Trimm Technologies UR8J2-4 Series User manual

Part Number 8519184-0000 Rev: B

Installation Guide

for

UltraRAIDFamily

UR8J2-4xxx – Ultra Rack

SCSI-3 Ultra 2 (Low Voltage Differential – LVD)

UT8J2-4xxx – Ultra Tower

SCSI-3 Ultra 2 (Low Voltage Differential – LVD)

Part Number 8519184-0000 Rev: B

Page iPart Number 8519184-0000 Rev: B

Table of Contents: UltraRAID Family

Text:

Description Page

General Information: ………………………………………………………......1

Description: …………………………………………………………………......1

First – Unpack, Inspect and Check: ……………………………………….......1

Specifications: ………………………………………………………………......2

Dimensions: ………………………………………………………………......2

Power Supply: ……………………………………………………………......2

Cooling: …………………………………………………………………........2

Environment: …………………………………………………………….......2

Drive Type(s) Supported: ………………………………………………..…......3

Host Connection(s): ………………………………………………………….....3

Convert 2 x 4 Configuration to a 1 x 8 or vice versa: ..................................4

Installation Sequence: ……………………………………………………….....5

Mount Enclosure into Rack: ……………………………………………......5

Install Feet (Tower Enclosure only) ……………………………………......5

Install/Remove End Caps (Rack-mount Enclosure only) ……………........6

Drives into Canister: …………………………………………………….......6

Canister into Enclosure: ………………………………………………….....7

Power Supply Install/Remove: …………………………………………...........7

Fan (Auxiliary Blower) Install/Remove: ………………………………...........8

Electronic Circuit Boards: ………………………………………………..........8

Field Replacement Units (FRU’s): …………………………………………...10

Certifications, Cautions and Warranty: …………………………………......12

Certifications: ……………………………………………………………....12

Cautions: …………………………………………………………………....12

Warranty: …………………………………………………………………..13

Technical Support: …………………………………………………………....14

Figures:

Figure 1 Connection Illustration ………………………………….............4

Figure 2 Tower Enclosure Feet …………………………..……………….5

Figure 3 End Cap Install/Remove Illustration .………………………….6

Figure 4 Rear View …………..……………….............................................8

Figure 5 Saf-Te Daughter Board Option Connected to Alarm Board.....9

Page 1of 14 Part Number 8519184-0000 Rev: B

General Information

Congratulations on your choice of a Trimm Technologies Enclosure. The UR8J series of enclosures are

intended for rack-mounted applications. The UT8J series of enclosures are tower types for desktop

(deskside) applications. Both types of enclosures support up to eight (8) 3.5” SCSI hard drives. The drives

are to be mounted in drive canisters (modules), which accommodate standard or low profile SCA-2 style

drives. The enclosure provides power and cooling for up to eight drives of the 10,000 RPM class of hard

drives. The canister has been designed to accommodate the rotational characteristics of the 10,000 RPM

category of drives, while providing for fully seating the drive’s connector into the enclosure’s backplane.

Description

The enclosure (chassis) has been designed for Field Replaceable Units (FRU’s) to be interchangeable

between the different units within the family. The enclosure is a midplane (backplane) design with dual

redundant (N+1), hot pluggable power supplies and redundant (N+1) cooling. Likewise, the drive

canisters are hot-pluggable, plugging in from the front of the enclosure.

While the design has a mid-plane, no active components are on the mid-plane. All active components are

on/in pluggable FRU’s, which are accessible either from the front or rear of the enclosure. The N+1

design, along with the pluggable FRU’s provides for maximum uptime.

The drives, accommodated by this family of enclosures, are those that conform to SCSI-3 specifications

with SCA-2 connections. The single-ended and host only low-voltage differential (LVD) versions support

drives up through SCSI-3 Fast 20 (Ultra) for transfer rates up to 40 MB/s, while the LVD native (Host

and Drive) supports SCSI-3 Ultra 2 transfer rates up to 80 MB/s.

The drives must meet the SCSI specifications for bus loading to work properly in an Ultra SCSI

environment. The drive must mechanically comply with the Small Form Factor (SFF) committee (SCSI

working committee) dimensional specifications for SCA drives (or in the alternate, Seagate dimensional

specifications for SCA drives).

