Trention Systems MBS1000 User manual

MBS1000

1U MODULAR BLADE

SERVER

No. MBS1000-xxx Revision B

INSTALLATION GUIDE

Publication No. 8401000-08205

WARRANTY

The following is an abbreviated version of Trenton Systems’ warranty policy for modular blade server

products. For a complete warranty statement, contact Trenton or visit our website at

http://www.trentonsystems.com/.

All Trenton manufactured boards used in systems delivered by Trenton Systems, Inc. carry a five-year

warranty. All non-Trenton manufactured boards and system sub-components including but not limited to

power supplies, DVDs, CD-ROMS, etc. are covered under their original manufacturer’s warranty. All

systems built by Trenton are warranted against defects in material, workmanship and design for a period of

one year from date of delivery. Repair or replacement products will be warranted for a period of three

months from the date of shipment or for the remainder of the original warranty period for that particular

product, whichever is longer. Any software or firmware that is delivered by Trenton will be warranted for a

period of one year to perform in accordance with published specifications prepared, approved and issued by

Trenton and/or the appropriate 3rd party vendor. Contact Trenton for the complete system warranty policy.

Buyer agrees that if a Trenton product proves defective, Trenton is only obligated to repair, replace or

refund the purchase price of this product at Trenton's discretion. The warranty is void if the product has

been subjected to alteration, neglect, misuse, or abuse; if any repairs have been attempted by anyone other

than Trenton; or if failure is caused by accident, acts of God, or other causes beyond the control of Trenton.

Trenton reserves the right to make changes or improvements in any product without incurring any

obligation to similarly alter products previously purchased.

In no event shall Trenton Systems, Inc. be liable for any defect in hardware or software or loss or

inadequacy of data of any kind, or for any direct, indirect, incidental or consequential damages arising out

of or in connection with the performance or use of the product or information provided. Trenton Systems,

Inc.’s liability shall in no event exceed the purchase price of the product purchased hereunder. The

foregoing limitation of liability shall be equally applicable to any service provided by Trenton Systems,

Inc.

RETURN POLICY

Products returned for repair must be accompanied by a Return Material Authorization (RMA) number,

obtained from Trenton Systems prior to return. Freight on all returned items must be prepaid by the

customer, and the customer is responsible for any loss or damage caused by common carrier in

transit. Items will be returned from Trenton Systems via Ground, unless prior arrangements are made by

the customer for an alternative shipping method

To obtain an RMA number, call us at (800) 875-6031 or (770) 287-3100. We will need the following

information:

Return company address and contact

Model name

Serial number from chassis label

Description of the failure

An RMA number will be issued. Mark the RMA number clearly on the outside of each box, include a

failure report for each item and return the product(s) to our Gainesville, GA facility:

TRENTON Systems, Inc.

2350 Centennial Drive

Gainesville, GA 30504

Attn: Repair Department

Contact Trenton for our complete service and repair policy.

TRADEMARKS

Trenton Systems is a registered trademark of TRENTON Systems, Inc.

IBM, PC/AT, VGA, EGA, OS/2 and PS/2 are trademarks or registered trademarks

of International Business Machines Corp.

Intel is a registered trademark of Intel Corporation.

MS-DOS and Microsoft are registered trademarks of Microsoft Corp.

All other brand and product names may be trademarks or registered trademarks

of their respective companies.

LIABILITY DISCLAIMERS

In no event will Trenton Systems be responsible or liable for indirect or consequential damages resulting

from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the

many system variables and application requirements associated with any particular installation, Trenton

Systems cannot assume responsibility or liability for actual system use based on the examples and

diagrams. No patent liability is assumed by Trenton Systems with respect to the use of the information,

components, equipment or software described in this manual. This manual is as complete and factual as

possible at the time of publication; however, the information in this manual may have been updated since

that time. Trenton Systems, Inc. reserves the right to change the functions, features or specifications of

their products at any time, without notice.

Reproduction of the contents of this manual, in whole or part, without written premission of Trenton

Systems is prohibited.

Copyright ©2015 by Trenton Systems, Inc. All rights reserved.

E-mail: Support@TrentonSystems.com

Web: www.TrentonSystems.com

TRENTON Systems, Inc.

2350 Centennial Drive • Gainesville, Georgia 30504

Sales: (800) 875-6031 • Phone: (770) 287-3100 • Fax: (770) 287-3150

MBS1000 Installation Guide

Trenton Systems, Inc.

