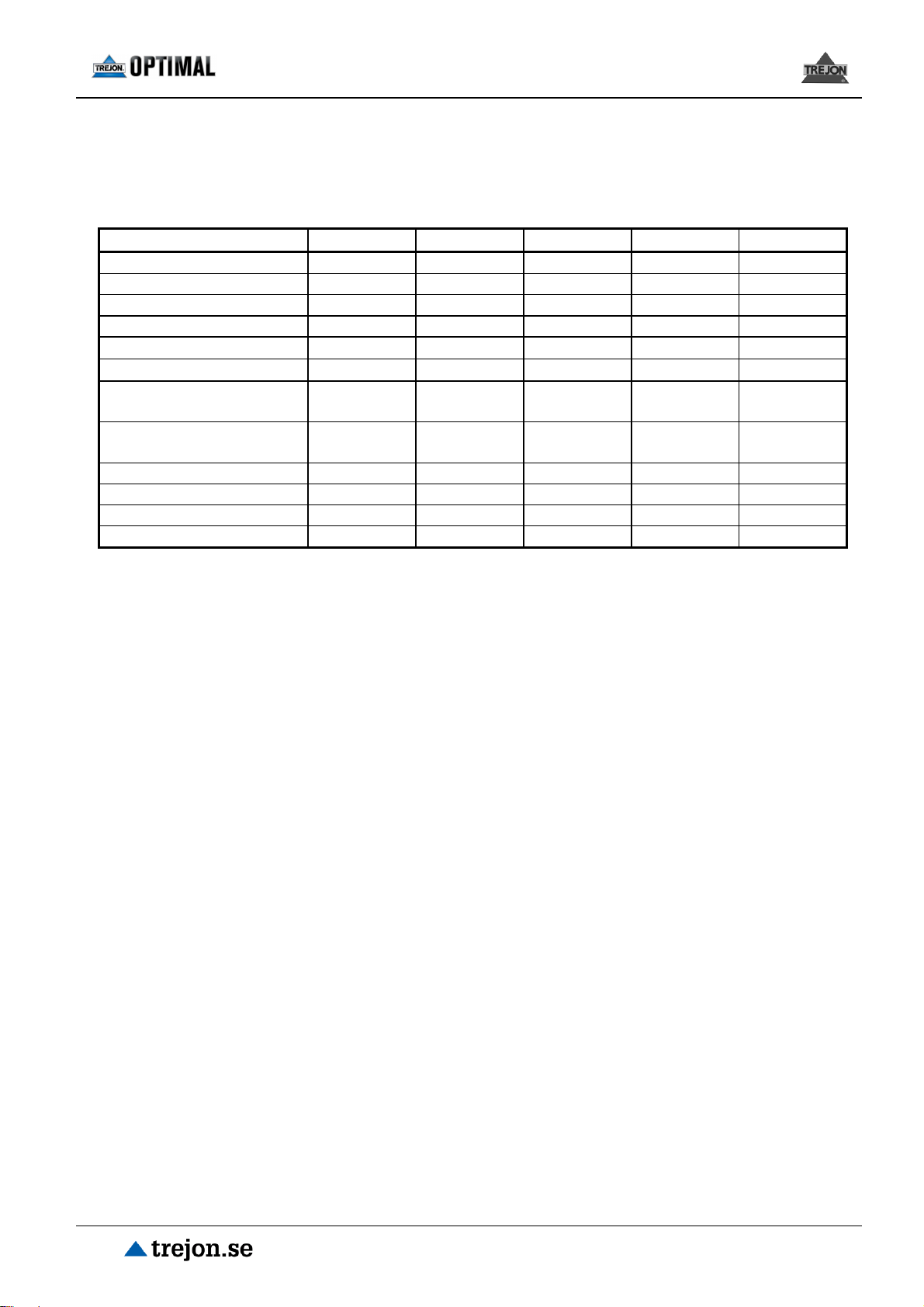

1.5 Technical data

Technical data / model

1800HD

2000HD

2002HD

2202HD

2402HD

Working width, mm

1820

1950

1950

2150

2350

Frame height, mm

820

820

820

820

820

Cutting auger, units

1

1

2

2

2

Cutting auger, mm

340

340

340

340

340

Ejecting rotor, mm

680

680

680

680

680

Recommended tractor

power (kW)

45-100 kW

50-110 kW

50-110 kW

55-120 kW

55-120 kW

Rotating ejector tube,

standard

Hydraulic

Hydraulic

Hydraulic

Hydraulic

Hydraulic

Flap control, standard

Mechanical

Mechanical

Mechanical

Mechanical

Mechanical

Weight, basic unit (kg)

560

590

730

760

790

PTO operational rpm

540/1000

540/1000

540/1000

540/1000

540/1000

Mounting variations

R-T-F

R-T-F

F-R

F-R

F-R

Due to continuous product development, any data is subject to change without prior notice.

