Tricor TCE-8000 Operating instructions

Coriolis TCM Series

Rev. 2.2

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 3

TCE-8000 Transmitter Programming Guide

This guide contains instructions on how to reconfigure the TCE-8000 Coriolis transmitter using its integral

keyboard and display. There are two packaging configurations of the TCE-8000 transmitter: field mount

(cast aluminum housing) and panel mount (plastic housing). These programming instructions apply to

both. The TRICOR TCE-8000 transmitter’s keyboard and display consists of:

an LCD graphic display

two LEDs labeled “OK” and “ERR”

four pushbutton keys labeled “P,” “Reset,” “Display,”and “Info”

Normal Operation

When the TRICOR flow meter is operating properly, “OK” flashes green. With the factory defaults, the

display indicates FLOW RATE on the upper line and BATCH TOTAL on the lower line. When viewing this

display, press the “Reset” key to reset the BATCH TOTAL to zero. Press the “Display” key to view the

DENSITY on the upper line and TEMPERATURE on the lower line of the display. Press the “Display” key

to toggle back to the FLOW RATE and BATCH TOTAL display. You can reconfigure the normal operation

displays to show data other than the factory defaults (see DISPLAY programming).

Abnormal Operation

When the LED labeled “ERR” flashes red, the internal diagnostics of the transmitter is sensing that there

may be a measurement error occurring. Press the “Info” key to view the problem and to see additional

parameters that are important to the operation of the unit. Note: Press the “Info” key during normal

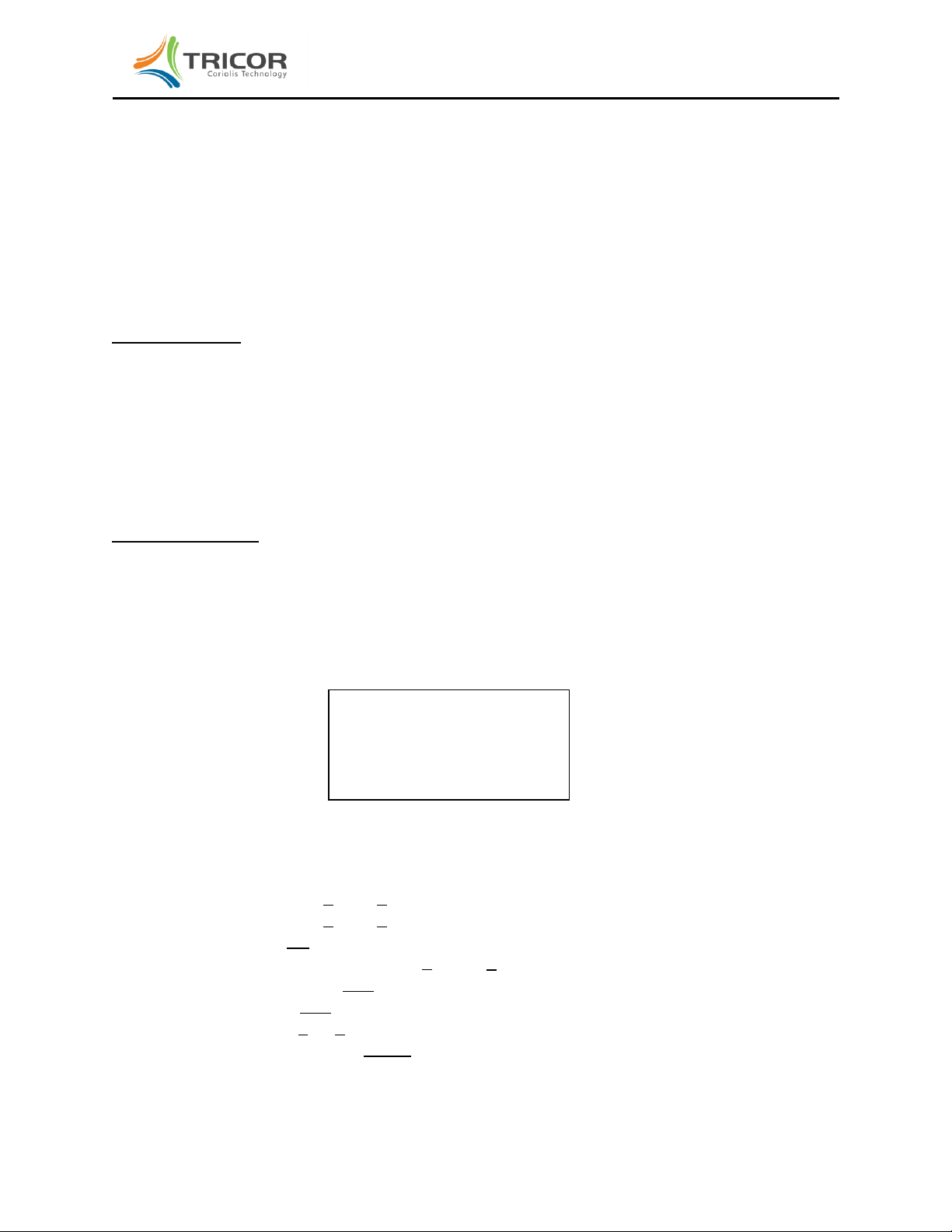

operation to view these additional parameters. The display that appears is similar to the following:

These parameters are important when discussing operational problems with a TRICOR service technician

and they correspond to the following data:

