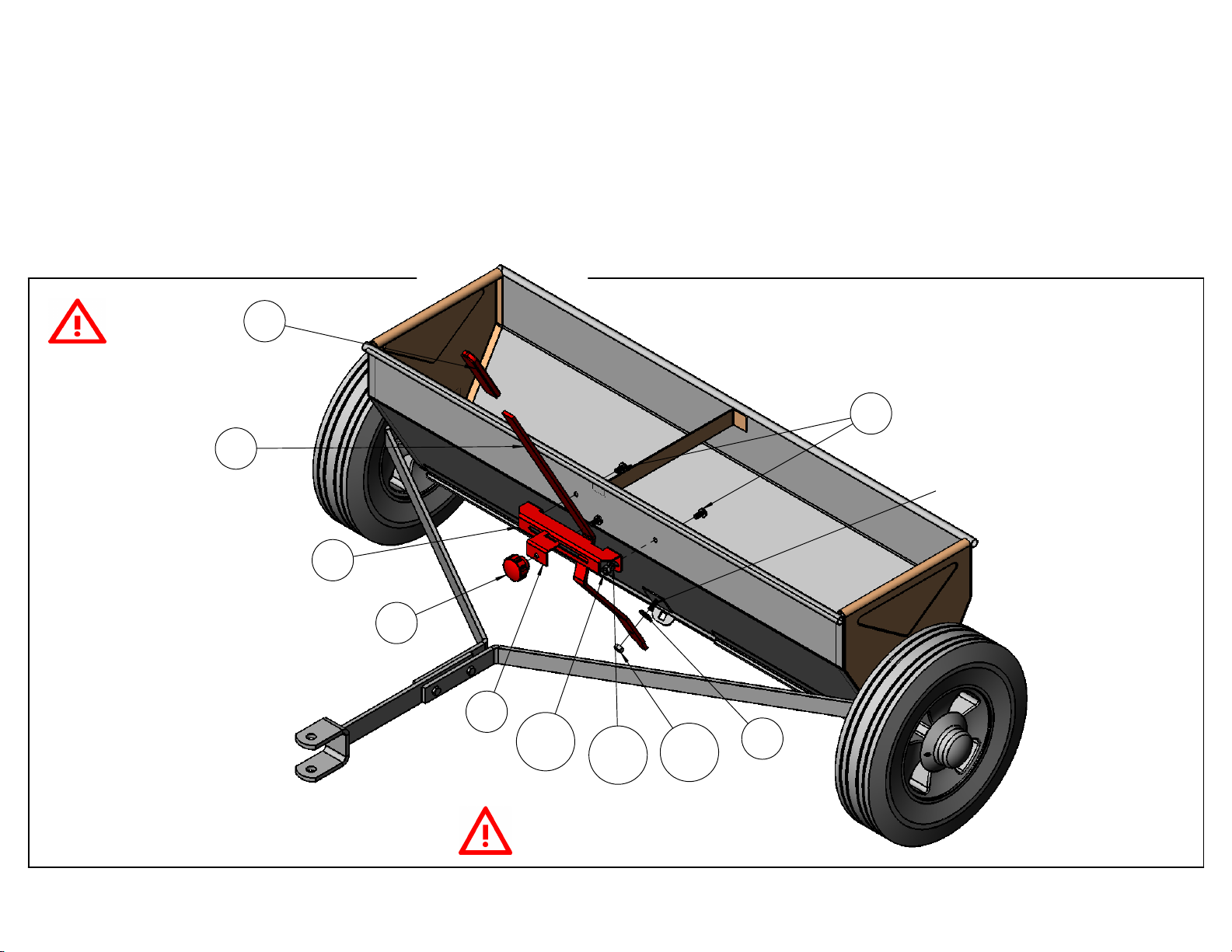

18LW

27

23

22

21

26 17

2018N

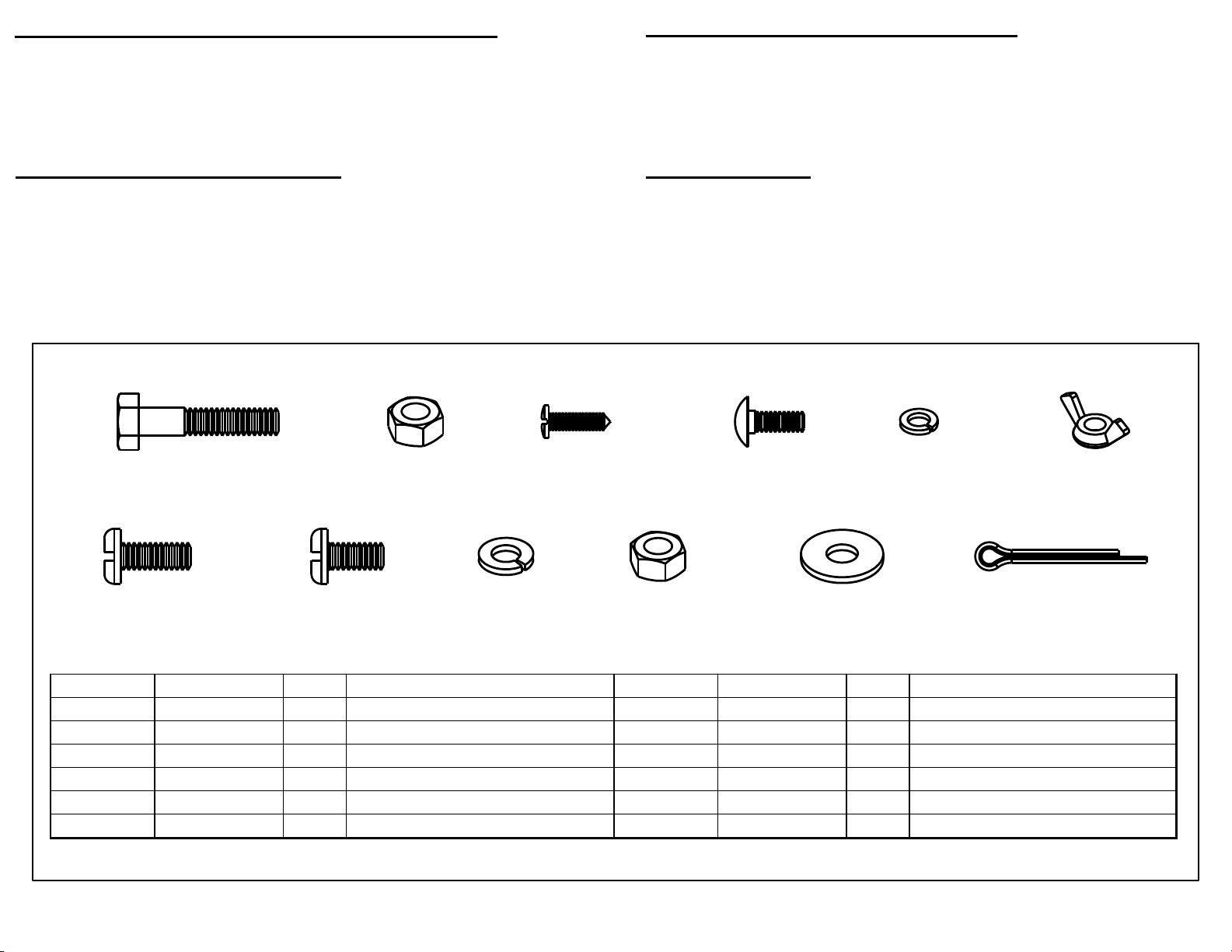

TOOLS SUGGESTED FOR ASSEMBLY

7/16" wrench and/or socket

large blade screwdriver

pair o pliers

SAFETY INSTRUCTIONS

cordless drill

19LN

19

To stop spreading, return the lever to the closed position.

It is important to clean the spreader a ter each use.

Keep all oreign objects out o the hopper.

Avoid sudden turns or maneuvers.

MAINTENANCE & STORAGE

OPERATION

Operate up and down slopes, never across the ace o slopes.

Never exceed load capacity o 100 pounds.

Never stand, sit or carry passengers on hopper.