Each drive is mounted into a canister (module) and is attached from the bottom. The drive is mounted in

the canister such that the drive connector is fully seated in the midplane (backplane) when the canister

handle is closed and latched into the enclosure. Noting that the drive canister is hot-pluggable, the drive is

not spun down prior to unplugging. To remove a drive, the canister handle is opened (released) from its

latch. Opening the handle on the canister disengages the drive’s connector from the enclosure’s

connector, thereby removing power from the drive, which will then permit the drive to spin down. The

person removing the drive should wait at least ten (10) seconds after opening the handle, for the drive to

spin down, before removing the canister from the enclosure.

First - Unpack, Inspect and Check:

Unpack the enclosure and visually inspect it for damage that may have occurred during shipment. Retain

the shipping carton in case reshipment is necessary.

Check your Drive Manual for inspection, installation and setup information.

Page 2of 14 Part Number 8519184-0000 Rev: B

Specifications:

Dimensions:

Enclosure: (external dim.) (Rack Style) (Tower Style)

Height: 5.25” 13.34cm 20.0”50.80cm

Width: (w/foot) N/A N/A 12.05” 30.61cm

Width: (w/o foot) 19.0” 48.26cm 7.0” 17.78cm

Depth: 22.0” 55.88cm 24.0 60.96cm

Drive Canister (Module):(Internal dim.)

Height: 1.65” 4.19cm (max to permit airflow)

Width: 4.03” 10.24cm

Depth: 7.62” 19.35cm

Weight: (Canisters) 1.7 lbs. 0.77 kg

(Rack Style) Approx. 45.4 lbs. 20.64 kg

(Tower Style) Approx. 65.0 lbs. 29.55 kg

(Rack) Total with eight canisters and no drives = 59.0 lbs. 26.82 kg

(Tower) Total with eight canisters and no drives = 79.0 lbs. 35.91 kg

Power Supply: 350 watt (dual redundant, hot-pluggable)

A/C: 100 – 240 VAC auto-ranging, 50 - 60 Hz

D/C: +5 VDC @ 25 A

+12 VDC @ 25 A

Note: each supply output capable of 25 A,

however, total output power not to exceed 350 watts

Cooling: Three blower fans

Provides for N+1, with a blower in each Power Supply, plus a separate blower

Air-flow – front to rear

Environment:

Temperature:

Operating: 0ºC to 25ºC

Storage: -20ºC to 85ºC

Humidity:

Operating: 0 – 95% non-condensing

Storage: 0 – 95% non-condensing

Altitude:

Operating: 0 – 10,000 feet

Storage: 0 – 40,000 feet

Page 3of 14 Part Number 8519184-0000 Rev: B

Drive Type(s) Supported:

•3.5” full-size (1.65” H) and low profile (LP) (1.00” H) (25mm).

•Hard drive rotational speeds up to 10,000 RPM.

•Using a Single Connect Attach (SCA-2) type connector (80pin).

•Low Voltage Differential (LVD) interface, with transfer abilities up to SCSI-3 Ultra

2, at 40 Mhz for data transfer rates up to 80 MB/s (wide interface). also supported are

Single-Ended drives, however, while Ultra 2 permits a mix of LVD and Single-

ended, as soon as one single-ended device is connected into the SCSI bus, ALL of the

transfer rates and cable distances revert to the lowest common denominator, the

single-ended specifications.

•Drives conforming to the Industry Standard Small Form Factor (SFF) committee

specifications for size and mounting criteria.

