TRIMETALS Protect-a-cycle User manual

ASSEMBLY INSTRUCTIONS

issue number: 1, October 6th 2008

2

FOR FASTER ASSEMBLY WE RECOMMEND

THE USE OF AN ELECTRIC SCREWDRIVER

STEP 1

- For ease of assembly we recommend that the base be assembled

on a flat surface and care must be taken to ensure the base is

square before the fasteners are fully tightened. Check squareness by

measuring from corner to diagonal corner - and then repeat for the

other side - the measurements should be the same.

- The product is designed to be bolted down onto a flat and level

concrete base with a recommended thickness of 100mm (4”).

The concrete used must be of a grade offering compatible

resistance to attack.

STEP 2

- From now on all fasteners should be loosely fixed. Do not fully tighten

them until you are told to do so.

- When you see the Red Spanner icon

tighten indicated fasteners.

- All bolts on this page are part 14 and all nuts are part 36.

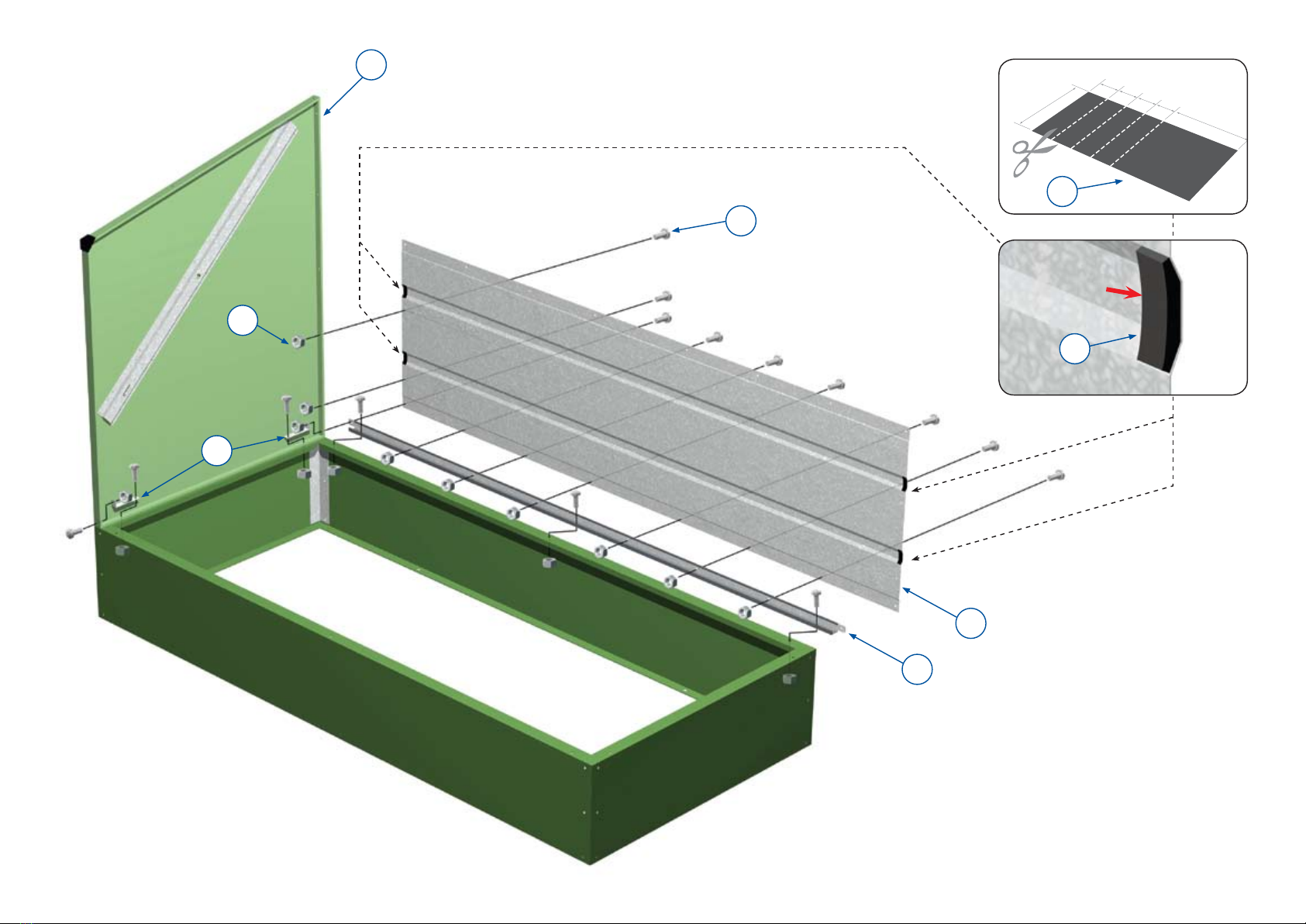

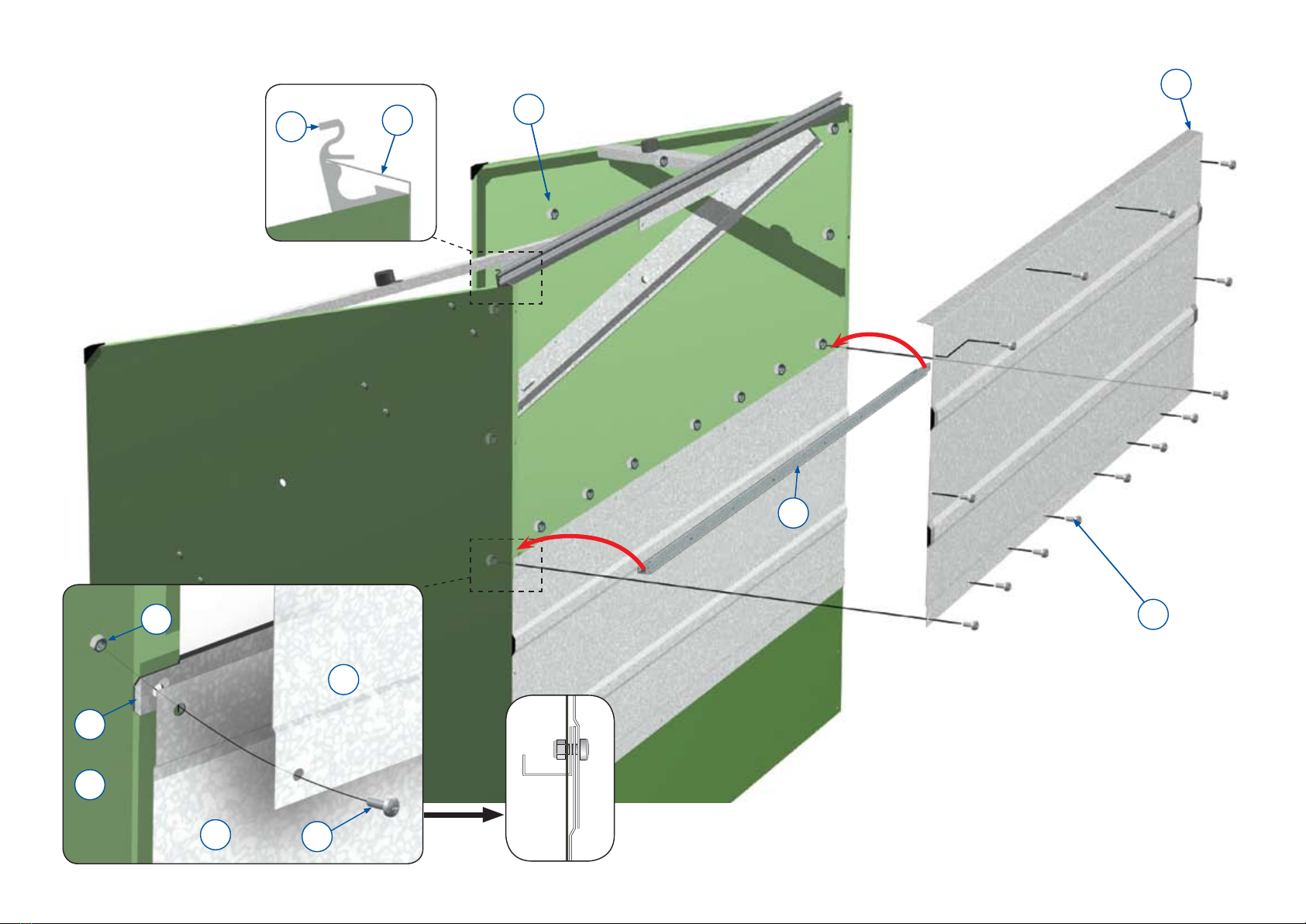

STEP 3

- Remember to only loosely fix the fasteners until you are told

to tighten them.

