Merida Procraft Lenker User manual

Installation and

operating instructions

Cockpit

Thank you for purchasing a

MERIDA component.

About these instructions

Carefully read and follow these installation and

operating instructions before use. Keep these

instructions for future reference.

These instructions are valid for the following

MERIDA components (Fig. an example):

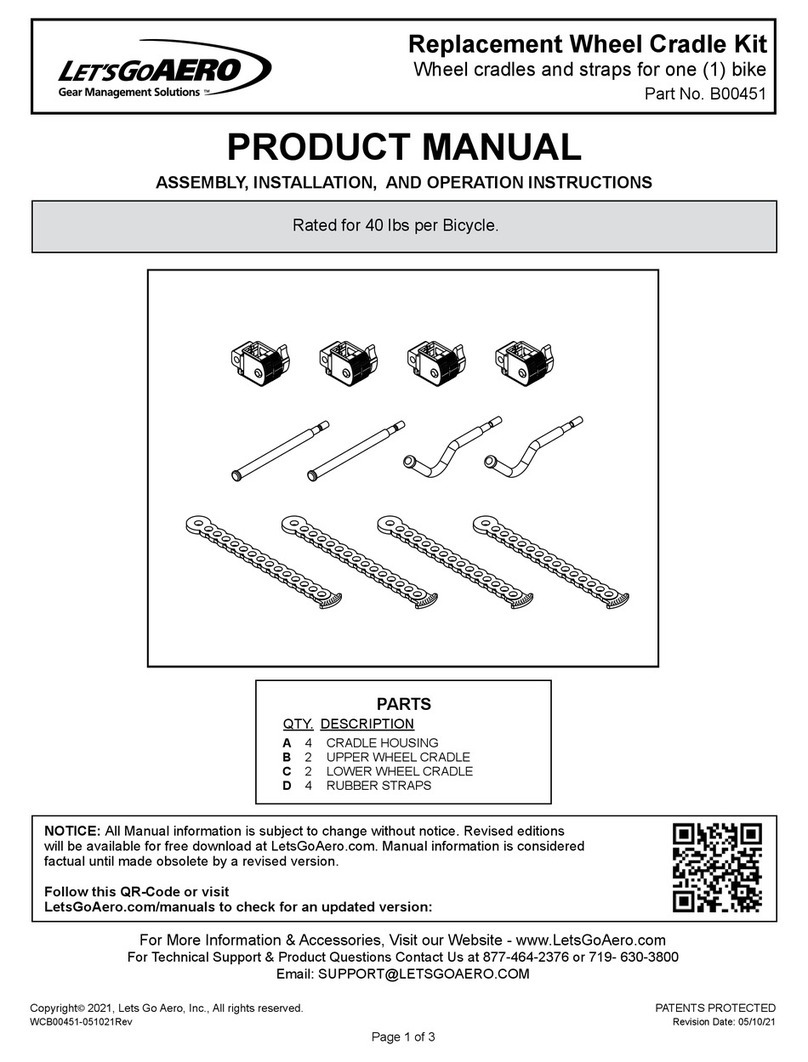

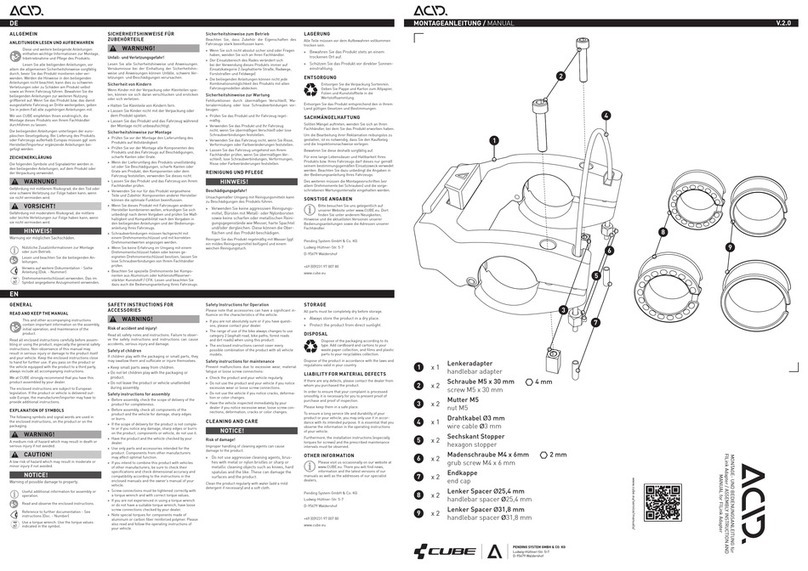

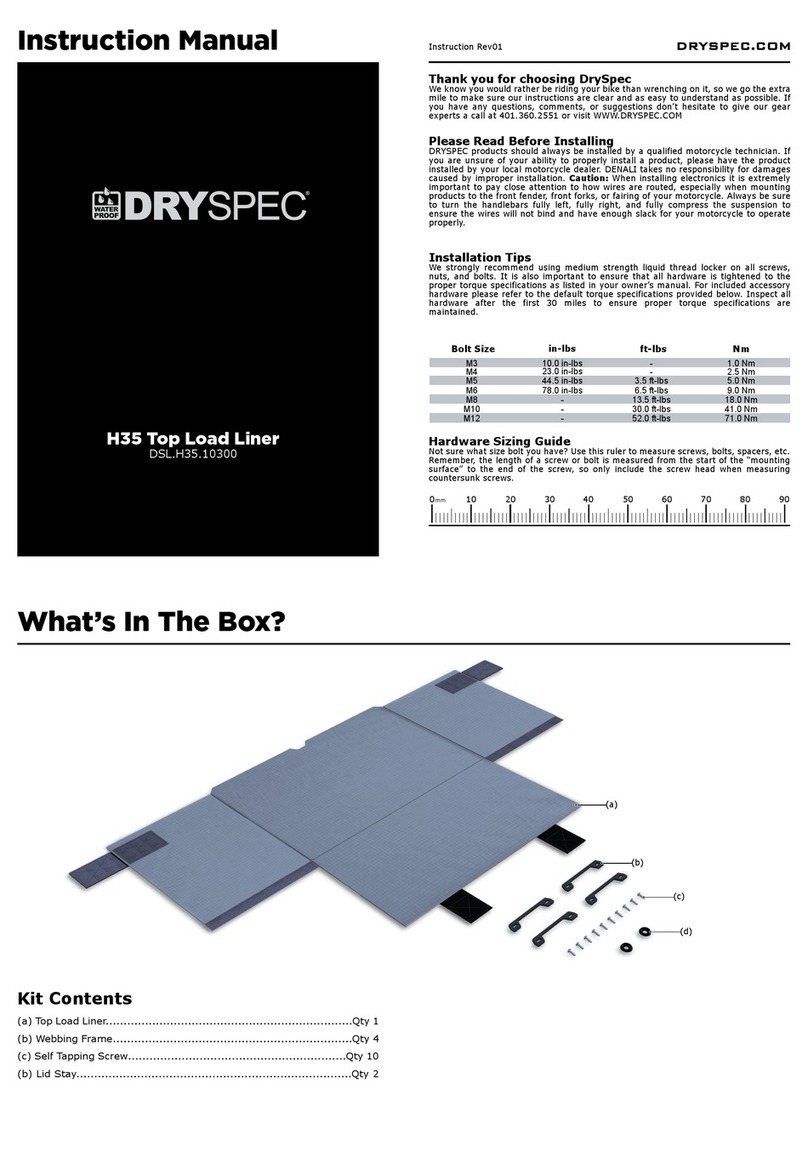

1. Handlebar grips

2. Spacer

3. Ahead stem

4. Bar ends

5. Stem steerer tube

6. Handlebar adjuster

7. Handlebar

8. Headset

Special features

All carbon components require special care and

attention. The material is very durable and has a

low weight. However, the material is also very

brittle. Therefore, have you bicycle inspected by

your dealer following accidents or other incidents.

1. Intended use

The majority of MERIDA components are

designed for use on racing, trekking, and

mountain bikes, and their typical use.

The majority of stems are designed for use

exclusively with threadless fork steerers and so-

called Aheadset®headsets.

Use in combination with threaded fork steerers

can lead to sudden failure, resulting in a crash.

The models with steerer tube are suitable for use

in conventional threaded forks.

Before your first ride

Do not file or drill and holes in the components as

this damages their structure and voids the

warranty.

Adjust your bicycle so that you can reach the

brake levers at all times.

Carbon

After being overstressed, a previously damaged

carbon component may fail with continued use

without warning.

If your MERIDA carbon component has been

exposed to such stress, take your bicycle to your

MERIDA dealer. Damaged carbon components

must never be fixed or repaired! They must be

replaced immediately.

Carbon components must never be exposed to

high temperatures. Therefore, never have them

painted. Avoid storage near to heat sources.

Carbon components have a limited life cycle.

Therefore, replace the handlebars and stems at

regular intervals, as a precaution.