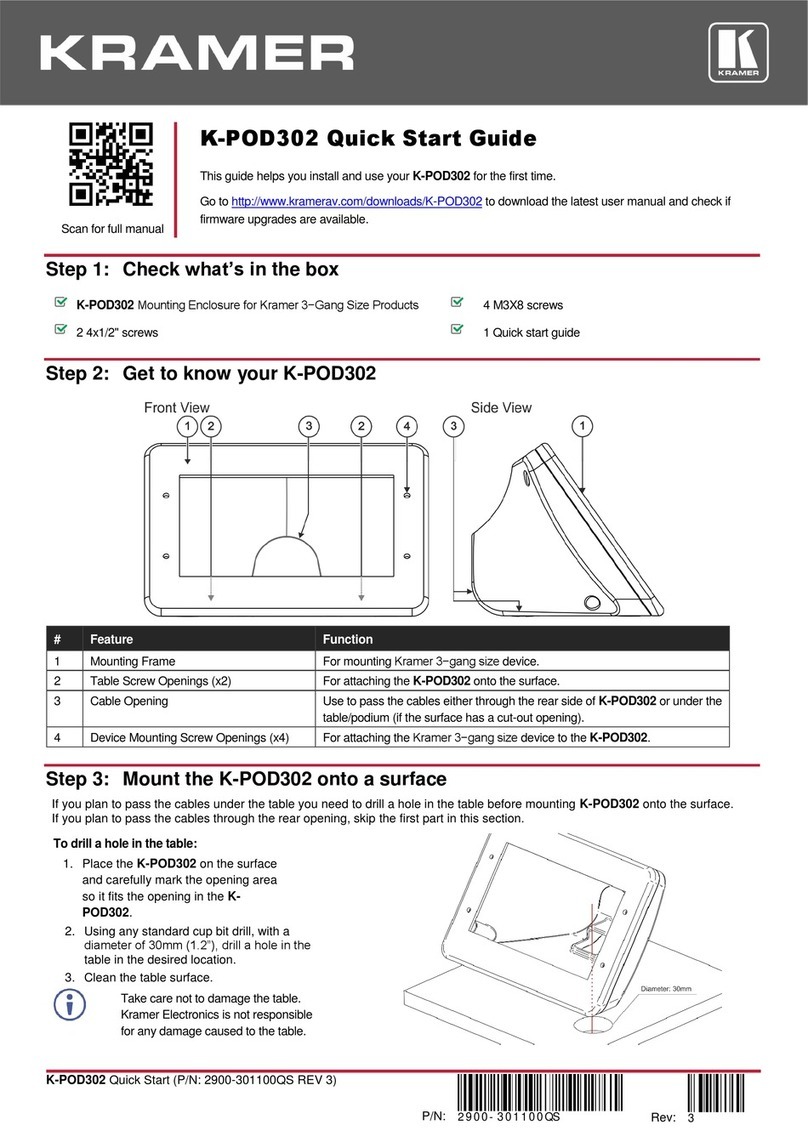

Host Connection(s) (Reference Figure 1)

Provides two separate host channels. The host connection is via HD68 type connectors, with each channel

daisy-chaining through four (4) drives in the enclosure, then out to the second connector at the

rear of the enclosure. This second connector must be terminated or daisy-chained to a point that is

terminated.

The enclosure contains two channels of four (4) drives. To set up a configuration of 1 channel of

8 drives or 2 channels of 4 drives, see “Convert 2 x 4 Configuration to a 1 x 8 or vice versa”.

The host connections, are identified as SCSI A and SCSI B. SCSI A is on the right side (rack) or top

(tower), (rear view), with SCSI B on the left side (rack) or bottom (tower), (rear view). Viewing

the enclosure from the front, SCSI A connects to the four (4) drives starting from the left side of

the enclosure. SCSI B connects to the four (4) drives starting with drive bay number five (5),

counting from the left.

The drive addresses are established based on a base address that is set via the Base Address Switch for

each channel. The switches are located at the rear of the unit. SCSI A base address switch sets the

base address for the drive in the bay at the far left (rack) or top (tower), (viewing from the front),

with the next three (3) bays having addresses that are incremented by one for each bay. SCSI B

base address switch sets the base address for the 5th drive bay, counting from the left (top), with

each subsequent bay incrementing by one. SCSI B base address sets the base address for these

drives, even if the interface has been jumpered for a one channel by eight drive configuration.

(NOTE: when setting drive addresses, the host address is normally set to 7).

(NOTE: the drive address switches control their respective bank of drives regardless of the

interface configuration, such as a 1 x 8 or 2 x 4 configuration.

Page 4of 14 Part Number 8519184-0000 Rev: B

Figure 1

Connection Illustration

Convert 2 x 4 Configuration to a 1 x 8 or vice versa:

To convert either way, either connect or disconnect a jumper cable between the 2nd connector for

the SCSI A and SCSI B connectors at the rear of the enclosure (reference Figure’s 1and 4).

For a 1 x 8 configuration, install the a SCSI jumper cable between the second connectors for the

SCSI A and SCSI B connectors. The host is connected to SCSI A, while SCSI B is either

terminated or connected to the next device in the chain (reference Figure’s 1 and 4).

For a 2 x 4 configuration, disconnect the cables between SCSI A and SCSI B connectors and

either terminate the second connector for each of SCSI A and SCSI B, or connect them to the

next device in the chain, with a terminator at the end of the chain.