SA is the amplitude of Sensor A in millivolts

SB is the amplitude of Sensor B in millivolts

DR is the sensor DRive current in milliamps

PT is the resistance indicated by the Platinum Temperature probe in Ohms

FRE is the vibrating tube FREquency in Hz

TOT is the internal TOTalizer value

ZP is the captured Zero Point calibration in microseconds

RS485 is the address of the RS485 communication port

SA: 140 FRE: 142.74

SB: 140 TOT: 1007.69

DR: 5.51 ZP: -0.02

PT: 1071.2 RS485: 01

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 4

TCE-8000 Transmitter Programming Guide

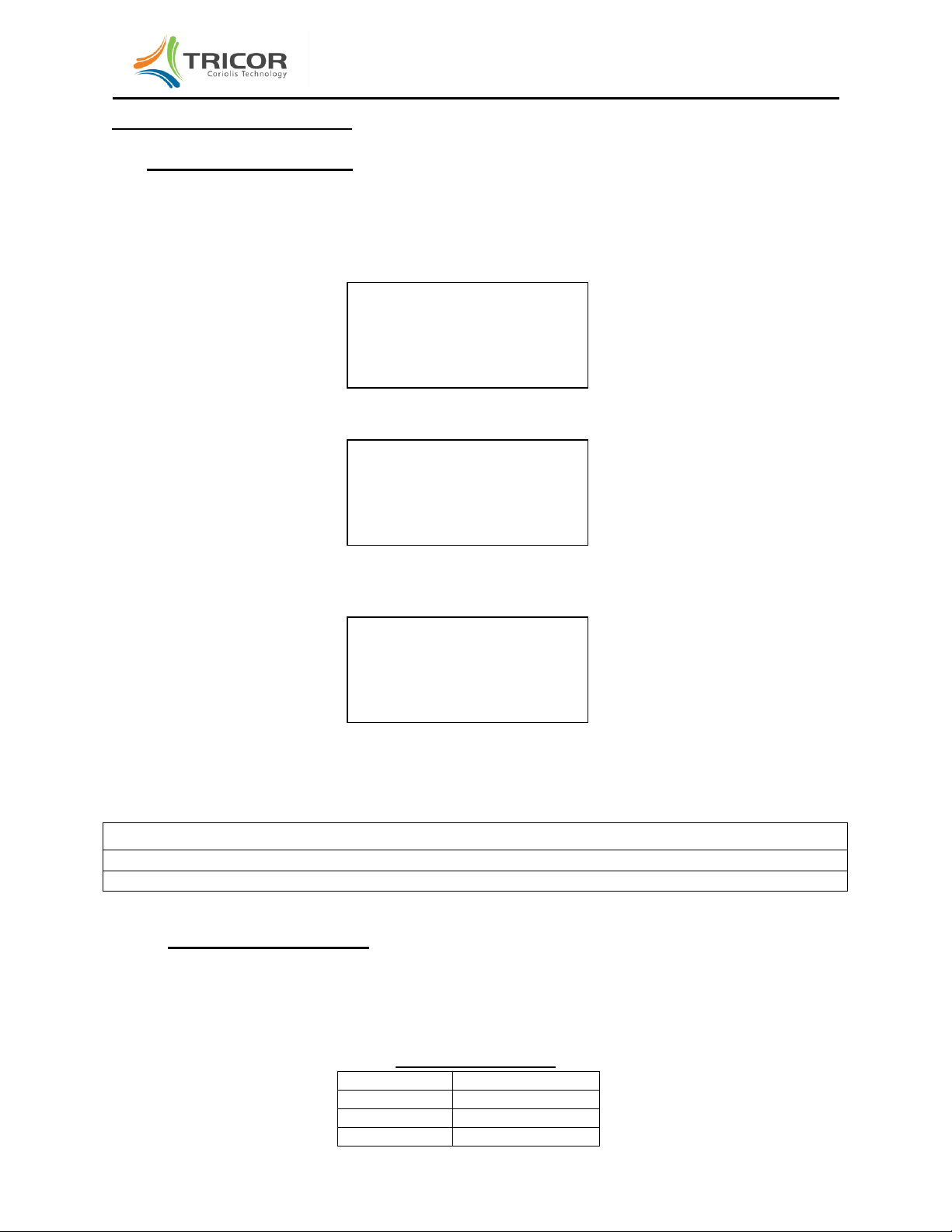

ZERO OFFSET procedure

Note: ON NEW INSTALLATIONS, A ZERO POINT CALIBRATION MUST BE PERFORMED TO

ENSURE ACCURATE METERING.

Shut off the flow and block in the flow line with a downstream valve to ensure that the flow rate is

truly zero.

Press and hold the “P” key until the following screen appears:

Press the “P” key again and the following screen appears

Press the “UP” softkey to change 2206 to 2207, then press the “P” key. The following screens

appear:

Press the “SLOW” softkey for long averaging (about 30 seconds) or the “FAST” key for short

averaging (about 10 seconds) to initiate zero point calibration. Caution: Do not flow through the

sensor while the following screens are displayed:

The zero point calibration is complete. Press the INFO key to return to the ZERO OFFSET

display.

Press EXIT softkey to return to the RATE and BATCH TOTAL display.