- Be sure to place part 34 the correct way round - see small

detailed diagram.

STEP 4

- See illustration

STEP 5

- See illustration

STEP 6

- All bolts on this page are part 14 and all nuts are part 36.

- Make sure part 20 (top back panel) is inserted into top rail (part 34)

as illustrated.

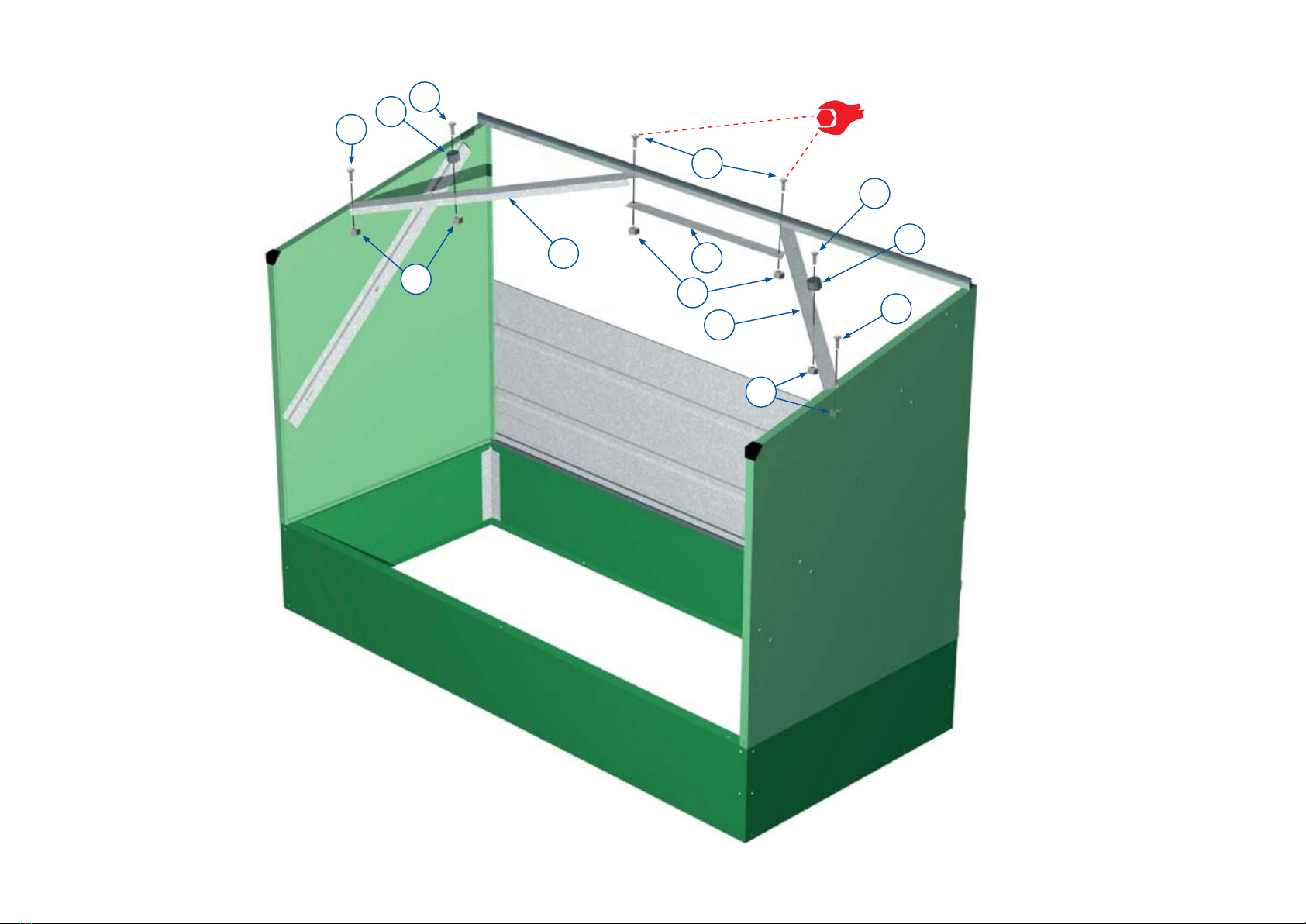

STEP 7

- The left hand link arm part 12L (which is marked by a circle of coloured tape) must be fitted

to the left hand side of the unit as shown in the diagram.

- Identify part 12L and feed one washer (part 13) onto it followed by a link arm bracket (part

11). Push both round until they are on the length of tube that has two holes pierced through

it and so that the raised end of the bracket (part 11) will be facing away from the unit when

attached. Feed the link arm (part 12L) through the hole in the left hand side panel (part 4L)

from the outside and then through the side panel stiffener located on the inside of the side

panel (part 4L) then feed another washer (13) onto the link arm (part 12L) from the inside

and secure the assembly with two clips (part 19) through the two holes provided in the link

arm (12L), one on the outside of the unit and one on the inside. Secure the link arm bracket

(part 11) with parts 14 and 36.

- Repeat the above procedure to attach the right hand link arm (part 12R).

- In stage 7d make sure the hook on part 16 is facing the side panel

(part 4) and do not over tighten the nut (part 35) at any time as the spring lever (part 16)

must move freely.

STEP 8

- Slide part 9 into the top rail (part 34) and secure with the end stop (part 23) and thread

forming screw (part 17).

STEP 9

- Note that part 27 is placed on the back of door panel.

- The torsion bar (part 25) should already be in place at the back of the door.

- Push the left hand link arm (12L) through the hole in the side of the door panel (part 9) and

into the torsion bar (part 25), repeat this on the right hand side and twist the bar to line up