Store inside a clean, dry area when not in use.

Oil lever at the pivot screw. Oil wheel bearings.

Periodically check all nuts and bolts or tightness.

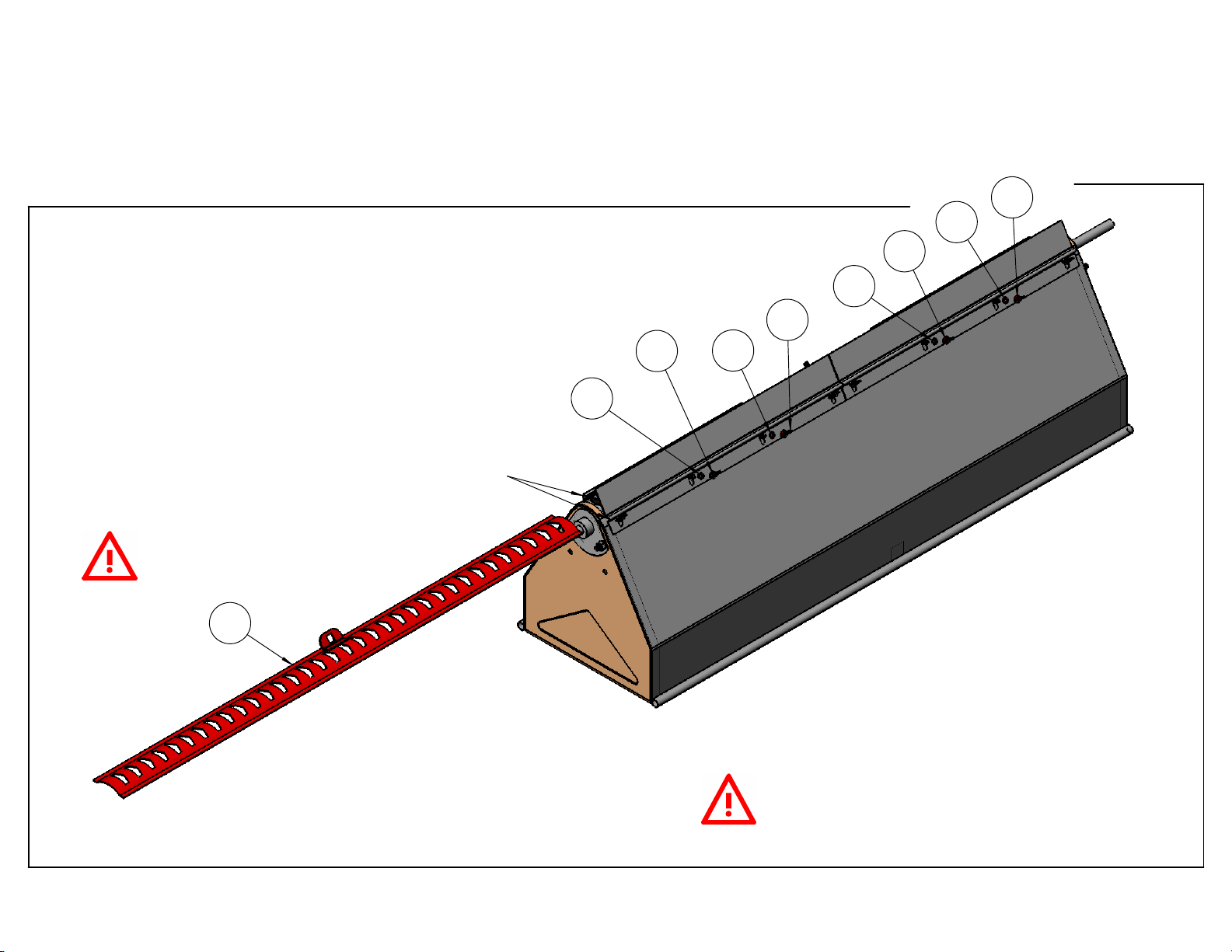

Set the adjustment lever to the "close" position.

Re er to the materials application chart with the product

you are using or adjustment setting.

Set adjustment stop to recommended setting by loosening

knob and moving to correct position and tightening knob.

