Instinct

Display Module Replacement

3

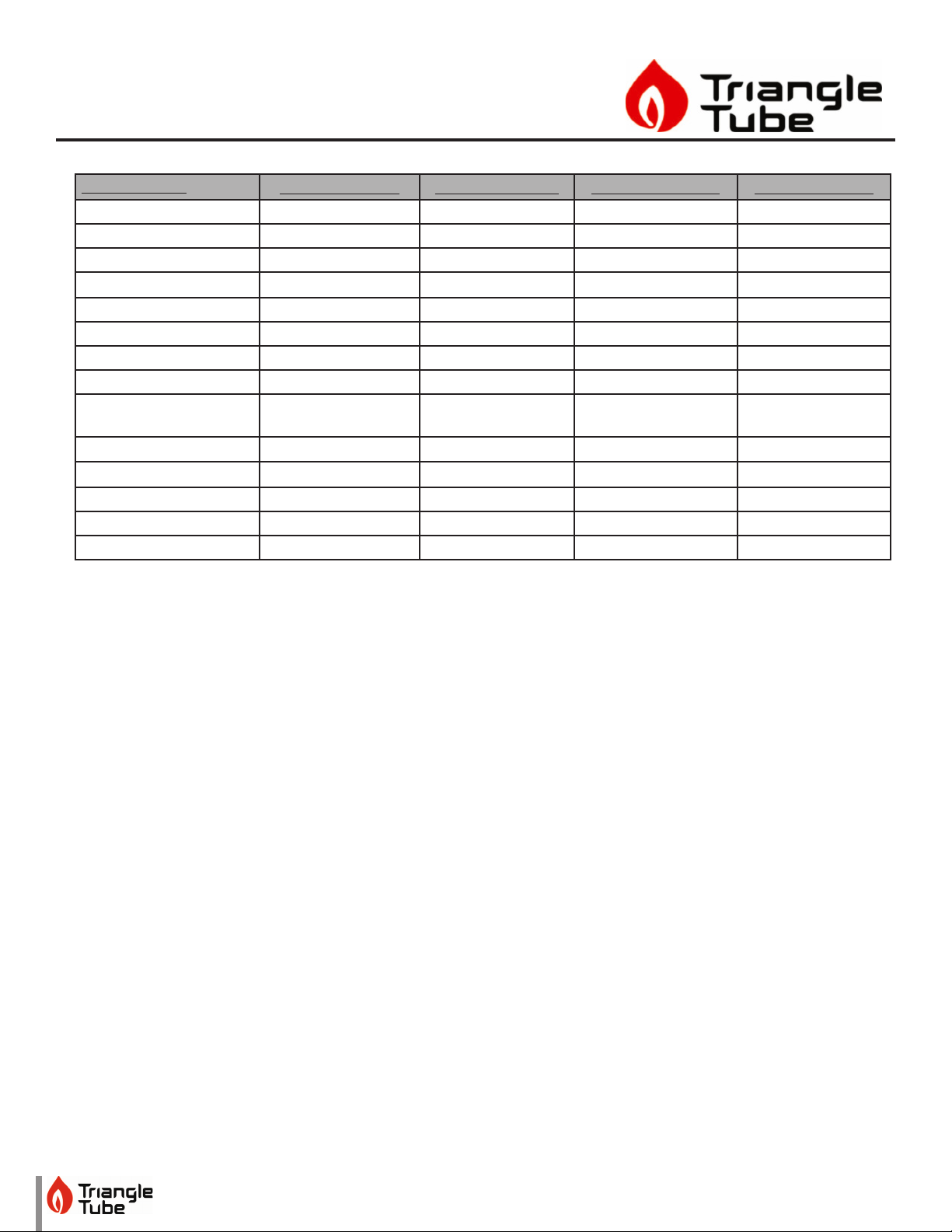

6. Record all CH Settings in Table 1. Once completed,

press the RIGHT button to highlight the Previous

Screen icon, then press the OK button.

7. Press the RIGHT button to highlight the DHW Set-

tings icon then press the OK button.

Fig. 6: DHW Settings

8. Press the UP and DOWN buttons to scroll thru the

various settings and record all DHW Settings in Ta-

ble 1. Once completed, press the RIGHT button to

highlight the Previous Screen icon, then press the

OK button.

Fig. 7: DHW Settings

9. Press the DOWN button to highlight the Boiler Set-

tings icon if present icon, then press the OK button.

10. Press the UP and DOWN buttons to scroll through

the various settings and record all Boiler Settings

in Table 1. Once completed, press the RIGHT but-

ton to highlight the Previous Screen icon, then

press the OK button.

NOTICE

Perform the following steps if the Instinct is part of a Cascade

System or the System Temperature Sensor is being used on a

single HeatMaster.

11. Press the RIGHT then DOWN buttons to highlight

the Previous Screen icon, then press the OK button.

12. Press the RIGHT then DOWN buttons to highlight

the Cascade icon, then press the OK button.

13. Press the RIGHT button to highlight the Cascade

Settings icon, then press the OK button.

14. Press the UP and DOWN buttons to scroll thru the

various settings, and record all Cascade Settings in

Table 1.

3. Replace Display Module

1. Turn the electrical power“OFF”.

NOTICE

The display module comes preinstalled in the front red dis-

play enclosure as shown in Fig. 8.

Fig. 8: Display Module

2. Remove the front jacket by removing the screw on

the bottom. Lift and remove the front cover. Do not

discard this screws as they will be reused.

3. Pull the retaining clip on top of the enclosure and

pull the front cover o.

4. Disconnect the yellow cables by squeezing the clip

on the back of the plug in and pulling rmly out

from the back of the display module. Use care not

to damage the plug.

5. Remove the rubber grommet holdind the yellow

cables from the old display ensloure.

6. Install the rubber grommet with the yellow cables

onto one of the tabs in the bottom of the new dis-

play ensloure.