Trejon Optimal DS1300 Specification sheet

Instructions for use

and maintenance

TREJON AB

Företagsvägen 9

SE-911 35 VÄNNÄSBY

SWEDEN

Tel: +46 (0)935 399 00

Fax: +46 (0)935 399 19

NB! Read the manual carefully

before operating the machine

Sandspreader

DS1300, DS1500, DS2500

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se2

Table of contents

1 General information 6

1.1 Introduction 6

1.2 Description 6

1.3 Detailed description 8

1.4 Techical data 12

1.5 Right and left hand 12

2 Safety instructions 13

2.1 Safety precautions 13

2.2 Explanation of the symbols 16

2.3 Protective equipment 17

3 Operating the machine 17

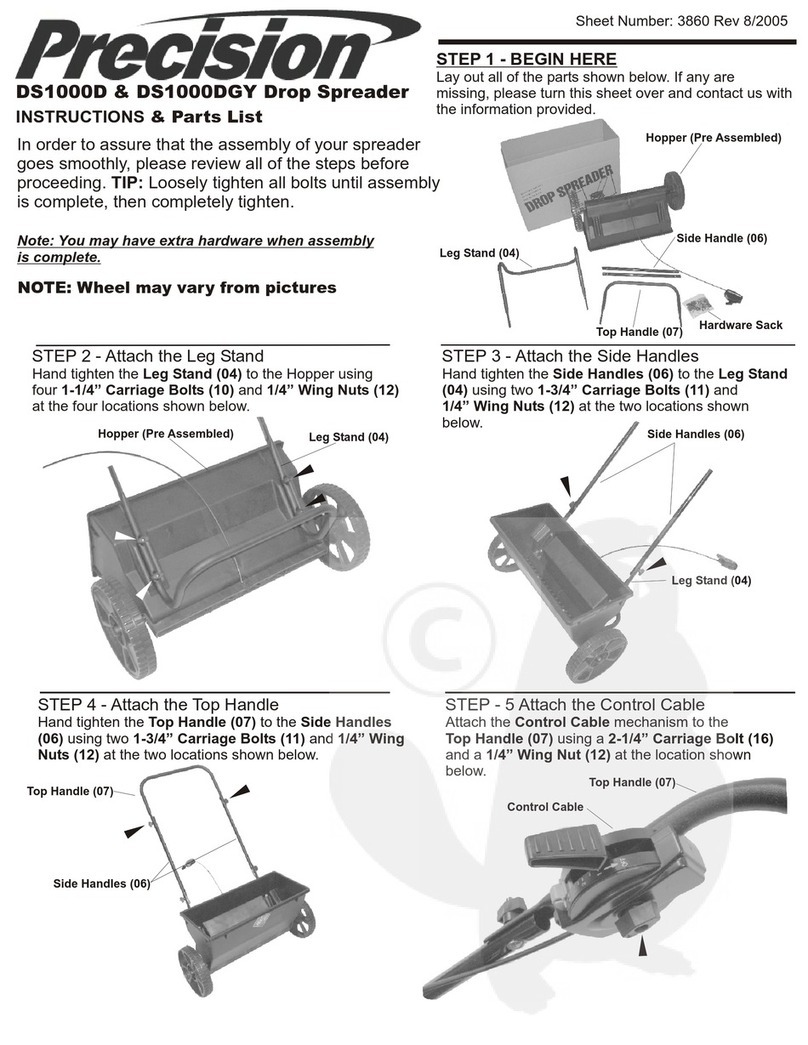

3.1 Assembly 17

3.2 Attaching the machine 18

3.3 Before starting up 19

3.4 Adjustments 19

3.5 Operating 22

3.6 Detaching machine 24

3.7 Storage of machine 24

4 Service and maintenance 24

4.1 General about 24

4.2 Maintenance schedule 25

4.3 Before the season starts 26

4.4 After the season ends 26

4.5 Wiring diagram 27

4.6 Hydraulic diagram 28

5 Troubleshooting 29

6 Options 29

6.1 Self-loading equipment (optional) 30

EC-Certicate of Conformity 32

Warranty- / assignment certicate 33

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 3

Safety symbols

Note! This warning symbol is used throughout this instruction manual to call attention to

safety precautions that you, your employees or any other people that come near the machine

must read and understand. Failure to follow these instructions may result in serious injure or

even death.

