tricab ALI-FLEX B21 User manual

B21

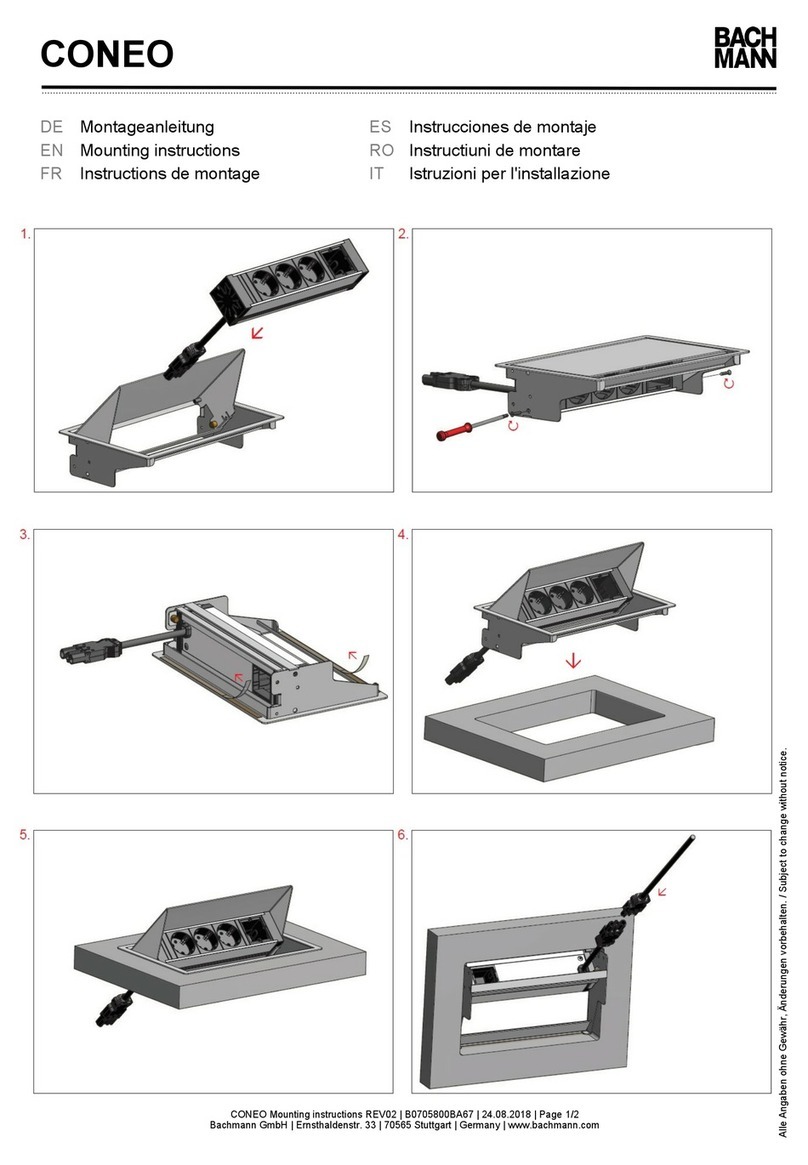

1. Select suitable size of ALI-FLEX®

Bi-Metallic Reducing Link by verifying that

the markings on the link and cables match.

Select the appropriate Copper Cable and mark

the stripping length as specified in Table 1:

Installation of Copper Conductor.

This Installation Guide was designed with great care and proper testing before publication to ensure the product works perfectly with TriCab

flexible cables. ALI-FLEX® Bi-Metallic Reducing Links are specifically designed, tested and certified for use with TriCab ALI-FLEX® cables

only. TriCab is not liable for any errors, omissions, damages etc. due to improper use of this product, included but not limited to improper

installation deviating from this Guide, safety and warning rules violation, using unsuitable cable other than TriCab flexible cable. TriCab

reserves the right to modify this Installation Guide at any time without prior notice.

www.tricab.com

2.