Table of Contents

HANDLING PRECAUTIONS I

BEFORE YOU BEGIN II

INTRODUCTION II

EXTERNAL POWER SOURCE –REDUNDANT 900W AC/DC

POWER SUPPLY VERSION II

EXTERNAL POWER SOURCE –REDUNDANT 750W -48VDC

POWER SUPPLY VERSION II

CHASSIS RACK MOUNTING II

CHAPTER 1 - SYSTEM OVERVIEW 1-1

DESCRIPTION 1-1

MBS1000 MODULAR BLADE SERVER CONFIGURATIONS 1-1

ADDITIONAL SYSTEM ELEMENTS 1-2

SBC BATTERY 1-2

PACKING LIST 1-2

CHAPTER 2 - PHYSICAL DIMENSIONS & LAYOUT

DRAWINGS 2-1

LAYOUT DIMENSION DRAWINGS 2-1

CHAPTER 3 - INSTALLATION INSTRUCTIONS 3-1

ENVIRONMENTAL CONSIDERATIONS 3-1

RACK MOUNTING 3-1

RACKMOUNT INSTRUCTIONS 3-1

SLIDE RAIL INSTALLATION 3-1

CONNECTING AC POWER –MBS1000-002 SYSTEM

CONFIGURATION 3-4

CONNECTING DC POWER –MBS1000-001 SYSTEM

CONFIGURATION 3-4

CONNECTING A VIDEO MONITOR,REAR ETHERNET AND USB

TO THE MBS1000 3-5

CHAPTER 4 - REPLACING SYSTEM COMPONENTS 4-1

MBS1000 FIELD REPLACEMENT UNITS (FRUS) 4-1

COOLING FAN REPLACEMENT 4-3

STORAGE DRIVE REPLACEMENT 4-3

MBC8240 MODULAR BLADE CARD REPLACEMENT 4-4

MEMORY DIMMS AND BATTERY REPLACEMENT 4-5

OPTION CARD INSTALLATION 4-5

POWER SUPPLY REPLACEMENT -REDUNDANT -900W 100-

240VAC/200-250VDC OPTION 4-6

DVD REPLACEMENT 4-6

PREPARATION FOR SHIPMENT 4-6

CHAPTER 5 - CHASSIS SPECIFICATIONS 5-1

ENVIRONMENTAL 5-1

ELECTRICAL –MBS1000-002 SYSTEM CONFIGURATION 5-1

PHYSICAL 5-1

SHOCK &VIBRATION 5-1

AGENCY APPROVAL 5-1

MBS1000 Installation Guide

i Trenton Systems, Inc.

Handling Precautions

WARNING: This system has internal components which may be damaged by electrostatic discharge.

To protect internal components from electrostatic damage, be sure to observe the following precautions

when handling or storing the system:

• The MBS1000 has a net chassis weight of approximately 35.2lbs. (16.0kg). This base chassis

weight includes the chassis, an MBC8240 modular blade card, an MPI8241 mid-plane inteface

board, rack mounting hardware, and a rear-mounted, redundant, AC/DC power supply. Use

proper lifting techniques when moving and installing the system.

• When removing or installing boards and sub-components, keep these components in their static-

shielded bag and/or packaging until you are ready to for component installation.

• Handle the sub-components by their edges.

• Do not touch any sub-component I/O connector pins. Do not apply pressure or attach labels to the

board-level sub-components.

• Use a grounded wrist strap at your system or ground yourself frequently by touching the metal

chassis of the system before handling any sub-components.

• Ensure the systems external power source has a solid connection to an earth ground.

• Use antistatic padding on all work surfaces when installing or removing sub-components.

• Avoid static-inducing carpeted areas.

MBS1000 Installation Guide

Trenton Systems, Inc. ii

BeforeYouBegin

INTRODUCTION

It is important to be aware of the information listed below before installing your Trenton modular blade

server. System performance may be affected by incorrect usage of these features.

EXTERNAL POWER SOURCE –REDUNDANT 900W AC/DC POWER SUPPLY VERSION

Incoming AC power must be supplied to both of the power supply receptacles located at the rear of the

chassis.These dual AC power connections ensure that the active system power supply; as well as the

stand-by/fail-over supply, is each connected to a power source with a solid earth ground, and each supply

must have an incoming power source of: 100-127/200-240VAC, 10A/5A at 50 to 60Hz.

This power supply option may also be connected to incoming DC power sources capable of delivering 200-

250VDC at 5.5A to each power supply receptacle. A breaker rated at 125% of the marked DC input rating

must be provided as part of building installation.

Under each incoming power connection scenario, this power supply option delivers +12VDC and +12VDC

AUX to the system at 73.8A and 2.5A respectively. Total output power must not exceed 900W.