This symbol means:

WARNING!

CAUTION!

YOUR SAFETY IS ENDANGERED!

A word of advice

Pay special attention to the words WARNING! and CAUTION! and NOTE! in the safety

instructions. The word have been chosen after the following guidelines.

Warning!:

This safety sign is used to identify potential hazards that can lead to serious injury or even

death. These hazards include situations that may occur when the safety equipment and/or

the safety shields are removed. Signal words can also be used to alert about dangerous use.

NOTE!

Failure to observe this warning sign could result in light personal injuries. The sign is also

used to indicate that the disregarding of these instructions may cause damage to the

implement.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se4

Dear Customer

You have made a good choice. We congratulate you to your selection of a TREJON product

that offers quality and performance with reliable service.

By reading the manual and following it’s recommendations you will ensure the long and

effective use of the equipment.

We have produced this manual for you to get a good understanding of the functioning of the

equipment and what safety and maintenance instructions to follow when working with it.

If any question should arise when using the equipment or when reading this manual, you are

welcome to contact your dealer or us for further information.

TREJON AB

Företagsvägen 9

SE-911 35 Vännäsby

Sweden

Tel: + 46 (0)935 399 00

Fax: + 46 (0)935 399 19

E-mail: [email protected]

Website: www.trejon.se

Honoured retailer

In order for the guarantee to be valid and to forll all legal requirements, we ask you to ll out

the warranty form together with the customer and return it to TREJON.

The warranty is valid from the day the equipment is handed over to the customer.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 5

Delivery checklist

Check for damages caused in transporting. Inform the transporting company.

Check if delivery is complete with help from machine order/packing list.

Check if machine is lubricated. (see section 4,2)

Check chain tension (see section 4,2)

Having gone through and explained to the customer, with the help of the manual, the

startup, use and maintenance of the equipment and it’s accessories.

Test drive machine

Instruction manual given to the customer.

Fill out the warranty form with the customer and send it to TREJON AB. It can be

found as an attachment to this manual and as a copy on the last page.

Enter the serialnumber of the equipment to the

right.

S/N:

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se6

1 General information

1.1 Introduction

Thank you for choosing this Optimal product. We have worked hard to manufacture a strong

and reliable machine that will last for many years. As the machine’s service life does not

depend solely on us but also on you we have prepared these guidelines that describe the

proper use and maintenance of the machine. Please read the whole manual carefully before

operating the machine. If you want to order spare parts or need service, please contact

the company where you bought the machine. When submitting the order for the spare

parts, specify the model, type and serial number from the name plate on the chassis of the

machine.

1.2 Description

The OPTIMAL sand-spreader is a simple and easy-to-operate machine for spreading sand

(0-4 mm), chip stone (2-8 mm) and salt. It is recomended that the spreading material is sifted

into correct fractions. Spreading material with larger size than described can damage the

machine. A to ne grained sand material that hold water must be avoided, when it builds up

vaults which prevent material to ow down for spreading. The sand-spreader is installed on a

frontloader or to a tractor’s hitch linkage with TREJON connection frame.

The spreader is driven by the tractor’s hydraulics and the sand-spreading operation is

regulated with an electric control box in tractor cabin. It is easy to ll the spreader; the

lling principle is the same as a loader’s bucket. To facilitate the lling when the spreader is

mounted on the 3-p hitch linkage a special “self-loading” kit can be supplied as an option.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 7

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se8

1.3 Detailed description

Top view (g.1)

Front view (g.2)

1

2

3

5

6

7

910

11

12

13

14

15

16

4

18 17

8

19

17

6

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 9

1Feeding auger 14 Support leg long (2pcs)

