Pneumatic Connection

Cleanall pipelines to remove dirt and scale before installation.Apply

a minimum amount of pipe compound to the male threads of the

fitting only. Do Not use teflon tape as a sealant. Start with the third

thread back and work away from the end of the fitting to avoid

contaminating the transducer. Install the transducer in the air line.

The inlet and outlet ports are labeled on the ends of the transducer.

Tightenconnections securely. Avoidundersized fittings that will limit

the flow through the transducer and cause pressure drop down

stream.

NOTE: Oil free air is required. Use a filter to remove dirt and

liquid in the air line ahead of the transducer. If an air

line lubricator is used, it MUST be located down-

stream to avoid interference with transducer perfor-

mance.

The user is responsible for insuring that the environ-

ment in which the unit will be installed and the

operating gas are compatible with the materials in the

transducer.

Electric Connection

Make connections as shown in Figure 8.

CAUTION: Effective November 1997 (DATE CODE NE), the DIN

Connector terminal connections have been changed. The ground

connection has been moved from terminal #3 to the ( ) terminal.

When replacing an existing unit, correct wiring on the mating

connector.

Wiring in Hazardous Areas

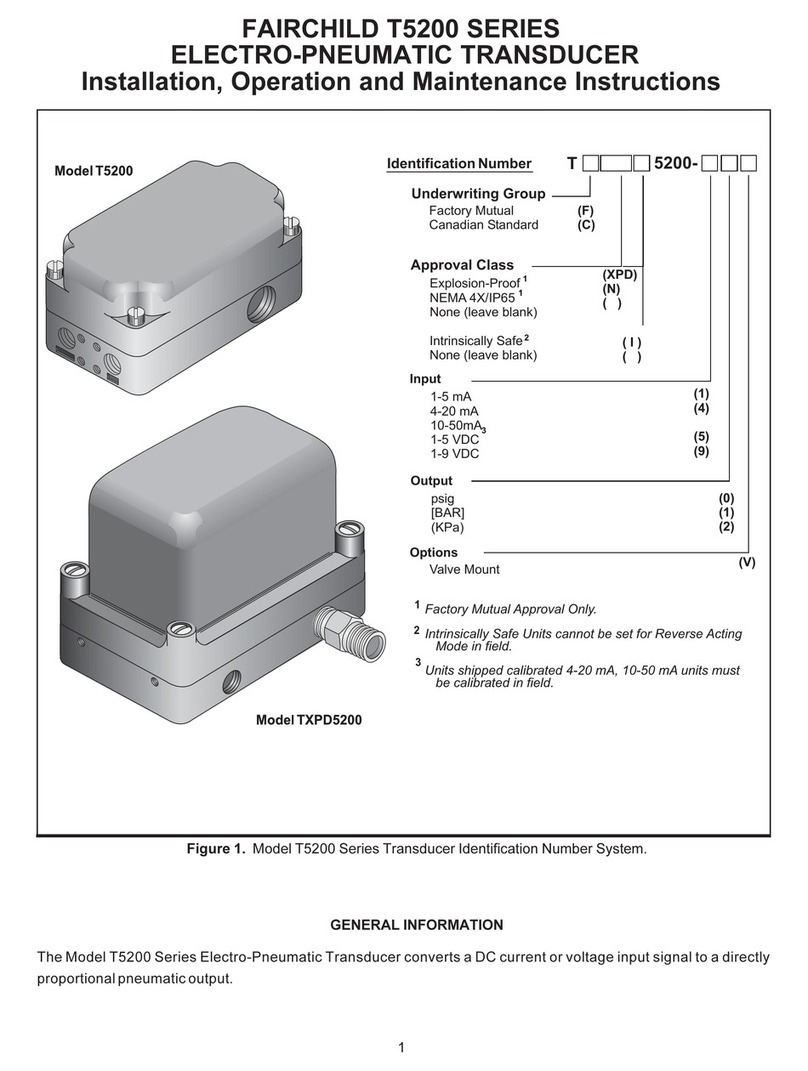

Table 1. Hazardous Location Wiring Practices.