EXTERNAL POWER SOURCE –REDUNDANT 750W -48VDC POWER SUPPLY VERSION

Incoming -48DC power must be supplied to each three-position connector located at the rear of the chassis

on the two DC power supply assemblies.These dual DC power connections ensure that the active system

power supply; as well as the stand-by/fail-over supply, is each connected to a power source with a solid

earth ground. Each supply must have an incoming power source of:-48 to -60VDC, 20.4A DC typical, and

the maximum input current must not exceed 23A. The -48VDC power supply option delivers +12VDC and

+12VDC AUX to the system at 61.5A and 2.5A respectively. Total output power must not exceed 750W.

A breaker rated at 125% of the marked DC input rating must be provided as part of building installation.

The power supply must only be used with Trenton power cable P/N 193500001938-00. Contact Trenton for

this part.

CHASSIS AIRFLOW

When installing the chassis, ensure that a minimum free air space is available around the system. The

installation should have a minimum of 4-6 inches (101-152mm) behind the chassis and 7-8 inches

(178-203mm) in front of the chassis. Any front cabinet doors or access aisles must accommodate a

MBS1000 front chassis clearance of at least 7.0” (178mm) in order to provide proper clearance for the fan

FRU replacement. Ideally, a chassis clearance of 0.5-1.5 inches (13-38mm) above the system is desirable.

CHASSIS RACK MOUNTING

The MBS1000 system can be installed in a rackmount cabinet that conforms to EIA standards for server

equipment with 19-inch wide panels. The cabinet must be tall enough to accommodate the server’s height

and deep enough to accommodate the system’s depth, while providing the proper clearances for air flow

and cabling. A cabinet with a standard depth of 31.5 inches (800mm) will provide the suggested minimum

rear chassis clearances needed for an installation.

MBS1000 Installation Guide

1-1 Trenton Systems, Inc.

Chapter 1 -System Overview

DESCRIPTION

The Trenton MBS1000-xxx is a CE-compliant and UL recognized*, 1U modular blade server optimized for

system performance, longevity, and easy field support. The 1U rackmount enclosure of the MBS1000 is

designed for both server room and rugged field deployment locations that both require outstanding system

performance in a stable 1U computing platform.

At the heart of the MBS1000 is Trenton’s U.S. designed and Made in America MBC8240 modular blade card

or SBC. The MBC8240 SBC supports a long-life Intel® processor that delivers superior multi-core

processing performance with the thermal characteristics necessary for reliable and long-term 1U rackmount

server operation in a wide variety of application environments. The MBS1000 chassis supports two, 2.5”

front-access/hot-swap HDD carriers, one media drive bay, and a choice an AC/DC or a DC-only redundant

power supply. These components maximize power delivery and cooling to ensure long-life system reliability

with minimal Mean-Time-To-Repair (MTTR) times.

The MBS1000 1U server solution supports seven Ethernet interfaces with one port dedicated to remote

system management, up to two HDD or SDD storage drives, an optical media drive, and a choice of either

AC/DC or DC-only redundant power supplies. The MBS1000 also has the ability to support an off-the-shelf

PCI Express plug-in option card. Some typical MBS1000 applications include data servers, industrial

automation machinery, and weapon control systems.

*Refer to the agency approval section in chapter five and the MBS1000 Certificate Of Compliance document in chapter six for a

complete listing of the Council Directive: 2004/108/EC-EMC Directive standards to which conformity is declared.

MBS1000 MODULAR BLADE SERVER CONFIGURATIONS

NOTE: The chart below illustrates the SBC, mid-plane interface board, system power supply configurations

supported in the Trenton MBS1000-xxx modular blade server. The three characters to the right on the

hyphen indicate the blade server’s power supply configuration. Other system configuration parameters

include the SBC’s installed processor and system memory DIMMs.

System Model

Number

Mid-Plane

Interface

Board

Modular

Blade Card

(SBC)

Power Supply

Description of Mid-Plane, SBC, and System Power

Supply Combination

MBS1000-000

MPI8241

MBC8240

None

Mid-Plane:Two MBC8240 interface connectors, one x8

PCIe 3.0 electrical/x16 mechanical option card slot for use

with a x16 PCIe riser card such as the Trenton BRC8244

SBC:Single processor MBC8240 with one Intel®Xeon

E3-1225 v3 processor (part no. 92-824001300000), and four

8GB DDR3-1600 DIMMs (part no. 198500001112-00)

System Power Supply: None

MBS1000 Installation Guide

Trenton Systems, Inc. 1-2

MBS1000 Modular Blade Server Configurations (continued)