*ENTER USER_CODE*

2206

LEFT UP EXIT

* USERCODE *

OKAY

MAIN MENU

ZERO OFFSET

UP DOWN EXIT

START OFFSET

PROCEDURE

SLOW FAST EXIT

MAKE ZERO

OLD ZERO: x.xxx uS

NEW ZERO: uS

*END OF ZERO POINT*

PRESS INFO TO RETURN

OLD ZERO: x.xxx uS

NEW ZERO: y.yyy uS

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 5

TCE-8000 Transmitter Programming Guide

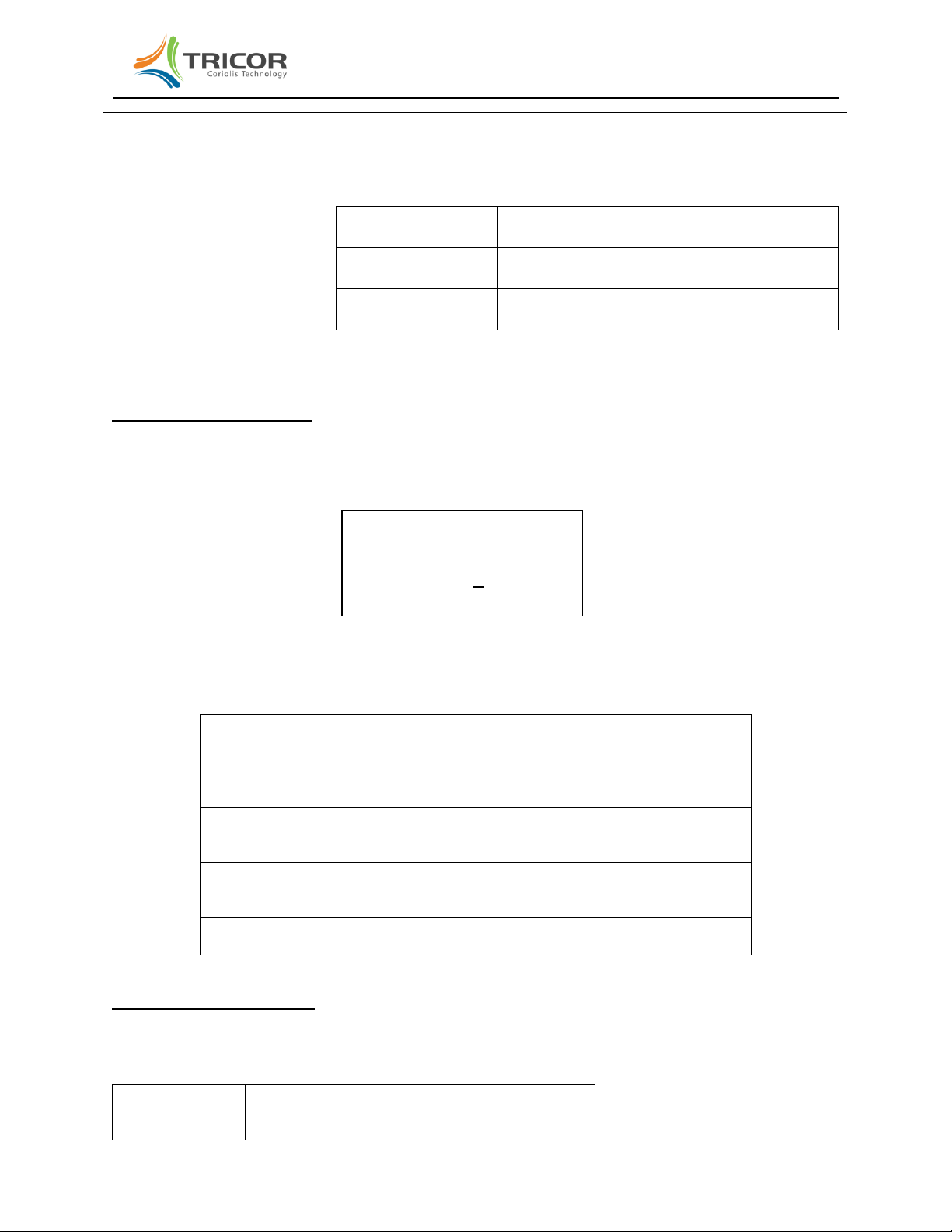

REPROGRAMMING OPERATION

FLOW DISP reprogramming

To enter the function that allows you to reconfigure the transmitter display of flow, total, density and

temperature, perform the following steps:

Press and hold the “P” key until the following screen appears:

Press the “DOWN” key and the following screen will appear:

Press the “P” key and the following screen will appear:

Press the “P” key to access the flow rate parameter(s) that can be changed under the FLOW

DISP submenu.

Displayed Parameter Description

FLOW UNITS select unit of measure for flow rate display

FLOW DP select decimal point location in flow rate display

DISP FILTER define filter value used to smooth flow rate display

FLOW UNITS programming

With FLOW UNITS displayed, press the “P” key to bring up the current flow rate units. Press the “UP” or

“DOWN” softkey to select the desired unit of measure. If the METER MODE selected in SETUP is MASS

METER the list consists of the following:

Mass Flow Rate Units

FLOW-UNITS

Description

G/S

Grams/second

KG/S

Kilograms/second

LB/S

Pounds/second

SELECT PROG-POINT

FLOW DISP

UP DOWN EXIT

MAIN MENU

ZERO OFFSET

UP DOWN EXIT

MAIN MENU

DISPLAY

UP DOWN EXIT

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 6

TCE-8000 Transmitter Programming Guide

OZ/S

Ounces/second

T/S

Metric tons/second

ST/S

Stones/second

G/M

Grams/minute

KG/M

Kilograms/minute

LB/M

Pounds/minute

OZ/M

Ounces/minute

T/M

Metric tons/minute

ST/M

Stones/minute

G/H

Grams/hour

KG/H

Kilograms/hour

LB/H

Pounds/hour

OZ/H

Ounces/hour

T/H

Metric tons/hour

ST/H

Stones/hour

G/D

Grams/day

KG/D

Kilograms/day

LB/D

Pounds/day

OZ/D

Ounces/day

T/D

Metric tons/day

ST/D

Stones/day

If the METER MODE selected in SETUP is VOLUME METER the list consists of the following:

Volumetric Flow Rate Units

Flow Rate Unit

Description

CC/S

Cubic centimeters/second

L/S

Liters/second

UGAL/S

US gallons/second

LOZ/S

Fluid ounces/second

EGAL/S

English gallons/second

BBL/S

English barrels/second

CC/M

Cubic centimeters/minute

L/M

Liters/minute

UGAL/M

US gallons/minute

LOZ/M

Fluid ounces/minute

EGAL/M

English gallons/minute

BBL/M

English barrels/minute

CC/H

Cubic centimeters/hour

L/H

Liters/hour

UGAL/H

US gallons/hour

LOZ/H

Fluid ounces/hour

EGAL/H

English gallons/hour

BBL/H

English barrels/hour

CC/D

Cubic centimeters/day

L/D

Liters/day

UGAL/D

US gallons/day

LOZ/D

Fluid ounces/day

EGAL/D

English gallons/day

BBL/D

English barrels/day

With the desired flow rate unit displayed, press the “P” key; the display returns to FLOW UNITS. Note:

To compute volume flow, the device divides the measured mass by the measured density.

