TRIATEK FMS-2000M Lite User manual

1

FMS-2000M Lite

Critical Environment Monitor

LIT-12013692

December 2020

Installation Guide

FMS-2000M Lite

LIT-12013692

2

Risk of Personal Injury or Property Damage.

For use in a controlled environment only. Refer to installation instructions for environmental conditions.

Risk of Electric Shock.

Disconnect the power supply before making electrical connections. Contact with components carrying hazardous voltage can cause

electric shock and may result in severe personal injury or death.

Risk of Property Damage.

Use a 24 VAC 30 VA Class 2, LPS or Limited Energy transformer for the monitor. Failure to follow the wiring diagrams may result in

damage to the monitor and could void your warranty.

Risk of Property Damage.

Do not apply power to the system before checking all wiring connections. Short circuited or improperly connected wires may result in

permanent damage to the equipment.

Risk of Property Damage.

Do not run low-voltage cable in the same conduit or wiring troughs with high-voltage wires. Running low- and high-voltage wires in the

same conduit or wiring troughs may damage the equipment or cause system malfunction.

Risk of Property Damage.

Ensure that the power source conforms to the requirements of the equipment. Failure to use a correct power source may result in

permanent damage to the equipment.

Risk of Property Damage.

Do not run network communication cables in the same conduit, raceway, or panel with any high-voltage (greater than 30 VAC) wiring.

Isolate all network wiring and all network devices from high-voltage wiring and equipment. Failure to isolate network wiring and

network devices from high-voltage wiring and equipment can result in damage to network devices or poor network performance.

Risk of Property Damage.

Label all wires prior to disconnecting the equipment. Failure to label the wires may cause improper equipment operation after

reconnecting the equipment.

Risk of Property Damage.

Do not connect the 24 VAC power supply directly to the FMS-2000M Lite display four-position terminal block. You must terminate the

power at the remote sensor's nine-position terminal block on the +Vin and -Vin terminals. Failure to follow the wiring instructions may

cause permanent damage to the FMS-2000M Lite monitor and void your warranty.

IMPORTANT: Do not install or use this FMS-2000M Lite Critical Environment Monitor in or near environments where corrosive

substances or vapors could be present. Exposure of the FMS-2000M Lite monitor to corrosive environments may damage the device’s

internal components and will void the warranty.

IMPORTANT: Install the FMS-2000M Lite Critical Environment Monitor with a Class 2, Limited Energy, or LPS isolated power supply and

connect it to an electrical circuit protected by a minimum 20 A circuit breaker. Mount the circuit breaker in an approved electrical enclosure

located separately, but in close proximity, to the FMS-2000M Lite monitor.

IMPORTANT: Do not install this FMS-2000M Lite Critical Environment Monitor in condensing, wet, or damp environments. Moisture may

cause damage to the FMS-2000M Lite monitor.

FMS-2000M Lite

LIT-12013692

3

IMPORTANT: Make all wiring connections in accordance with the National Electrical Code and local regulations. Use proper Electrostatic

Discharge (ESD) precautions during installation and servicing to avoid damaging the electronic circuits of the FMS-2000M Lite Critical

Environment Monitor.

IMPORTANT: Maintain proper polarity and voltage or current ratings. Improper polarity or exceeding the voltage or current ratings will

void the warranty.

IMPORTANT: Do not install the FMS-2000M Lite Critical Environment Monitor where the maximum temperature exceeds 125°F (52°C).

Installing the device where maximum temperatures exceed 125°F (52°C) may cause damage to the FMS-2000M Lite Critical Environment

Monitor and may void the warranty.

IMPORTANT:

personnel. Carefully follow all instructions in this document and all instructions for the FMS-2000M Lite Critical Environment Monitor.

IMPORTANT: Use copper conductors only. Make all wiring connections in accordance with local, national, and regional regulations. Do

not exceed the FMS-2000M Lite Critical Environment Monitor’s electrical ratings.

FMS-2000M Lite

LIT-12013692

4

Risque de blessure corporelle ou de dommages matériels.

Pour utilisation dans un environnement contrôlé uniquement. Consulter le guide d’installation pour les conditions environnementales.

Risque de décharge électrique.

dangereuses risque d’entraîner une décharge électrique et de provoquer des blessures graves, voire mortelles.

Risque de dégâts matériels.

Utilisez un transformateur de classe 2 à 24 V CA 30 VA, à limitation d’alimentation ou LPS pour le moniteur. Ne pas respecter les

schémas de câblage peut causer des dommages au moniteur et peut annuler votre garantie.

Risque de dégâts matériels.

connectés de façon incorrecte risquent d’endommager irrémédiablement l’équipement.

Risque de dégâts matériels.

Ne pas faire courir un câble basse tension dans les mêmes gaines ou goulottes électriques que des câbles haute tension.

l’équipement ou de provoquer des dysfonctionnements du système.

Risque de dégâts matériels.

d’alimentation électrique inappropriée risque d’endommager irrémédiablement l’équipement.

Risque de dégâts matériels.

Ne passez pas les câbles de communication réseau dans les mêmes gaines, chemins de câbles ou panneaux que les câbles à

haute tension (supérieure à 30 Vca). Isolez tous les câbles et appareils réseau des câbles et appareils à haute tension. Un défaut

d’isolement des câbles et appareils à haute tension peut provoquer des dommages aux appareils réseau et réduire les performances

du réseau.

Risque de dégâts matériels.

Etiquetez tous les câbles avant de débrancher l’équipement. Le non-respect de cette précaution peut amener un fonctionnement

anormal après redémarrage de l’équipement.

Risque de dégâts matériels.

Ne pas brancher le bloc d’alimentation de 24 V CA directement au bornier à quatre positions de l’écran du FMS-2000M Lite. Vous

devez raccorder l’alimentation aux bornes +Vin et -Vin du bornier à neuf positions du capteur à distance. Ne pas respecter les

instructions de câblage peut causer des dommages permanents au moniteur FMS-2000M Lite et annuler votre garantie.

