Trerice TA901 Manual

541-622-021 Trerice TA901 I/P Transducer Page 1

Trerice TA901

I/P Current to Pressure

Transducer

Installation,

Operation and

Maintenance

Instructions

Contents

Section Description Page

1.0 Description & Installation 2

2.0 Operation 3

3.0 Maintenance 5

4.0 Troubleshooting 5

Pilot Pressure

Atmospheric Pressure

Supply Pressure

Output Pressure

H.O. Trerice Co

12950 W. Eight Mile Rd., Oak Park, MI 48237-3288

(810) 399-8000 ~ Fax: (810) 399-7246

MANUFACTURERS OF TEMPERATURE / PRESSURE INSTRUMENTS & CONTROLS - SINCE 1923

541-622-021 Trerice TA901 I/P Transducer Page 2

DANGER, WARNING, CAUTION and NOTE statements

Refers to conditions or hazards which could result in serious personal injury or death.

Refers to conditions or hazards which could result in personal injury.

Refers to conditions or hazards which could result in equipment or property damage.

Alerts you to facts or special instructions.

ALL DANGER, WARNING, AND CAUTION NOTICES MUST BE COMPLIED WITH IN FULL

SPECIFICATIONS

Min./Max. Supply Pressure Minimum - 3 psig (0.21 BAR)

Above maximum output Maximum

- 100 psig (7 BAR)

Supply Pressure Sensitivity <± 0.1% of span per psig

(<± 0.15% of span per 1 BAR)

Linearity <± 0.75% of span

Repeatability < 0.5% of span

Hysteresis < 1.0% of span

Flow Rate 4.5 scfm (127 Nl/min) at 25

psig (1.7 BAR) supply

12.0 scfm (340 Nl/min) at 100

psig (6.8 BAR) supply

Maximum Air Consumption .05 scfm (1.4 Nl/min) midrange typical

Port Sizes 1/4 NPT (Pneumatic)

1/2 NPT (Electric)

1. DESCRIPTION and INSTALLATION

1.1 Description

1.1.1 This I/P Current to Pressure Transducer converts a current or voltage input signal to a linearly proportional

pneumatic output pressure. This versatile instrument is designed for control applications that require a high

degree of reliability and repeatability at an economical cost.

1.2 Principle of Operation

1.2.1 This I/P Transducer is a force balance device in which a coil is suspended in the field of a magnet by a flex-

ure. Current flowing through the coil generates axial movement of the coil and flexure. The flexure moves towards

the nozzle and creates back pressure which acts as a pilot pressure to an integral booster relay. Input signal

increases cause proportional output pressure increases.

Zero and Span are calibrated by turning adjust screws on the front face of the unit. Adjustment of the zero screw

repositions the nozzle relative to the flexure. The span adjustment is a potentiometer that controls the amount of

current through the coil.

.

1.3 Mounting

1.3.1 Unit may be pipe, panel, or bracket mounted. Mounting may be at any angle, though may require field

adjustment. High external vibration may cause output fluctuations. Mounting in a vibration-free area is recommended.

NOTE

CAUTION

WARNING

DANGER

541-622-021 Trerice TA901 I/P Transducer Page 3

1.4 Pneumatic Connections

(00( )1?@(@)@87446,@=<3@97>47>@49;>8@=;?@2=;&?3@@=<3@)@;?84?5>:*?6,@9<@>1?@-=8?@9.@>1?@7<:>0@6?=<@=66@

4:4?@6:<?8@>9@;?29*?@59<>=2:<=>:9<@-?.9;?@:<8>=66=>:9<0@'446,@4:4?@592497<3@>9@2=6?@>1;?=38@9.@>1?@=:;@6:<?@9<6,0@

'*9:3@/?>>:</@592497<3@:<@>1?@=:;@6:<?80

6?=<@3;,@:<8>;72?<>@7=6:>,@=:;@278>@-?@78?30@)9@:<87;?@94>:272@4?;.9;2=<5?@87446,@4;?887;?@819763@-?@

;?/76=>?30@)9@4;9*:3?@8>=-6?@:<6?>@4;?887;?@=<3@4;?*?<>@59<>=2:<=>:9<@9.@>1?@:<>?;<=6@8?5>:9<@9.@>1?@>;=<8375?;@>1?@

78?@9.@=<@<8>;72?<>@':;@:6>?;@?/76=>9;@:8@;?5922?<3?30

)1?@>+9@7<2=;&?3@49;>8@9<@>1?@-=8?@9.@>1?@7<:>@=;?@/=/?@49;>8@-7>@2=,@-?@78?3@=8@=6>?;<=>:*?@97>47>@49;>80@'<,@

7<78?3@49;>8@278>@-?@467//?30

The I/P transducer enclosure contains aluminum and is considered to constitute a potential risk of

ignition by impact or friction and must be taken into account during installation.