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 7

TCE-8000 Transmitter Programming Guide

FLOW DP programming

When FLOW DP displays, press the “P” key to bring up the current position of the flow rate decimal point

position. Press the “LEFT” softkey to select the desired position of the flow rate decimal point, then press

the “P” key; the display returns to FLOW DP.

DISP FILTER programming

With DISP FILTER displayed, press the “P” key to bring up the current time constant (in seconds) for the

flow rate display. Press the “RIGHT” and “UP” softkeys to define the time constant between the limits of 0

and 99.9 seconds. Press the “P” key; the display returns to DISP FILTER. Note: The larger the time

constant used in the DISP FILTER, the steadier the rate display; however, it will take longer to reach final

value when a change in the flow rate is made. The factory default is 1.0 second for moderate filtering.

TOTAL DISP reprogramming

TOTAL DISP is below FLOW DISP is the DISPLAY submenu. Follow the steps above to get to FLOW

DISP then press the “DOWN” key to bring up TOTAL DISP.

Press the “P” key to access the totalizer parameters that can be changed under the TOTAL DISP

submenu.

Displayed Parameter Description

TOTAL UNITS select unit of measure for BATCH TOTAL display

TOTAL DP select decimal point location in BATCH TOTAL display

TOTAL UNITS programming

With TOTAL UNITS displayed, press the “P” key to bring up the current totalizer units. Press the “Up” or

“Down” softkey to select the desired unit of measure. If the METER MODE selected in SETUP is MASS

METER the list consists of the following:

TOTAL UNITS

Description

GRAMS

Grams

KILO

Kilograms

POUNDS

Pounds mass

OUNCES

Ounces mass

TONS

Metric tons

STONES

Stones

If the METER MODE selected in SETUP is VOLUME METER the list consists of the following:

TOTAL UNITS

Description

CC

CubicCentimeters

LITER

Liters

US-GAL

US Gallons

L-OUNC

Liquid Ounces

UK-GAL

UK Gallons

UK-BBL

UK Barrels

With the desired totalizer unit displayed, press the “P” key; the display returns to TOTAL UNITS.

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 8

TCE-8000 Transmitter Programming Guide

TOTAL DP programming

When TOTAL DP displays, press the “P” key to bring up the current position of the totalizer decimal point.

Press the “LEFT” softkey to select the desired position of the flow rate decimal point, then press the “P”

key; the display returns to TOTAL DP.

DENS DISP programming

DENS DISP is below TOTAL DISP in the DISPLAY submenu. Follow the steps above to get to FLOW

DISP then press the “DOWN” key twice to bring up DENS DISP.

Press the “P” key to access the DENS UNITS submenu.

DENS UNITS programming

With DENS UNITS displayed, press the “P” key to bring up the current density unit of measure. Press the

“Up” or “Down” softkey to select the desired unit of measure from the list below:

DENS-UNIT

Description

G/CC

Grams/Cubic centimeter

G/L

Grams/Liter

KG/L

Kilograms/Liter

LB/FT3

Pounds/Cubic foot

LB/GAL

Pounds/US Gallon

BRIX

Degrees Brix

With the desired density unit displays, press the “P” key; the display returns to DENS UNITS.

TEMP DISP programming

TEMP DISP is below DENS DISP in the DISPLAY submenu. Follow the steps above to get to FLOW

DISP then press the “DOWN” key three times to bring up TEMP DISP.

Press the “P” key to access the TEMP UNITS submenu.

TEMP UNITS programming

With TEMP UNITS displayed, press the “P” key to bring up the current temperature unit of measure.

Press the “Up” or “Down” softkey to select the desired unit of measure from the list below:

TEMP UNIT

Description

°C

Celsius Degrees

°F

Fahrenheit Degrees

Kelvin

Kelvin Degrees

When the desired temperature unit displays, press the “P” key; the display returns to TEMP UNITS.

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 9

TCE-8000 Transmitter Programming Guide

DISP MODE

With normal operating factory defaults, display 1 is set to show RATE on the upper line and BATCH

TOTAL on the lower line. Default display 2 is set to show DENSITY on the upper line and

TEMPERATURE on the lower line. Use the “Display” key to toggle between display 1 and display 2

during normal flowmeter operation. Display 1 and display 2 can be customized to have a single

line/single parameter displayed in a larger font. Also, the double line display can be reconfigured to show

different parameters of interest.

DISP MODE is below TEMP DISP in the DISPLAY submenu. With DISP MODE displayed, press the “P”

key to begin configuring display 1 or display 2. Select from the list below:

MODE

Description

DISPLAY 1

Select Display 1

DISPLAY 2

Select Display 2

Select the desired display (1 or 2) and press the “P” key. The current configuration of the display

will appear. Press the “P” key to change it or the “EXIT” key for no change.

Press the “P” key to display the current line mode:

SELECT LINE MODE

DUAL LINE

SINGLE LINE

Select the desired line mode and press the “P” key. Then select the parameter from the list

below:

SELECT LINE 1

RATE

BATCH TOTAL

DENS.

TEMP.

GRAND TOTAL

F-OUT

CURR-1

Press the “P” key and repeat this procedure for LINE 2 if 2-LINES was previously selected.