IMPORTANT : N’installez ou n’utilisez pas FMS-2000M Lite Critical Environment Monitor dans, ou près, d’environnements où des

substances ou vapeurs corrosives peuvent être présentes. L’exposition du FMS-2000M Lite à des environnements corrosifs peut

endommager les composantes internes de l’appareil et annulera la garantie.

IMPORTANT : N’installez pas FMS-2000M Lite Critical Environment Monitor dans un environnement humide, mouillé ou il se produit de

la condensation. L’humidité peut causer des dommages au FMS-2000M Lite.

IMPORTANT : Installez le FMS-2000M Lite Critical Environment Monitor en utilisant un bloc d’alimentation de classe 2, à limitation

d’alimentation ou LPS et raccordez-le à un circuit électrique protégé par un disjoncteur d’un minimum de 20 A. Placez le disjoncteur du

FMS-2000M Lite dans un panneau électrique approuvé et situé à l’écart, mais à proximité.

FMS-2000M Lite

LIT-12013692

5

IMPORTANT :

réglementations locales. Utilisez une bonne protection contre les décharges électrostatiques (ESD) pendant l’installation et l’entretien

pour éviter d’endommager les circuits électroniques du FMS-2000M Lite Critical Environment Monitor.

IMPORTANT : Conservez la bonne polarité et la bonne tension ou le bon courant. Une mauvaise polarité ou le dépassement de la

tension ou du courant annulera la garantie.

IMPORTANT : N’installez pas le contrôleur d’environnement critique FMS-2000M Lite où la température maximum dépasse 52 °C

(125 °F). Installer l’appareil dans un environnement où la température maximum dépasse 52 °C (125 °F) peut endommager FMS-2000M

Lite Critical Environment Monitor et peut annuler la garantie.

IMPORTANT :

Environment Monitor.

IMPORTANT :

pour ce type de personnel. Suivez attentivement toutes les instructions de ce document et toutes les instructions du FMS-2000M Lite

Critical Environment Monitor.

FMS-2000M Lite

LIT-12013692

6

Introduction.................................................................................................................................................................................. 7

Location considerations............................................................................................................................................................. 8

Installing the FMS-2000M Lite Thin Mount display for a retrot application......................................................................... 9

Installing the FMS-2000M Lite Thin Mount display for a new application............................................................................ 11

Mounting the remote pressure sensor.................................................................................................................................... 15

Wiring the system and BACnet MS/TP communications ...................................................................................................... 17

Wiring one remote pressure sensor to the monitor............................................................................................................... 18

Conguring the display module settings................................................................................................................................ 20

BMS integration......................................................................................................................................................................... 20

Ordering information................................................................................................................................................................. 21

Cleaning the display.................................................................................................................................................................. 21

Technical specications ........................................................................................................................................................... 22

Repair information..................................................................................................................................................................... 23

Table of contents

FMS-2000M Lite

LIT-12013692

7

Introduction

touch screen.

administrators and one for restricted level users, such as nurses.

