4. STRIKE ADJUSTMENT

5. BASIC OPERATION

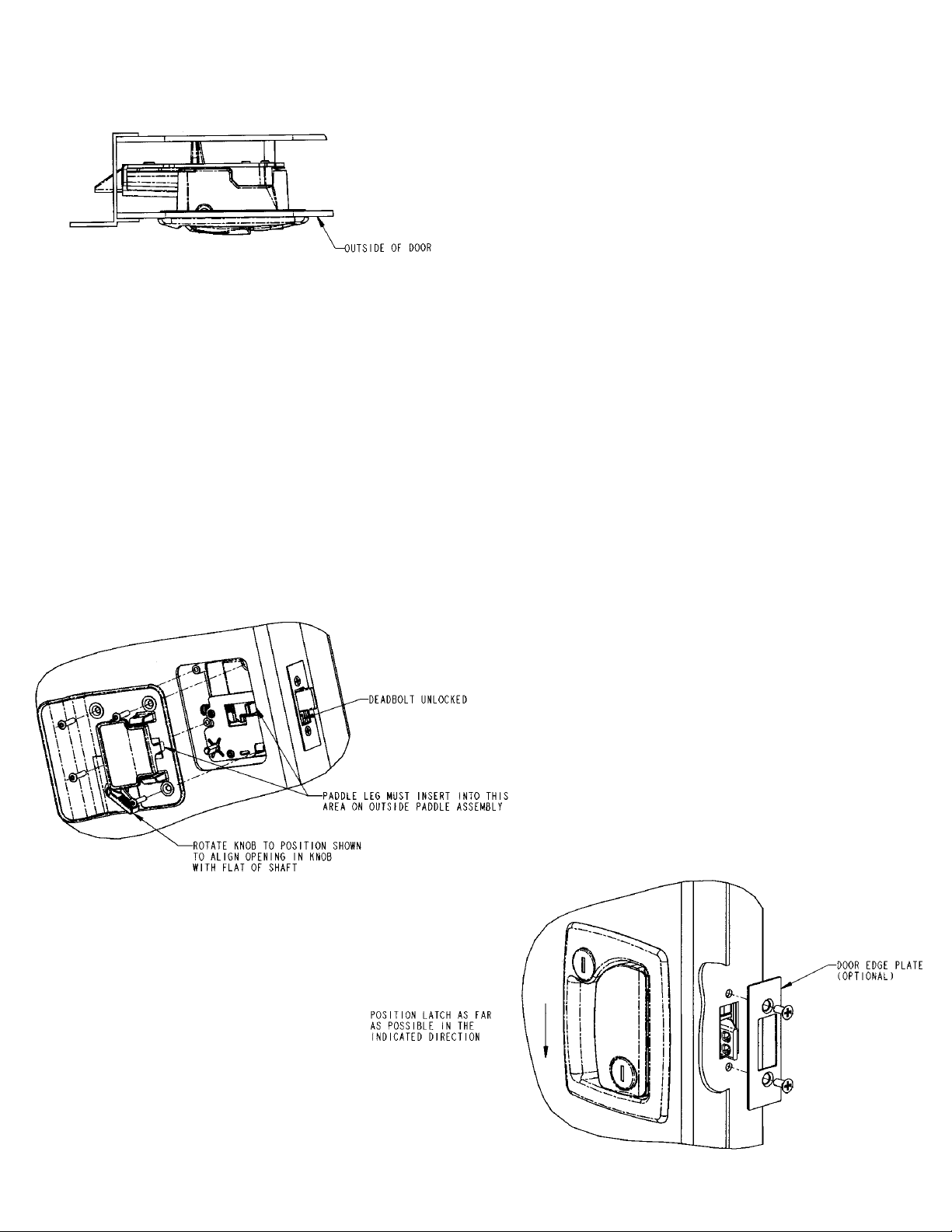

Carefully close door. Door should easily latch

shut. If door does not shut tightly enough for

desired sealing, adjust strike as follows:

1. Use a pencil to mark the existing position

of the strike plate on the door jamb.

2. Loosen the strike plate mounting screws

so that strike plate can slide on door jamb.

3. Slide strike plate inward no more than

1/16”.

4. Tighten strike plate mounting screws so

that closing of door and vibration will not

move strike plate. Do not tighten

excessively as stripping of the threads

may result.

5. Carefully close door and check for proper

sealing, door closing effort, and latch

operating efforts. The strike should not

be adjusted in so far that excessive

force (25 pounds maximum) is required

to push the door shut to latch. The

door should be able to be pushed shut

by hand without slamming. If adequate

sealing is still not achieved go back to

step 1.

OPERATION OF THE PADDLE LOCK:

The paddle can be locked by rotating the

lock cylinder in the paddle clockwise 1/4

turn and can be unlocked by rotating the

lock cylinder counterclockwise 1/4 turn.

When locked, the outside paddle will not

be able to be pulled. When locked, the

inside paddle will still be able to be pulled

and open the door. If the latch is locked

with the door open, it can be shut and will

stay locked. The paddle lock can not be

locked or unlocked from the inside.