Press the “P” key to return to DISPLAY 1. Press “DOWN” to display DISPLAY 2 and repeat the

above procedure.

Press “EXIT” to return to DISPLAY 2. Press “DOWN” to display the following selection:

DISPLAY

Description

BACKLIGHT

Select to turn on/off the display backlight

TIME MODE

Select to FIXED or ALTERNATE display

Select BACKLIGHT and press the “P” key to display the following selection:

BACKLIGHT SETTINGS:

ON

OFF

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 10

TCE-8000 Transmitter Programming Guide

Select ON or OFF softkey then press the “P” key to return to BACKLIGHT.

Press the “DOWN” softkey to display TIME MODE.and press the “P” key to display the following

selection:

TIME MODE

SETTINGS:

FUNCTION

FIXED

Display stays on Display 1 or Display 2.

Toggle using “Display” key.

ALTERNATE

Display toggles between Display 1 and

Display 2 every 5 seconds

Press “P” key then “EXIT” softkey to leave the programming mode.

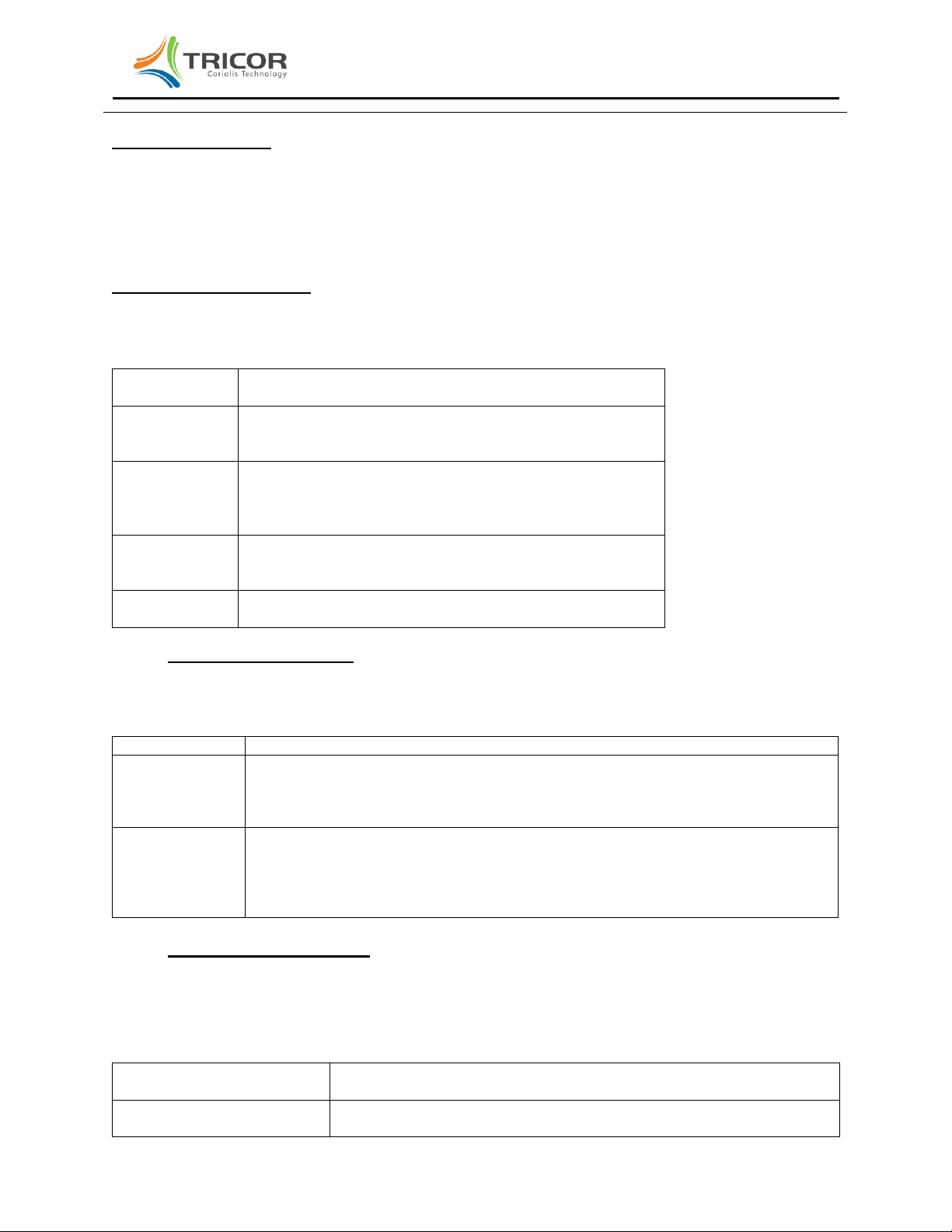

SETUP REPROGRAMMING

SETUP is below ZERO OFFSET and DISPLAY in the main menu structure. From the normal display,

press the “P” key then press the “DOWN” softkey twice until SETUP is displayed then press the “P” key

and the following screen will be displayed:

Press the “UP” softkey to display user code of 2207 then press the “P” key to access the SETUP

MENU. There are several submenus in the SETUP MENU, they are:

PARAMETER

Allows setup of various metering parameters.

FILTER

Allows programming of FLOW and DENSITY

filters.

IN/OUTPUTS

Allows programming of the various I/O terminal

functions.

DATA

CONFIGURATION

Allows saving and restoring of the configuration

memory.

RESET TOTAL

Allows zeroing of the grand total and batch total.

PARAMETER programming

When PARAMETER is displayed press the “P” key to access the PARAMETER submenu which

contains the following parameters:

METER MODE

Allows selection of MASS METER or VOLUME

METER

*ENTER USER_CODE*

2206

LEFT UP EXIT

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 11

TCE-8000 Transmitter Programming Guide

CUTOFF

Set the value of a low flow cutoff as a percent of

the full scale rating of the flow sensor.