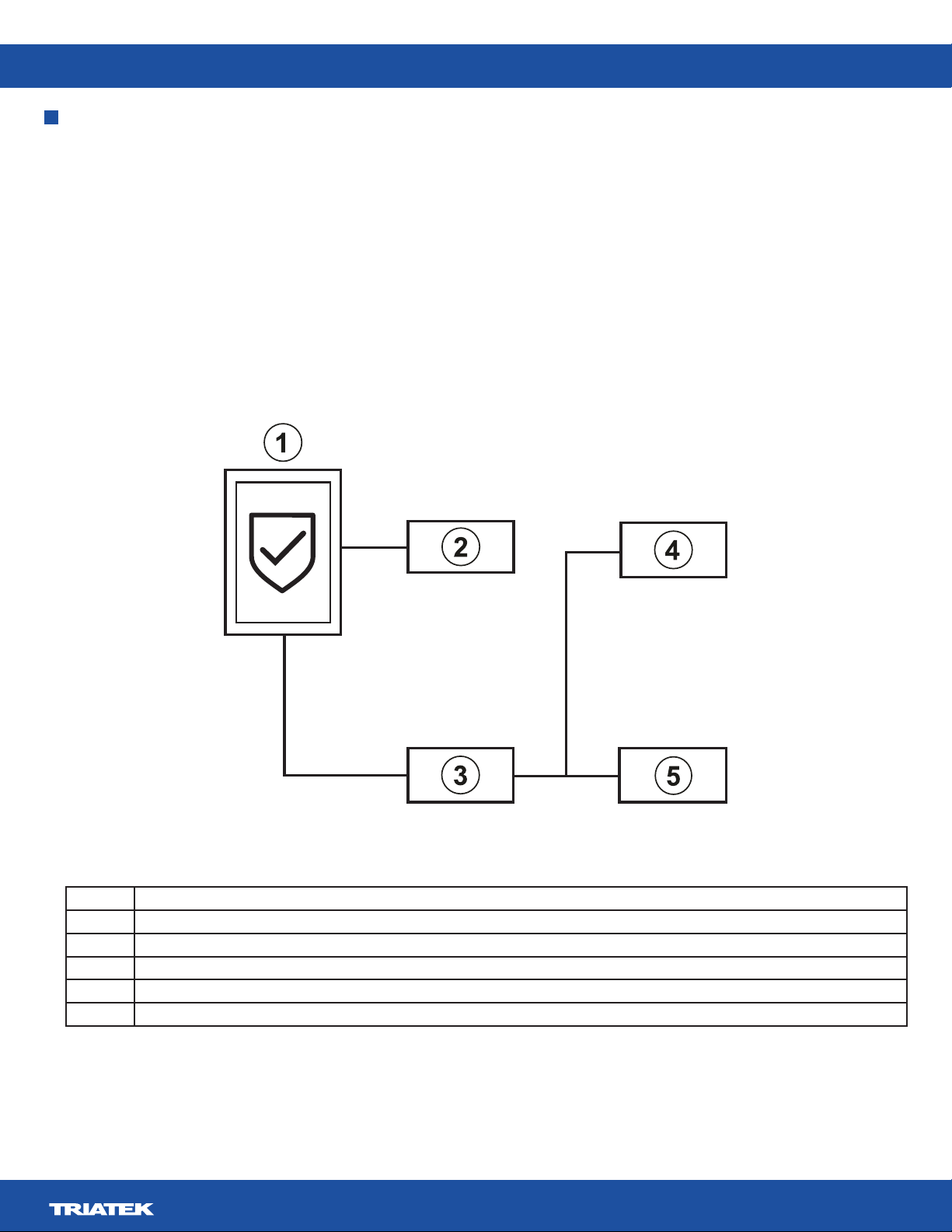

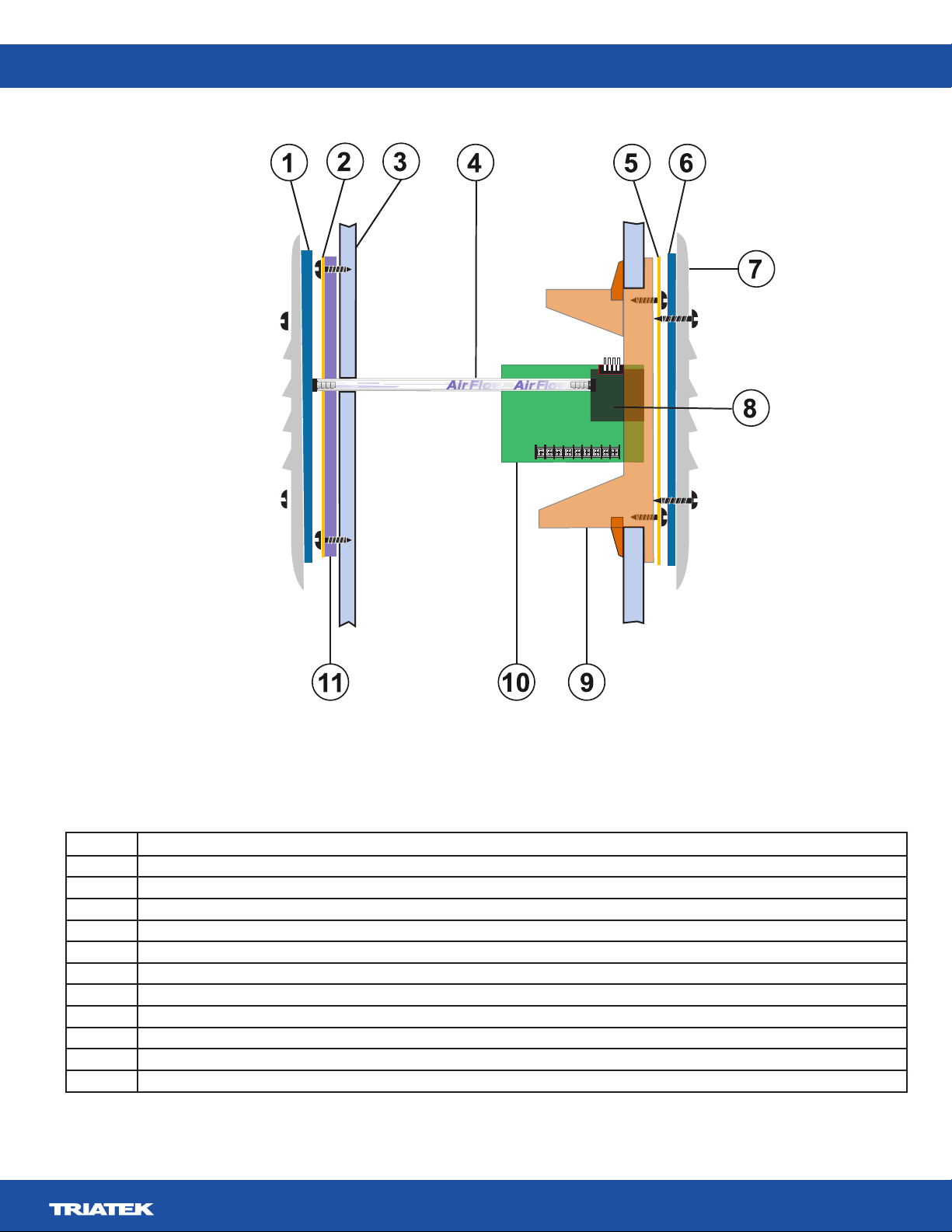

Item Component

1 FMS-2000M Lite monitor

2 Remote pressure sensor

3

4

5 Humidity sensor

Figure 1: FMS-2000M Lite system diagram

FMS-2000M Lite

LIT-12013692

8

Location considerations

location that you need. Place the sensors away from any moving air source like ceiling air registers, because this can cause unstable

sensor behavior.

Ferrite Installation Instructions for FMS-2000M Lite series

included in the package are used in the installation as described below. Install the three cable ferrites included on the AC input cable to

the isolated power supply module, and on the wires that supply 24 VAC power to the pressure sensor module.

Power Supply Input Cable Ferrite

Install the cable ferrite A

clasp on the side of the ferrite to expose the core, place it on the power cable near to the power supply enclosure, and close the ferrite

around the cable. Ensure that the clasp latches securely.

Power Supply Output Cable Ferrites

Install the cable ferrite B

below. Locate this cable ferrite about 10-12 inches away from the end of the two wires. Unlatch the clasp on the side of the ferrite

to expose the core, place it over the two supply power wires, and close the ferrite around the wires. Ensure that the clasp latches

securely. Install the cable ferrite labeled Cabout an inch after ferrite Band complete one wrap or loop of the two 24 VAC supply power

wires. Leave at least four inches of length to connect to the green terminal block.