with the holes (either end) in the link arms then screw in the thread forming screws (part 17)

to secure. Do not close the door until these screws are fully tightened.

- Identify the weatherstrip (part 22) and apply to side panels (part 4) along both the top and

front edges. Strip the backing off a little at a time and starting at the top of the side panel

butt the strip up against the top rail (part 34) and stick along the top edge of the side panel

down to the plastic corner moulding. Cut weatherstrip (part 22) and continue from below the

corner moulding down to the front base section. Repeat for the other side.

- Both springs (part 18) are identical; one hooks upwards and the other hooks downwards.

- Note that as fastener packs are standard for all units you may have some fasteners spare

after completion of assembly.

IMPORTANT ATTENTION

A Before commencing assembly

check parts in box with

illustrations on components

page and thoroughly read the

assembly instructions.

B These products must be secured

to a hard concrete base

(see Step 1).

C Extra care should be taken to

avoid cuts and abrasions from

exposed edges during assembly.

We strongly recommend the use

of protective gloves.

D We recommend that two people

work on the assembly.

E Precautions should be taken

when storage units are being

used in exposed areas subject

to high wind speeds. In these

circumstances the products

should be locked and care

should be taken if they are to be

opened to avoid damage.

Please ensure that children are

always supervised when using

this product

F For additional weatherproofing

we recommend the use of a

mastic type sealant that can be

used to create a seal between

panels.

G In the unlikely event that this

product has been delivered

damaged, there are any parts

not included or you are having

difficulties with assembly please

contact Trimetals direct NOT THE

RETAILER. We will endeavour to

correct any problems as quickly

as possible.