Page 5of 14 Part Number 8519184-0000 Rev: B

Installation Sequence:

•Unpack & Inspect

•Install Enclosure in Rack (Mount Enclosure) (rack style) / Install Feet (tower style)

•Install End Caps (Rack Style)

•Mount Drives in Canisters (Drive Modules)

•Install Canisters in Enclosure

•Set Base Addresses for each Host Channel (in)

•Connect AC Power

Mount Enclosure into Rack (standard 19” RETMA rack):

The standard enclosure is a fixed mount configuration. Install the Rack-Mount kit supplied with

the enclosure, per the instructions supplied with the kit. Empty the enclosure (remove all canisters

and power supplies), remove the end caps from the front ears (use a screwdriver at the bottom of

the end caps to release the flexible latch), then insert enclosure into the rack and attach the front

ears of the enclosure to the rack. Reinsert power supplies and canisters.

Install Feet (Tower only)

The enclosure is shipped with three feet. Two of the feet have a self-adhesive to permit them to

be attached to the bottom (near the rear – see Figure 2). The other foot, is a stabilizer base, which

provides an anti-tip function to the enclosure. This foot is attached with the two screws included

with the foot (see Figure 2).

Figure 2

Tower Enclosure Feet

Remove protective cover

from the adhesive on the

feet and attach feet in the

area where shown.

Attach stabilizer foot to the base of the

enclosure, near the front, as located by

the mounting holes

Page 6of 14 Part Number 8519184-0000 Rev: B

Install/Remove End Caps (Rack-Mount Enclosure only)

The end caps are dress items, which mount on the rail flanges at the ends of the enclosure. The

caps snap in place with a notch at the bottom of the caps. To snap the caps in place, insert the top

notch in place first and then push the bottom in until the flexible flange at the bottom is captured

in the mating indent.

The notch at the bottom, provides access for a screwdriver (or similar instrument) to be inserted

to lift up on the flexible flange to disengage it from the indent and permit the bottom of the cap to

be pulled forward to remove the cap(s).

Figure 3

End Cap Install/Remove Illustration

Drives into Canisters

Mount the drive via the mounting holes at the bottom of the drive to the canister, which will

position the drive to properly engage the drive connector to the mid-plane board in the enclosure.

Use cautions and hardware as defined by the Drive manual/installation guide.

Drive Mounting Holes

Insert end cap notch in

slot on flange

Push in at

the bottom

of the end

cap to snap

flexible

notch into

slot on

flange

To remove end

caps, insert

screwdriver in

notch at the

bottom and

press up on the

flexible tab

until released,

then pull

forward

Page 7of 14 Part Number 8519184-0000 Rev: B

Canister into Enclosure

Insert the canister with the drive in place in a manner similar to the above illustration. The

canister has slides on the sides to help guide the canister into position, The canister has a lever at

the front which cams the canister into the final closed position. (NOTE: To remove, the front

lever is pulled open, which disconnects the drive power. When the power is removed from the

drive it will then park the heads and spin down. After releasing the front lever, pause for

approximately ten (10) seconds to permit the drive to spin down before completing the removal).

The canister has two (2) light pipes, which carries the drive “Active” (amber/yellow) LED signal

from the midplane to the front of the canister. The red (Drive Fault) is not used.

Power Supply Install/Remove

To remove a power supply (reference Figure 4), turn the power switch “off”, remove the attached

power cord, undo the thumbscrews (two for each supply), then grab handle and pull to the rear.

To install, insert supply into opening in enclosure to point where thumbscrews engage, then

tighten thumbscrews to secure power supply in place, then attach power cord, then turn power

switch “on”. (Note, each supply has a green and a red LED to indicate if supply is good or bad –

green on = good; red on = defective supply, needs to be replaced).

Each power supply assembly also houses a fan, power switch and power connection in addition to

the LEDs. If the fan fails the red LED is activated on the supply, along with the alarm and front

panel LED to indicate a failure. The assembly as shown in Figure 4 is the lowest Field

Replacement Unit (FRU).

In a live system, use CAUTION to remove only the failed supply (the one with the red LED on).

CAUTION, with either supply removed, the air flow is misdirected and the drives will overheat

in a matter of minutes, replace supply as quickly as possible in an operating enclosure.

Light pipes

(LED Outputs)

Lever

Page 8of 14 Part Number 8519184-0000 Rev: B

Figure 4

Rear View

Fan (Auxiliary Blower) Install/Remove

To remove the fan assembly (Reference Figure 4), undo the thumbscrew and pull the assembly to

the rear, by pulling on the thumbscrew. To install, push assembly into place and tighten the

thumbscrew. (Note, the fan assembly has a bi-color LED to indicate whether or not the fan is

okay; green = okay; red = fan is defective and needs replacement).

