Triminator Rosin TRP stack User manual

®

RosinTRPstack

OWNER'S MANUAL

V 1.4

CONTENTS

INTRODUCTION............................................................... 2

SAFETY MESSAGES ....................................................2

ROSIN PRESS SAFETY ................................................... 3

IMPORTANT SAFETY INFORMATION .........................3

SAFETY LABEL LOCATIONS........................................... 4

CONTROLS AND COMPONENTS.................................... 5

STARTING THE ROSIN PRESS ....................................... 7

ROSIN PRESS OPERATION ............................................ 8

PID TROUBLESHOOTING................................................ 9

LIMITED WARRANTY...................................................13

EXCLUSIONS FROM WARRANTY COVERAGE ...........14

CUSTOMER SERVICE................................................ 14

INTRODUCTION

Congratulations on your selection of the Triminator Rosin TRP Stack! We want to help you to get

the best results from your new press and to operate it safely. This manual contains the informa-

tion on how to do that; please read it carefully before you set up and use your rosin press.

We suggest you read the LIMITED WARRANTY (page 13) to fully understand coverage and your

responsiilities of ownership. Keep this owner’s manual handy, so you can refer to it at any time.

This owner’s manual is considered a permanent part of the rosin press and should remain with

the press if resold. The information and specifications included in this publication are those that

were in eect at the time of approval for printing. Mosman Machinery Company, Inc. reserves

the right, however, to discontinue or change specifications or design at any time without notice

and without incurring any obligation whatsoever. No part of this publication may be reproduced

without written permission.

SAFETY MESSAGES

Your safety and the safety of others are very important. We have provided important safety

messages in this manual and on the Triminator. This information alerts you to potential hazards

that could hurt you or others. Please read these messages carefully. Of course, it is not practical

or possible to warn you about all the hazards associated with operating or maintaining a hydrau-

lic press. You must use your own good judgment.

You will find important safety information in a variety of forms:

Safety Labels - located on the rosin press.

Instructions - how to use this rosin press correctly and safely.

Safety Messages - preceded by a safety alert.

A symbol and one of two signal words: DANGER, CAUTION. These signal words mean:

Each message tells you what the hazard is, what can happen, and what you can do to avoid inju-

ry.

Damage Prevention Messages - You will also see other important messages that are preceded by

the word NOTICE. This word means:

2

DANGER

!CAUTION

You WILL be KILLED or SERIOUSLY HURT

if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if

you don’t follow instructions.

NOTICE Your rosin press or other property can be dam-

aged if you don’t follow instructions.

ROSIN PRESS SAFETY

IMPORTANT SAFETY INFORMATION

Triminator rosin presses are designed to extract essential elements from plants containing resin

glands utilizing heat and pressure and from a variety of herbal material. Other uses could result

in injury to the operator or damage to the rosin press and or other property. Injuries and prop-

erty damage arising from the use of the Triminator rosin press can be prevented by following

all instructions in this manual and on the rosin press. The most common hazards are discussed

below, along with the best way to protect yourself and others.

OPERATE ON FLAT SURFACE

To avoid overturning, only operate the rosin press on flat, hard, durable surfaces. Preferably at

table height or higher for best access and operator visibility. Press is heavy and must be posi-

tioned on a flat surface so as to prevent any accidental upset or tip-over.

AVOID CONTACT WITH HEAT PLATENS

Heat platens can operate at temperatures up to 225 degrees fahrenheit. Prolonged contact can

cause serious burns. Note red indicator light on power button indicating power ON and platens

hot.

TURN ELECTRIC POWER OFF AND UNPLUG WHEN NOT OPERATING THE ROSIN PRESS

If you need to leave the rosin press for any reason, always turn electric power o.

MANUAL HYDRAULIC PUMP

Do not place fingers or other body parts in area between heat platens when hand pumping hy-

draulic pump. Pinching or crushing injuries could result.

AIR OR ELECTRIC HYDRAULIC POWER OPTIONS

Do not place fingers or other body parts in area between heat platens.

Keep BOTH hands on power unit contols at all times when hydraulicly closing press platens.

All rosin press loading and closing functions are to be activated by a single person operator ONLY.