R=Reversing: 540 rpm, T=Towed: 540 rpm, F=Front mounted: 1000 rpm.

Instructions for Use and maintenance 1800HD-2402HD (1810)

10

Breddningsvinge

n monteras på

insidan av

maskinen

2 Safety instructions

2.1 Safety precautions

Read operator’s manual. All drivers of the machine must read and understand all the contents

of this operator’s manual, so there is no doubt about management before using the equipment

for the first time. If any hesitation, ask your Trejon dealer about advise. It is forbidden to use the

equipment if user don’t know the risk factors at handling, and don’t know how to act in an

emergency situation.

Read, observe and understand meaning of all safety-, use-, warning- and position- symbols at

machine and in user manual.

Safety is the primary concern in the design and manufacture of our products. Unfortunately our

efforts to provide safe equipment can be wiped out by a single careless act of an operator.

In addition to the design and configuration of equipment, hazard control and accident prevention

are dependent upon the awareness, concern, prudence and proper training of personnel

involved in the operation, transport, maintenance and storage of equipment.

Allow only properly trained personnel to operate the equipment.

The machine is intended only for outdoor use.

Management. Learn how to operate the machine and how to use the controls properly before

operating the machine.

Connect the machine. Attach the machine correctly; don’t stand behind the tractor during

installation. Ensure machine is properly mounted, adjusted and in good operating condition.

Failure to ensure a secure coupling of the implement to the tractor can cause injury and

damage to the implement or tractor.

Secure the working area. Unauthorized persons, particularly children, are not allowed near the

machine while it is running or is being repaired. Before backing up, look behind carefully.

Pay attention to the injury and damage that can be caused by material thrown by machine

during operating, therefore clear area of stones, branches or other debris that might be thrown,

causing injury or damage. Take care never to aim the snow outlet towards people, animals or

buildings.

The rotating parts of this machine have been designed and tested for rugged use. However,

they could fail upon impact with heavy, solid objects such as steel guard rails and concrete

abutments. Such impact could cause the broken objects to be thrown outward at very high

velocities. To reduce the possibility of property damage, serious injury, or even death, never

allow the cutting blades to contact such obstacles.

Machines protective equipment. Do not operate the machine if not all safety guards and

shields for moving parts are in place and in good condition.

Ensure that all safety and operating signs are in good condition.

Additional safety and operating decals are available at no extra charge. Please specify model

and serial number when ordering.

Moving parts. Keep hands, feet, hair and clothing away from moving parts of the machine.

Let the machine work by it self, don’t try to help the machine with hands and fingers.

Instructions for Use and maintenance 1800HD-2402HD (1810)

11

Breddningsvinge

n monteras på

insidan av

maskinen

PTO-shaft. When changing tractor always check the length of the PTO-shaft, a to long shaft

can damage both tractor and machine. It is forbidden to use PTO-shaft that does not fulfill

requirements from manufacture.

Make sure that PTO-shields are in good condition and fastened securely to the tractor. It is

forbidden to use a PTO-shaft with damaged or missing shield. Purchase a new shield if old

shield is damaged or missing.

Lifting and lowering machine. Be careful when lifting or lowering the machine.

Stability. The machine should not be mounted on a tractor with insufficient front shaft /back

shaft weight when the tractor becomes unstable and difficult to operate. When using a unit, a

minimum 20% of tractor and equipment weight must be on tractor front wheels. Without this

weight, tractor could tip over, causing personal injury or death. The weight may be attained with

a front end loader, front wheel weights, and ballast in tires or front tractor weights, read the

tractor’s instructions manual for more information.

In extremely uneven terrain rear wheel weights, front tractor weights, and/or tire ballast should

be used to improve stability.

Operating machine. Be careful and reduce the speed when working on uneven surfaces.

Watch for holes, roots, rocks or other hidden objects. Do not drive near the edge of a gully,

ditch or stream bank. When mowing over uneven terrain, observe the type of terrain and

develop a safe mowing pattern.