Electronic Circuit Boards

Within the enclosure, there are three (3) (four if optional Saf-Te is installed) circuit boards:

1. On the left front ear (end cap), there is an enclosure status (front display) board, which has

three (3) bi-color LEDs which indicate the status of the power supplies (top LED), enclosure

fans (middle LED) and temperature (bottom LED) within the enclosure. The temperature

LED is red if the enclosure temperature exceeds 45°C. Green indicates okay operation, while

red indicates a problem with the associated function. This board contains the audible alarm

reset switch. When an alarm is triggered, it can be deactivated by pressing the reset switch.

This board is a FRU.

For access to the Display Board , in the Rack Mount, remove the left End Cap. In the Tower

enclosure, remove the stabilizer foot (2 philips screws), then remove the cover (3 philips

screws at rear and then pull cover to the rear), next, remove the front bezel (4 Torx screws,

requires a T20 Torx bit).

Host ConnectionsBase Address Switches

Fan

Power Supply

Front Display

Board (mounted

on left ear)

Alarm Reset

Switch

LEDs

To remove the end cap, insert a

screwdriver in the notch at the

bottom of the cover to release the

tab, then pull the cap forward

Page 9of 14 Part Number 8519184-0000 Rev: B

2. The mid-plane (backplane) board is located approximately in the middle of the enclosure and

connects the drives to the host connection board. This board is not a FRU and is only repaired

by returning the enclosure to Trimm. Generally, this board does not contain any active

components. However, it does contain LED’s, terminator power diodes and fuses.

3. The alarm board is accessible from the rear of the enclosure. (There are two types; one in the

standard JBOD; and one for the JBOD connected in a castle (UR16R) configuration). (The

second type (UR16R) does not have a Saf-Te option as it uses a different communications

method). To remove, undo the mounting screws and pull the board out, using the metal lip

that is mounted at the rear of the board. This board contains the audible alarm circuit. The

board is a FRU. Generally, any active components that are within the enclosure are mounted

on this board. Also, the optional Saf-Te board is mounted on this board as a daughter board.

IF the optional Saf-Te board is installed, then the alarm board CANNOT be removed

from the rear, until and unless the Saf-Te board is removed.

4. The optional Saf-Te board is connected as a daughter-board to the alarm board via two

headers and is also connected to a drive channel via a separate connector. The Saf-Te board

has provisions for setting the address of the Saf-Te device to either SCSI ID 4 or 5 via an on-

board jumper, using jumper P3 (reference Figure 5). To replace the Saf-Te board requires

removing the top cover from the enclosure. With the top cover removed, lift the Saf-Te board

off of the alarm board (connected via two headers) and remove the cable connector (this

connector off disables the Saf-Te device from communicating on the SCSI bus. This board is

a FRU.

Figure 5

Saf-Te Daughter Board Option Connected to Alarm Board

P3 location for SCSI-ID jumper

OFF = 4

ON = 5

Cable connector connectingSaf-Te

to Drive Channel 1

Connectors, connecting Saf-Te

daughter board to Alarm Board

Page 10 of 14 Part Number 8519184-0000 Rev: B

Field Replaceable Units FRU’s

Description Trimm Part Number

Power Supply, 350W (PFC) 5417240-0100

Power Supply, 350W (non-PFC) 5420009-0100

Drive Canister (2 each), 5417239-002*

Drive Canister (8 each), 5417239-008*

End Caps (pair), 5417418-010*

Alarm Board (standard JBOD) Assembly 5418868-0100

Alarm Board (Castle UR16R JBOD) Assembly 5419533-0000

Saf-Te Board Assembly 5418887-0100

Front Display Board 5417335-0100

Fan Assembly (Auxiliary Blower Fan) 5417241-0100

Where * = color:

1 = Light Grey

4 = Charcoal

5 = Black

6 = Taupe

Power Supply Assembly

350W (PFC)

5417240-0100

Fan Assembly

Auxiliary Blower

5417241-0100

Front Display Board

Part Number 5417335-0100

Drive Canister (Module)

Available in several color schemes and

shipped in groups of 2 or 8

5417239-xxxx

Slides

Lever to install or

remove canister

Light Pipes for

Drive Activity and

Drive Failure

Power Supply Assembly

350W (non-PFC)

5420009-0100

Please

Note the type of Handle to determine which type power supply you

have, as they are not interchangeable

Page 11 of 14 Part Number 8519184-0000 Rev: B

Terminator, SE/LVD Multimode

Part Number 5417847-0100

Cable,

multimode (external)