1.5 Electrical Connections

(00( 6?5>;:5=6@59<<?5>:9<8@=;?@2=3?@>9@>1?@-6=5&@=<3@+1:>?@6?=38@?#>?<3:</@97>@.;92@>1?@( @)@59<37:>@.:>>:</0@

1?<@>1?@498:>:*?@8:3?@9.@>1?@:<47>@8:/<=6@:8@59<<?5>?3@>9@>1?@-6=5&@6?=3!@>1?@97>47>@4;?887;?@+:66@:<5;?=8?@=8@>1?@

:<47>@8:/<=6@:<5;?=8?80@9;@;?*?;8?@=5>:</@293?@:<5;?=8:</@:<47>@8:/<=6@3?5;?=8?8@97>47>@4;?887;?!@59<<?5>@

498:>:*?@8:3?@9.@>1?@:<47>@8:/<=6@>9@>1?@+1:>?@6?=30

Figure 1 DIN 43650 Connector

2. OPERATION

2.1 Calibration

0(0( ?;9@=<3@4=<@819763@=6+=,8@-?@51?5&?3@=.>?;@297<>:</0@.@7<:>@:8@5=6:-;=>?3@:<@=@*?;>:5=6@498:>:9<@=<3@>1?<

297<>?3@=>@=<@=</6?!@;?=3%78>2?<>@9.@>1?@"?;9@:8@<?5?88=;,0@)9@5=6:-;=>?@78?@>1?@.9669+:</@4;95?37;?

(0 4?<@4;9>?5>:*?@59*?;8@>9@?#498?@"?;9@=<3@84=<@=3%78>2?<>@85;?+80

0 9<<?5>@>1?@;?5922?<3?3@=:;@87446,@>9@>1?@:<6?>@9.@>1?@>;=<8375?;@=<3@=<@=557;=>?@4;?887;?@/=/?@>9@>1?@97>6?>0

0 9<<?5>@>1?@?6?5>;:5=6@:<47>@=<3@8?>@>1?@:<47>@8:/<=6@>9@>1?@2:<:272@*=67?@9.@>1?@;=</?@-?:</@78?3@

?0/0@@2'@.9;@=@ $@2'@7<:>0

0 -8?;*?@>1?@97>47>@4;?887;?0@.@<?5?88=;,@=3%78>@"?;9@85;?+@7<>:6@;?=51:</@2:<:272@97>47>@4;?887;?@8?>>:</0@

)7;<@"?;9@85;?+@597<>?;@5695&+:8?@>9@:<5;?=8?@4;?887;?!@5695&+:8?@>9@3?5;?=8?@4;?887;?0

0 <5;?=8?@?6?5>;:5=6@:<47>@8:/<=6@>9@:>8@2=#:272@*=67?@?0/0@ $@2'@.9;@=@ $@2'@7<:>0

0 -8?;*?@>1?@97>47>@4;?887;?0@.@<?5?88=;,@=3%78>@>1?@84=<@85;?+@7<>:6@;?=51:</@2=#:272@97>47>@4;?887;?@8?>>:</0

For I/P (current) input models turn span screw counter clockwise to increase pressure,

clockwise to decrease pressure. For E/P (voltage) input models turn span screw clockwise

to increase pressure, counter clockwise to decrease pressure.

0 )1?@?;9@=<3@4=<@=3%78>2?<>8@=;?@:<>?;=5>:*?0@'.>?;@=3%78>:</@>1?@84=<@:>@+:66@-?@<?5?88=;,@>9@;?51?5&@>1?@"?;90@

?4?=>@8>?48@@7<>:6@-9>1@?<3@49:<>8@=;?@=>@>1?@;?7:;?3@*=67?80

Figure 2 Electrical Schematic

WARNING

NOTE

Notes:

@C 81F5DAEF?6F>9%F@EDF?6F/B7F@F>BF:8B=;=7F=9:/;C

AC 81F@ED<EF?6F-.>9,7F#5F;8F@EEF+.?BC

0C 81F@D"F'*F>9%FED@EF'*F17?87F#AF/B7F<F>BF

:8B=;=7F=9:/;C

2.2 Dimensional Drawings :2?<8:9<8@=;?

2.3 Intrinsically Safe Operation

00( This I/P@9..?;8@=5>9;,@7>7=6@<>;:<8:5=66,@=.?@

=44;9*=6@=8@=@8>=<3=;3@.?=>7;?@9<@=66@7<:>8@+:>1@=@ $@2'@:<47>@8:/<=60

:<0

22

541-622-021 Trerice TA901 I/P Transducer Page 4

1.10

27.9

.55

14.0

(2) #18 GA. Wire Leads,

18" Long.