STEP RESP.

Set the value of the step response as a percent

of the full scale flow rating of the sensor.

RESET KEY

Activate (ON) or deactivate (OFF) the “Reset”

for the displayed BATCH TOTAL.

FLOW-DIREC

Define the flow direction through the sensor as

either FORWARD (in the same direction of the

arrow on the flow sensor) or REVERSE (in the

opposite direction of the arrow on the flow

sensor).

K-FACTOR

Default K-FACTOR (also known as meter

factor) is 1.000. Adjusting this value

proportionally will alter the meter output flow

function by that proportion.

FAULT TIME

The time in seconds after a fault is detected

before it is declared as an error.

LANGUAGE

Select the language used on the display.

METER MODE programming

The METER MODE submenu allow selection of MASS METER when the application requires mass units

of measure for both flow rate and flow totals or VOLUME METER when the application requires volume

units of measure for both flow rate and flow totals. When VOLUME METER is selected the volume is

determined by dividing the measured mass by the measured density.

CUTOFF programming

CUTOFF is a low flow cutoff. Because the meter at zero flow has a live zero, that is, there is some

residual amount of noise being measured at zero flow, there will be some small amount of flow noise

being displayed when the flow is actually zero. To avoid this problem which can cause confusion, a cutoff

must be in place so that any detected flow noise below this cutoff is displayed as zero flow rate and the

totalizer is stable and not counting. Ideally, the cutoff should be as low as possible to assure that the

least amount of flow is missed when true flow starts up or shuts off. CUTOFF is programmed as a

percentage of the maximum flow rate for the meter and can be set to a minimum of 0.1% (or higher if

necessary). For example, the TCM28K meter is rated at a maximum flow rate of 28000 kilograms per

hour. Therefore, a CUTOFF setting of 0.1% would mean that any flow below 0.001 x 28000 = 28

kilograms per hour would not be registered. The amount of CUTOFF needed for stable zero indication

may be installation dependent. Enter the lowest value of CUTOFF to obtain a stable zero flow reading.

STEP REPONSE programming

STEP RESPONSE works in conjunction with the FLOW FILTER in that, if a rapid change in flow rate

above the amount specified in the STEP RESPONSE occurs, the filter is temporarily cancelled and the

meter output goes rapidly to the new flow rate value.

In a few applications, it is desirable to have a very stable flow rate displayed when flow is constant

thereby dictating a longer time constant in the FLOW FILTER (e.g. greater than 4 seconds). However, in

this case if STEP RESPONSE is not employed and the actual flow rate makes a rapid step, the meter

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 12

TCE-8000 Transmitter Programming Guide

outputs will be slow to respond to it.

In most cases it is more desirable to keep the FLOW FILTER at a low value (e.g. 1 second or less) and

accept a little variation in the flow rate display by deactivating the STEP RESPONSE entirely. The

default value for STEP RESPONSE is therefore deactivated. It is recommended that TRICOR customer

support be consulted before STEP RESPONSE is activated and employed.

RESET KEY programming

The “Reset” key on the display can be programmed to either ON or OFF. When programmed to be ON,

the displayed BATCH TOTAL can be reset to zero by pressing this key at any time. If it is undesirable to

have a local reset then change RESET KEY to OFF. Note that the CONTROL INPUT line can be

programmed for a remote BATCH TOTAL reset.

FLOW DIRECTION programming

The TRICOR meter is bidirectional. That is, the sensor is fully symmetrical and can be installed in the

flow line in either orientation independent of the FLOW symbol on the label. The arrow

indicates the direction of FORWARD flow in the software configuration. If the sensor is installed in the

opposite orientation simply change FLOW DIRECTION to REVERSE in order to show positive numbers

in both the FLOW RATE and BATCH TOTAL.

Note that flow in the opposite direction will indicate negative values of FLOW RATE and the BATCH

TOTAL will decrement rather than increment. If the BATCH TOTAL decrements down to zero and

continues on down, it will show negative numbers in the BATCH TOTAL.

K-FACTOR programming

The meter calibration can be changed in one of two ways. The first is to change the “factory calibration

factor” known as METER VARIABLE which is accessed under the SERVICE menu. A more convenient

recalibration method is to modify the K-FACTOR (while preserving the factory calibration factor). The

default K-FACTOR is 1.00000. Increasing the K-FACTOR will increase the meter output. Conversely,

decreasing the K-FACTOR will decrease the meter output.

EXAMPLE: A field recalibration is performed using a calibrated weight scale. The meter registers 105.62

pounds and the weight scale registers 105.51 pounds. The meter is high by 0.104%. Recalculate the K-

FACTOR as follows:

(old K-FACTOR) X (scale ÷ meter) = new K-FACTOR

(1.00000) x (105.51 ÷ 105.62) = 0.99896. Change the K-FACTOR to 0.99896 to improve the meter

accuracy.

FAULT TIME programming

Should an error be detected by the meter electronics it may be desirable to delay the declaration of it in

order to not disrupt the operation of the meter, especially if the error is short lived such as an air bubble

passing through the meter causing a temporary reduction in amplitude of the Coriolis sensors. The

default is 2.7000 seconds delay and should suffice for most applications but can be increased or reduced

as needed.

LANGUAGE programming

The default language on the display is ENGLISH but can be changed to others as they become available.

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 13

TCE-8000 Transmitter Programming Guide

FILTER programming

When FILTER is displayed press the “P” key to access either the FLOW FILTER or the DENSITY FILTER

by pressing the UP or DOWN key. Enter the “time constant” for the filter selected. The time constant is

defined as the time in seconds that is required to reach 63% of the final value after a step change in the

actual flow or density. The filter used is a software representation of a classical single pole RC filter used

in analog electronics.