When driving in slopes:

Operate the machine up and down steep slopes, not across slopes, to prevent the tractor from

tipping. Avoid sudden stops and starts, slow down before changing directions on a slope. Pass

diagonally through sharp dips and avoid sharp drops to prevent hanging up the tractor and

machine. If tractor overturns, hold tight to steering wheel.

Operating in darkness. When working in the dark hours, make sure there is sufficient lighting

in the working area.

Driver. Do not operate the equipment when you are tired, sick or when using medication.

Only properly trained people with driver’s license is allowed to operate this machine.

Do not allow riders on the machine or tractor at any time. There is no safe place for riders.

Personal protective equipment. Personal protection equipment including hard hat, safety

glasses, safety shoes, and gloves are recommended during assembly, installation, adjustment,

maintaining and/or repairing the implement. Avoid loose fitting clothing which can become

entangled. Wear sturdy, tough-soled work shoes and protective equipment for eyes, hands,

ears and head.

Safety cabin. Operate the machine only with a tractor equipped with an approved Roll-Over-

Protective-System (ROPS). Keep doors at tractors cabin closed during operating, serious injury

or even death could result from falling off the tractor.

Daily maintenance. Inspect the entire machine periodically. Look for loose fasteners, worn or

broken parts, and leaky or loose fittings. Periodically tighten all bolts, nuts and screws and

check that all cotter pins are properly installed to ensure unit is in a safe condition.

No wrappings or foreign objects are around the machine.

Frequently check mower blades. They should be sharp, free of nicks and cracks and securely

fastened.

Instructions for Use and maintenance 1800HD-2402HD (1810)

12

Breddningsvinge

n monteras på

insidan av

maskinen

Safety during maintenance and repairing. Apply hand brake and place the machine on a

hard level surface when maintaining or adjusting it. Always stop the tractor, set brake, shut off

the tractor engine, remove the ignition key, and allow machines moving parts to come to a

complete stop before dismounting tractor. Ensure that all moving parts have stopped completely

before making adjustments, servicing or cleaning the machine. If the machine has been raised

for cleaning, maintenance, inspection or repairs, it is imperative that you prevent it from sinking

or falling down by placing supports under the machine. Never work under equipment unless it is

blocked securely. Keep service area clean and dry. After servicing, be sure all tools, parts and

service equipment are removed. Clean the machine thoroughly before repairs or storage. Be

sure to thoroughly wash the machine without using excessive pressure especially on the moving

parts, bearings and electric components. After cleaning, carefully dry the machine and lubricate

it and perform a short test drive.

Vibrations. Do not use the machine if it is vibrating or shaking. Stop and investigate the cause.

Change any damaged parts.

Emergency stop. Know how to stop the tractor and machine quickly in case of an emergency.

After striking an obstacle, shut the tractor down and thoroughly inspect for damage before

restarting.

Hydraulic hoses. The machine’s hydraulic hoses contain oil under high pressure. Never

touch the hoses or other hydraulic components while there is still pressure in the system. In

case of leakage, oil under high pressure can penetrate the skin and cause serious injuries. If

accident happen, contact doctor.

Check the condition of the hydraulic hoses every day. Worn or leaking hoses must be replaced

immediately with new hoses that meet the manufacturer’s technical requirements.

The hydraulic motor and the hoses become hot during work; there is a risk for burn injury.

Never loosen the hoses while the oil is still hot. Wait until it cools down. When changing tractor,

check length of hydraulic hoses, if to long or short, they can easily be damaged.

Welding. Protect bearings, electronic and hydraulic components before any welding is done.

Place earth connection close to the place for welding.

Fire danger. If any component gets over heated, stop machine and check reason. There is an

increased risk of fire when working in dry areas.

Spare parts. Use only original repair parts

Where replacement parts are necessary for periodic maintenance and servicing, genuine

replacement parts must be used to restore your equipment to original specifications. The

company will not claim responsibility for use of unapproved parts and/or accessories and other

damages as a result of their use.

Unauthorized modifications to the machine may impair the function and/or safety of the machine

and reduce its life. If equipment has been altered in any way from original design, the

manufacturer does not accept any liability for injury or warranty.