System Model

Numbe

r

Mid-Plane

Interface

Board

Modular

Blade Card

(SBC)

Power Supply

Description of Mid-Plane, SBC, and System Power

Supply Combination

MBS1000-001

MPI8241

MBC8240

-48VDC,

redundant

Mid-Plane:Two MBC8240 interface connectors, one x8

PCIe 3.0 electrical/x16 mechanical option card slot for use

with a x16 PCIe riser card such as the Trenton BRC8244

SBC:Single processor MBC8240 with one Intel®Xeon

E3-1225 v3 processor (part no. 92-824001300000), and four

8GB DDR3-1600 DIMMs (part no. 198500001112-00)

System Power Supply: :-48 to -

60VDC, 20.4A DC typical,

and the maximum input current must not exceed 23A,

750W, rear-mount, redundant

MBS1000-002

MPI8241

MBC8240

100-240VAC or

200

-250VDC,

redundant

Mid-Plane:Two MBC8240 interface connectors, one x8

PCIe 3.0 electrical/x16 mechanical option card slot for use

with a x16 PCIe riser card such as the Trenton BRC8244

SBC:Single processor MBC8240 with one Intel®Xeon

E3-1225 v3 processor (part no. 92-824001300000), and four

8GB DDR3-1600 DIMMs (part no. 198500001112-00)

System Power Supply: 100-127/200-240VAC, 10A/5A at

50 to 60Hz, or 200-250VDC at 5.5A, 900W, rear-mount,

redundant

ADDITIONAL SYSTEM ELEMENTS

Each MBS1000-xxx configuration contains the following active components:

•2 – SATAIII, 2.5” HDD, 1TB, installed in front access/hot swap drive carriers

•1 – Slim-Line R/W DVD

•6 – 30.5CFM redundant system fans, installed in individual, front access/hot swap fan module

carriers with two tandem fans per carrier

Consult with Trenton for available storage drives and optical media drives compatible with the MBS1000.

SBC BATTERY

The MBC8240 modular blade card uses a Panasonic CR2032 battery available from Trenton. The Trenton

Systems part number for an MBC8240 replacement battery is 198500001114-00.

CAUTION: Risk of explosion if the MBC8240 modular blade card (SBC) battery is replaced by an incorrect

type. Dispose of used batteries according to the instructions.

PACKING LIST

The CE-compliant and UL recognized system is shipped with the following:

• MBS1000 1U modular blade server

MBS1000 Installation Guide

2-1 Trenton Systems, Inc.

Chapter 2 -Physical Dimensions & Layout Drawings

LAYOUT DIMENSION DRAWINGS

Note: Ensure

that there is at

least 4-6 inches

(101-152mm)

behind the

chassis and 7-8

inches

(178-203mm) in

front of the

chassis of open

space in order to

allow for cable

connections,

airflow, and

system fan

maintenance.

MBS1000 Front View

MBS1000 Rear View

Side View MBS1000 Inside Top View

28”/711mm

17”/432mm

1.75”/44.5mm

MBS1000 Installation Guide

3-1 Trenton Systems, Inc.

Chapter 3 -InstallationInstructions

ENVIRONMENTAL CONSIDERATIONS

When installing the chassis, ensure that a minimum free air space is available around the system. The

installation should have a minimum 4-6 inches (101-152mm) of clearance behind the chassis and 7-8

inches (178-203mm) in front of the chassis. Ideally, a chassis clearance of 0.5-1.5 inches (13-38mm)

above the system is desirable, but not required. The server is equipped with fans to help ensure proper

cooling.

RACK MOUNTING

The MBS1000 system can be installed in a rackmount cabinet that conforms to EIA standards for server

equipment with 19-inch wide panels. The cabinet must be tall enough to accommodate the server’s height

and deep enough to accommodate the system’s depth, while providing the proper clearances for air flow

and cabling. A cabinet with a standard depth of 31.5 inches (800mm) should be sufficient.

The MBS1000 is designed to be supported in the cabinet with rack slides or placed on a cabinet shelf.

Optional front flanges may be attached to the modular blade server and are designed to secure the

MBS1000 to the rack cabinet’s front mounting rails

RACKMOUNT INSTRUCTIONS

A) Elevated Operating Ambient - If installed in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore, consideration should be

given to installing the equipment in an environment compatible with the maximum ambient temperature

(Tma) specified by the manufacturer.

B) Reduced Air Flow - Installation of the equipment in a rack should be such that the amount of air flow

required for safe operation of the equipment is not compromised.

C) Mechanical Loading - Mounting of the equipment in the rack should be such that a hazardous condition

is not achieved due to uneven mechanical loading.