HELP LINE:

Tel: +44(0)1258 459441

Fax: +44(0)1258 480408

ASSEMBLY INSTRUCTIONS (to be read in conjunction with illustrations)

3

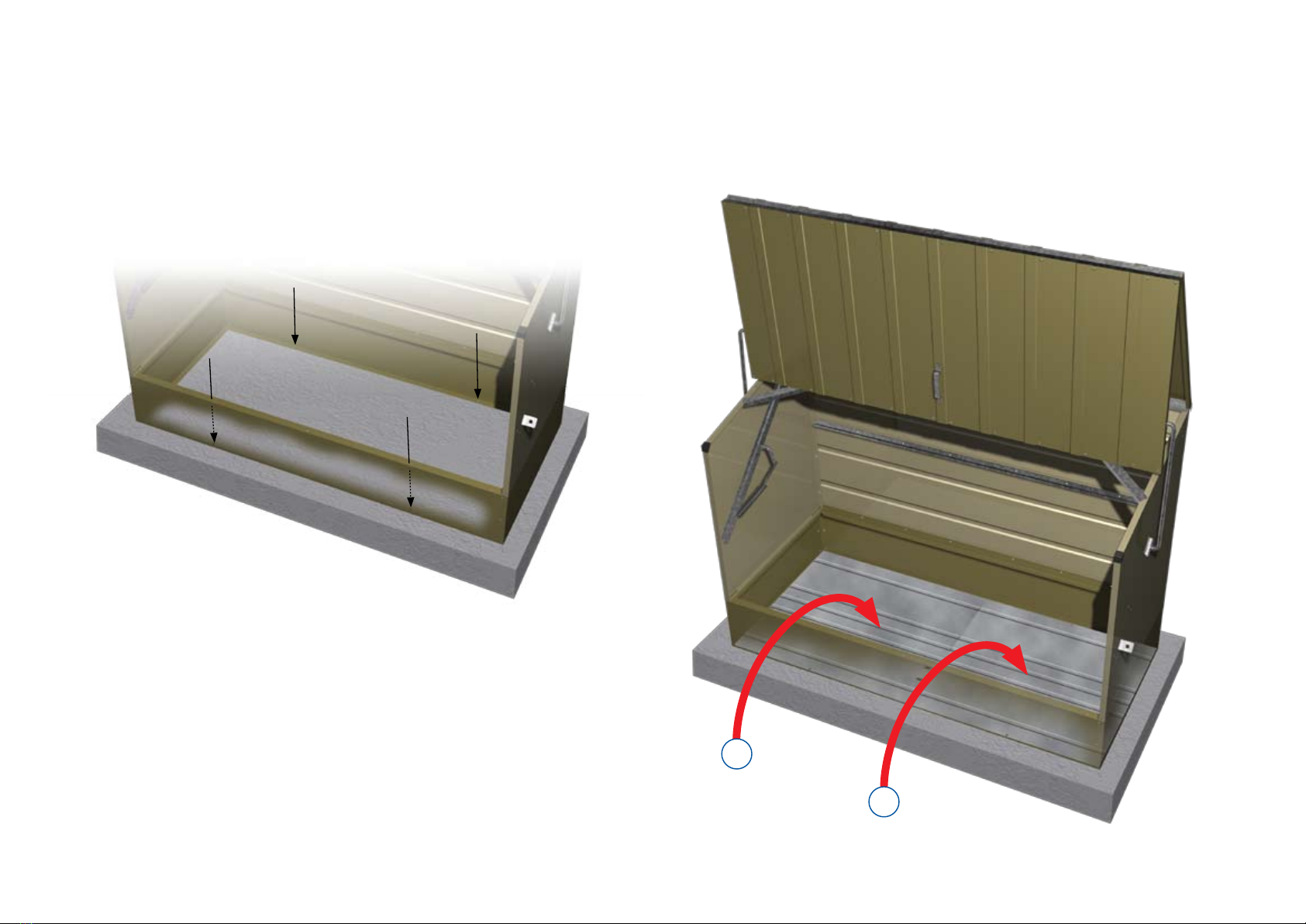

STEP 10

- Completed assembly view

STEP 11

- Move the assembled unit on top of the concrete base (using two people) and use a pencil

to mark the position of the four holes in the product’s base (two holes in each of the long

bases). Carefully move the unit to one side as you will now need to drill the holes you have

marked on the concrete. Firstly drill holes (always wear goggles) with a 10mm ø masonry

drill to a depth of 10mm then re-drill the holes with a 14mm ø masonry drill to a depth

of 70mm. Vacuum the dust from the holes.

- Select the four M8 anchor bolts (these are gold in colour) and unscrew the bolts from

their expanding anchors. Place the bolts (with washers) to one side and then firmly push

the four anchors into the holes you have drilled.