Black = Positive

White = Negative

(2) #10-32 UNF-2A x .38 DP.

Mounting Holes (Shown with

Bracket Screws Installed)

1.15

29.2

1.12

28.4

4.24

107.7

1.13

28.7

1.04

26.4

1.50

38.1

1.50

38.1

.55

14.0

1.13

28.7

Diameter

2.88

73.1

.21

.53

Diameter

MNTG.

Holes

1.250

31.7

2.18

55.4

1.44

36.6

SIGNAL

1/4

NPT

TYP.

Removable

Mounting

Bracket

1/2

NPT

IN OUT

Max (Square)

SPAN

ZERO

Alternate

Out/Gauge

Port

TYP. 180°Apart

Drawing No. 531-990-016

127(6

,167$//$7,2172%(,1$&&25'$1&(:,7+7+(1$7,21$/

(/(&75,&&2'(1)3$$57,&/($1'$16,,6$53

$33$5$786&211(&7('727+(6<67(06+$//12786(25

*(1(5$7(92/7$*(*5($7(57+$19

,167$//,175,16,&$//<6$)(%$55,(56,1$&&25'$1&(:,7+

%$55,(5,16758&7,216

)$&725<0878$/$33529('$6,175,16,&$//<6$)()25

&/$66,,,$1',,,',9,6,21*52836&'()$1'*:+(1

,167$//('$66+2:1

)$&725<0878$/$33529('$6121,1&(1',9()25&/$66,

',9,6,21*52836$%&$1''$1'68,7$%/()25&/$66,,

',9,6,21*5283)*$1'&/$66,,,',9,6,21$1'

%$55,(56$5(1275(48,5(')25121,1&(1',9(5$7,1*0$;

9 9'&

&$87,2168%67,787,212)&20321(1760$<92,')$&725<

0878$/$33529$/

$0%,(177(03(5$785(5$1*(&72&

)$&725<0878$/$33529('$6,175,16,&$//<6$)()25

&/$66,,,$1',,,',9,6,21*52836&'()$1'*:+(186('

$662&,$7('$33$5$7867+(/,1($5%$55,(53$5$0(7(560867

0((77+()2//2:,1*5(48,5(0(176

9RFRU9W9PD[&D!&L&FDEOH

,VFRU,W,PD[/D!/L/FDEOH

(17,7<3$5$0(7(56)2502'(/TA901

9PD[ 9&L

,PD[ P$/L 2P+

&L,6&$3$&,7$1&(&2175,%87('%<7+(75$16'8&(5

/L,6,1'8&7$1&(&2175,%87('%<7+(75$16'8&(5

541-622-021 REV 1/24/8Trerice TA901 I/P Transducer Page 5

3. MAINTENANCE

Under normal circumstances, no maintenance should be required. If clean dry air is not used the orifice can become blocked. To

clean, first turn off supply air, unscrew and remove orifice assembly. The unplug orifice by using a wire that has a smaller

diameter than 0.015 in. (0.38 mm). Use compressed air to blow out any loose particles inside the orifice assembly. Replace

orifice assembly back into unit.

4. TROUBLESHOOTING

PROBLEM CHECK

No output or low output Zero adjustment

Supply pressure too low

Clogged orifice

Leakage Connections

Low or improper span Zero and Span adjustments

Supply pressure too low

Output leakage

Erratic operation Electrical input signal

Loose wires or connections

Liquid in air supply

Lead Wire

Bonnet

O-Ring

O-Ring

Body Subassembly

Circuit

Board

Bottom Plug

Spacer

Pintle Spring

Table of contents

Popular Transducer manuals by other brands

Simrad

Simrad ES120-7C - INSTALLATION REV A installation manual

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD AFF-20 operating instructions