FMS-2000M Lite

LIT-12013692

9

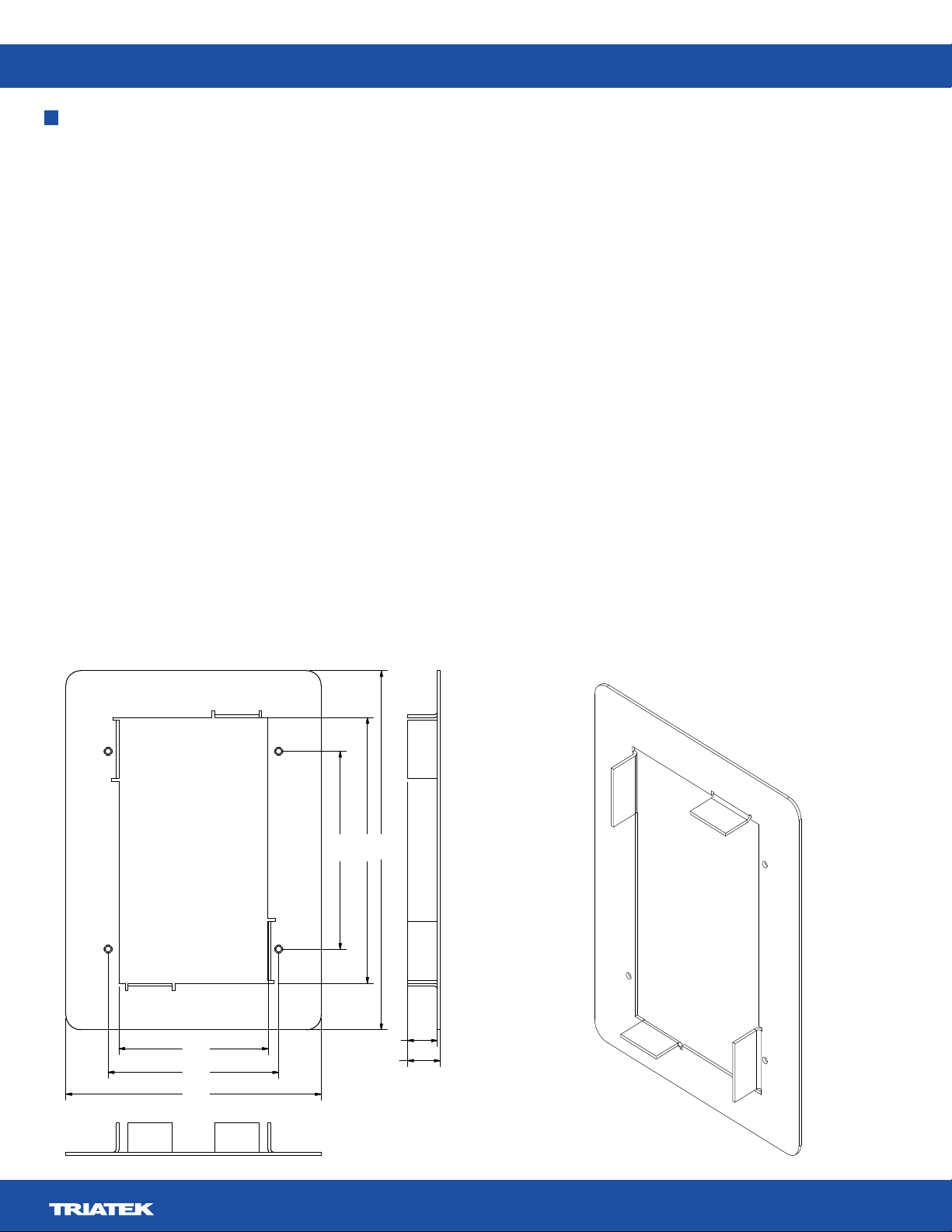

6.06in.

4.485in.

3.338in.

0.548 in.

0.5 in.

4.311 in.

2.519 in.

2.878 in.

(63.983 mm)

(73.101 mm)

(109.499 mm)

(12.07 mm)

(13.919 mm)

(84.785 mm)

(113.919 mm)

(153.924 mm)

• a drywall saw or an oscillating tool with a drywall saw blade

•

• a #2 Phillips head screwdriver

•

Note:

display to the wall.

1. Choose the location where you want to place the FMS-2000M Lite monitor.

2.

choose to use landscape orientation.

3. Mark both screw holes and the corners of the rectangular section.

4. Use a drywall saw or oscillating tool to cut out the entire rectangular section inside the marked opening and drill the screw holes.

5.

6.

7.

8.

to secure both the box and the bracket.

Note:

9. Connect the wires to the back of the monitor. For more information, refer to Figure 11.

10. Align the two slots on the back of the monitor with the tabs on the bracket, then swing the monitor towards the wall so that the

single tab on the bracket slots into the back of the monitor.

11.

Halo bezel lights up green to represent the current system status.

Installing the FMS-2000M Lite Thin Mount display for a retrot application

FMS-2000M Lite

LIT-12013692

10

Item Component

1 FMS-2000M Lite Critical Environment Monitor

2 Monitor bracket

3

4 Retrofit ring

5 Mounting screw

6 Set screw

FMS-2000M Lite

LIT-12013692

11

Use the rough-in box for new construction applications when the walls have not yet been installed.

• a drywall saw or an oscillating tool with a drywall saw blade

•

• a #2 Phillips head screwdriver

•

Note: If you want to install the FMS-2000M Lite in a new construction application, attach the rough-in box before the walls are installed.

You can then attach the display once the walls are in place.

1.

choose to use landscape orientation.

2. Mount the rough-in box to the side of a stud.

that you install later.

3.

4. If the 2-conductor power cable terminates at the monitor, pull the 2-conductor power cable through the opening in the rough-in box.

5.

precisely with the rough-in box.

6. Align the monitor’s mounting bracket to the four screw holes on the mounting tabs of the rough-in box. Use a #2 Phillips head

screwdriver to secure the bracket with the screws provided. Make sure the bracket is level.

Note:

7. Connect the wires to the back of the monitor. For more information, refer to Figure 11.

8. Align the two slots on the back of the monitor with the tabs on the bracket and swing the monitor towards the wall so that the single

tab on the bracket slots into the back of the monitor.

9.

drive the screw into the monitor until it engages with the tab on the bracket.

Safety Halo bezel lights up green to represent the current system status.