STEP 12

- Carefully move the unit back into place lining up the holes in the base with those you have

drilled. Place the right hand metal base inside the unit as shown (make sure that the two

large holes punched in the metal floor are toward the front of the unit as this is where the

ground anchor will be placed).

- Place the left hand metal base inside the unit (again with the two large holes nearest the

front of the unit) then move both floors so the four holes on the long edges line up with

the holes you have drilled in the concrete (the metal floors will overlap slightly).

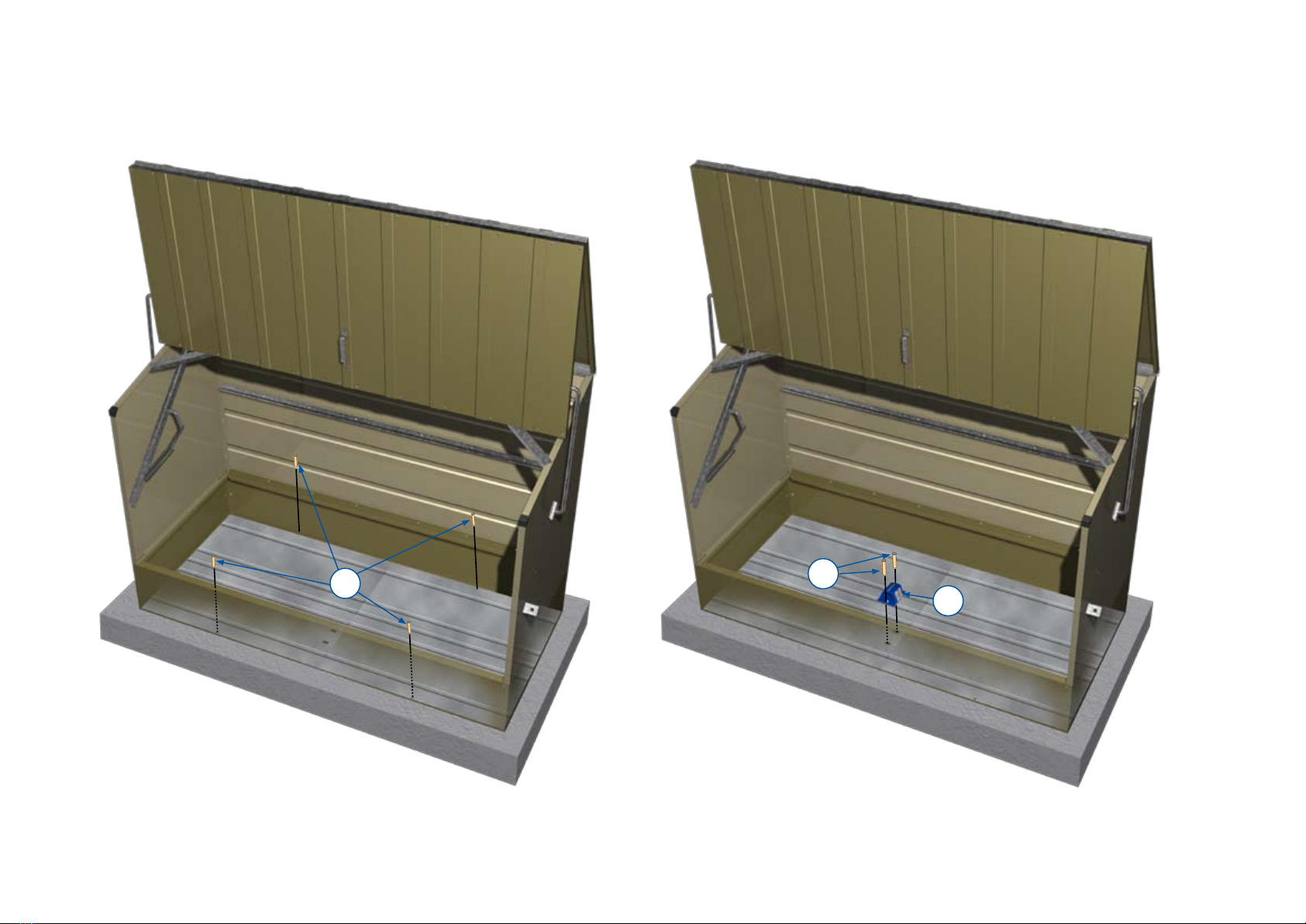

STEP 13

- Select the four M8 bolts (with washers) and place them through the metal floors and

down through the base then screw into the expanding anchors. Using a spanner tighten the

bolts (it is recommended that you tighten each bolt evenly in turn until all are as tight

as possible to ensure the base lays flat).