2 Mixer 15 Sequence valve

16 Hydraulic valve

17 Locking for connection frame

3 Positionlight (2pcs) 18 Connection for control box

4 Curtain cover 19 Hydraulic motor for spreading disc

5 Cylinder for adjusting spreading

position

6 Support leg short (2pcs)

7 Hoses for manoeuvring Pos5 25 Knob for control of disc

8 Manual adjusting damper 26 Switch for lights

9 Spreading disc 27 Knob for control of feeding auger

10 Cylinder for manoeuvring closeing

damper

28 Connection for sandspreader

11 Hose to hydraulic valve 29 Power supply

12 Chain for mixer and feeding auger

operation

13 Hydraulic motor for drive of mixer

and feeding auger

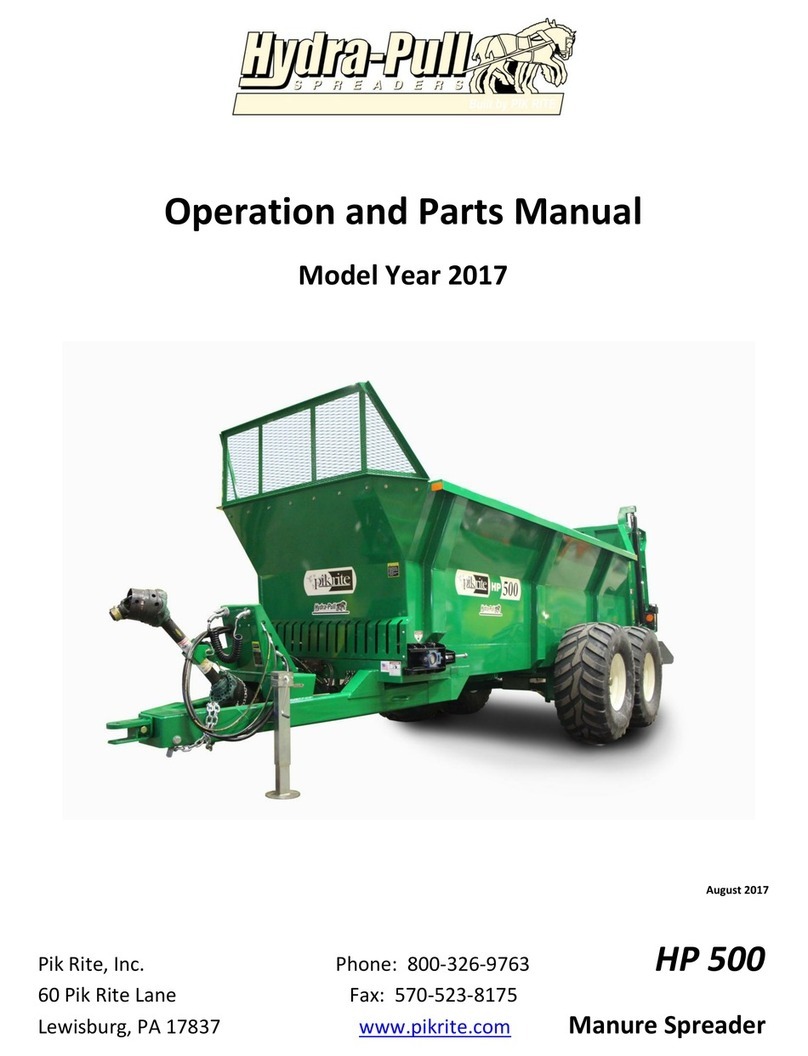

Control box ELSK (g.3)

25 26 27

29

28

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se10

Control box ELMP (g.4A)

(only for 12V power supply)

1

9 10 11

23 4 5 6

7 8

Control box rear view ELMP (g.4B)

15

16

17

Cable between control box ELMP and Sandspreader (g.4C)

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 11

Pos. Function description

1 Knob for control of spreading disc (adjusting spreading width)

2 Knob for control of feeding auger (adjusting amount)

3 Switch for temporary max spreading amount (self returning)

4 Not used

5 Switch for hazard waring (maximum 3A current)

6 ON / OFF -swithch for control box

7 Switch between inner and outer scales for Pos. 1 and 2 (inner = sand, outer = salt)

8 Switch for emptying of bucket (disc = off, feeding auger = on)

9 Switch for function test (disconnecting road depending function)

10 Light switch

11 Not used

15 Connection for control cable to sand spreader

16 Connection for road depending steering (GPS or ISO-cable from tractor)

17 Connection for power supply to control box

20 Control lamp that shines when motion is registrated.

21 Control lamp that shines when device has sufcent GPS-signal.

22 Control lamp for power supply to GPS-device.

23 GPS-signal receiver (place outside cabin for better signal reception)

24 Connection for control box.

GPS-device 90-02371 (ELMP) (g.4D)