Ensure that clamp areas are absolutely free of

grease and lubricant when a clamping surface is

made of carbon. Use a special carbon assembly

paste for the assembly.

2. General assembly instructions

Only use MERIDA components that are designed

to be used together. MERIDA assumes no

responsibility for the combination of a MERIDA

handlebar with an unsuitable stem, or MERIDA

stems and bar ends with an unsuitable

handlebar.

If you do, however, use components from

another manufactures, use the clamp diameters

found in their manuals to ensure their safe use

with MERIDA components.

Check all clamp areas of the components for

burrs and sharp edges prior to assembly. Ask

your MERIDA dealer to check any components

with such burrs or sharp edges. When you

replace the handlebar, also inspect the old

handlebar for damage.

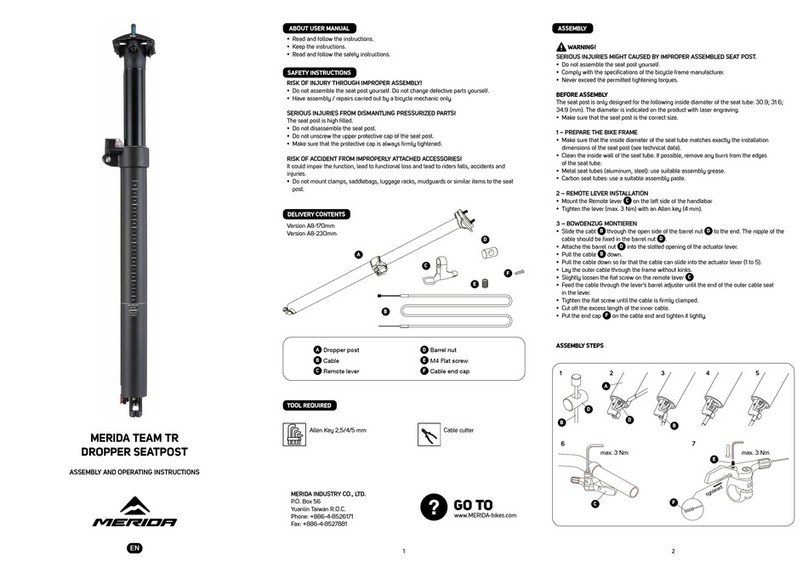

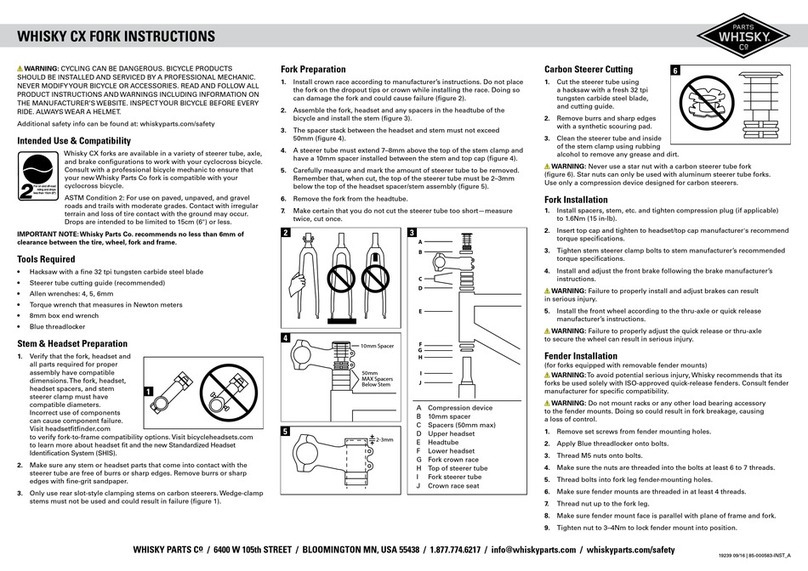

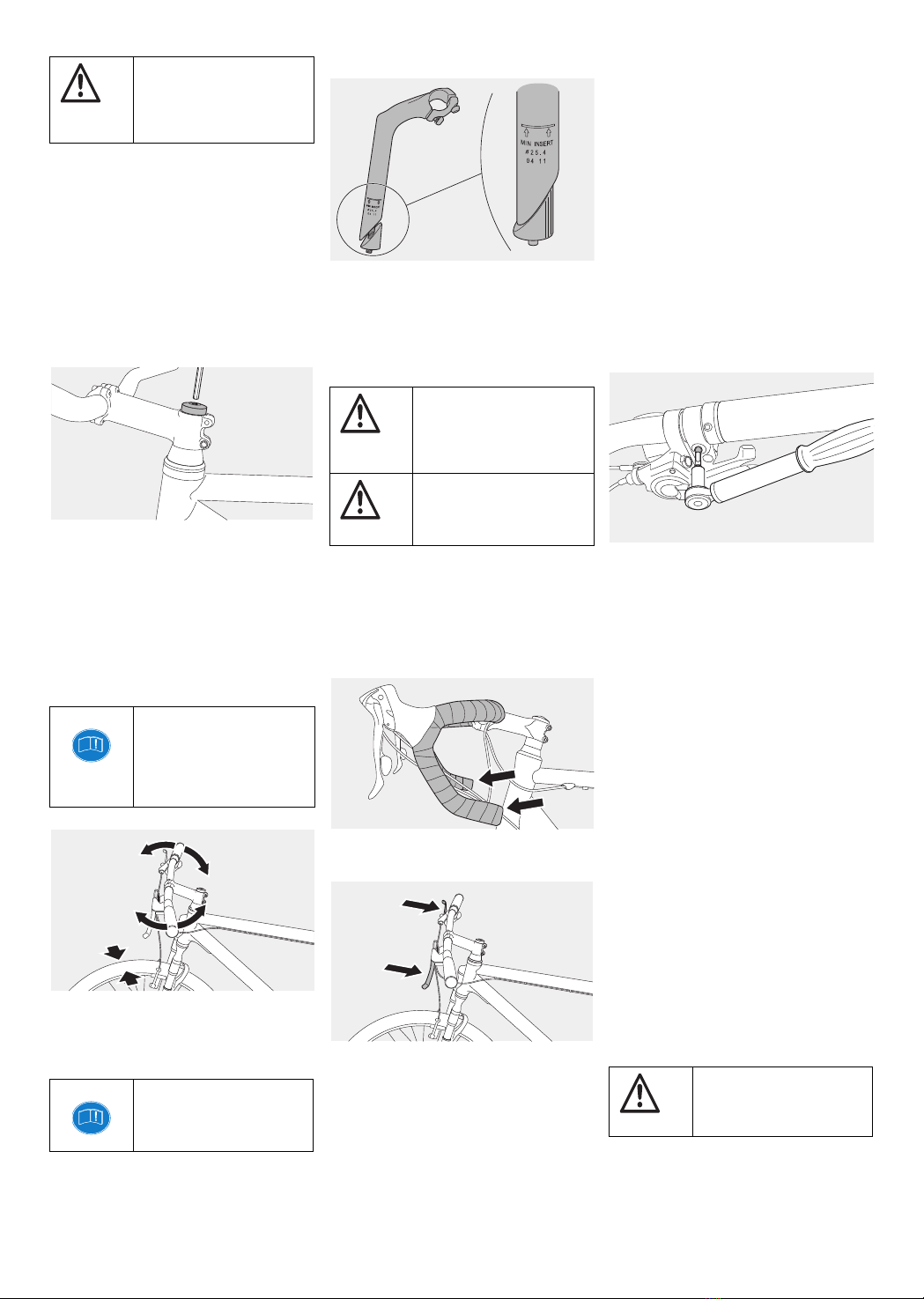

3. Aheadset®stems

Check the clamp diameter.

When using a larger stem, use a suitable

reducing sleeve.

Make sure that the slots of the stem and sleeve

are positions above each other, and that the slot

of the sleeve is facing backward.

If you are replacing the stem on a fork, check the

clamp area for damage. Carbon clamp areas

must be absolutely free of grease.

Use carbon paste on the clamp areas instead.

Lubricate the thread and the head contacts of the

steerer clamping bolts with a high-quality

lubricant. Keep lubricants away from the clamp

areas of the fork and stem. Apply a thin layer of

carbon paste to the fork’s clamp area. Slide the

stem onto the fork.

Depending on the steerer tube length and the

desired stem position, you may have to insert

spacers on the fork steerer above the headset,

and/or on the stem.

Danger

Indicates essential safety

instructions.

Note

Indicates additional

information.

8

6

8

5

4

12

7

3

Note

If you have any questions,

contact your MERIDA dealer.

Danger

Never use bar ends or clip-on/

aero bars with carbon

handlebars, unless the

handlebar is approved for

them.

Danger

Each of the following

instructions must be strictly

observed.

Non-observance of these

instructions may lead to the

failure of the components

and result in an accident.