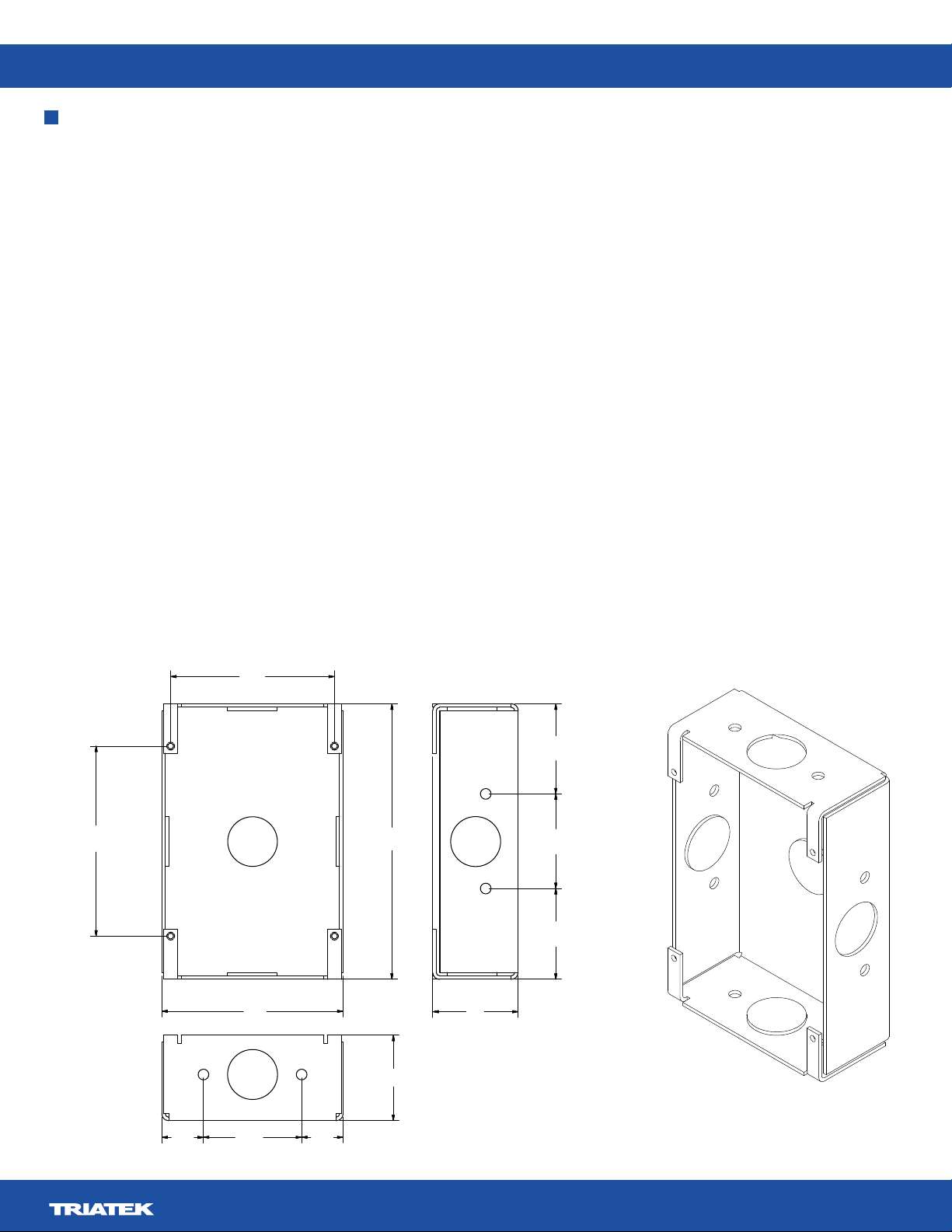

Installing the FMS-2000M Lite Thin Mount display for a new application

1.583in.

1.662in.

1.596in.

1.5 in.

3.18 in.

2.878 in.

3.338in.

4.84in.

1.5

in.

0.728in. 1.725 in. 0.728in.

(84.785 mm)

(122.94 mm)

(40.208 mm)

(42.215 mm)

(40.538 mm)

(73.101 mm)

(80.77 mm) (38.1 mm)

(18.491 mm) (43.815 mm) (18.491 mm)

(38.1 mm)