18

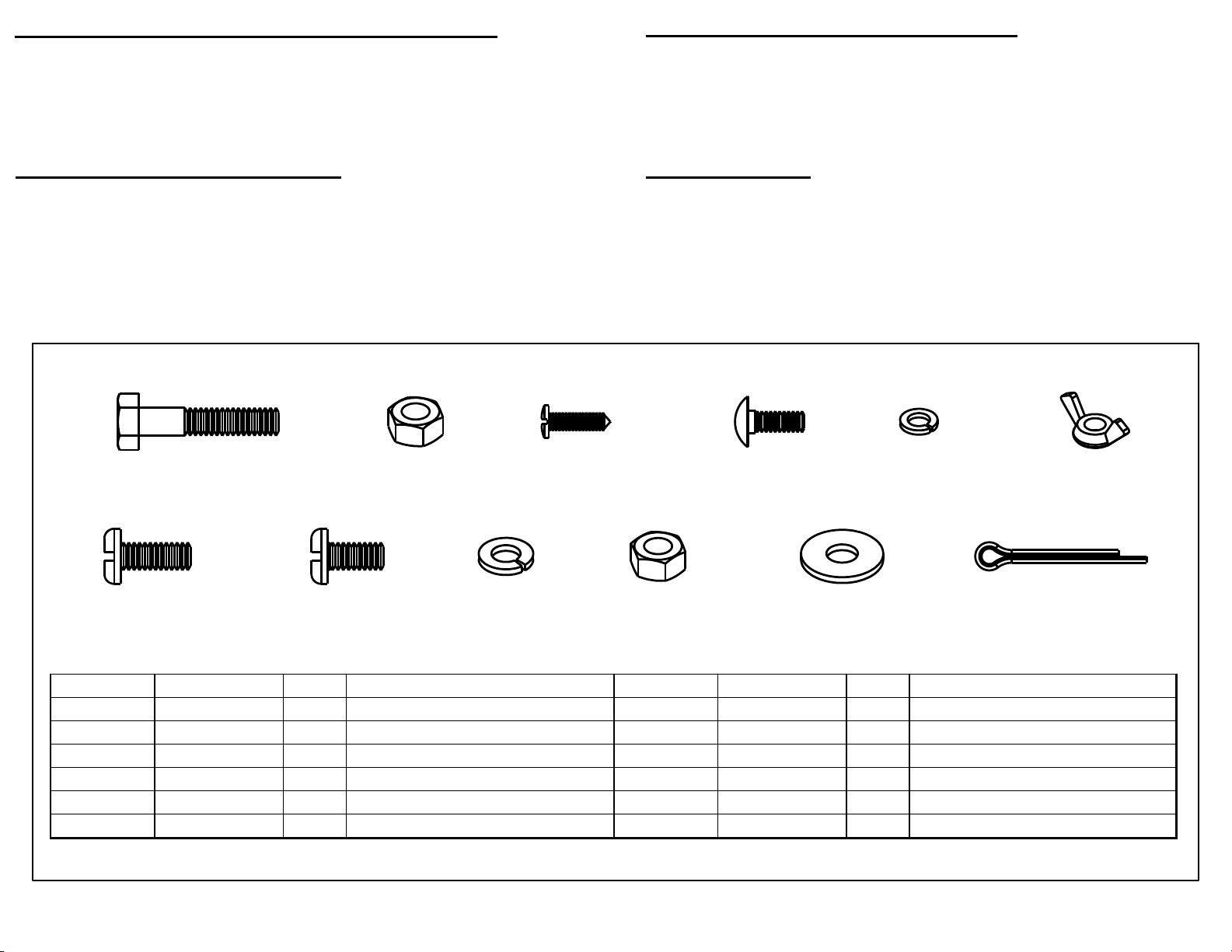

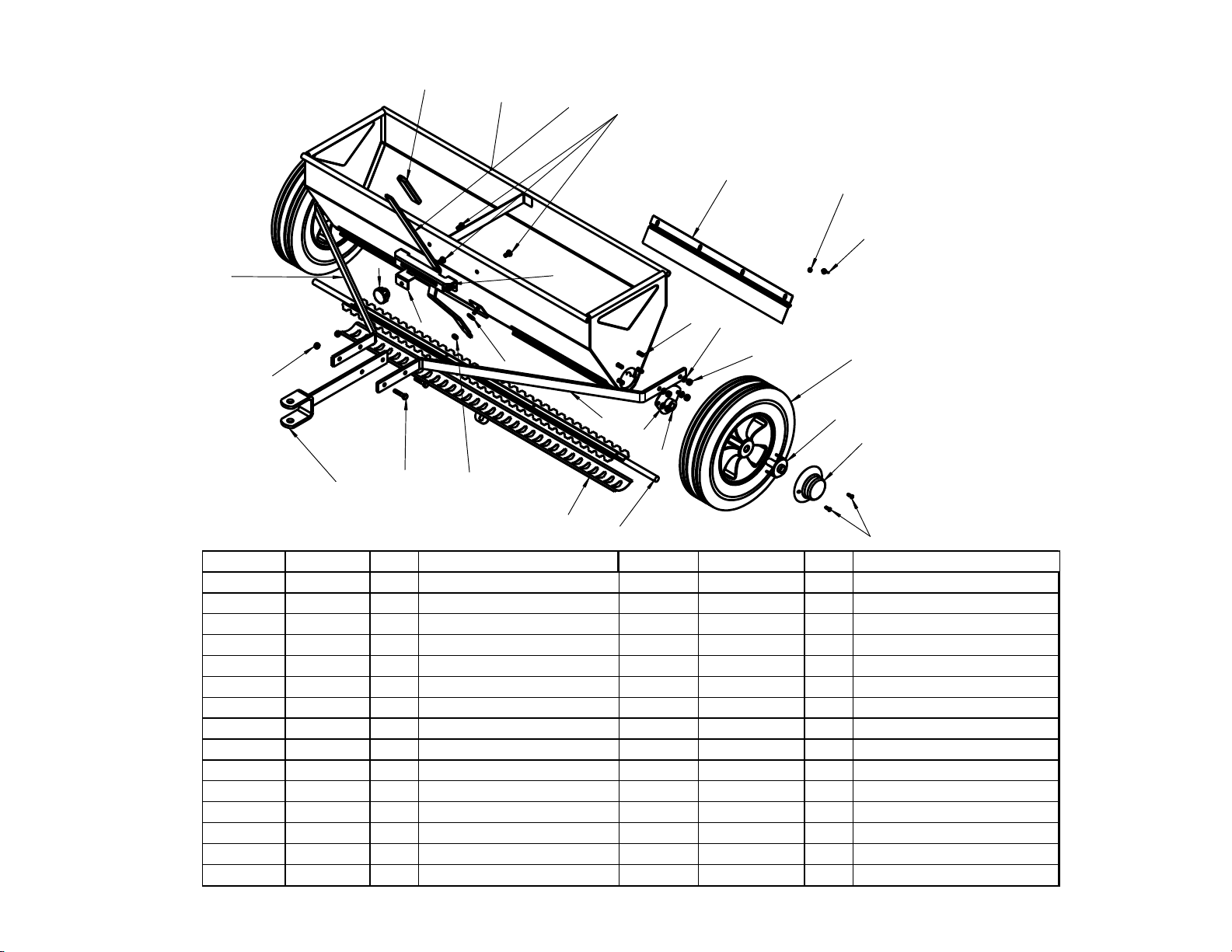

Bolt Bag Contents - 610.241942

FOR MISSING PARTS, Call 1-800-652-2321, Monday - Friday, 8 a.m. - 5 p.m. E.S.T.

Page 2.