STEP 14

- You now need to drill through the center of the two large holes in the metal bases (always

wear goggles). Use a 12mm ø masonry drill go down to a depth of 10mm then re-drill

holes using a 16mm ø masonry drill to a depth of 75mm. Vacuum the dust from the holes.

Unscrew the two bolts from the expanding anchors and place the bolts through the ground

anchor then reattach the anchors on the other side by a few turns. Place the ground anchor

over the metal base and align with your drilled holes. Push the two M10 anchor bolts

through the ground anchor into the holes then use the Allen key provided to fully tighten

evenly. Place the steel ball bearings on top of the two socket heads and hammer into place

(this prevents the bolts from being undone).

STEP 15

- The security cable is then used to secure your bike(s) to the ground anchor. Place the cable

through both the frame and wheel of the bike(s) for increased security.

STEP 16

- With the door held open measure in 250mm from the side of the door (on the inside) and

place the hasp centrally on this point. Hold the hasp against the bottom section of the door

(on the inside) and keeping it level mark where the two holes are to be drilled.Remove the

hasp and drill carefully through the part of the section you have marked (with the drill bit

provided). Drill through the section on the back of the door – do not drill

through the door itself.

- Secure the hasp in position using the bolts and locknuts provided as shown above (make

sure you place the backplate in position).

- Close the door and hold the staple against the base. Line the staple up centrally with the

hole in the hasp and mark the four holes. Remove the staple and drill through the base

using these four holes as a guide.

- Secure the staple as shown (make sure you place the backplate in position).

Repeat for other side.

Should you have any problems then please ring our helpline: 01258 459441.

4

12L

12R

4L

4R

6

26

13

23

11

18

10

7b

9

2

30

22

1 x2

2 x2

3 x4

4L x1

4R x1

5 x2

6 x1

7 x2

7a x1

7b x2

8 x2

9 x1

10 x4

11 x2

12L x1

12R x1

13 x4

16 x2

18 x2

19 x4

20 x1

21 x2

22 x2

23 x2

26 x1

27 x1

30 x1

34 x1

Part No

Bike

Store

534

1

7a 7

20

16

21

3

8

35 x28

Tighten

nuts & bolts

33 x2

24 x2

31x26

14x53

17 x4

36 x55

19

27

4 x M8 Rawlbolt

2 x M10 Rawlbolt (in anchor box)

1 x Right hand metal base section

1 x Left hand metal base section

1 x Ground anchor

1 x Cable lock

3 x Padlocks

2 x Hasps (with fasteners)

A

B

C

D

E

F

G

H

Drill bit (for step 16 ONLY)

5

Step1

Bike store

2

1

1

2

3

31

35

6

Step 2

Bike Store

Îx

£ä

£ä

£ä

£ä

Îx

£ä

£ä

£ä

£ä

{ä

10

5

6

14

36

30

30

4L

7

Step 3

Bike Store 14

34

14

14

36

14

7b

36

10

14

4R

7b

36

36

14

34

8

Step 4

Bike Store

14

14

33

8

36 36

14

8

33

7a

36

7

7

9

Îx

£ä

£ä

£ä

£ä

Îx

£ä

£ä

£ä

£ä

{ä

30

Step 5

Bike Store

30

20

20

10

Step 6

Bike Store

36

20

5

14

4R

20

36

14

20

6

34

5

11

12L

14

21

21

36

36

14

12R

Step 7

Bike Store

Step 7b

12L

Step 7a 13

11

Step 7c

19

14

36

4L

4R

12L

Step 7d

16

19 13

24

35

It is critical that the

correct link arm is used

on each side of the unit

- 12L (with the circle of

coloured tape) must be

used on the left side of

the unit as shown.