FMS-2000M Lite

LIT-12013692

12

Item Component

1 FMS-2000M Lite Critical Environment Monitor

2 Mounting bracket

3

4 Stud

5 Rough-in box

6 Mounting screw

7 Set screw

FMS-2000M Lite

LIT-12013692

13

FMS-2000M Lite

LIT-12013692

14

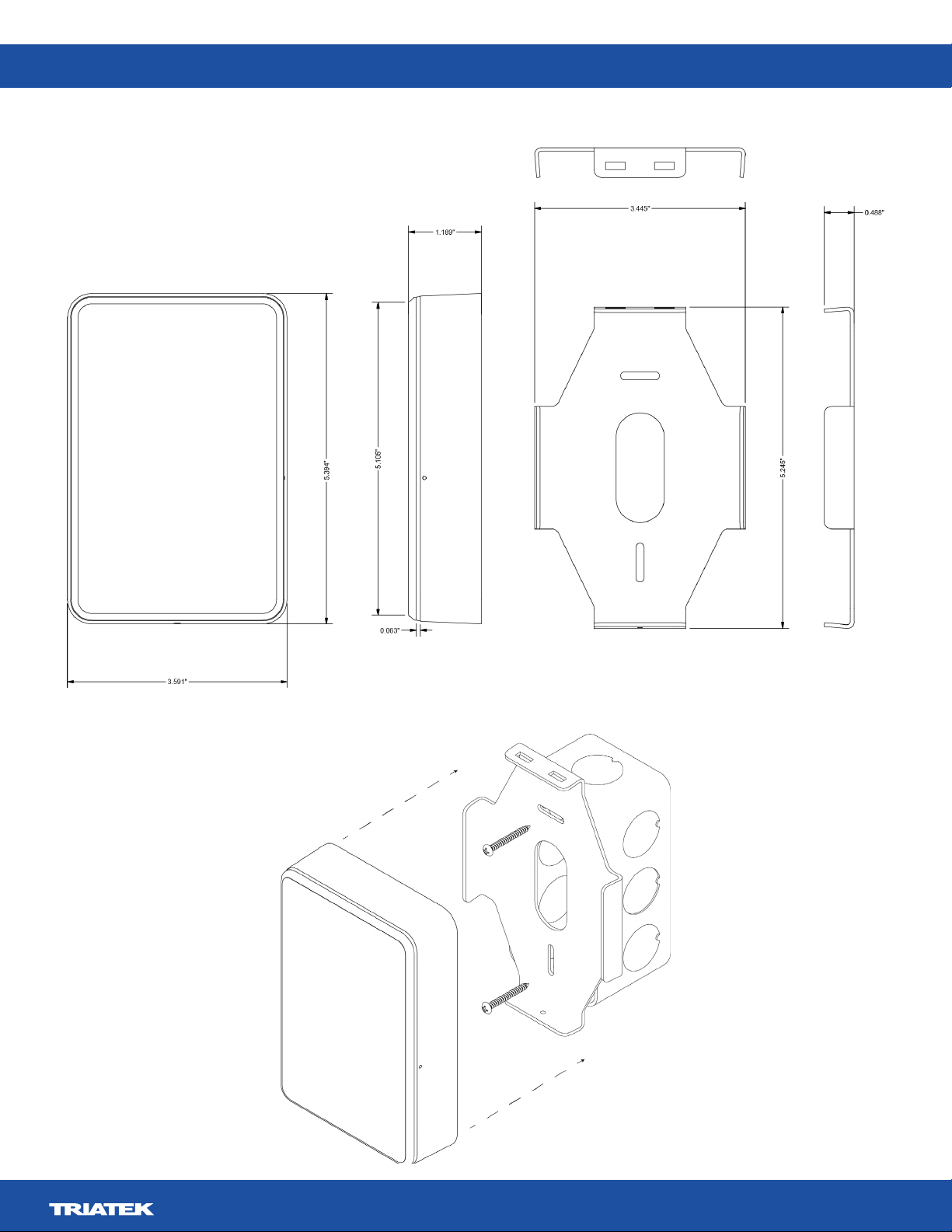

Number Description

1Surface mount display

2Existing wall box

3Mounting plate

FMS-2000M Lite

LIT-12013692

15

monitored spaces. Install the remote pressure sensor module in the wall facing the monitored space such as an isolation room. Install

positive pressure value indicates that the monitored space is positive with respect to the reference space. Choose a location that is

See Figure 8 for more

information.

•

• a #2 Phillips head screwdriver

• a drywall saw or an oscillating tool with a drywall saw blade

1.

1,000 ft.

2. Remove the sensor’s louvered cover plate and stainless steel backplate from the orange wall bracket.

3. Cut an opening in the wall of the monitored space for the orange low voltage mounting bracket and for the remote pressure sensor

4. Use the rotating clamps to secure the bracket to the wall safely.

5.

6. Pull the 4-conductor signal wire through the cut out.

7. Install the mounting bracket in the drywall opening and pull the 4-conductor signal cable through the mounting bracket.

8.

9.

as possible to prevent kinks.

10.

11. Screw the louvered cover plate to the front.

12. Apply thin silicone caulking around

the tube, between the stainless steel plate and the wall to seal against penetration.

13. Press the mounting plate into place. Allow the excess tube length to go into the wall space. Secure the mounting plate with the

screws and anchors.