REF. NO. PART NO. AMT. DESCRIPTION REF. NO. PART NO. AMT. DESCRIPTION

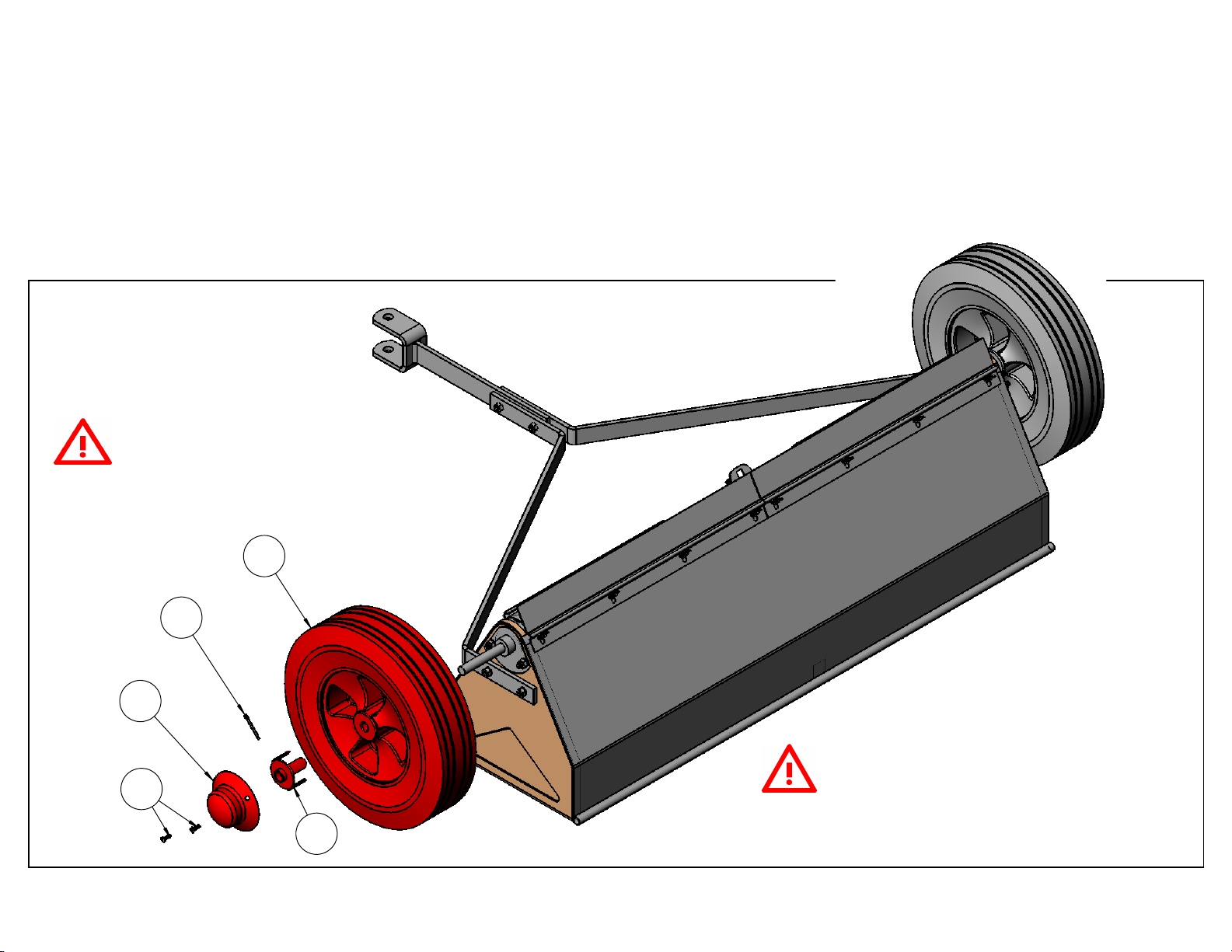

17 STD541610 8 10-24 wing nut 20 STD551025 1 1/4" lat washer

18 94-18 4 bolt 1/4" x 5/8" pan 21 94-21 3 bolt 1/4" x 1/2" pan

18LW STD551125 6 1/4" lock washer 22 94-22 4 #8 sel tapping screw

18N STD541025 6 1/4" hex nut 23 94-23 2 1/8" x 1" cotter pin

19 STD522512 2 bolt 1/4" x 1 1/4" hex 26 94-26 8 10-24 x 1/2" carriage bolt

19LN STD541425 3 1/4" lock nut 27 STD551110 8 3/16" lock washer