Instructions for Use and maintenance 1800HD-2402HD (1810)

13

Breddningsvinge

n monteras på

insidan av

maskinen

2.2 Explanation of the symbols

The warning symbol must always be recognizable. If the warning symbols are missing from your

equipment or if they are damaged, replace them at once.

The symbol to the right shows:

Warning!

Read and follow the manual and the safety instructions

before using the equipment. Pass on all safety instructions

to other users of the equipment.

Warning!

Do not touch moving parts. Do not move about near the

PTO when the equipment is operating.

Warning!

Matter such as stones and clumps of ice may fly away

when the equipment is being used. The operator must pay

attention to where the snow is blown, and should avoid

working where people, animals and buildings are.

Maintain the safety distance.

Instructions for Use and maintenance 1800HD-2402HD (1810)

14

Breddningsvinge

n monteras på

insidan av

maskinen

Warning!

Do not touch the feed blades or the feed screws as long as

the tractor’s engine is running and the PTO shaft is

engaged.

Maintain the safety distance.

Warning!

Crushing hazard! When connecting, never stand between

the tractor and the equipment as long as the tractor is

moving. The tractor must be immobilized with the parking

brake whenever the operator leaves the cabin.

Warning!

Crushing hazard! When the ejector tube is lowered the

engine of the tractor and the PTO must be switched off.

Never use your arms or your legs to clear the ejector tube.

The CE symbol mounted by the manufacturer

confirms that the equipment altogether meets all

requirements concerning machinery directives

and other corresponding EG directives.

The serial number and model is stamped on the

identifying plate (see the picture).

Instructions for Use and maintenance 1800HD-2402HD (1810)

15

Breddningsvinge

n monteras på

insidan av

maskinen

3 Using the equipment

3.1 Assembly

Caution!

No persons is allowed to be in danger area during lifting

Be carefully when cutting bands and wire because they can be very tensed. They can

also be very sharp.

Following steps will be performed during the assembling:

Take away all packing and wrapping material, and discard it in an environmentally friendly way.

Assemble the ejector pipe and tighten the bolts.

The 3-point/A-Frame towing connection is bolted to the equipment. When delivered, the

equipment is fitted for front/reverse drive operation.

The towing frame can be mounted at different heights. The towing frame can be adjusted

according to the tractor to which it is attached. Adjust the height so that you can lift the

equipment off the ground and at the same time being able to lower it when working.

The towing frame can be mounted at different heights.

Screws and nuts - M20, 30 mm spanner.

Instructions for Use and maintenance 1800HD-2402HD (1810)

16

Breddningsvinge

n monteras på

insidan av

maskinen

If the equipment is mounted on the front, or is to be used on a reversing machine, one

should strive to mount the towing frame so low that the lifting arms of the tractor steers

the equipment as low as possible. This insures that the equipment goes over obstacles

as smoothly as possible.

Check that all protective devices are undamaged and correctly attached to the equipment.

Before operating the machine, tasks in section 3.3 –“Before starting up” must be cleared.

3.2 Attaching machine to the tractor

Warning!

Crushing hazard! When connecting, never stand between the tractor and the equipment

as long as the tractor is moving. Always immobilize the tractor when leaving the cabin

for any coupling/decoupling work.

The machine should not be mounted on a tractor with insufficient front shaft weight,

when the tractor becomes unstable and difficult to operate. If necessary use attain

ballast weights, read the tractor’s instructions manual for more information.

Only use original PTO-shaft. Read carefully instructions attached at PTO-shaft.

Information in this snow blower instruction manual doesn’t replace information from

PTO-shaft manufacturer.

Caution!

Check that rpm-speed and direction at tractors PTO, agree with signs and symbols at

machine.

Machine front mounted to a tractor

using the A-frame connection.

Instructions for Use and maintenance 1800HD-2402HD (1810)

17

Breddningsvinge

n monteras på

insidan av

maskinen

Attach the machine at a hard level surface.

Attach tractors lifting arms to lower connection points at machine, and there after the top link,

(choose connection points that make lifting arms and top link as parallel as possible, all to make

machine levelled during lifting)

Turn of tractor’s engine and apply the hand brake.

Adjust the length of the PTO shaft. Pull the shaft apart, and fit the end with the shear pin and

mounting flange on to the tractor. Check that the shaft does not bottom out in any position,

(min. play 30mm) and that the sliding part is sufficiently seated in the cuff part (min. 300 mm)*.