Carefully cut and strip the outer layers of the

cable (sheathing, insulation, fleece tape). Be

very careful not to nick or cut any strands of

the conductor.

Adjust the stripping tool so that

it cuts close to the conductor but leaves a

small amount of insulation to tear away by

hand. This will help protect the fine wires

during the stripping process.

Place the link at the end of the copper

conductor.

1

TCIM-ACC-B21 Rev. 07

ALI-FLEX® Bi-Metallic Reducing Link

Installation Guide

Striping Length of

Cable Insulation

5-10mm Clearance

3.

Gently push both the link and the remaining

section until they meet the jacket.

Cut and remove the section specified by the

dashed line.

4.

Carefully insert the copper conductor into the end

of the copper barrel making sure all strands are

contained within the barrel.

Do not twist the conductor.

This Installation Guide was designed with great care and proper testing before publication to ensure the product works perfectly with TriCab

flexible cables. ALI-FLEX® Bi-Metallic Reducing Links are specifically designed, tested and certified for use with TriCab ALI-FLEX® cables

only. TriCab is not liable for any errors, omissions, damages etc. due to improper use of this product, included but not limited to improper

installation deviating from this Guide, safety and warning rules violation, using unsuitable cable other than TriCab flexible cable. TriCab

reserves the right to modify this Installation Guide at any time without prior notice.

www.tricab.com

2

TCIM-ACC-B21 Rev. 07

B21 ALI-FLEX® Bi-Metallic Reducing Link

Installation Guide

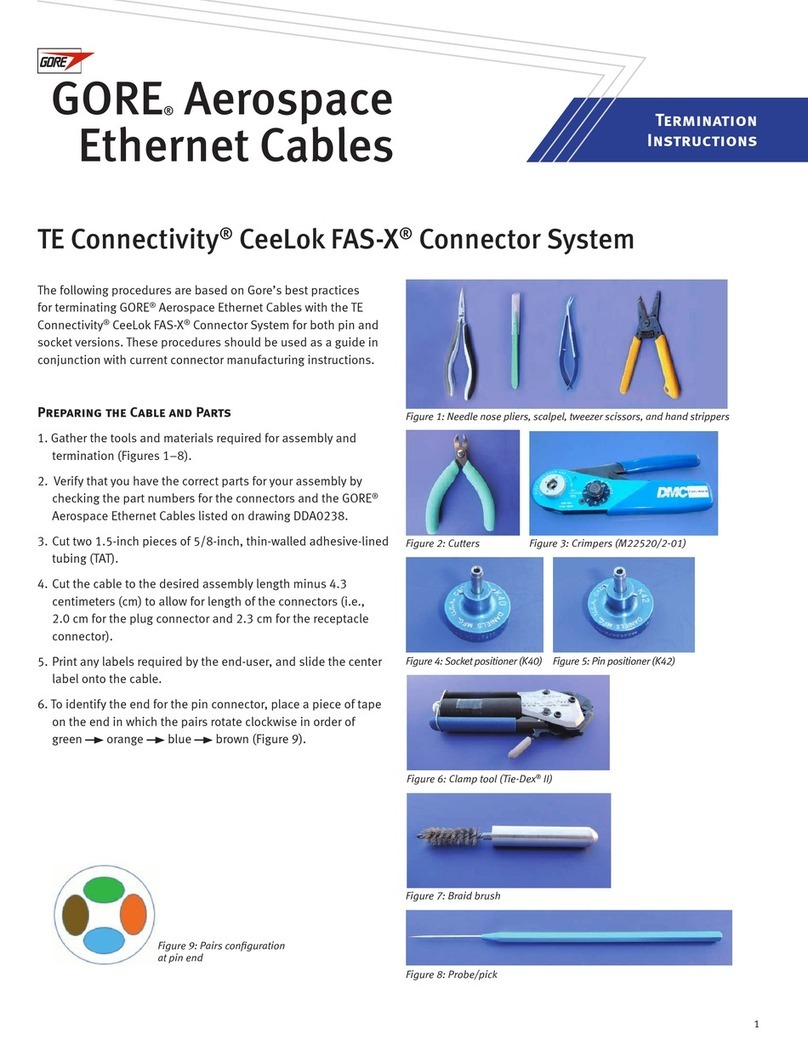

5.