OPERATOR RESPONSIBILITY

Know how to stop and reverse press action immediately in case of emergency. Understand the

use of all rosin press controls. Never permit anyone to operate the rosin press without proper

instruction. Do not let children operate the rosin press.

3

3

SAFETY LABEL LOCATIONS

4

The labels shown here contain important safety information. Please read them carefully.

These labels are considered a permanent part of your rosin press. If a label comes o or be-

comes hard to read, promptly contact your authorized Triminator dealer for a replacement.

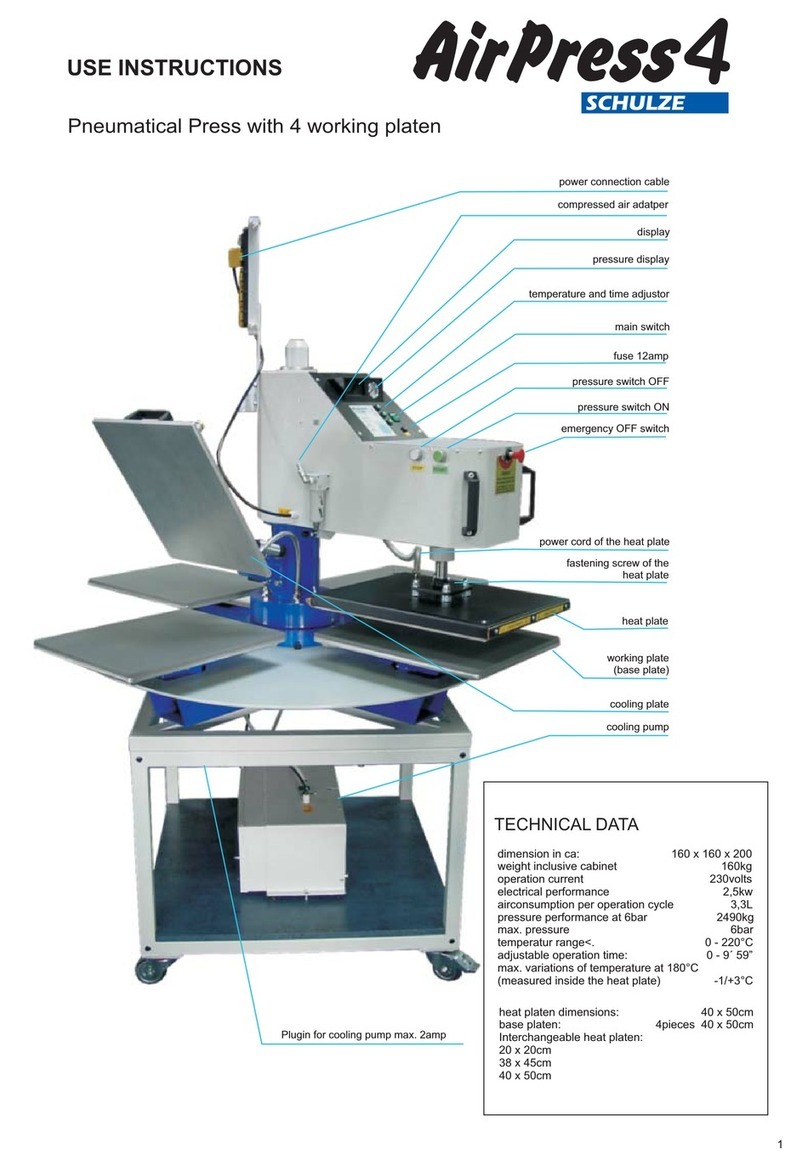

CONTROLS AND COMPONENTS

PID Temperature Gauge

Controls temp for each

platen.

Power Button

Aluminum Platens

6 inch by 10 inch with two

heating elements per plat-

en.

Hydraulic Cylinder

Steel Frame

Cast in NorCal.

Drip Tech Handle

Pull down & up to

operate.

Hose Interface

Connect pump to hy-

draulic cylinder with

hose interface.

Drip Tech Pivot

See graphic at

bottom of page

Drip Tech Pivot

View of machine piv-

oted to allow rosin to

fall below.

5

BEFORE OPERATION

Read and understand this manual. Know what the controls do and how to operate them.