If not, shorten the shaft. See the instructions that came with the shaft, (trim any cutting edges of

, to avoid damages on pipes when telescoping). Try to attain longest possible shaft overlap. Be

extra careful with shaft overlap when using hydraulic top link, when this equipment can make

quick changes at measure. Note that usually the shaft is shorter when mounting at the front

than when mounting at the rear.

*Alternative for PTO-shafts shorter than 1000mm, use at least half of maximum overlap.

Duty rpm’s and rotational directions for drive shafts 1-3/4” Z6

When used on a reversing tractor and when mounted on the front, the shear bolt clutch must

always be closest to the tractor. A wrongly mounted PTO shaft can result in a breakage of the

drive shaft.

Use the chains to fasten the PTO-shaft guards, so they don’t rotate.

Lock lifting arms sideways with the stabilizer rods.

Attach hydraulic hoses for ejecting pipe control to double acting outlets at tractor. Clean the

connections carefully before attaching. Before using the equipment, test the operation of the

ejector pipe control.

Check that machine can work freely from tractor in all predictable situations.

1000 rpm

540 rpm

Instructions for Use and maintenance 1800HD-2402HD (1810)

18

Breddningsvinge

n monteras på

insidan av

maskinen

3.3 Before starting up

Before starting up, following items must be checked.

Check the screws and bolts at the machine and tighten if necessary. See table with

recommended torque settings in section “Service and maintenance”.

Check that all protective devices are undamaged and correctly attached to the equipment.

Lubricate the machine (see section ”Service and maintenance”).

Check the oil level in the gearbox. The oil should reach the lower part of the glass (see section

“Service and maintenance”). The gearbox is filled with oil SAE 80W/90 API GL4/GL5, Industrial

gear oil ISO VG 220.

Adjust height of scraper steel with support pads, and machine tilt with top link (see section

“Adjustments”)

Check that no objects have wrapped themselves around moving parts.

Perform a trial run of entire machine.

3.4 Adjustments

Warning!

No work is allowed unless the equipment is safely secured (don’t completely rely on

tractors 3-point connection).

Be careful when undoing the pierced rod of flap control, crushing hazard!

At any time when performing repairs and maintenance, the engine must be switched off

and the PTO shaft disconnected. Withdraw the ignition key from the switch.