Select a suitable crimping tool with the correct crimp

force and note the required No. of crimps as speci-

fied on Table 1 (12, 25 or 60 Tonne). Choose the

appropriate Copper die by referring to the correct

A/F (across flats) die size on Table 1. The correct A/F

size is also printed on the copper barrel of each B21

lug. Please note that the mm² cable size markings

on AF dies from brands other than TriCab, have

no relationship to the mm² cable sizes for

CU-FLEX or ALI-FLEX cables.

Center of Barrel

Single Crimped Method

Min Gap

7mm

Two Crimped Method

6.

For hydraulic hex crimpers, place the lug on the

non-moving die and allow the other die to move up to

crimp. If more than 1 crimp is required (refer Table

1 for more details), begin crimping from the linked

end of the barrel and work towards the open end.

Position the lug to the correct crimp location on the

barrel as specified in Table 1. Do not crimp closer

than the minium gap specified in Table 1 from the link

end of the barrel.

Begin the crimping process and continue until the full

cycle is complete. Make sure the dies are fully closed

for sufficient crimping force. Release the ram and

repeat the process if more than 1 crimp is required.

Leave a 7mm gap between each crimp. Do not crimp

closer than 4mm from the open end of the barrel.

Refer Table 2 and repeat Steps 1-7 for the Aluminium

conductor

Check crimping result. Us a file if necessary to remove

burrs to have a smooth crimp surface. Apply suitable

ALI-FLEX® G03 Glue Lined Heatshrink over the entire

link to complete the crimping. Two layers of the

heatshrink should be applied if the link is outside an

enclosure. The heatshrink should cover both barrels and

approximately 50mm of the cable jacket on either end.

Min 4mm

7mm

8.

9.

Min Gap

7.

Min 4mm

(*) In case of using dies with different length of crimp face from specified above, the total effective crimp length

(crimp length x no. of crimp) should be equivalent or greater to maintain a secured mechanical and electrical

connection.

This Installation Guide was designed with great care and proper testing before publication to ensure the product works perfectly with TriCab

flexible cables. ALI-FLEX® Bi-Metallic Reducing Links are specifically designed, tested and certified for use with TriCab ALI-FLEX® cables

only. TriCab is not liable for any errors, omissions, damages etc. due to improper use of this product, included but not limited to improper

installation deviating from this Guide, safety and warning rules violation, using unsuitable cable other than TriCab flexible cable. TriCab

reserves the right to modify this Installation Guide at any time without prior notice.