1

Spacers are available in different heights and

must be stacked so that the steerer tube ends 2–

3 mm below the top edge of the stem. The

maximum height of the installed spacers must not

exceed 40 mm. Observe the fork manufacturer’s

guidelines.

The stem must provide support for a sufficient

length of the steerer tube. This ensures reliable

clamping if the clamping bolts of the steerer tube

are clamped to the prescribed torque value.

3.1. Adjusting the Aheadset®

headset

Open the side clamping bolts of the stem tube.

Adjust the headset by carefully turning the top

sunk screw. The screw is only used for adjusting

the bearing play.

Align the stem with the front wheel so that the

handlebar is not at an angle to the front wheel

when it is pointing straight ahead. Stand over the

top tube and look down over the stem to the front

wheel to check the alignment. Tighten both

clamping bolts alternately. The recommended

tightening torques can be found marked near the

bolt.

The handlebar/stem units must be checked for

resistance to torsion and the torques specified on

the components must be observed when

tightening.

In case of doubt, contact your MERIDA dealer.

4. Conventional stems

Open the stem spindle. Slide the stem tube into

the head tube on the frame.

Pay attention to the maximum extension height.

The stem must not be askew.

For max. torque, refer to the information on the

stem.

If the seat can be twisted, you must tighten the bolt.

5. Mounting the handlebar

The chosen stem must always have the correct

clamp diameter. During mounting, the handlebar

should sit centrally in the handlebar clamp area.

If the handlebar cannot be inserted without the

application of force and there is play between the

two components, contact your MERIDA dealer.

On a road bike, the straight piece of the drops

should be positioned parallel to the ground or

angled slightly downward.

Mountain bike and trekking handlebars are

angled at an ergonomic hand position.

Tighten the greased bolts of the handlebar clamp

a few turns with your fingers. Turn all the bolts

with an Allen key until the upper and lower

clamping slots of the handlebar clamp between

the stem faceplate and stem body are the same

width. Use a torque wrench to alternately and

gradually tighten the bolts to the lower torque

limit. With a 4-bolt faceplate, tighten the bolts

evenly in a cross pattern.

Refer to the information on the stem for the

torque.

Mounting the controls

Examine the clamp areas of the shifter/brake

levers, handlebar/remote levers, and grips (Lock-

On grips) for burrs and sharp edges. Note the

limitation of the handlebar clamp area, if present.

Loosen the clamping bolts as much as possible

before sliding them onto the handlebar. Avoid

rotational movements during assembly. Tighten

the bolts again.

After aligning the controls and grips, tighten the

clamping bolts to the lower limit of the

recommended tightening torque. If the controls or

grips still do not clamp tightly, increase the torque

until you reach the upper torque limit specified by

the component manufacturer. If they can still be

twisted, contact your MERIDA dealer.

6. Adjusting the handlebar height

with Aheadset®

With the Aheadset®system, the stem is part of

the headset system. To adjust the position, the

stem must be dismounted and remounted. If the

stem is changed, the bearing must be

readjusted – see “3.1. Adjusting the Aheadset®

headset” on page 2. The height of the handlebar

can be adjusted by changing the spacers.

Remove the bolt for the bearing preload at the top

of the steerer tube and remove the cap. Loosen

the bolts on the side of the stem and pull the stem

out of the fork. You can now remove the spacers.

Place them back on the steerer tube above the

stem to position the handlebar at the desired

height.

To turn the stem around, the bolts clamping the

handlebar need to be loosened. In the case of

stems with caps, the handlebar can simply be

removed; otherwise, the handlebar controls need

to be dismantled. Turn the stem around and

mount it. Check that the Bowden cables tense

and do not limit the steering angle.

Check the seat of the stem. If the stem twists,

increase the torque to the maximum permitted

torque, or reassemble the stem.

Danger

The space between the top of

the stem and the upper edge of

the steerer tube should not

exceed 2–3 mm.

Note

For forks with carbon steerer

tubes, make sure that there is a

cone mechanism inside as a

counter-bearing for adjusting

the headset.

Note

If the stem cannot be clamped,

the components are not

compatible.

Danger

Never ride a bicycle whose

stem has been pulled out

beyond the maximum

extension height mark.

Danger

Never open the head nut of the

headset bearing. This changes

the bearing play.

Danger

Tighten screws and bolts

correctly.