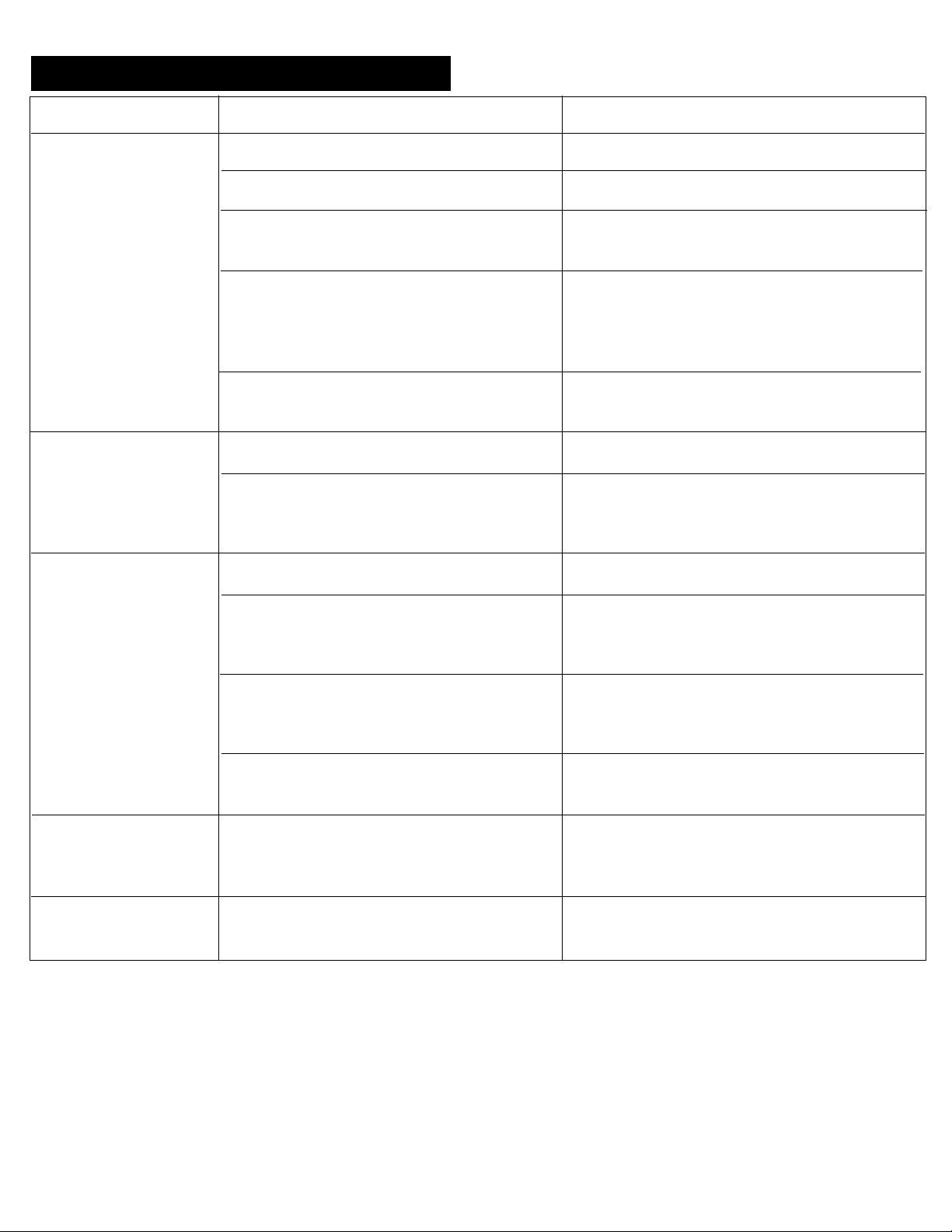

OPERATION OF THE DEADBOLT

FROM THE OUTSIDE:

From the outside the deadbolt can be

locked and unlocked only with the keys

provided for the customer. It can’t be

locked and unlocked with the master key.

To lock (extend) the deadbolt, rotate the

key a little more than 1/4 turn clockwise.

A light click should be felt and heard. The

lock cylinder will have to be returned back

to center to remove the key. To unlock

(retract) the deadbolt, rotate the key a

little more than 1/4 turn counterclockwise.

A slight click should be felt and heard.

The lock cylinder will have to be returned

back to center to remove the key. The

deadbolt must be operated while the door

is shut. If the deadbolt is locked

(extended) while the door is open, it will

not shut.

OPERATION OF THE DEADBOLT

FROM THE INSIDE:

The deadbolt can be locked and unlocked

from the inside by rotation of a red knob

near the paddle. This knob can be rotated

a little more than 1/4 turn clockwise to

lock and a little more than 1/4 turn

counterclockwise to unlock. A designation

is provided on the inside plate to show the

direction to lock and unlock.

LATCHING/UNLATCHING:

The latch uses a single latching position that

is achieved by the engagement of the

plunger in the opening of the strike plate. The

deadbolt engages into this same opening

and if extended, will prevent closing and

opening of the door.

USE OF A MASTER KEY:

If the lock cylinder in the paddle has a letter

stamped on its face, it can be unlocked and

locked with a master key. For example, if it

has a “1R” stamped on its face, a “1R” series

master key will lock and unlock the paddle.

The master key will not lock or unlock the

deadbolt. If there is not a letter stamped on

the face of the paddle lock cylinder, it cannot

be operated with a master key.