S+S Regeltechnik

S+S Regeltechnik Thor II Series Operating Instructions, Mounting & Installation

JDC Instruments

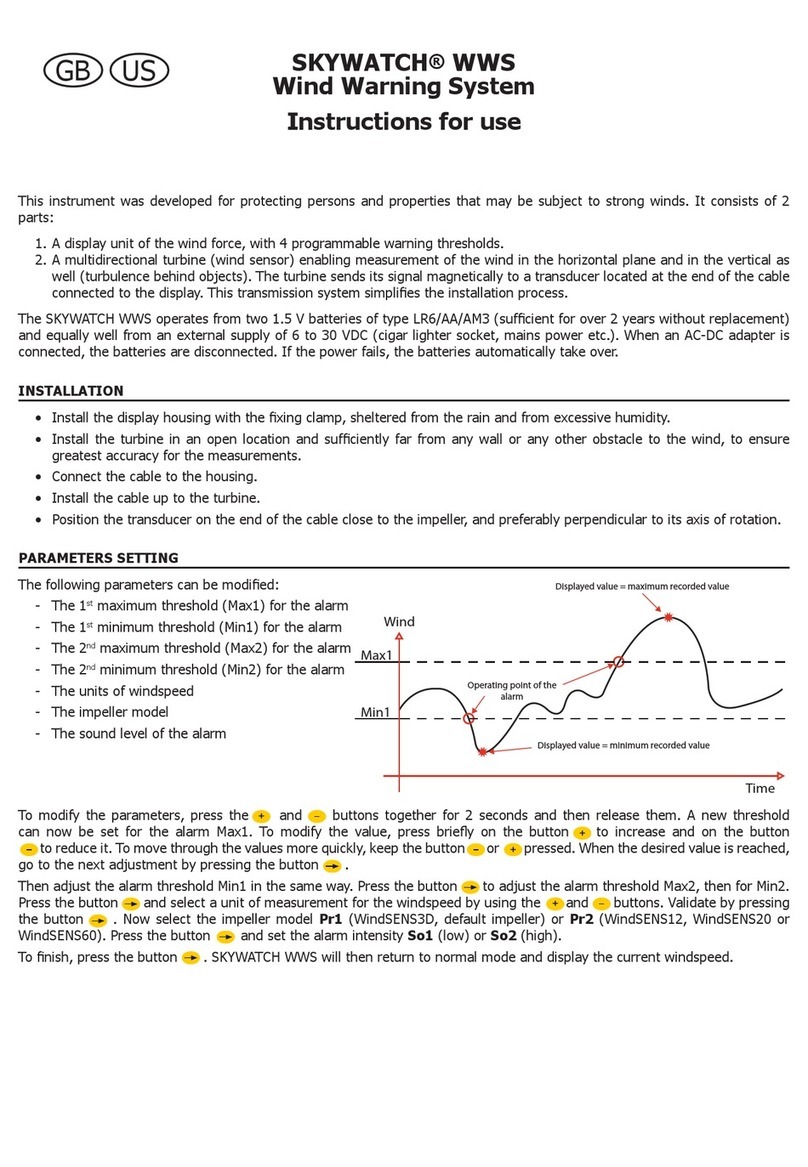

JDC Instruments SKYWATCH WWS Instructions for use