(only for 12V power supply)

20 21 22

23 24

Cable ELMP - Tractor (g.4E)

(Only for connection between ELMP-

box and DIN-outlet in tractor)

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se12

1.4 Techical data

Model DS1300 DS1500 DS2500

Control system ELSK Manual/Electronic Manual/Electronic Manual/Electronic

Control system ELMP Automatic road depending Automatic road depending Automatic road depending

Volume (l) 1300 1500 2500

Measure WxH (cm) 210x147 240x147 240x163

Weight excl. conn.frame (kg) 825 860 980

Spreading width up to 8m up to 8m up to 10 m

Oil ow, min./max. (l/min) 35/70 35/70 35/70

Oil pressure min./max. (bar) 180/200 180/200 180/200

Supply voltage (V) 12 /(24V if coils are excanged) 12 /(24V if coils are exchanged) 12 /(24V if coils are exchanged)

Connection system (option) Optional connection frame Optional connection frame Volvo BM

Colour yellow (RAL) 1003 1003 1003

Colour black (RAL) 9005 9005 9005

With continuing product development the technical specications are not binding and are

subject to change without prior notice.

The gures in the table above can show non-standard equipment.

The standard of equipment may differ from country to country.

1.5 Right and left hand

In this manual, the terms right and left hand refer to right and left as seen from the rear side

of the tractor or from behind the tractor toward the direction of travel.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 13

2 Safety instructions

2.1 Safety precautions

Read this user manual and the safety directions carefully before using the equipment for

the rst time.

Erroneous or negligent use of this equipment can lead to serious accidents. This

equipment is only for outdoor use.

Should you require additional information regarding the machine or its operation, contact

your authorised dealer or TREJON AB.

• Read and understand the contents of this manual on the use of this equipment.

• Learn how to operate the machine and how to use controls properly before operating the

machine.

• Check, adjust and maintain the equipment according to this manual.

• When connecting, never stand between the tractor and the equipment as long as the

tractor is moving.

• Be careful when lifting or lowering the equipment.

• Unauthorised persons, particularly children, are not allowed near the machine while it is

running or is being repaired.

• Make sure that the work area is clear of all persons and particularly children.

• Take care never to aim the material outlet towards people, animals or buildings. Stones in

material can be thrown longer than sand and salt.

• It is forbidden to work with this equipment if the protections for the moving parts or axles

are missing.

• The equipment should only be used if all the original protective parts installed by the

manufacturer are properly tted and in good condition.

• Take care that arms or legs do not touch the moving parts of the equipment.

• Let the machine work by itself; do not try to help using your ngers or hands.

• To ensure that the towing vehicle has sufcient steering and braking, at least 20% of the

weight of the towing vehicle must rest on the front/rear axle. If this is not the case, add

weights to achieve the correct ratio. See the manual for the tractor.

• Adapt your driving to the prevailing terrain and ground conditions.

Be careful when working on uneven ground, reduce speed.

• When working in the dark hours, make sure there is sufcient lighting in the working area.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se14

• You may not transport people on the equipment.

• Persons under the inuence of alcohol, medication or drugs are prohibited to work with

the equipment.

• Individuals without a proper driver’s licence are not allowed to use the machine.

• Whenever you clean, adjust, maintain or repair the equipment, you must stop the engine

of the tractor. The tractor must be immobilized with the parking brake, and the spreader

must be lowered to the ground. Ensure that all moving parts have stopped completely.

• It is forbidden to adjust the equipment or to remove material from the spreader while the

tractor engine is running.

• To maintain and adjust this equipment, it must be placed on a rm, level surface.

• If the equipment has been raised for cleaning, maintenance, inspection or repairs, it

is imperative that you prevent it from sinking or falling down. Place supports under the

equipment to prevent it from sinking or falling down.

• Clean the equipment thoroughly before repairs or storage.

• Do not use the equipment if it is vibrating or shaking. Stop and investigate the cause.

Change any damaged parts.

• The hydraulic hoses and tubes contains oil under high pressure. Do not touch hoses

and hydraulic components if there is pressure in the system. Oil under high pressure can

penetrate the skin and cause serious damage.