D) Circuit Overloading - Consideration should be given to the connection of the equipment to the supply

circuit and the effect that overloading of the circuits might have on over current protection and supply

wiring. Appropriate consideration of equipment nameplate ratings should be used when addressing this

concern.

E) Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular

attention should be given to supply connections other than direct connections to the branch circuit (e.g. use

of power strips).

F) Chassis Access – Use in a RESTRICTED ACCESS LOCATION only.

NOTE: Only trained personnel shall install or operate this equipment

MBS1000 Installation Guide

Trenton Systems, Inc. 3-2

SLIDE RAIL INSTALLATION

Trenton offers a slide rail kit to help with the installation of a 1U Trenton Systems’ MBS1000 modular

blade server. Here are the installation instructions for the Trenton 26” Slide Rail kit (part no.

198500001127-00).

1. Remove slide rails from the box along with the rail frames, optional rack frame mounting brackets

and the mounting hardware. The Trenton 26” Slide Rail kit includes the following items.

2, 26”, three-section slide rails

2, chassis rack slide brackets

2, 1U chassis mounting ears

2, 1U component rack mounting ears

1, mounting hardware bag 10, #8-32 thumb screws

2. Remove the two chassis rack slide brackets from the slide rail kit and attach each one to the sides

of the MBS1000 by aligning the bracket’s mounting holes with the server’s slide bracket

mounting posts. When all three are aligned, slide the bracket toward the rear of the chassis until

you hear an audible click indicating that the bracket has locked into place. Refer to Figures 1 & 2.

3. Remove the 1U mounting ear screws and discard the spacing washers. Use the screws to attach

the 1U chassis mounting ears to the MBS1000.

4. Standard 19” instrument racks have a wide variety of mounting hole types. Some mounting holes

are threaded, but most of not, some mounting holes are located on side flanges rather than the

front and back of the rack supports and finally some holes are round while others are rectangular.

Our installation photos and the following steps assume that your 19” instrument rack has

rectangular, non-threaded mounting holes (i.e. window holes) for the slide rail frames. If your

rack has other mounting-hole types or placements, then you may need to consult with your rack

supplier to obtain the correct slide rail mounting hardware.

5. Using five #8-32 thumb screw, attach a three-section slide rail to the left side of the component

rack with the three-hole bracket toward the rear of the rack as shown in Figure 3A.

Chassis rack slide bracket

(2)

Rack slide bracket

mounting post

(3 per side)

1U mounting ears

(2)

Figure 1 – Chassis rack slide detail

1U mounting ear

attachment screws

(2 per side)

Figure 2 – Chassis rack slide and 1U mounting ear installed

Slide bracket lock

1U mounting ear installed

Right-side disconnect lever

Figure 3 – Slide rail installation

3A 3B

MBS1000 Installation Guide

3-3 Trenton Systems, Inc.

Slide Rail Installation (continued)

6. Attach the end of the rack slide with the two-hole bracket and the 1U component rack mounting

ears toward front of the rack as shown in Figure 3B.

a. Referring to Figure 4, adjust the hex nuts on the back side of each rack slide as necessary

for the required component rack depth.

b. Note: leave all slide mounting screws and depth-adjustment hex nuts until step 15.

Figure 4 – Slide rail depth adjustments

11. Repeat steps 4 and 5 for the right side slide rail referring to figures 3A, 3B and 4 as necessary.

12. If the mounting holes for you particular component rack are on the inside portions of your

rackmount supports, then mount each assembly directly to the rack supports as shown in figure 5.

13. CAUTION – Ensure that when mounting the completed rail and frame assemblies to the 19” rack

that the left and right assemblies are the same distance from the top or bottom of the rack. Failure

to align the slide rails properly will result in the modular blade server binding when moving in and

out of the component rack or not being level inside the rack. If the slides are grossly misaligned

then you may not be able to slide the chassis into the slide rails.

14. Refer to figure 6. Extend the slide rails to their maximum setting until they lock into position.

Slide the chassis into the rails attached to the frame of the rackmount enclosure. (You should have

another person help you lift and slide the chassis into the enclosure.)

Figure 5 – Rail/Frame Mounting – Inside

Rackmount Hole Locations

Figure 6 – Chassis Installation

Slide rail depth-adjustment hex nuts

(4 per rack slide)

Right-side disconnect lever

Left-side disconnect lever

MBS1000 Installation Guide

Trenton Systems, Inc. 3-4

Slide Rail Installation (continued)

NOTE 1: Lift the lever on the left slide rail UP while moving the right slide rail lever

DOWN while sliding the chassis into the slide rails in order to move the chassis

completely into the component rack.