Familiarize yourself with the rosin press and its operation before you begin using it. Know

how to quickly shut o the machine in case of an emergency.

Your safety is your responsibility.

IS YOUR ROSIN PRESS READY FOR OPERATION?

For your safety, and to maximize the service life of your equipment, it is very important to

take a few moments each time before you operate the press to check its condition. Be sure

to take care of any problem you find before you operate the rosin press.

Improperly maintaining this rosin press, or failing to correct a problem before operation,

could cause a malfunction which could cause you to be seriously injured.

Always perform a pre-operation inspection before each operation, and correct any problem.

Before beginning your pre-operation checks, be sure the rosin press is on a level surface,

the power button is in the OFF position, and power cord is unplugged.

CHECK THE GENERAL CONDITION OF THE ROSIN PRESS

Check each control for proper operation.

Check parts for wear. Replace if necessary.

Check that all nuts, bolts, and clamps are tightened appropriately.

OPERATING THE DRIP TECH PIVOT SYSTEM

To operate the Easy Pivot Drip Tech system, pull down the on the Drip Tech handle on the

top of the machine.

CONTROLS AND COMPONENTS (CONT)

65

STARTING THE ROSIN PRESS

7

CONNECT POWER CORD

Connect the Rosin Press power cord to a 20A 120V AC circuit. Optional air or electric power

units may be plugged in to the same outlet. Do not connect and disconnect the power cord

with wet hands. Do not operate in the rain.

NOTICE

Rosin Press machine alone draws approximately 15 amps. With optional electric power

unit, total current draw will be approximately 30 amps.

ATTACH HYDRAULIC PUMP UNIT

Connect hose from manual, air, or electric hydraulic pump to Rosin Press cylinder. Engage

hose fitting by pushing into mating cylinder and turning locking ring to secure.

STARTING THE ROSIN PRESS

Push power putton in. Button will illuminate in red color indicating power on condition.

Heat platens will take up to 15 minutes to heat and stabilize at desired temperature. When

starting the rosin press the temperature may overshoot programed temperature before

stabilizing.

STOPPING THE ROSIN PRESS

To turn o Rosin Press, push power button in, release, red light will stop, and power will be

in o mode.

DISCONNECT POWER CORDS

Unplug Rosin Press cord from power outlet. Unplug optional air or electric hydraulic power

unit from AC outlet.

COOL DOWN

Allow sucient time in power o mode for Rosin Press to cool before attempting to move

machine.

NOTICE: Be sure to hold the plug when disconnecting the power cord from the electrical

outlet. Do not disconnect by pulling on the power cord.

7

ROSIN PRESS OPERATION

8

Program optimal press platen temperature into temperaure control (PID) units. Typically

press operation will be between 195 to 220 degrees fahrenheit.

To adjust set value temperature on PID control push and hold up arrow button for three

seconds.

Wait at least 15 minutes after Rosin Press starts for press platens to reach desired and

stable temperature. Note that some slight fluctuation is normal.

Insert prefilled filter bag packet(s) and PTFE catchment paper between press platens. To

optimze press performance, position bags close to center of press platen surface. Multiple

small bags may be used.

Close press platens by activating hydraulic pump, either by hand unit or with power pump

options. Pressure gauge on pump will read approximately 500 psi. Wait until liquid can be

seen forming along packet edges, then slowly increase pump pressure to 7000 psi. Com-

bination of heat and intense prssure will push out all liquid rosin material from filter bag

packets.

Maximum recommended pressure as viewed on pump gauge is 7000 psi.. Approximately

20 Tons at press platens.

When all rosin has been extracted, release pump pressure. Platens will return to open posi-

tion. Remove spent filter bag packet and catchment paper, reload with fresh material, and

repeat press operation.

When filter bag packet and catchment paper have cooled suciently, dried rosin material

may be removed.

Increase temperature

Press and hold the up button for 3 seconds. At desired

temp, press the set button.

Decrease temperature

Hold the up arrow for 3 seconds. Then, press the down

arrow until the desired temp is shown. Press the set

button.

Check current temperature setting

Press the up button and the set temp will show. Press

the set button, and the current temp will show again.