2

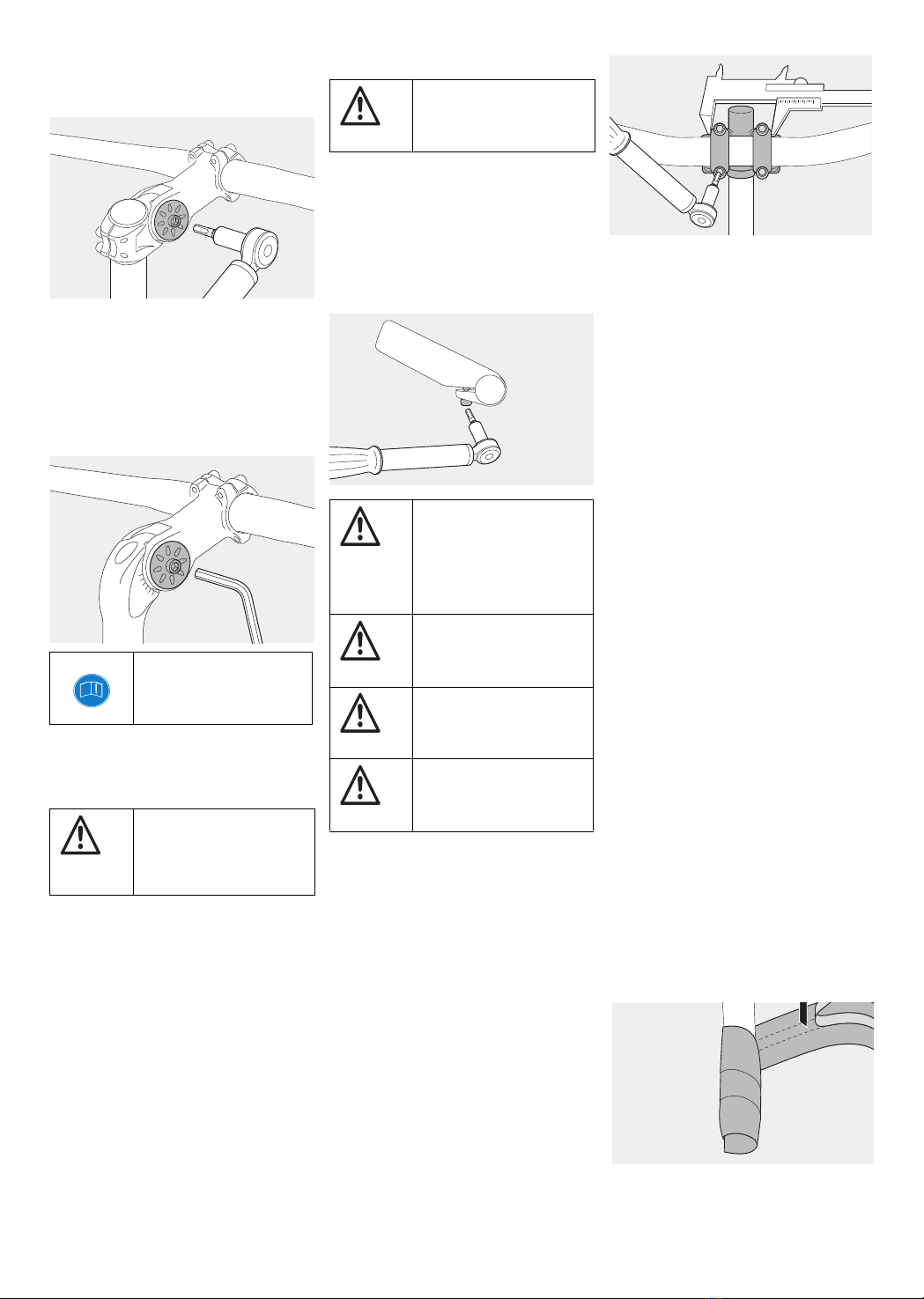

Adjustable Aheadset®stems

With adjustable MERIDA Aheadset®stems, the

height can be varied via the tilt adjustment of the

front stem area.

Loosen the side bolt of the pawl 3–5 turns and

open the steerer tube clamp. Do not remove the

bolt completely. Slide the bolt to the opposite side

of the head. Adjust the movable stem. Slide the

loosened adjusting part back into the stem until

the pawl engages with the teeth of the gear.

Tighten the bolt. For maximum torque, refer to

the information on the component.

Conventional stems

To adjust conventional stems, open the stem

spindle 2–3 turns. With Allen screws, the key

must be inserted into the screw heads. Hit the

tool with a rubber mallet.

Do not put the stem out beyond the marking on

the tube. Align the handlebar again so that it is

not askew when riding straight ahead. Retighten

the stem spindle. For maximum torque, refer to

the information on the component.