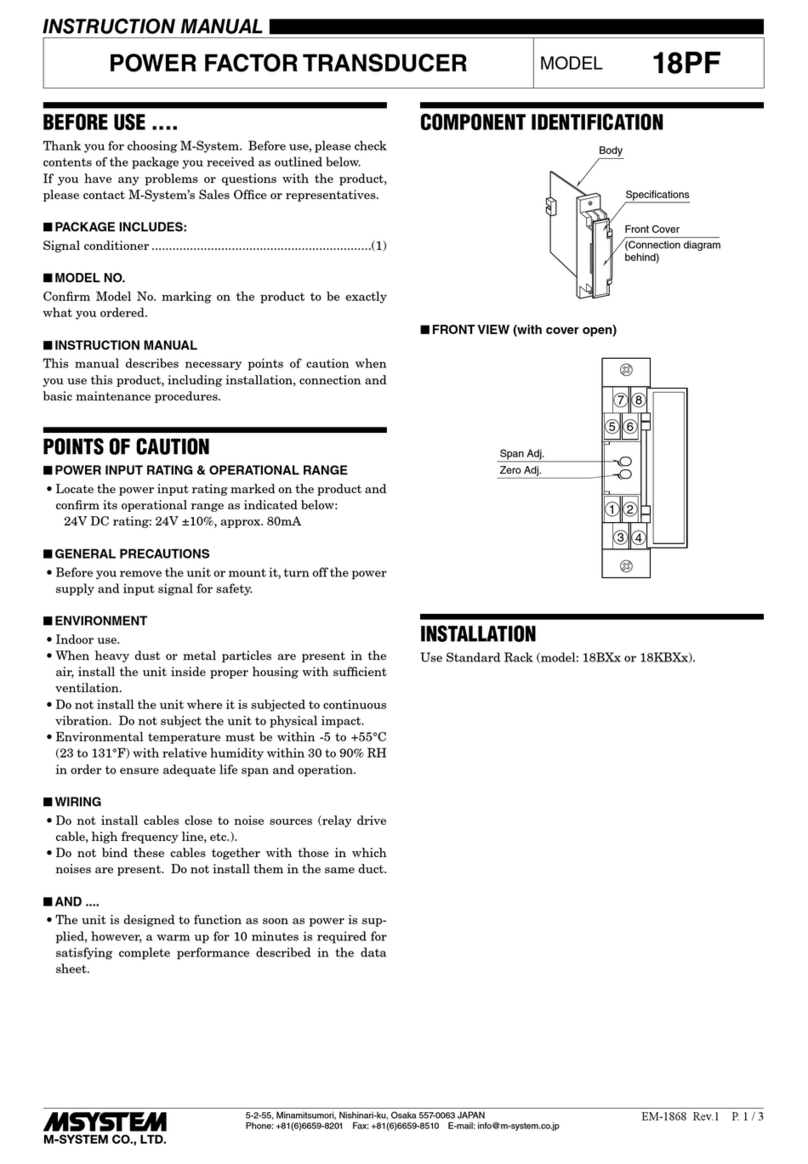

M-system

M-system 18PF instruction manual

Fairchild

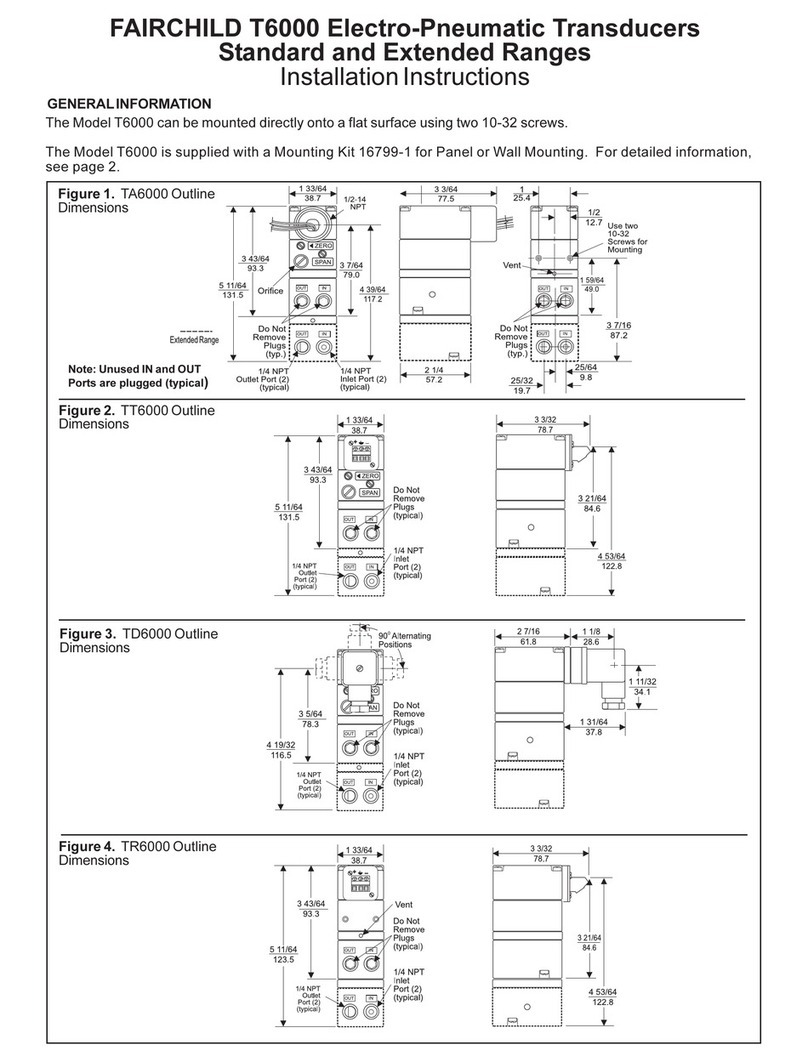

Fairchild T6000 installation instructions