PID TROUBLESHOOTING

Your press has a PID controller on it, it has a temperature sensor and two heating cartridg-

es per platen. These elements communicate with each other in a permanent closed loop

controlled by a microcomputer.

Your PIDs come preset with standard operational parameters however some users may

want to adjust or fine tune the PIDs further. For this reason we have included the following

guide for advanced troubleshooting.

PID Standard Operational Parameters

The below graphic shows the pre-set advanced settings menu and general setting menu on

the Rosin TRP Stack.

9

PID TROUBLESHOOTING (CONT)

Troubleshooting the PID

If you find a platen or platens are not functioning properly, you may wish to reset the PID.

Some of the most common issues people may have are below.

Press Doesn’t Reach the Preset Temperature

A press that doesn’t reach the preset temperature usually has the PID parameters set up

incorrectly. Verify “standard operational parameters” on page 9. Go through all the settings

and verify that they match. If they don’t match, write down the current PID parameters. To

reset parameters, follow steps on page 11 & 12.

Temperature Gun Shows a Dierent Temperature

Temperature guns can be highly inaccurate when reading temperatures in reflective surfac-

es or at an angle. We suggest an actual thermometer and some kind of lubricant between

the tip of the reader and the specific surface area for which you want to read the tempera-

ture.

If you want to use a temperature gun, you should paint a black spot on the surface of the

platen with some kind of permanent marker, and take the reading as close as possible to

that spot, and perpendicular to the surface.

When it’s determined that a reset is necessary, the following is a guide showing how to

properly reset a single PID. You will need to repeat the steps for each PID that needs to be

reset.

10

PID TROUBLESHOOTING (CONT)

Unlock General Settings PID Menu 1

»Push SET button and hold for 3 seconds.

»Push SET button to advance through settings until you get to the screen Loc.

»Push UP to increase number or DOWN arrow to decrease number until you get to

the number 0, then push SET button again until you get to the main screen or allow

the screen to timeout to return to the main screen.

Unlock General Settings PID Menu 2

»Push SET button and UP arrow and hold for 3 seconds.

»Push SET button to advance through settings until you get to the screen Loc.

»Push UP to increase number or DOWN arrow to decrease number until you get to

the number 0, then push SET button again until you get to the main screen or allow

the screen to timeout to return to the main screen.

Now the PID is unlocked and the parameters can be reset.

Reset the General Settings PID Parameters to Default Values Menu 1

The following settings have been optimized by Triminator engineers to provide the best

platen performance. Refer to the PID Manufacturing Settings graph. Follow these settings

exactly.

»Push SET button and hold for 3 seconds.

»Push SET button to advance through settings.

»Push UP to increase number or DOWN arrow to decrease number until you get to

the desired value. Enter the setting based on the numbers provided in the PID Man-

ufacturing Settings graph.

»Push SET button again and continue setting all the values.

For P, I, D, the settings are dependent on top, middle or bottom platen.

Use chart numbers shown in the graphic below to set the platens.

11

»Once all values have been set, push SET button

again until you get to the main screen or allow

the screen to timeout to return to the main

screen.

PID TROUBLESHOOTING (CONT)

Once you have your PID parameters set. Lock your PID Menu to prevent any changes.

Relock General Settings PID Menu 1

»Push SET button and hold for 3 seconds.

»Push SET button to advance through settings until you get to the screen Loc.

»Push UP to increase number or DOWN arrow to decrease number until you get to

the number 1, then push SET button again until you get to the main screen or allow

the screen to timeout to return to the main screen.

Relock General Settings PID Menu 2

»Push SET button and UP arrow and hold for 3 seconds.

»Push SET button to advance through settings until you get to the screen Loc.

»Push UP to increase number or DOWN arrow to decrease number until you get to

the number 0, then push SET button again until you get to the main screen or allow

the screen to timeout to return to the main screen.

Now the parameters are locked which will prevent any accidental changes.

Setting Maximum Platen Temperature

If you prefer to set a maximum platen temperature, you’ll need to unlock the General Set-

tings PID Menu 1 and 2 before following the steps below.

»Push SET button and UP arrow and hold for 3 seconds.

»Push SET button to advance through settings until you get to the screen d1H.