NOTE 2: To remove the chassis from the component rack slides, lift the lever on the left

slide rail UP while moving the right slide rail lever DOWN while sliding the chassis out

of the slide rails.

15. Check slide rail alignment for any signs of binding by slide the chassis into and out of the

component rack. A binding condition indicates undue slide rail stress or misalignment. Adjust

slide rail positions until the chassis movement is smooth. Tighten all screws and the depth

adjustment nuts to complete the installation.

CONNECTING AC POWER –MBS1000-002 SYSTEM CONFIGURATION

The MBS1000-002 configuration requires a single-phase power source providing 100-240VAC at 50 to

60Hz to each AC input power outlet located at the rear of the chassis for the incoming AC power

implementation of this power supply configuration. Power must be available at both three-pin AC input

receptacles located at the rear of the system. An over-current protection device shall protect each power

cord. Under this incoming power connection scenario the power supply delivers +12VDC and +12VDC

AUX to the system at 73.8A and 2.5A respectively. Total output power must not exceed 900W.

To connect AC power to the server:

1. Establish a chassis to earth ground connection to the MBS1000 chassis.

2. Connect the AC power cords to the AC receptacles.

3. Connect the plug end of the power cords into the main outlets.

NOTE: The system’s power monitoring circuits will shut the system down if the maximum current

limit is are drawn from the power supply for the system supply’s 12VDC and 12VAUX power rails.

CONNECTING DC POWER –MBS1000-001 SYSTEM CONFIGURATION

The MBS1000-001 configuration requires a -48VDC power source connected to each three-position

connector on the -48VDC power supplies. Power must be available at both three-position DC connectors

located at the rear of the system.

Each DC supply must have an incoming power source of:-48 to -60VDC, 20.4A DC typical, and the

maximum input current must not exceed 23A. The -48VDC power supply option delivers +12VDC and

+12VDC AUX to the system at 61.5A and 2.5A respectively. Total output power must not exceed 750W.

MBS1000 Installation Guide

3-5 Trenton Systems, Inc.

CONNECTING A VIDEO MONITOR,REAR ETHERNET AND USB TO THE MBS1000

The figure below illustrates various connection points to the rear system I/O and network communication

functions available on the system’s MBC8240 single board server blade. Follow the connection label

located below the MBC8240 SBC to make the necessary connections for your specific MBS1000

application. Note that the orange Ethernet LAN cable in the illustration below is connected to Ethernet Lnk

0. This LAN port indicated; by the black connection label identifier, is dedicated to the system

management function and cannot be used as a general purpose Ethernet LAN.

MBS1000 Installation Guide

4-1 Trenton Systems, Inc.

Chapter 4 -Replacing System Components

MBS1000 FIELD REPLACEMENT UNITS (FRUS)

The MBS1000 is designed as a completely modular blade server. The server’s top cover should never be

removed in the field since all of the filed replacement units are accessible from either the front or rear of

the server chassis. However, a trained electronics technician is required to install or remove the

MBS1000’s FRUs and PCI Express plug-in option card.

NOTE: When installing an option card into the MBS1000 modular blade server you must ensure that the

card installation does not result in non-conformance to the safety or EMC requirements for this product.

MBS1000 Field Replacement Units (FRUs)

Description

Trenton Systems P/N

IBM P/N

IBM FRU #

1

1U Rack Mount System w/o PS, IBM

262500003084-00

00RY451

N/A

2

1U Base System

198500001101-00

00RY465

3

MBC8240 SBC with Intel Xeon E3-1225v3, 32GB, Battery

198500001100-00

N/A

4

MBC8240 SBC with Intel Xeon E3-1225v3, w/o DIMMs, Battery

198500001110-00

00RY462

5

8GB DDR3-1600 ECC Memory DIMM

198500001112-00

00RY460

6

MBC8240 SBC Battery

198500001114-00

00RY455

7

900W 100-240VAC/200-250VDC System Power Supply

198500001098-00

00RR363

00RR365

8

750W -48VDC System Power Supply

198500001117-00

00RR406

00FX892

9

Fan Module

198500001102-00

00RY463

10

DVD with Carrier

198500001104-00

00RY461

11

2.5” HDD Carrier

198500001105-00

00RY471

12

1TB 2.5” SATAIII HDD with Carrier

198500001106-00

00RY459

13

Bezel, Fan Cover

198500001123-00

00RY464

14

26” System Slide Rail Kit

198500001127-00

00RY466

The design of the MBS1000 enables all FRUs to be accessed from either the front or rear of the modular

blade server. In the course of normal system maintenance in the field, there should never be a need to open

the modular blade server by removing the system’s top cover. Refer to the MBS1000 FRU table and the

figures below for each FRU location.