Adjustable conventional stems

With adjustable conventional MERIDA stems

with side adjustment bolts, the height can be

varied via the tilt adjustment of the front stem

area.

Loosen the side bolt of the pawl approx. 3–5

turns until the teeth release. Do not unscrew it

completely. Slide the bolt to the opposite side of

the head, and now adjust the stem. Reinsert the

adjusting part until the pawl engages. For

maximum torque, refer to the information on the

component.

With adjustable conventional stems with an

adjustment bolt on the bottom, the tilt is set by

a mechanism on the bottom. The procedure is

similar, but the bolt cannot be removed

completely.

Bar ends

Bar ends offer additional grip options. Ensure that

the handlebar is suitable for use with bar ends

before mounting them.

The clamp areas must be free of burrs.

Loosen the bolts of the brake levers and shifters,

and slide the grips inward over the width of the bar

end cuffs so that they have sufficient clamping

space. Do not use liquids or grease to loosen the

grips. If necessary, use compressed air.

Loosen the bolts on the bottom of the bar ends by

1–2 turns.

Place the bar ends on the ends of the handlebar

and adjust them. Both sides must be at the same

angle.

Tighten the bolts in 0.5 Nm increments. For

maximum torque, refer to the information on the

component.

7. Handlebar adjuster

The handlebar adjuster adjust the angle of the

stem without dismantling the handlebar controls.

Only components with a 25.4 mm clamp may be

combined with a handlebar adjuster with a

25.4 mm clamp diameter. The stem must not be

wider than 50 mm.

Remove the handlebar from the stem – “5.

Mounting the handlebar” on page 2 and mount

the handlebar adjuster so that it sits centrally in

the stem clamp. Only tighten the four screws

enough so that the handlebar turns.

Attach the clamping arms as close to the stem as

possible. The clamping arms can be pushed to a

maximum of 55 mm apart.

After adjusting the angle, secure the clamping

arms with clamping bolts. For maximum torque,

refer to the information on the component.

The handlebar must be positioned in the middle

between the two clamping arms. The brake

levers and shifters must be easy to reach.

Tighten the bolts handlebar clamp until the top

and bottom clamping slots are the same width.

Tighten the bolts alternately to the lower

recommended torque limit. For maximum torque,

refer to the information on the component.

8. Adjusting the inclination of the

handlebar grips and brake levers

Adjust the handlebar so that the wrists are

relaxed and not twisted outward too much.

Adjusting the brake levers is a jobs for a specialist.

Adjusting the handlebar position by twisting the

handlebar

Loosen the hex screw on the stem 1–2 turns.

Turn the handlebar to the desired position. The

handlebar must be clamped in the middle by the

stem. Retighten the bolts to the prescribed torque

value.

To adjust the brake levers and shifters, loosen

the hex screw on the grip binders. Twist the grip

on the handlebar. Sit on the saddle and place a

finger on the brake lever. Your hand must form a

straight line with your lower arm. Retighten the

bolts to the prescribed torque value.

9. Grips and bar tape

Mounting the grips

Keep the grips and bar tape in good condition

and free from grease or the like.

Conventional grips are usually pushed onto the

oil and grease-free handlebars. The easiest way

to mount these grips is with compressed air.

Grips with screw attachments are pushed on and

secured to the handlebar with screws. For

maximum torque, refer to the information on the

component.

Grips with open ends should be sealed with the

included bar plugs.

Wrapping the bar tape

The handlebar must be free of dirt and oil.

Start at the open handlebar end. Allow the tape to

overhang one turn. Wrap the tape diagonally

upward, so that a third of the tape overlaps. Hold

the tape under tension during this process and

Note

Never adjust the heat nut of

the headset bearing when

adjusting the stem.

Danger

Never ride a bicycle whose

stem has been pulled out

beyond the maximum

extension height mark.

Danger

Do not mount or use bar ends

on MERIDA carbon

handlebars.

Danger

If the bar ends do not clamp

properly to the contact

surfaces despite the use of

MERIDA carbon paste, the

components might not be

compatible.

Danger

Components must be

tightened to the specified

torque.

Danger

Clamping bar ends to an

unsuitable handlebar may

result in a break.

Danger

Braking distance increases

when you are riding with your

hands on the bar ends.

3

remove the paper backing from the self-adhesive

side as you go.

Place a single piece of tape on the brake lever so

that the handlebar is completely covered.

Continue wrapping the tape evenly until you

reach the thicker handlebar cuff. Cut the tape

diagonally with scissors for a straight finish.

Secure the tape with the enclosed adhesive strip.

