Installation Instructions for the

Heavy Duty Pressure Transducers

PX3 Series, 1 bar to 50 bar | 15 psi to 700 psi

32313758

Issue B

General Information

Honeywell’s PX3 Series Pressure Transducers use piezoresistive

sensing technology with ASIC (Application Specific Integrated

Circuit) signal conditioning in a brass housing and Metri-Pack

150 electrical connector. The PX3 Series are fully calibrated and

temperature compensated from -40 °C to 125 °C [-40 °F to

257 °F].

Safety and Productivity Solutions

Table 1. Electrical Specifications

Characteristic Parameter

Supply voltage:

5 Vdc

3.3 Vdc

±0.25 Vdc

±0.25 Vdc

Over voltage and reverse voltage ±16 Vdc

Current consumption:

5 Vdc supply

3.3 Vdc supply

3.0 mA max.

1.6 mA to 2.1 mA

Short circuit protection yes

Nominal output transfer function:

5 Vdc supply

3.3 Vdc supply

0.5 Vdc to 4.5 Vdc (ratiometric to supply)

0.33 Vdc to 2.97 Vdc (ratiometric to supply)

Table 2. Performance Specifications (At 25 °C [77 °F] and under unless otherwise noted.)

Characteristic Parameter

Operating temperature range1-40 °C to 125 °C [-40 °F to 257 °F]

Storage temperature range1-40 °C to 125 °C [-40 °F to 257 °F]

Compensated temperature range -40 °C to 125 °C [-40 °F to 257 °F]

Total Error Band2:

-20 °C to 85 °C [-4 °F to 185 °F]

<-20 °C, >85 °C [<-4 °F, >185 °F]

±1.0 %FSS

±2.0 %FSS

Accuracy BFSL3±0.25 %FSS

Response time <2 ms (10% to 90% step change in pressure)

Turn on time4<7 ms

EMC rating5:

surge immunity (all leads)

electrostatic discharge

radiated immunity

fast transient burst

immunity to conducted disturbances

radiated emissions

radiated immunity

±1000 V line to ground per IEC 61000-4-5

±4 kV contact, ±8 kV air per IEC 61000-4-2

10 V/m (80 MHz to 1000 MHz) per IEC 61000-4-3

±1 kV per IEC 61000-4-4

3 V per IEC 61000-4-6

40 dB (30 MHz to 230 MHz), 47 dB (230 MHz to 1000 MHz) per CISPR 11

200 V/m per ISO 11452-2

Insulation resistance >100 MOhm, 1500 Vdc

Dielectric strength AC1500V, 1 min. or AC1800V, 1 s

Load resistance >5 kOhm

Life greater than 10 million full scale pressure cycles over the calibrated pressure range

1Dependent on external and internal seal and cable jacket materials. See Table 5 and Figure 5 for temperature range details.

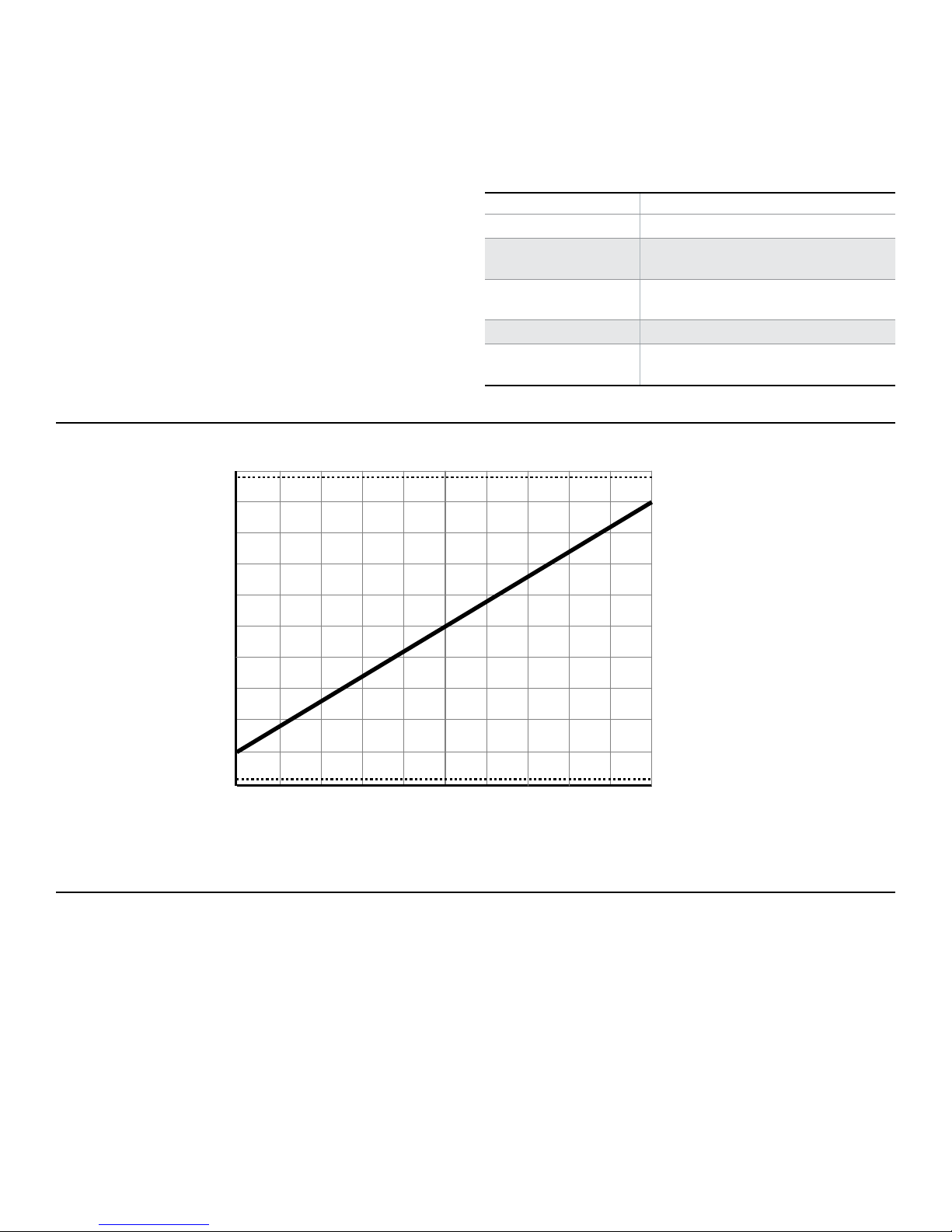

2Total Error Band: The maximum deviation from the ideal transfer function over the entire compensated temperature and pressure range. In-

cludes all errors due to offset, full scale span, pressure non-linearity, pressure hysteresis, pressure non-repeatability, thermal effect on offset,

thermal effect on span, and thermal hysteresis. See Figure 1.

3Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure range at

25 °C [77 °F]. Includes all errors due to pressure non-linearity, pressure hysteresis, and pressure non-repeatability. See Figure 1.

4Turn on Time: Duration from power applied until first valid output.

5 Tested using 1,5 m [59.1 in] cable.