14. Screw the louvered cover plate to the front.

Mounting the remote pressure sensor

FMS-2000M Lite

LIT-12013692

16

Monitored spaceReference space

Number Description

1

2 Stainless steel flow tube mounting plate

3

4 Flow tube

5 Stainless steel mounting plate

6

7 Louvered cover plate

8 Remote pressure sensor

9 Mounting bracket

10

11

FMS-2000M Lite

LIT-12013692

17

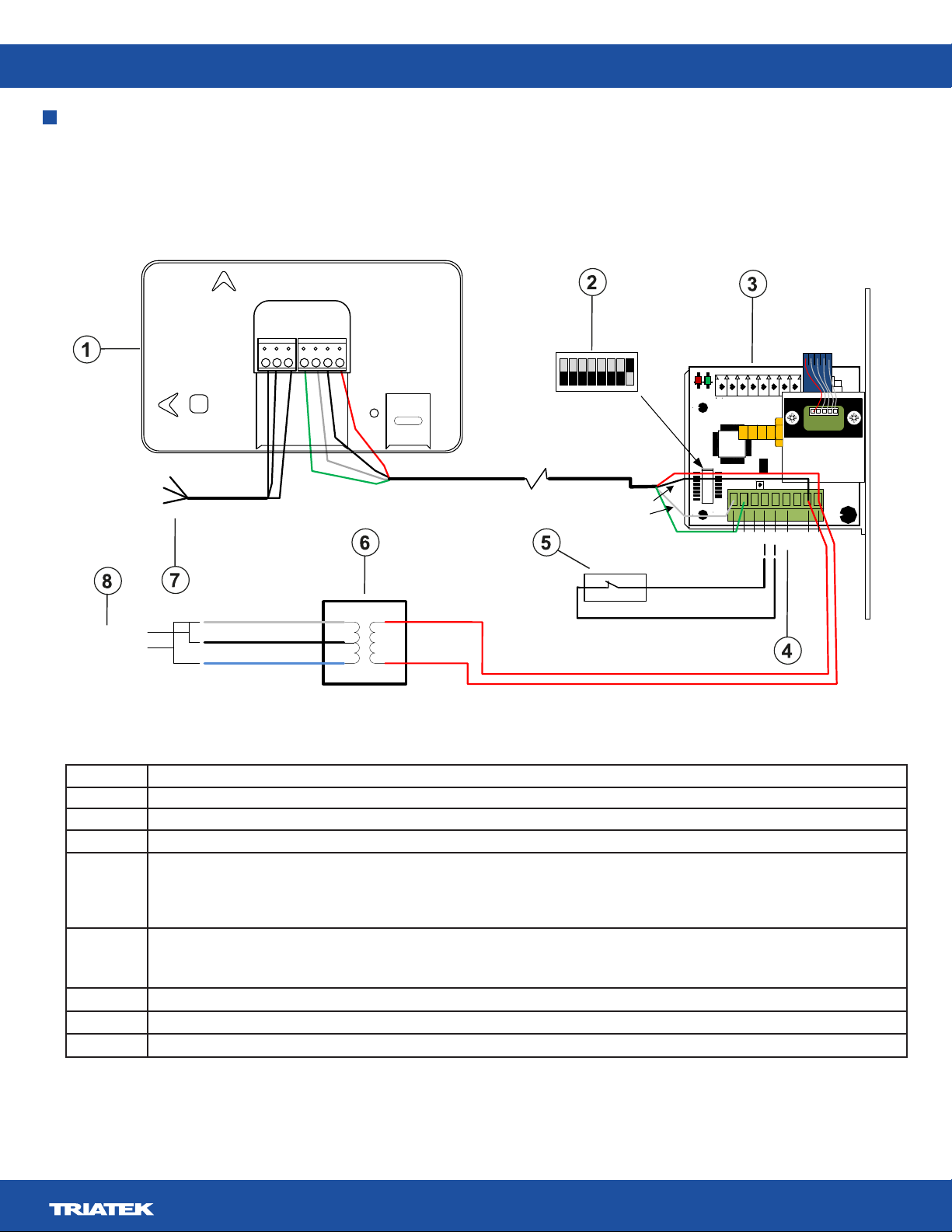

Wiring the system and BACnet MS/TP communications

Callout Component

1 DIP switch

2 Remote pressure sensor

3 Power supply

• Wiring one remote pressure sensor to the monitor

Note:

4 Supervisory device

5 FMS-2000M Lite Critical Environment Monitor

+

24V_IN

–

+

DSPLY

RS485

–

+

BACnet

MS/TP

–

REF

120 VAC 24 VAC

FMS-2000M Lite

LIT-12013692

18

Wiring one remote pressure sensor to the monitor

Note: For optimum network communications, connect the reference signal (REF) to the COM terminal on the supervisory device’s FC

bus terminal block.

17

1

U2

33

49

75

1

CN1

S2

SW1

+Vin

-Vin

Io

+Vs

IN

GND

-

+

RS485

21

43

ADDR

6

JP4

LED1

LED2

RUN

PWR

JP5

CN3

5

JP2

24 VAC

Output

To BAS

network

-

+

Ref.

22 AWG stranded 3-wire

twisted pair, shielded

Supplied 10 � cable

Green

White

Black

Red

Green

White

Black

Red

}

Power input

P1

P2

COMMON

120 VAC input

240 VAC input

White

Black

Blue

+

-

+

-

+

-

REF

24V_IN

DSPLY

RS485

BACnet

MS/TP

Landscape

Portrait

120 VAC/240 VAC

60/50Hz input

Callout Component

1 FMS-2000M Lite monitor

2

3 Supplied remote pressure sensor

4 Io terminal

Note: A 4mA to 20mA signal is present at the sensor’s Io terminal which represents the monitored room pressure. You can use it to

5 Optional door switch

Note: Configure the door switch setting on the monitor. It can be normally closed or normally open.