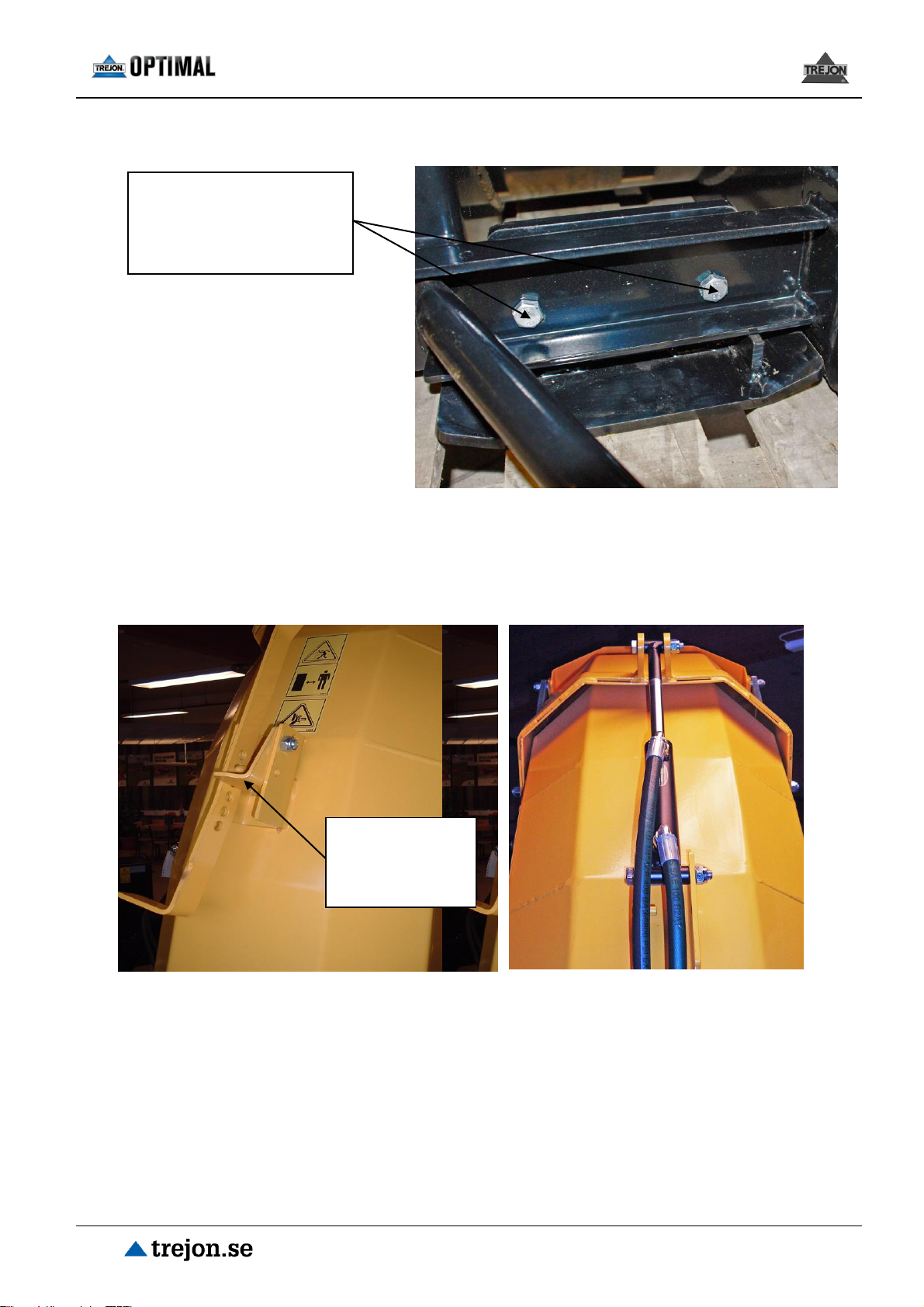

Support pads

The height of the equipment is adjusted with two supporting pads located at the back. The

angle of the equipment is adjusted with the top-link. This determines the how well the

equipment follows the variations in the surface. If the equipment is angled forward, it is easier

for it to cut through packed snow and ice. A suitable basic adjustment when the machine rest on

the support pads, is that the wearing edge of the scraper steel is 10mm above ground. Aim at

keeping the machine levelled during work.

The supporting pads are to be adjusted as the wearing edge is being worn down. The

supporting pads are adjusted by undoing the mounting screws, and mount them in other holes.

Instructions for Use and maintenance 1800HD-2402HD (1810)

19

Breddningsvinge

n monteras på

insidan av

maskinen

Ejector tube

The equipment comes fitted with a hydraulically turntable ejector tube as standard. At the end of

the tube is a flap that regulates the distance the snow is thrown. Turn up the handle that locks

the pierced rod, move the rod to the desired position and lock it again.

A hydraulically (or electrically) operated flap is available as an option. This is suitable for those

that need to change the placing of the ejected snow while operating the equipment.

Mechanical flap control (Standard) Hydraulic flap control (Option)

Screws that must be

taken away, when the

height is adjusted at the

support pads.

Locking handle

for mechanical

flap control.

Instructions for Use and maintenance 1800HD-2402HD (1810)

20

Breddningsvinge

n monteras på

insidan av

maskinen

The ejector tube has two mounting holes. These will enable you to regulate the distance the

ejected snow is thrown.

The height of the equipment is adjusted with two supporting pads located at the back. The

angle of the equipment is adjusted with the top-link. This determines the how well the

equipment follows the variations in the surface. If the equipment is angled forward, it is easier

for it to cut through packed snow and ice.

The supporting pads are to be adjusted as the wearing edge is being worn down. The

supporting pads are adjusted by undoing the mounting screws and move the pads. When the

pads are worn out they have to be replaced by new ones.

3.5 Operating the machine

Warning!

Operator must have a good view over the working area and the area where the ejected

snow lands. Heavy items in the snow, such as stones etc., can be propelled much further

than the snow itself.

Before leaving tractors cabin ensure that all moving parts have come to a complete stop.

Caution!

The shear bolt is No guarantee for machine not being damaged at impact with heavy,

solid objects.

To avoid damages on machine, lift snow blower before going backwards with the

equipment.

A doubled driving speed, make the stress at the equipment four times higher. Damages

on snow blower caused by impact with heavy, solid objects isn’t covered by the

warranty.

Optional mounting holes for the ejector

tube.

This manual suits for next models

4

Table of contents

Other Trejon Snow Blower manuals