NOTE 1: The system fans and drives are completely hot pluggable, and there is no need to

disconnect the MBS1000 incoming power connections.

NOTE 2: Trenton recommends disconnecting the MBS1000 incoming power connections before

removing the systems’ MBC8240 SBC. To remove power, disconnect the plug of the power

cord.

To remove all power from the equipment, disconnect power from both power supplies.

Table 1 – MBS1000 Field Replacement Units (FRUs)

MBS1000 Installation Guide

Trenton Systems, Inc. 4-2

Figure 6 – MBS1000 Front FRUs

Figure 7 – MBS1000 Rear FRUs

Figure 8 – MBC8240 Modular Blade Card FRUs

MBS1000 Installation Guide

4-3 Trenton Systems, Inc.

COOLING FAN REPLACEMENT

The five cooling fan assemblies of the MBS1000 are each integrated into individual fan modules that slide

into the front of the system. Each fan module contains two redundant fans. Referring to Figure 10, lift the

two levers on the fan cover bezel (13) to remove the bezel. Pull the ring of the FRU fan module (9) that

you wish to replace straight out to remove. Slide the new fan module in until you feel it seat into the

connector and re-install the fan bezel cover.

STORAGE DRIVE REPLACEMENT

The storage drives of the MBS1000 are mounted in drive carriers that are accessible on the front of the

system as shown in Figure 11. Drive carrier mounted HDDs are secured to the chassis with black carrier

release lever. Slide the black HDD catch to the left, grasp the drive carrier handle, and then pull out the

carrier to remove. Once the carrier is removed, you may mount or remove the drive or drives as necessary.

Figure 10 – MBS1000 Fan Module Removal

Figure 11 – MBS1000 Drive Removal

MBS1000 Installation Guide

Trenton Systems, Inc. 4-4

MBC8240 MODULAR BLADE CARD REPLACEMENT

The MBC8240 SBC is removed from the rear of the MBS1000 by loosening the captive screws on either

side of the SBC and opening the card-eject levers as shown in Figure 12.

NOTE 1: Trenton recommends disconnecting the MBS1000 incoming power connections before

removing the systems’ MBC8240 SBC.

NOTE 2: To protect MBC8240 components from electrostatic damage, be sure to observe the handling

precautions outlines on page i of this installation guide.

Reverse the card removal process to install the replacement MBC8240 modular blade card.

Figure 12 – MBC8240 SBC Removal

MBS1000 Installation Guide

4-5 Trenton Systems, Inc.

MEMORY DIMMS AND BATTERY REPLACEMENT

Following proper anti-static precautions mentioned earlier and referring to Figure 12, remove the

MBC8240 SBC to replace the memory DIMMs. Push down on the memory DIMM socket tab located on

opposite sides of each module. This downward action releases a memory DIMM from its socket and

pushes the module up. Remove the module and replace it with the FRU part five (8GB DDR3-1600 ECC

Memory DIMM ) as illustrated in Figure 8.

Refer to Figure 8 and locate the SBC’s battery. Again using proper anti-static precautions mentioned

earlier, slightly push the battery toward the inside of the SBC while lifting up on the battery to remove it

from its socket. Install the new batter ensuring that the + side of the board faces the outer edge of the SBC.

CAUTION: Risk of explosion if the system host board battery is replaced by and incorrect type. Dispose

of used batteries according to the instructions.

OPTION CARD INSTALLATION

Following proper anti-static precautions mentioned earlier and referring to Figure 13 below, install the

desired PCI Express option card into the riser card connected to the MBC8240 riser card slot. If the

MBC8240 does not have the riser card installed, plug it into the card slot on the SBC and secure it to the

two white plastic mounting tabs using the screw hardware provided by Trenton. Once the option card is

installed, ensure that it aligns properly with the MBC8240’s rear panel access slot.

Figure 13 – Option Card Installation

MBS1000 Installation Guide

Trenton Systems, Inc. 4-6

POWER SUPPLY REPLACEMENT -REDUNDANT -900W 100-240VAC/200-250VDC OPTION

The 900W redundant power supply used in the MBS1000 modular blade server is mounted in the rear of

the system as shown in Figure 14.

The system’s redundant, rear-mounted power supplies should only be removed and replaced by a trained

electronics technician using the proper anti-static precautions mentioned earlier.Disconnect both supplies

from the power source. Push the orange power supply release lever to the right while pulling on the power

supply handle. Slide out the supply and replace it with Trenton FRU part number 198500001098-00.