6 Power supply

7

8 AC power input options

FMS-2000M Lite

LIT-12013692

19

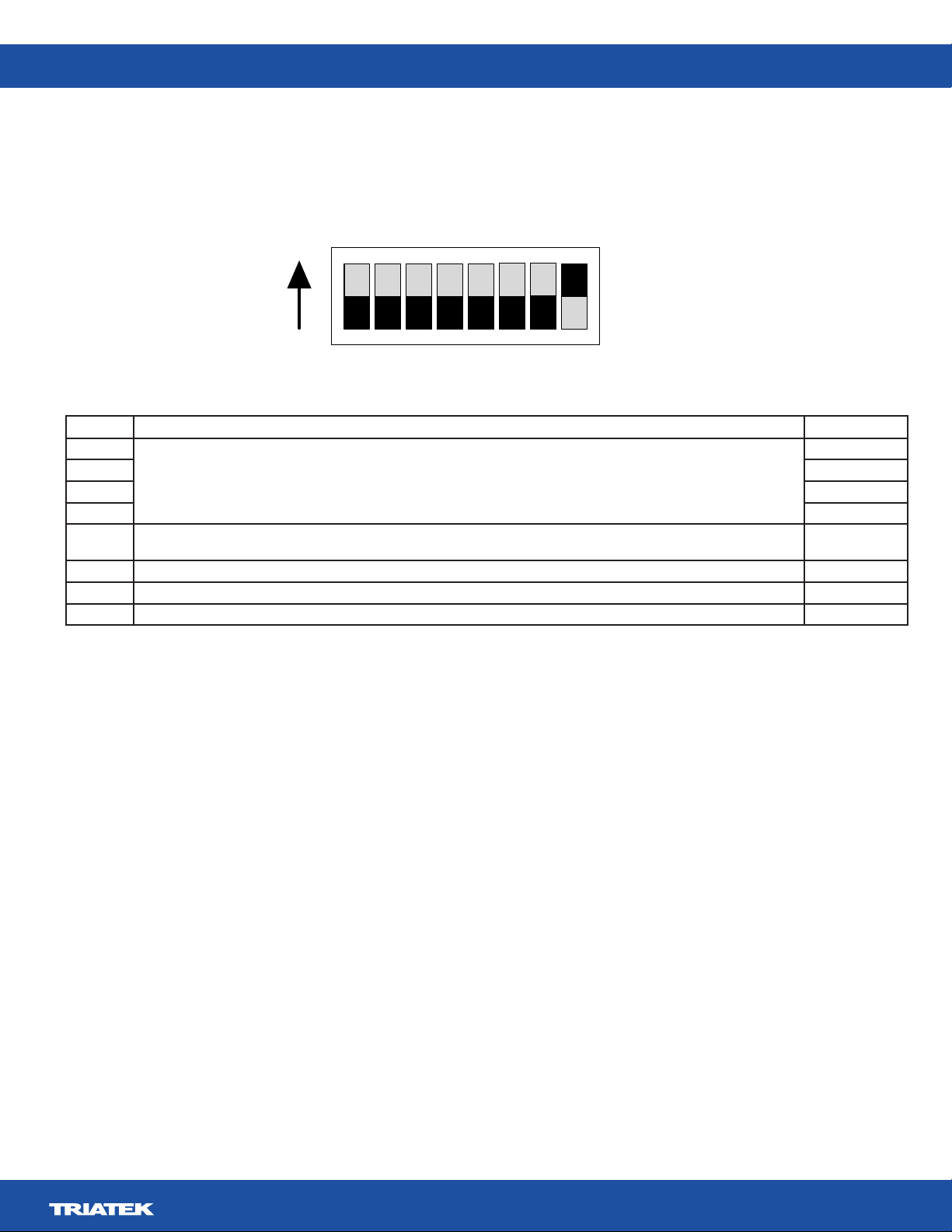

Switch Description Sensor 1

1

Sensor address

On

2 On

3 On

4 On

5

power to the sensor for the mode change to take effect.

On or off

6 Reserved

7 Reserved

8 Sensor communications termination Off

SW1

12345678

On

FMS-2000M Lite

LIT-12013692

20

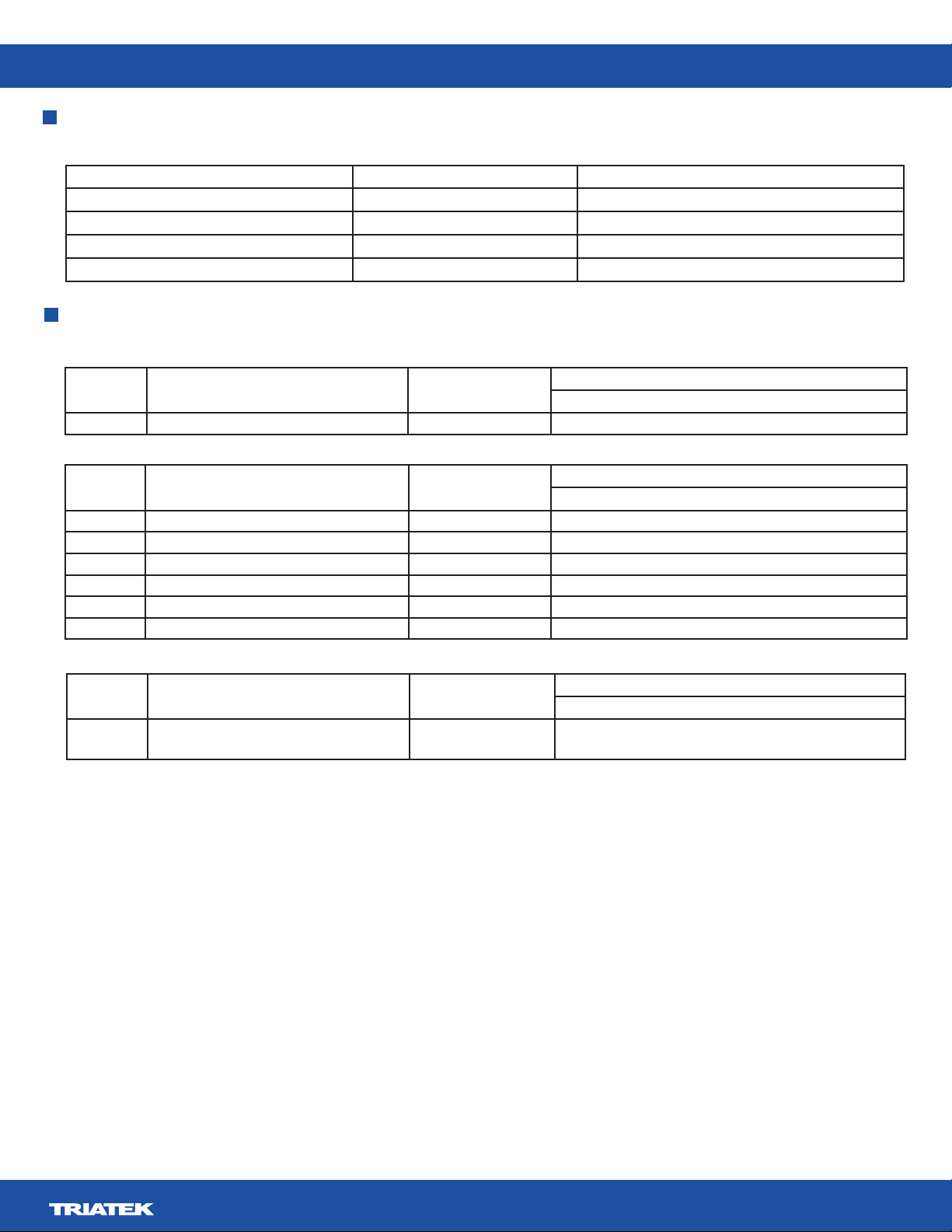

BMS integration

Conguring the display module settings

FMS-2000M Lite DIP switch position Demo mode Run mode

Position 1 On On

Position 2 On On

Position 3 Off On

Position 4 On Off

Objects Analog inputs Read/Write Availability of analog input objects

FMS2ML–BxR

AI-1 Analog input 1, differential pressure Read only Yes

Objects Analog values Read/Write Availability of analog value objects

FMS2ML–BxR

AV-1 Network Variable temperature 1 Read or write Yes

AV-2 Differential Pressure low alarm setpoint 1 Read or write Yes

AV-3 Differential Pressure low warning setpoint 1 Read or write Yes

AV-4 Differential Pressure high warning setpoint 1 Read or write Yes

AV-5 Differential Pressure high alarm setpoint 1 Read or write Yes

AV-6 Network Variable humidity 1 Read or write Yes

Objects Multistate value objects Read/Write Availability of multistate value objects

FMS2ML–BxR

MV-1 AI-1 Alarm Status

1 = positive, 2 = negative, 3 = neutral

Read only Yes

Table of contents

Other TRIATEK Monitor manuals