IN/OUTPUTS programming

When IN/OUTPUTS is displayed press the “P” key to access the IN/OUTPUTS submenu which

contains the following I/O terminals:

FREQ OUT

Scaling of flow pulses on f-out (terminals #5 to 8)

CTRL OUT

Definition of the function of digital control output (terminals

#6 to 8).

ANALOG OUT

Scaling of analog 1 output (terminals #1 to 2)

Scaling of analog 2 output (terminals #3 to 4)

CTRL IN

Definition of the function of digital control input (terminals

#7 to 8).

INTERFACE

Definition of communications interface used

FREQ-OUT programming

With FREQ-OUT displayed, press the “P” key to bring up the current function of the f-out output of the

transmitter. Press the “Up” or “Down” key to select the desired function from the list below:

FREQ-OUT

Description

FREQUENCY

f-out produces a frequency that is proportional to the flow rate. Frequencies up to

10,000 Hz can be produced in the FREQUENCY mode of operation. Note:

Because this mode outputs a frequency proportional to flow rate, totalizing these

pulses may result in a slight discrepancy from the TOTAL display.

TOTAL COUNT

f-out produces pulses that are based on the internal totalizer. In the TOTAL

COUNT mode, a change in state from low to high, or high to low occurs when the

internal totalizer increases by a set amount of mass (or volume). Totalizing these

pulses results in an accurate representation of the TOTAL display. The maximum

output in this mode is about 15 pulses per second.

FREQUENCY programming

After selecting FREQUENCY mode of operation, press the “P” key to view and/or set the additional

scaling parameter required for the frequency mode of operation. In each of the following screens set the

numerical value using the “RIGHT” and “UP” keys, then “P” to advance to the next parameter.

FULL SCALE FLOW

Flow rate in the FLOW-UNITS selected that correspond to the

frequency selected in the next screen, FULL SCALE FREQUENCY.

FULL SCALE FREQUENCY

Frequency corresponding to the flow rate entered in the previous

screen, FULL SCALE FLOW.

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 14

TCE-8000 Transmitter Programming Guide

Example 1: The application is expected to reach a full scale flow rate of 600 pounds per minute. The

display totalizer is set to display BATCH TOTAL to 0.001 pound resolution and it is desired to have the

external pulse counter have the same resolution, 1 pulse per 0.001 pound. The FULL SCALE

FREQUENCY is entered in Hz which is equivalent to pulses per second but the flow rate is expressed in

pounds per minute. Perform the following calculation.

600 pounds / minute ÷ 60 seconds per minute = 10 pounds per second

10 pounds per second ÷ 0.001 pulses / pound = 10000 pulses per pound = 10000 Hz

Therefore:

FULL SCALE FLOW = 600.00 lbs/min

FULL SCALE FREQUENCY = 10000 Hz

Example 2: The application is expected to reach a full scale flow rate of 36000 pounds per hour. The

display totalizer is set to display BATCH TOTAL to 0.01 pound resolution and it is desired to have the

external pulse counter have the same resolution, 1 pulse per 0.01 pound. The FULL SCALE

FREQUENCY is entered in Hz which is equivalent to pulses per second but the flow rate is expressed in

pounds per hour. Perform the following calculation.

36000 pounds /hour ÷3600 seconds per hour = 10 pounds per second

10 pounds per second ÷ 0.01 pulses / pound = 1000 pulses per pound = 1000 Hz

Therefore:

FULL SCALE FLOW = 36000.0 lbs/hr

FULL SCALE FREQUENCY = 1000 Hz

TOTAL COUNT programming

After selecting the TOTAL COUNT mode of operation, press the “P” key to view and/or set the SELECT

VALUE in total units to the value for each output pulse. To ensure that the TOTAL COUNT output does

not exceed the maximum frequency of 15 Hz, the SELECT VALUE must be checked against the

maximum flow rate expected or a delay of the pulses out could result.

Press the “P” key to return to FREQ-OUT display.

Example : The application is expected to reach a full scale flow rate of 600 pounds per minute. The

TOTAL COUNT mode of operation is selected to produce a low frequency pulse output. One pulse per

0.1 pound is to be sent to an external PLC device. SELECT VALUE is set to 0.1000 POUNDS. Perform

the following calculation to verify that at the maximum flow rate of 600 pounds per minute the pulse output

will not exceed 15 Hz.

600 pounds per minute ÷ 60 seconds/minute = 10 pounds per second

10 pounds per second ÷ 0.1 pounds per pulse = 100 pulses per second = 100 Hz

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 15

TCE-8000 Transmitter Programming Guide

This exceeds the maximum frequency of 15 Hz which is a limitation of the TOTAL COUNT functionality

and, therefore, will not work properly. The SELECT VALUE could be increased to 1.0 pounds per pulse

in order to reduce the maximum frequency to 10 Hz which does not exceed the 15 Hz limit.

CNTL OUT programming

When CNTL OUT is displayed press the “P” key to select the function of the Control Output terminal #6

with respect to #8.

FAULT

Control output goes from low to high when a fault is declared.

FREQ OUT DIR

If the application requires bi-directional flow through the meter the Control Output can

be set to indicate the direction of flow through the meter so that the frequency output

can be qualified to be FORWARD FLOW (Control Output low) or REVERSE FLOW

(Control Output high).

BATCH

The Control Output can be used to control a batch control valve.

If BATCH is selected the Control Input terminal must previously have been programmed to RESET

BATCH as a start switch for the batch control function. Additionally, two more parameters must be

programmed:

BATCH VALUE

Enter the preset amount of the batch to be

delivered each start cycle.

SELECT OUTPUT LEVEL

ACTIVE LOW (a low signal when not flowing)

ACTIVE HIGH (a high signal when not flowing)

Press the “P” key to return to CNTL OUT display.