Push the overhanging bar tape into the open end

of the handlebar and close it with a bar plug..

10. Cleaning and care

Clean the components regularly with water and a

soft cloth. For stubborn dirt, use dish soap with

warm water. Do not use harsh cleaning agents

such as thinners.

After the components have dried, you should rub

the metallic surfaces and carbon with hard wax at

least two times per year. Polish the components

once the wax has dried.

11. Maintenance

Check the torque values of all bolts after the first

100–300 km (60–180 miles), and then again

every 2,000 km (1,200 miles).

12. Warranty and guarantee

Statutory warranty rights apply within the first two

years. This regulation only applies in states that

have ratified the EU bill. Bar tape and grips are

subject to natural wear, depending on use and

external conditions.

We also grant a manufacturer’s guarantee on all

MERIDA components, except grips and bar tape,

(from the date of purchase, to the first purchaser)

of 5 years on material and workmanship.

Should any defects occurs, contact your

MERIDA dealer. In a guarantee case where the

respective higher-quality model is unavailable,

MERIDA INDUSTRY CO., LTD. reserves the

right to deliver the respective current successor

model in the available color.

Assembly and/or conversion costs and any

accessories will not be refunded in a guarantee

case.

The manufacturer guarantee is only valid for the

first purchaser upon presentation of proof of

purchase with the purchase date, dealer

address, and model name.

The intended use is a prerequisite for the

guarantee. The guarantee does not cover labor

and transportation costs, or any follow-up costs

caused by defects.

Competition use in the context of road races,

triathlon, or the MTB sections of cross-country

races are covered by the guarantee.

Other visible fall damage resulting from jumps or

other types of overstress is likewise not covered

by the guarantee. The guarantee does not cover

damage caused by wear, neglect, crashes,

overstressing caused by overloading, improper

installation and care, or the modification of

components.

In the interest of a long life and durability of the

components, the manufacturer’s installation

instructions and the prescribed maintenance

intervals must be adhered to exactly. Failure to

comply with the installation instructions and

inspection intervals will void the guarantee.

Handlebar grips and tape wear during use.

Regular cleaning and care have a positive impact

on wear.

13. Technical specifications

Handlebar

Clamp area cuff

MTB, Cruiser, Traveller: 25.4 mm

Road bike: 26.0 mm

Oversized road bike and

MTB: 31.8 mm

Handlebar clamp max.

torque:

2-bolt stem: 8 Nm

4-bolt stem: 6 Nm

Bar ends

Clamp area: 22.2 mm

Torque: 6–8 Nm

Aheadset®stem

Handlebar clamp area:

MTB, Cruiser, Traveller: 25.4 mm

Road bike: 26.0 mm

Oversized road bike and

MTB: 31.8 mm

Steerer tube clamp area: 28.58 ± 0.05 mm

Torque:

Steerer tube clamp: 5–7 Nm

Handle bar clamp

2-bolt stem: 6–8 Nm

4-bolt stem: 5–6 Nm

Conventional stem

Handlebar clamp area: 25.4 mm

Steerer tube

internal diameter 25.4 mm

Handlebar clamp torque:

2-bolt: 15 Nm

Steerer tube clamp:: 20–22 Nm

Adjustment bolt adjustable

conventional stems: 10 Nm

Handlebar adjuster

Handlebar clamp area: 25.4 mm

Stem clamp area: 25.4 mm

Handlebar clamp: 8–10 Nm

Stem clamp: 8–10 Nm

Reducing sleeves

Handlebar clamp diameter:

from 31.8 mm to 26.0 mm

from 31.8 mm to 25.4 mm

Tube diameter:

from 28.6 mm to 25.4 mm (1 1/8” to 1”)

Spacer

For 1 1/8”

Available in heights of 2, 3, 5, 10 and 15 mm

Handlebar grips, Screw-on model

Torque: 2–3 Nm

Note

When cleaning, pay attention

to any damage to the

materials.

Note

If there is any doubt, always

adhere to the values specified

on the component.

If you have any questions, please contact:

MERIDA INDUSTRY CO., LTD.

P.O. Box 56

Yuanlin Taiwan R.O.C.

Phone: +886-4-8526171

Fax: +886-4-8527881

www.merida-bikes.com

5th Edition, February 2017

© No part of this document may be reprinted,

translated, reproduced, or otherwise used, e.g.

on electronic media without prior written consent.

Graphics, text, and design

2W Technische Informations GmbH & Co.KG

www.2wgmbh.de

4

Table of contents

Other Merida Bicycle Accessories manuals