Country Agency Code

U.S.

Canada

Europe

FM

CSA

ATEX

ANSI/ISARP 12.6 &ANSI/NFPA70

CEC Part 1

EN 50 039, EN 60079-14, IEC 60079-14

Intrinsically Safe Connections

Table 2. Intrinsically Safe Installation Drawings.

Underwriting Group Drawing Number

FM (Factory Mutual)

CSA (Canadian Standards)

ATEX

EC-16984

EC-18005

EC-18007

Limitations/Exceptions

Type 3R - TAF, TDF upright position

TFA- CL I, Div 2 wiring per NECANSI/NPFA70 for installation

without wiring parameters. TDF, TTF, TRF require an enclosure.

For dry locations and voltages less than 60Vdc, TTF & TRF

units must be in an enclosure.

Where loop voltages exceed 60Vdc (dry locations) or 30Vdc

(potentially damp locations), the TTF and TRF versions

must be installed meeting the electrical shock and fire

protection requirements of ANSI/ISA S82.01.

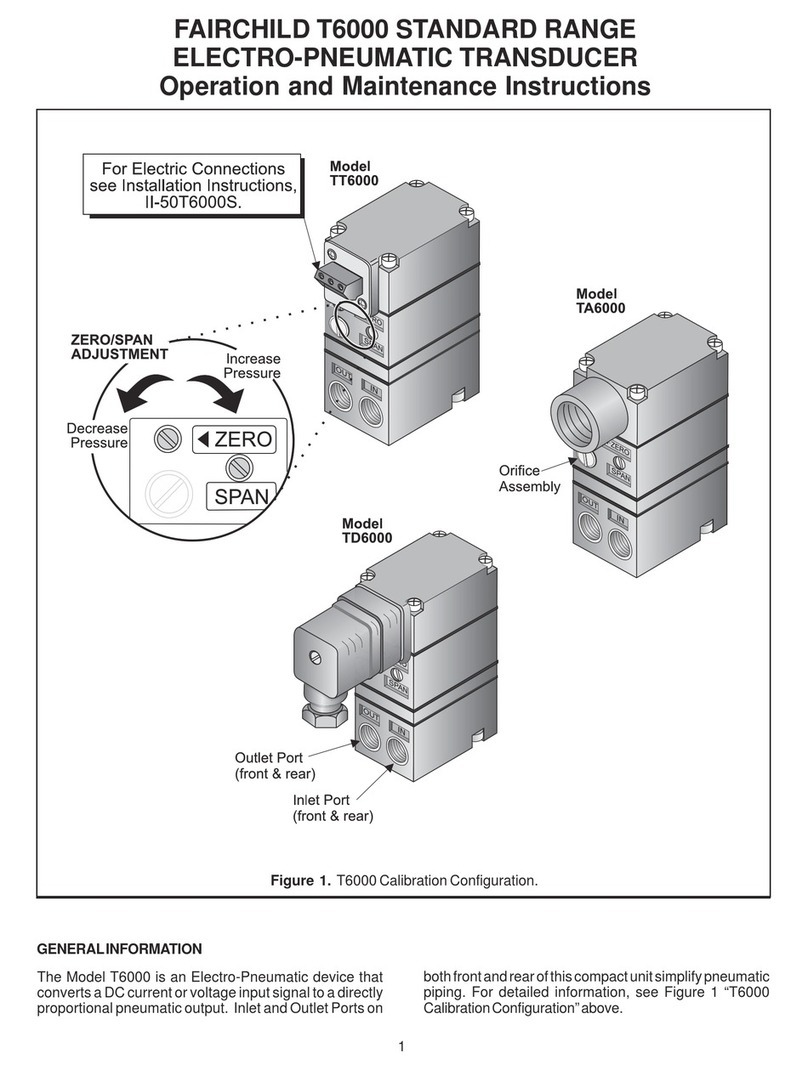

MAINTENANCE

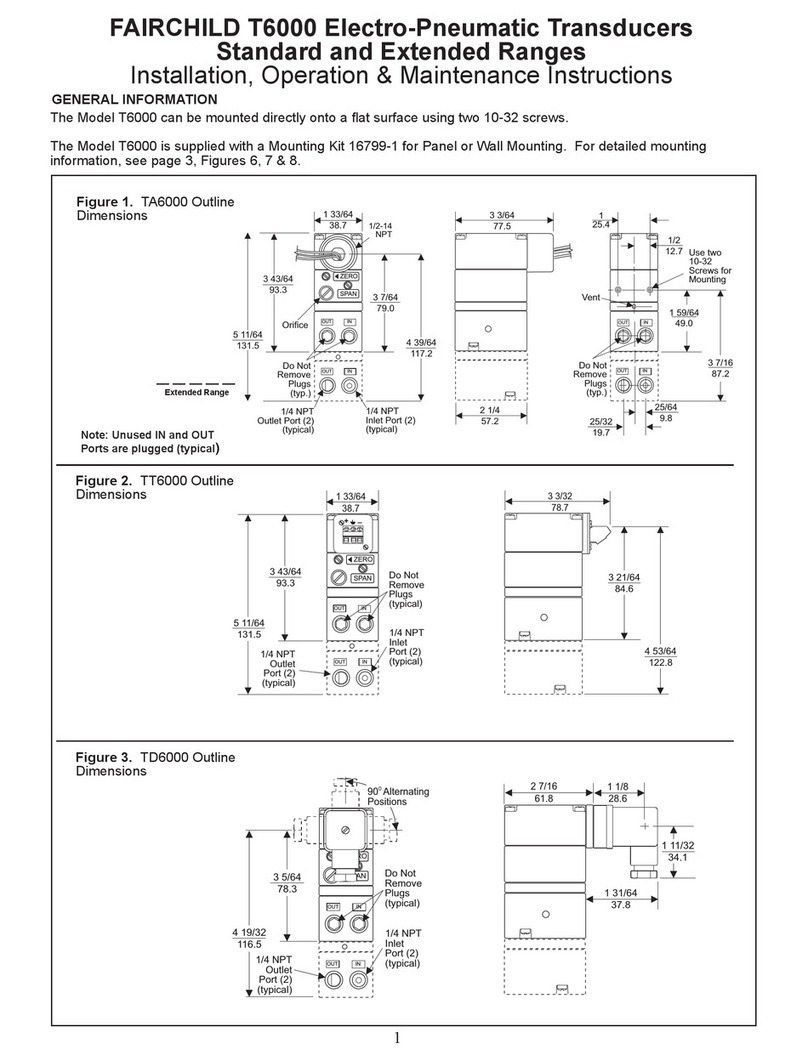

To clean the Orifice, use the following procedure:

1. Shut off the valve that is supplying air to transducer.

It is not necessary to remove the Transducer from

the air line.

2. Remove the Orifice Assembly from the unit. For

detailed information see Figure 1 “T6000 Calibration

Configuration on page 1.

3. Clean with alcohol and dry with compressed air.

NOTES:

Parts must be completely dry before reassembling.

If the standard maintenance procedure does not

correct the trouble, install the appropriate Service

Kit below:

16798-1 (3-15, 3-27 & 6-30 psig

Standard Range)

18238-1 (0-30 psig Extended Range)

18239-1 (0-60 psig Extended Range)

18240-1 (0-120 psig Extended Range)

18039-1 (Explosion-Proof Base)

Service Kits also include Gasket, O-Rings, and

Membranes to replace "W" Option product.

TROUBLE-SHOOTING

Table 1. Trouble-Shooting.

Problem Solution (check)

No Output Supply Pressure

Clogged Orifice

Input Signal

Leakage Pneumatic Connections

Low or Improper

SpanAdjust

Zero and Span Adjust

Supply Pressure Low

Output Leakage

Erratic Operation DC Signal

Loose Wires or Connections

Liquid in Air Supply

Dirt in Magnet Gap

WARNING: Failure of Transducer could result in out-

put pressure increasing to supply pres-

sure possibly causing personal injury or

damage to equipment.

3