• Daily check the hydraulic hoses of the machine with regards to damages and oil leakage.

Worn and leaking hoses must immediately be replaced with new ones, which full the

manufacturers technical demands.

• When changing tractor, please check the hoses length. Too long or too short hoses can

be damaged during use.

• Protect bearings and the hydraulic system before performing any welding operations on

the machine.

• Use only original spare parts for the equipment.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 15

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se16

2.2 Explanation of the symbols

The warning symbol must always be recognizable. If the warning symbols are missing from

your equipment or if they are damaged, replace them at once.

The symbol to the right shows:

Warning!

Read and follow the manual and the safety ins-

tructions before using the equipment. Pass on all

safety instructions to other users of the equipment.

Warning!

Do not touch moving parts. Do not move about

near the rotating parts when the equipment is

operating.

Failure to follow these instructions can result in

serious injury or even death.

Warning!

Crushing hazard! When connecting, never stand

between the tractor and the equipment as long as

the tractor is moving. The tractor must be immobi-

lized with the parking brake whenever the operator

leaves the cabin.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 17

2.3 Protective equipment

3 Operating the machine

3.1 Assembly

Caution!

Keep risk area clear while lifting.

When asseblying the machine, following is done:

• Unpack all parts of the machine and place them on a suitable surfaceur.

(handle the disposal of packing material in environmentally friendly way)

• Before opearting the machine check section 3,3.

The CE symbol mounted by the manufacturer

conrms that the equipment altogether meets

all requirements concerning machinery direc-

tives and other corresponding EG directives.

The serial number and model is stamped on

the identifying plate (see the picture).

Warning!

Crushing hazard!

TREJON AB

Företagsvägen 9

SE- 911 35 VÄNNÄSBY, SWEDEN

Tel. +46935-399 00 Fax +46935-399 19

www.trejon.se

Serial nr.

Ref. nr.

Model

Weight kg

4 x 3 cm

4.5 x 6 cm

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se18

3.2 Attaching the machine

Warning!

Crushing hazard! When connecting, never stand between the tractor and the equipment

as long as the tractor is moving. The tractor must be immobilized with the parking brake

whenever the operator leaves the cabin.

Warning!

The machine should only be attached to tractors with enough front and rear axle weight so

that steering and brakes function correctly after the implement is attached. Use additional

ballast if necessary, see the tractor’s operation manual.

• The attachment should only be done on a hard level surface.

• Attach tractor to optional connection frame (either to three link connection or to

loader), after that the connection frame can be attach to machine with it’s connection

device. (if machine is connected to a three link connection, the lower lifting arms must

be secured from moving sideways with it’s stabilization rods).

• Switch motor off and immobilized tractor with the parking brake.

• Connect hydraulic hoses to two pairs of double-acting outlets.(one extra double-

acting outlet is needed if machine is equiped with self loading device). Clean

connections well before attaching in outlet.

• Mount control box in a suitable place in tractor cabin. Attached 7-pole connector of

control box to connection at machine (Pos.18 in section 1,3). Connect power supply

plug from control box to 12V outlet in tractor (Pos.29 in g.3 for ELSK, and Pos.17 in

g.4B for ELMP) (if just 24V is available in tractor, coils at valve and lamps must be

excanged)

• Check if machine goes free from tractor in all thinkable situations.

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se 19

3.3 Before starting up

Check the following before you operate the machine:

• All screws and nuts should be tightened (inspect all screws and nuts and tighten

them if necessary after 4 hours of operation and after that after every fortieth hour of

operation. Table at section 4.1 lists the torques for the screws and bolts.

• Check that all protective devices are undamaged and correctly attached to the

equipment.

• Lubricate the machine before you start it (see section 4.2).

• Check roller chain tension, tension if necessary.

3.4 Adjustments

Warning!

If the equipment has been raised for adjustments, cleaning, maintenance, inspection or

repairs, it is imperative that you prevent it from sinking or falling down. Place supports under

the equipment to prevent it from sinking or falling down.

When starting up the machine there are some points that have to be checked and adjusted.