www.tricab.com

3

TCIM-ACC-B21 Rev. 07

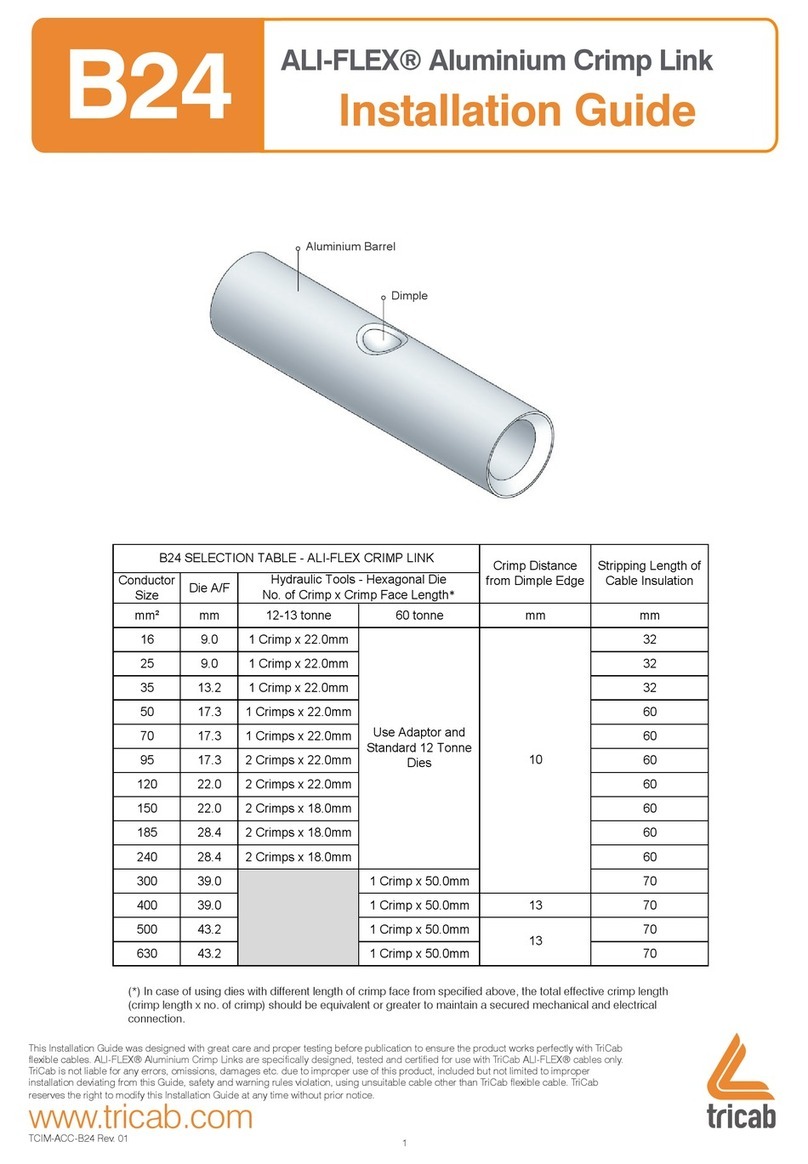

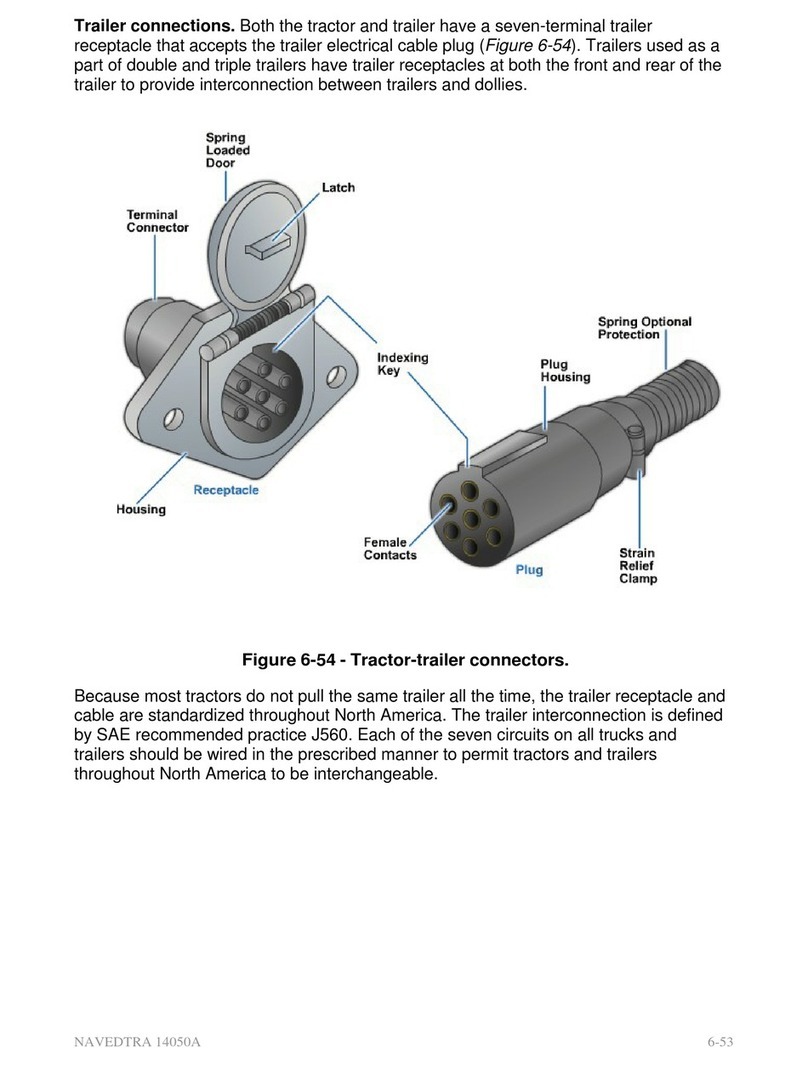

Table 1. Installation of Copper Conductor

B21 ALI-FLEX® Bi-Metallic Reducing Link

Installation Guide

Table 2. Installation of Aluminium Conductor

Conductor

Size Die A/F

mm² mm 12-13 tonne 25 tonne 60 tonne mm mm

16 9.0 1 Crimp x 22.0mm 32

25 9.0 1 Crimp x 22.0mm 32

35 13.2 1 Crimp x 22.0mm 32

50 17.3 2 Crimps x 22.0mm 60

70 17.3 2 Crimps x 22.0mm 60

95 17.3 2 Crimps x 22.0mm 60

120 22.0 2 Crimps x 18.0mm 60

150 22.0 2 Crimps x 18.0mm 60

185 28.4 2 Crimps x 18.0mm 60

240 28.4 2 Crimps x 18.0mm 60

300 39.0 1 Crimp x 50.0mm 13 70

400 39.0 2 Crimps x 25.0mm 1 Crimp x 50.0mm 10(25T)/13(60T) 70

500 43.2 1 Crimp x 50.0mm 70

630 43.2 1 Crimp x 50.0mm 70

Stripping Length

of Cable Insulation

Use Adaptor and

Standard 12 Tonne

Dies

Hydraulic Tools - Hexagonal Die

No. of Crimp x Crimp Face Length*

B21 AL SELECTION TABLE - ALI-FLEX BI-METTALIC REDUCING LINK Crimp Distance

from Barrel Front

Edge

Use Adaptor and

Standard 12 Tonne