»Push UP to increase number or DOWN arrow to decrease number until you get to

the maximum temperature, then push SET button again until you get to the main

screen or allow the screen to timeout to return to the main screen.

12

LIMITED WARRANTY

13

TRIMINATOR EQUIPMENT

This warranty is limited to the Triminator Machine distributed by Mosman Machinery Com-

pany, Inc., Nevada City, California 95959. The following warranty applies to all Triminator

products purchased directly or from retail outlets after January 1, 2013.

LENGTH OF WARRANTY

All Triminator products are covered under this warranty for a length of 24 months from the

date of original purchase.

TO QUALIFY FOR THIS WARRANTY:

The product must be purchased in the United States, directly from Mosman Machinery

Company, Inc. or from a dealer authorized by Mosman Machinery Company, Inc. to sell

those products. This warranty applies to the first retail purchaser during the applicable

warranty time period.

WHAT WILL BE REPAIRED OR REPLACED UNDER WARRANTY:

Mosman Machinery Company, Inc. will repair or replace, at its option, any part that is

proven to be defective in material or workmanship under normal use and proper mainte-

nance as prescribed in this Manual during the applicable warranty time period. Warranty

repairs and replacements will be made without charge for parts or labor. Any part replaced

under warranty becomes the property of Mosman Machinery Company, Inc. All new parts

replaced under warranty will be considered as part of the original product, and any warranty

on those parts will expire coincident with the original product warranty.

TO OBTAIN WARRANTY SERVICE:

You must call Triminator/Mosman Machinery Company, Inc. to discuss the warranty issue.

Phone: 530.265.4277

Following the qualifying phone conversation Mosman Machinery Company, Inc. may direct

you to do one of the following:

At your expense, take the Triminator product, part to be replaced, or the equipment on

which the part to be replaced is installed, and a proof of purchase to the Triminator deal-

er from whom you originally purchased the product, during the dealer’s normal business

hours.

Alternatively, Mosman Machinery Company, Inc. may direct you in writing (email) to deliver

your product to a dierent location at a distance less than or equal to the distance from

your current location to the dealer from which you originally purchased the product.

LIMITED WARRANTY (CONT)

14

EXCLUSIONS FROM WARRANTY COVERAGE

The following items and conditions are excluded from warranty coverage:

Any damage or deterioration resulting from the following:

»Neglect of the periodic maintenance as specified in this manual.

»Improper repair or maintenance.

»The use of non-genuine Triminator parts and/or products other than those approved

by Mosman Machinery Company, Inc.

»Exposure of the product to chemical agents, sea water, sea breeze, salt or other

damaging environmental phenomena.

»Collision, deterioration, neglect, unauthorized alteration, misuse, incorporation or

use of unsuitable attachments, products or parts.

»Natural wear and tear (natural fading of painted or plated surfaces, sheet peeling

and other natural deterioration).

Consumable parts: Mosman Machinery Company, Inc. does not warrant parts that deterio-

rate due to natural wear and tear.

Cleaning, adjustment, and normal periodic maintenance work (lubrication, blade sharpen-

ing, belt adjustments).

Any product that has ever been declared a total loss or sold for salvage by a financial insti-

tution or insurer.

DISCLAIMER OF CONSEQUENTIAL DAMAGE AND LIMITATION OF IMPLIED

WARRANTIES:

Mosman Machinery Company, Inc. disclaims any responsibility for loss of time or use of the

product, transportation costs, commercial loss, or any other incidental or consequential

damage. Any implied warranties are limited to the duration of this written limited warran-

ty. This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

CUSTOMER SERVICE

For all customer service inquiries or to help you diagnose any issues with your machine

contact Triminator directly:

Phone: 530.265.4277

Email: support@thetriminator.com

Web: www.theTriminator.com

Table of contents

Other Triminator Power Tools manuals

Popular Power Tools manuals by other brands

Bosch

Bosch GDR 10,8-LI Professional Original instructions

Ingersoll-Rand

Ingersoll-Rand LA428-EU Product information

Dynapac

Dynapac LH800 operation & maintenance

Staubli

Staubli M-PZ-T2600 operating instructions

Garden Gear

Garden Gear D2939 instruction manual

Chicago Electric

Chicago Electric 67632 Set up and operating instructions