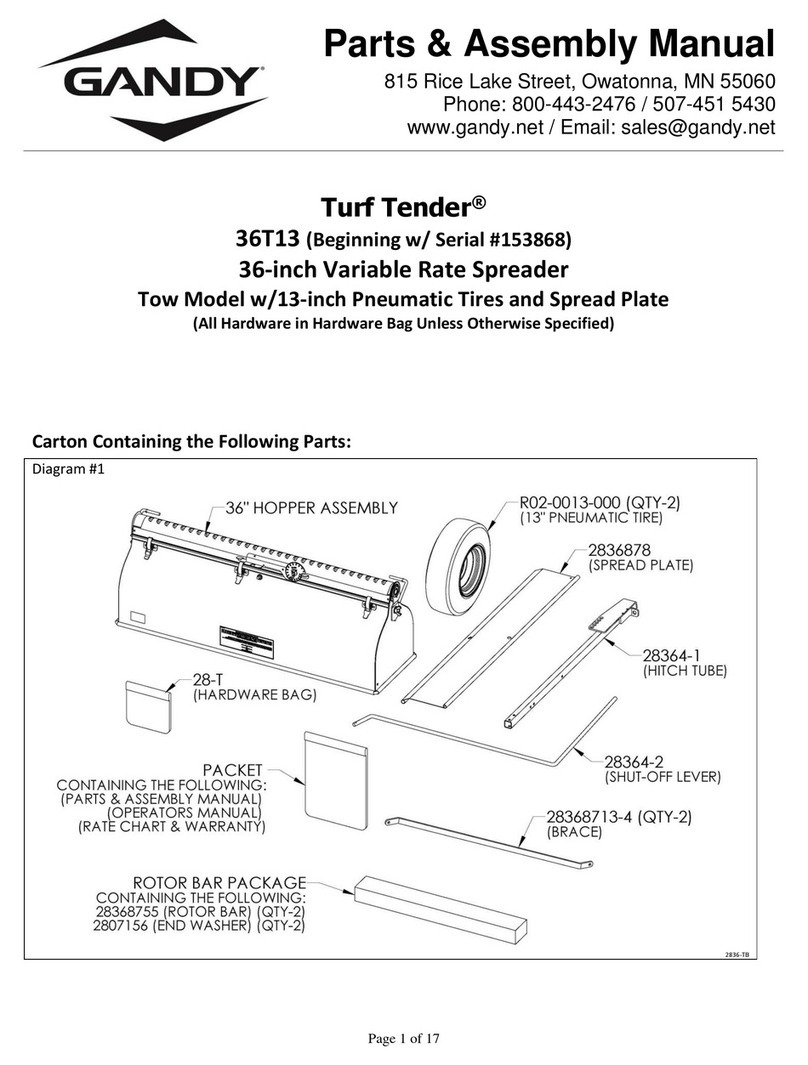

Manual adjusting dampers

Above the spreading disc there are two adjustment dampers, that will be a help when

optimizeing the spreading result. There are no denitely measures for the opening of the

dampers. The opening will be adapted after experience and circumstances.

Guideline for opening:

Large opening together with large output, material e.g. sand and chip stone

Smaller opening together with small output, material e.g. salt (start value e.g. 50mm opening)

Procedure for adjustment:

Losen the two nuts per damper. Adjust. Tighten the nuts.

Adjustment damper

(g.5)

Operating manual DS1300, DS1500, DS2500 (1001)