Part Number 5417823-0100 = 1 foot

Part Number 5417823-0200 = 3 foot

Part Number 5417823-0300 = 10 foot

Part Number 5417823-0400 = 25 foot

Alarm Board Assembly

Part Number 5418868-0100

Saf-Te Option Daughter Board

Part Number 5418887-0100

Page 12 of 14 Part Number 8519184-0000 Rev: B

Certifications, Cautions and Warranty

Certifications:

This enclosure, as a component, has been tested and has passed all safety

requirements. The integrator is responsible for End Product testing and agency

verifications. Do not use the enclosure in any manner other than the intended

use/purpose as advertised by Trimm Technologies. The enclosure meets the

requirements of the following agencies:

- - Underwriters Laboratories, Recognized Component

– - Component conformity with EU Directives

- -Canadian Underwriters Laboratories

Testing for other agencies can be done upon request.

In addition, the enclosure has been designed to meet FCC, Class B emission

requirements. System approval can only be obtained when the enclosure is loaded

with drives. The final step is the integrator’s option, with this task being made easier

due to Trimm’s compliance with agency regulations and attention to anti-emission

construction techniques.

This equipment generates, uses, and may emit radio frequency energy. If not

installed in accordance with the information provided in this manual, it may cause

interference to radio communications. It has been tested and found to comply with

the limits for a Class B computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection against such

interference when operated in a commercial environment.

Cautions:

Warnings/Cautions

Watch out for Static while handling/installing drives and/or FRU’s!

Although the enclosure is not sensitive to (Static) Electrostatic Discharge (ESD),

any of the electronic circuits, such as the board providing connection from the

external host connection to the internal drives or the drives themselves, are sensitive

to ESD. Heed the warnings and cautions in your drive manual(s). Take care to avoid

damaging your drive and any of the electronic circuit boards by mishandling.

Ideally, a conductive rubber mat and wrist strap should be used if possible,

whenever you are handling any of the drives or electronic circuit boards.

Page 13 of 14 Part Number 8519184-0000 Rev: B

CAUTION:Disconnect power before servicing.

ATTENTION:Débranchez la puissance avant l'entretien.

The power cord provided may not be suitable for the installation country. It is the

user’s responsibility to insure the power cord satisfies local electrical code.

CAUTION: For continued protection against risk of fire, replace only the same

type and ratings of fuse.

Power supplies must be handled with care. If you need to remove a power supply, be

sure not to subject the components to damage (dropping, stacking, etc.).

Warranty:

Trimm Technologies warrants its range of products to be free from defects in

material and workmanship for a period of ONE YEAR from date of manufacture.

The company makes this warranty only to purchasers who acquired the product

direct from the company, its authorized dealers or reps, or others who are

specifically authorized by the company to sell such products. The company’s sole

obligation and the purchaser’s remedy pursuant to this warranty are limited to

repair or replacement, at the company’s option, F.O.B. the company’s plant, of

products which, when used normally and pursuant to the company’s published

instruction, are proven to be defective within the period stated.

The company makes no warranty to purchasers who acquire products for personal,

family or household purposes. No person, firm or corporation is authorized to

assume for the company any liability in connection with the sale or installation of

company’s products except as stated above. THERE ARE NO OTHER

WARRANTIES, EITHER EXPRESS OR IMPLIED, INCLUDING ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE. The remedies stated herein are expressly set forth, irrespective of the

theory upon which any claim might be based, including breach of contract,

warranty, negligence, or strict liability of tort. Under no circumstances shall the

company be liable for incidental or consequential damages.

Page 14 of 14 Part Number 8519184-0000 Rev: B

Technical Support

If you have any problems or need advice on future expansion / products contact Trimm Technical Support

via:

US:

Mailing Address:

Trimm Technologies, Inc.

350 Pilot Road

Las Vegas, Nevada 89119

Phone: 702-263-2310

Fax: 702-361-6067

Email: [email protected]

Web Site: http://www.trimm.com

UK:

Trimm Technologies Limited

Millennium Way East

Phoenix Centre

Nottingham, England NG8 6AR

+44 (0) 115-951-9951

+44 (0) 115-951-9985

Part Number 8519184-0000 Rev: B

Trimm Technologies, Inc.

350 Pilot Rd.

Las Vegas, Nevada 89119 USA

Phone: 702-263-2310

Fax 702-260-3443

http://www.trimm.com

Trimm Technologies LTD.

Millennium Way East

Phoenix Centre

Nottingham, England NG8 6AR

Phone: +44 (0) 115-951-9951

Fax: +44 (0) 115-951-9985

This manual suits for next models

1

Table of contents