Dies

13

10

Conductor

Size Die A/F

12-13 tonne 25 tonne 60 tonne

mm

10 5.7 1 Crimp x 6.4.0mm 10 10

16 6.3 1 Crimp x 17.5mm 19

25 7.7 1 Crimp x 17.5mm 21

35 9.2 1 Crimp x 17.5mm 21

50 (AL-70) 10.4 1 Crimp x 17.5mm 22

50 10.4 1 Crimp x 17.5mm 40

70 11.5 1 Crimp x 17.5mm 40

95 14.2 1 Crimp x 17.5mm 40

120 16.5 2 Crimps x 14.0mm 40

150 18.3 2 Crimps x 14.0mm 1 Crimp x 16.0mm 15 40

185 20.0 2 Crimps x 14.0mm 1 Crimp x 16.0mm 15 55

240 23.1 3 Crimps x 10.0mm 1 Crimp x 16.0mm 55

300 26.0 3 Crimps x 10.0mm 1 Crimp x 16.0mm 1 Crimp x 25.0mm 55

400 28.1 1 Crimp x 16.0mm 1 Crimp x 25.0mm 55

500 31.0 1 Crimp x 16.0mm 1 Crimp x 25.0mm 55

Stripping Length

of Cable Insulation

Hydraulic Tools - Hexagonal Die

No. of Crimp x Crimp Face Length*

B21 CU SELECTION TABLE - ALI-FLEX BI-METTALIC REDUCING LINK

4

mm² mm 12-13 tonne 25 tonne 60 tonne

Crimp Distance from Barrel Front Edge

mm

Use Adaptor and

Standard 12 Tonne

Dies

Use Adaptor and

Standard 12 Tonne

Dies

6

13

5

10

24

20

Table of contents

Other tricab Cables And Connectors manuals