trejonindustries.se20

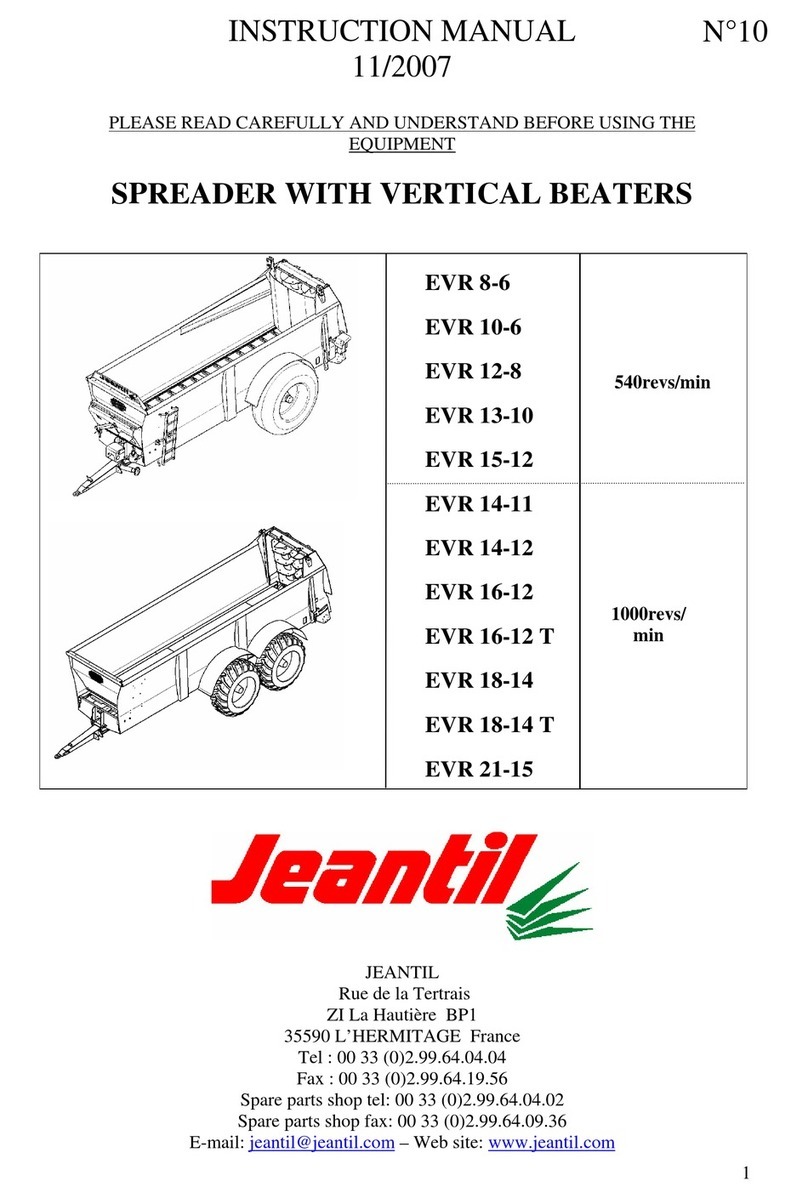

Control boxes (steering system)

Disc sandspreaders DS1300 and DS1500 is in standard version designed for use of both

control boxes ELSK (manual / electronic) and ELMP (automatic road depending). See

chapter 1,3 - Detailed description, for overview of both systems. It means that you can

change between steering systems without changing the machine. See following sections for

description of the systems.

Control box road depending (ELMP)

This steering system demands to be feeded with an speed signal. The speed signal can be

received from either the OPTIMAL GPS-system (item number: 90-02371) or by a ISO-cable

at tractors equipped with an outlet for speed signal (see g.4D respectively g.4E). Note that

the GPS-system only can be used together with 12V electrical system.

At practical use, the sandspreader is driven in working speed while spreading amount and

spreading width is adjusted with knobs 1 and 2 at g.4A. When right adjustment is found,

the road depending system ELMP will compensate spreading amount after driving speed and

chosen adjustment of width.

Note!

The control box is adjusted from factory, and is NOT allowed to be opened by the user.

At any questions about it’s function, the control box have to be handed over to your

TREJON dealer.

GPS-system can be used only together with 12V electrical system.

Control box manual / electronic (ELSK)

With this control system spreading width and spreading amount is manual contolled by the

driver, which choose suitable value with respectively control knob (pos.1 and 2 in g.6).

The control knobs at control box has got a basic adjustment for it’s minimum and maximum

value from factory.

If nesessary the minimum and maximum values can be adjusted, Note that if this is done the

warranty is NO longer valide.

A review over the adjustment can be found in following pages.

Note!

If control box is opened and adjustment is done, the warranty is NO longer valid.

This manual suits for next models

2

Table of contents

Popular Spreader manuals by other brands

Wolf Garten

Wolf Garten WE-B Original manual

Vogal

Vogal SPREADMAX EX750 Operation Maintenance & Parts Manual

Art's Way

Art's Way X350 Operator manual & illustrated parts list

Kramer

Kramer VM-4DVI-R user manual

Gardol

Gardol GST-E 451 Original operating instructions

HYDRA-PULL

HYDRA-PULL HP 700 Operation and parts manual