ANALOG OUT programming

ANALOG 1 (or ANALOG 2) programming

With ANALOG 1 (or ANALOG 2) displayed, press the “P” key to view and/or set the additional scaling

parameter required for each milliamp output.

SELECT OUTPUT MODE

FLOW

DENSITY

TEMPERATURE

BATCH COUNT

VALUE AT 4 mA

The value of the process variable selected at 4 mA.

VALUE AT 20 mA

The value of the process variable selected at 20 mA

The milliamp outputs can be freely programmed to set 4 mA at one value and 20 mA at another value for

the measured variable selected.

Press the “P” key to return to ANALOG 1 (or ANALOG 2) display.

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 16

TCE-8000 Transmitter Programming Guide

CNTL IN programming

When CNTL IN is displayed press the “P” key to select the function of the Control Input terminal #7 with

respect to #8.

EXT. ZERO

Initiate a ZERO OFFSET procedure using an external high signal into terminal 7

RESET BATCH

Reset the BATCH TOTAL from an external high signal into terminal 7 and/or start a

batch using the Control Output programmed to BATCH.

Press the “P” key to return to CNTL IN display.

INTERFACE programming

When INTERFACE is displayed press the “P” key to select the function of the digital communication

interface that will be serviced by the software configuration from the interface submenu below:

RS485

Communicate over the RS485 terminals 20, 21, and 22 using the TRICOR protocol. If RS485 is

selected an additional screen to set the node address will be displayed. The default node

address is 01.

HART

Communicate over ANALOG 2 terminals using the HART protocol

FF

Communicate over the Foundation Fieldbus terminals 30 and 31 using the Foundation Fieldbus

protocol

.

Press the “P” key to return to the INTERFACE display.

DATA CONFIGURATION programming

When DATA CONFIGURATION is displayed the EEPROM memory can be accessed to either SAVE

DATA as currently configured to EEPROM memory or RECALL DATA from the EEPROM memory.

SAVE DATA programming

With SAVE DATA displayed, you can save all new configuration settings in the non-volatile EEPROM

memory. If you made changes but have not saved them, a warning message appears during startup for

about 10 seconds as follows:

To initiate a SAVE DATA operation, press the “P” key and the following screen will appear:

***… WARNING…***

THERE IS NO RAM BACKUP

LOOK INTO YOUR MANUAL

PRESS ENT TO CONTINUE

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 17

TCE-8000 Transmitter Programming Guide

Press “START” and the following screens will appear:

RECALL DATA programming

With RECALL DATA displayed, you can delete any changes that have been made to revert to the settings

the last time SAVE DATA was performed. To initiate a RESTORE DATA operation, press the “P” key and

the following screen will appear:

Press the “START” softkey and the following screens will appear:

I/O –TEST programming

With I/O TEST displayed, you can drive the Frequency, Analog 1 and 2, or Control Outputs to fixed levels

to test your receiving device(s). You can also test the level of the Control Input being received. The I/O

TEST submenu is as follows:

FREQ OUT

Produce a fixed frequency (terminals #5 to 8).

CTRL OUT

Produce a low or high level (terminals #6 to 8).

ANALOG OUT

Produce a fixed current level on Analog 1 (terminals #1 to 2) or Analog 2 (terminals #3

to 4)

CTRL IN

Read back the status of the Control Input on terminals #7 to 8

READY TO SAVE DATA

START EXIT

MEMORY

ACCESS

READY

RESTORE BACKUP DATA

START EXIT

MEMORY

ACCESS

READY

©2011 AW-Lake Company. All rights reserved. All trademarks are the property of their respective holders and are hereby acknowledged. TCE-8000PG-012011 Page | 18

TCE-8000 Transmitter Programming Guide

FREQ OUT programming

With FREQ OUT selected, press the “P” key to ENTER FREQUENZ [HZ]. Valid entries are 1 to 9999 Hz.

Press the “P” key and the frequency that was displayed will be output while the display reads as follows:

Press “YES” to enter a different frequency or “EXIT” to stop the test.

CTRL OUT programming

With CTRL OUT selected, press the “P” key. When SELECT OUTPUT LEVEL is displayed select either

HIGH or LOW.

Press “EXIT” to return to CTRL OUT

ANALOG OUT programming

With ANALOG OUT displayed press the “P” key. OUTPUT 1 or OUTPUT 2 can be selected using the

“UP” or “DOWN” softkey.

With OUTPUT n selected, press the “P” key to ENTER CURRENT n [mA]. Valid entries are 1 to 22 mA.

Press the “P” key and the current that was displayed will be output while the display reads as follows:

Press “YES” to enter a different current or “EXIT” to stop the test. Press “EXIT” again to display I/O -

TEST. Press “EXIT” again to return to the normal display.

CHANGE VALUE

YES EXIT

CHANGE VALUE

YES EXIT

Americas:

8809 Industrial Drive

Franksville, WI 53126 USA

Tel.: 800-850-6110

Europe:

Liebigstraße 2

85757 Karlsfeld, Germany

Tel.:+49 (0)8131 59391-0

Asia:

Rm.2429, JinYuan Ofce Building, No. 36

CN- BeiYuan Road, Beijing 100012

P.R.CHINA

Tel.:+86 10 520 037 38

www.tricorflow.com ©2011 AW-Lake Company. All rights reserved.

Doc ID: TCE8000PROG-100512

Table of contents

Popular Transmitter manuals by other brands

Conrad

Conrad FS20 S8-2 operating instructions

Michell Instruments

Michell Instruments Easidew user manual

Emerson

Emerson Rosemount 2051 Reference manual

Cooper Security

Cooper Security 702r manual

Altinex

Altinex SIGNAL MANAGEMENT SOLUTIONS UT260-105 user guide

Becker

Becker Centronik SunWindControl SWC441 Assembly and operating instructions