12

23

17

9

Step 8

Bike Store

13

Step 9

Bike Store

26

35

31

27

25

17

17

18

18

18

16

24

35

24

35

16

9

12R

17

14

Step10

Bike Store

15

Step11

Bike Store

Step12

Bike Store

D

C

16

Step13

Bike Store

Step14

Bike Store

AB

E

17

Step15

Bike Store

Step16

Bike Store

F

G

E

G

18

GUARANTEE

EXCLUSIONS

Trimetals Ltd will not be liable under the Guarantee for:

1.1 Explosion, Fire Lightning, Theft and those other perils normally provided by household contents insurance.

1.2 Accidental damage including scratching, bruising or denting or from the direct application of a tool.

1.3 Mishandling or neglect by the Registration Holder or any member of his family, household or staff or use of the

product not in accordance with the manufacturer’s instructions.

1.4 Failure of the Registration Holder to maintain or service the product in accordance with the manufacturer’s

instructions.

1.5 Spillage of chemicals or hazardous substances causing erosion or discolouration of parts, or storage of items that

are not done in accordance with the manufacturer’s written instructions and normal laid down codes of practice.

1.6 War, Civil War, Hostilities (whether war declared or not), riots, strikes or civil commotion.

1.7 Ionising radiations, the hazardous properties of nuclear material or sonic bangs.

1.8 All fixings and fasteners.

2 Normal wear and tear, the cost of routine maintenance, adjustments or modifications or loss or damage arising

therefrom.

3 Loss of use of the appliance or consequential loss of any nature.

4 The cost of materials and labour charges for which any manufacturer, supplier or any other person may be held

responsible under the terms of the Sale of Goods Act or any Guarantee or Warranty.

5 Cost incurred outside the United Kingdom.

6 If the goods have been signed for as being received in good condition.

CONDITIONS

1 In the event of failure of the product Trimetals Ltd or their agents may at their option repair or replace the defective

part(s) or pay in cash for the cost of repair excluding labour and transport charges. In the event of the product as

a result of failure being deemed beyond economic repair Trimetals Ltd will pay the market value of the product

immediately prior to breakdown.

2 Trimetals Ltd shall in no case be bound to accept notice of any transfer of interest and nothing contained in our

Guarantee shall give any rights against Trimetals Ltd to any other person than the original Registration Holder who

shall be a private individual.

3 At the request of Trimetals Ltd the Registration Holder shall do and concur in doing all such acts and things as

Trimetals Ltd may reasonably require with a view to obtaining compensation for failure covered by this guarantee

and to enforce any rights that the Registration Holder may have against anyone in respect of any failure whether or

not payment has been made by Trimetals Ltd.

4 The Certificate of Registration will be rendered void in the event of the Certificate Holder’s fraud, non-disclosure,

alteration of risk or any attempt threat, or the use of the product other than normal domestic purposes.

5 These conditions in no way affect your statutory rights.

6 Terms and Conditions are governed by English law and you submit to the non-exclusive jurisdiction of the English

Court.

CLAIMS PROCEDURE

In the event of damage contact Trimetals Ltd on +44 (0)1258 459441. Please have the Model and Serial numbers

available when you call plus the details or your registration card and copy of payment receipt. You will then be advised

of the procedure in your area.

19

Trimetals has been established for 40 years and is firmly placed as Europe’s leading

producer of quality metal storage buildings and metal garden sheds.

The unique designs which maximise strength and rigidity are unmatched by any other

manufacturer and our 25 year panel guarantee is your assurance that our range of

buildings are the very best available.

Please do not confuse our products with cheap and flimsy substitutes or plastic

alternatives. Our buildings are strong, secure, fire resistant and maintenance free,

giving you real value for money. We pride ourselves in our reputation for superior

products and are sure you will be completely satisfied with any product in our

extensive range.

www.protectacycle.co.uk

Sunrise Business Park, Higher Shaftesbury Road,

Blandford Forum, Dorset, DT11 8ST. UK

Tel: +44(0)1258 459441

Fax: +44(0)1258 480408

Email: [email protected]

Web: www.trimetals.co.uk

This manual suits for next models

1