Use the same procedure when replacing the 750W -48VDC System Power Supply, but use Trenton FRU

part number 198500001117-00.

DVD REPLACEMENT

A DVD rarely fails, but if the DVD in the MBS1000 should fail it can be easily accessed from the front on

the unit for removal and replacement. Referring to Figure 15, insert the ICY Dock DVD carrier release

tool into the right slot of the DVD carrier as show in Figure 15 to release the DVD carrier door from the

system. After the carrier door releases, swing the door open and the DVD carrier will move out of the

chassis. Remove the DVD from the carrier and replace it with Trenton FRU part number 198500001104-

00. Reinstall the carrier and secure the DVD carrier door by closing it shut with an audible click.

PREPARATION FOR SHIPMENT

The MBS1000 should always be removed from the rack cabinet if the unit must be shipped to another site.

If possible, use the original shipping carton to ship the MBS1000.

NOTE: Never ship the MBS1000 when it is mounted inside a rack; damage to the server and rack cabinet

will likely result.

Reverse the installation steps in chapter three to remove the MBS1000 from the rack cabinet. Do not forget

to remove the chassis’ earth ground wire before attempting server removal.

Figure 14 – Power Supply Removal

Figure 15 – DVD Carrier Removal

Table of contents

Popular Server manuals by other brands

Intel

Intel SR1600UR - Server System - 0 MB RAM Service guide

Silex technology

Silex technology SX-2000U2 user manual

Omron

Omron ETHERNET DIRECT DR 170 14 user guide

Compaq

Compaq ProSignia 300 Maintenance and service guide

LG

LG Cloud Device 24CQ65 Series owner's manual

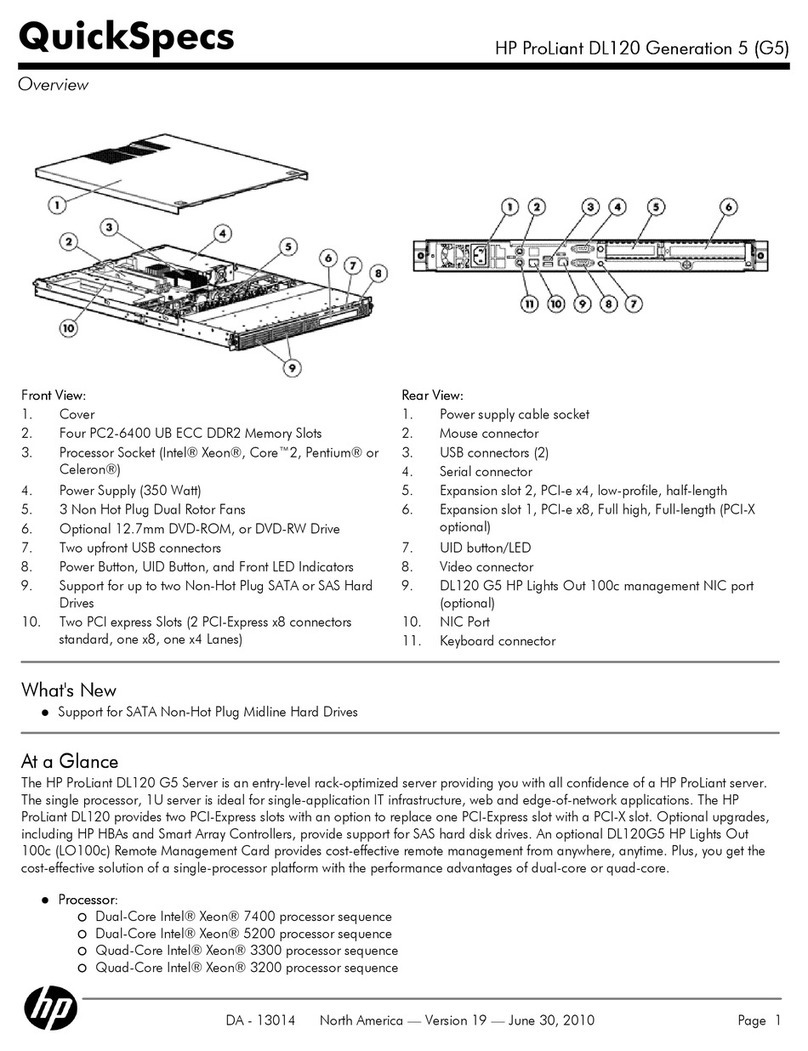

HP

HP DL120 - ProLiant - G5 Quickspecs