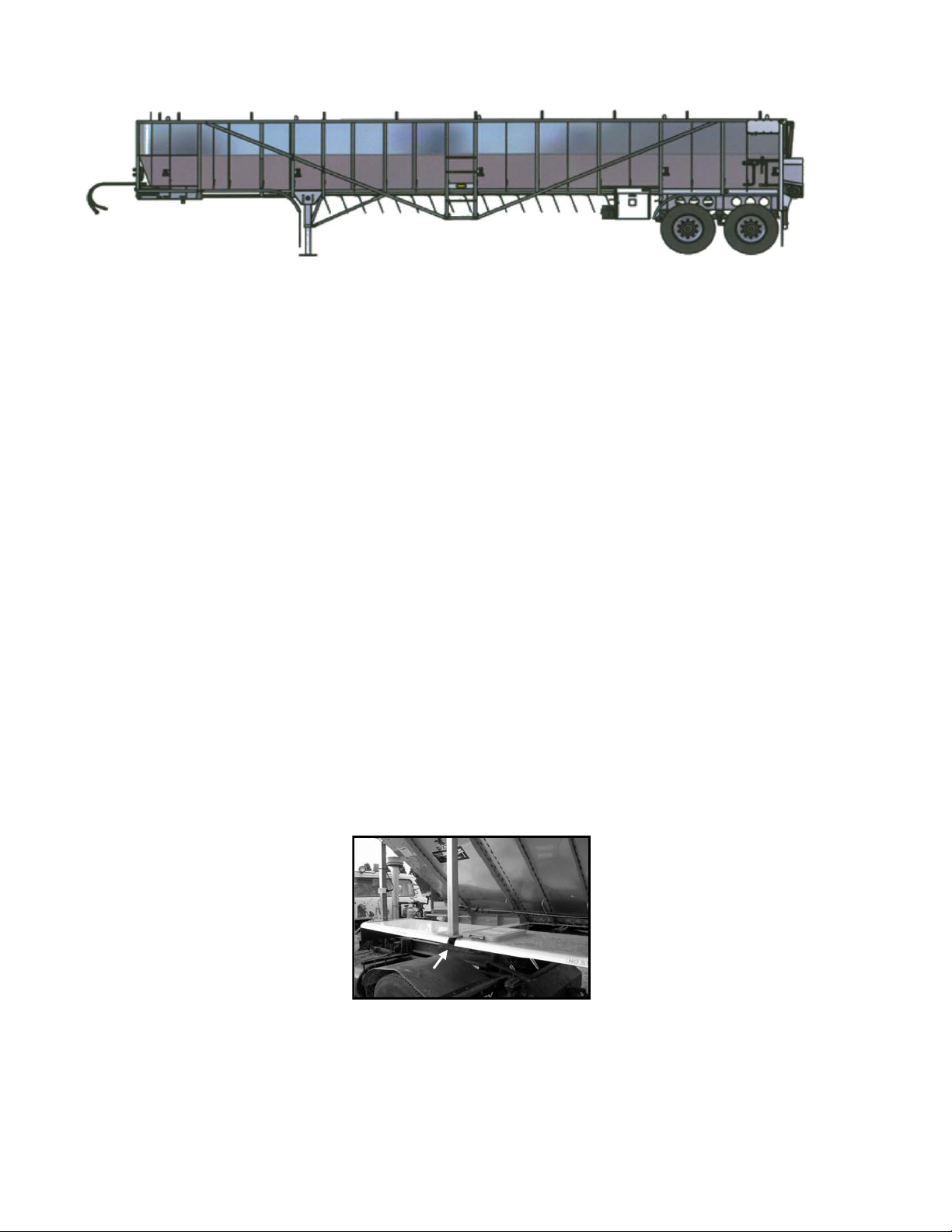

Trinity Trailer Eagle Bridge 2014 User manual

Jun 2014 Rev

Thank You for Purchasing an Eagle Bridge™ Trailer

The purpose of this manual is to address:

•Safety

•Warranty Information

•Service and Maintenance

•General Care and Use

•Conveyor Operating Instructions

•Rear Door Operating Instructions

•General Support Information

Please refer to the Table of Contents to locate the needed information. If you have questions about

the trailer which are not covered in this manual, please call us at (208) 336-3666 or toll free at

(800) 235-6577. Our hours of operation are Monday through Friday, 8:00 a.m. to 5:00 p.m., MST.

This manual is written to cover many versions of Eagle Bridge™ trailers. Because of this, some

sections are not applicable to your trailer. Thoroughly review the manual and any attached

supplements to determine what is applicable to your trailer.

Two print copies along with two CD’s are supplied with each trailer upon delivery; one copy with

the paperwork and the second in the registration box located on the front fender of the trailer,

shown in the figure below. This manual is considered a permanent part of the trailer and should

remain with the trailer if ownership is transferred in any way. To replace a missing or destroyed

manual, call 800-235-6577 or download at www.trinitytrailer.com\downloads.

Registration Box Location

Notice: Contents of this manual are subject to change without notice!

Registration Box

I

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

TABLE OF CONTENTS

TABLE OF CONTENTS II, III, IV

LIMITATION OF WARRANTIES V

IMPORTANT SAFETY INFORMATION VI

WARNING SYMBOLS USED IN THIS MANUAL 1

SAFETY LABELS 1

INSPECTION, SERVICE AND MAINTENANCE 2

DAILY INSPECTION 2

PREVENTATIVE MAINTENANCE SCHEDULE 2

After the first 50 to 100 miles 2

After the first 1,000 miles 2

After the first 50 hours of operation 2

Every 100 hours of operation 3

Every 250 hours of operation 3

Every 5,000 miles or once a month (whichever comes first) 3

Every 15,000 miles or three months 3

Once a year 4

HONDA 20HP GASOLINE ENGINE MAINTENANCE SCHEDULE 4

FIFTH WHEEL AREA INSPECTION 5

ADJUSTING AND LUBRICATING THE CONVEYOR SYSTEM 6

Conveyor Chain Adjustment 6

Adjusting the Chain 7

Removing Chain Links 7

Welding Chain Pins 7

Conveyor Chain Lubrication 9

Bearings and Sprockets 10

Planetary Gearbox 10

Changing Planetary Oil 11

LUBRICATION OF THE DOOR(S) 12

CARE OF THE PLASTIC LINER 12

High Molecular Weight (HMW) and Ultra-High Molecular Weight (UHMW) Liner12

COATING CARE AND CORROSION PREVENTION 13

STAINLESS STEEL BODIES 13

CLEANING THE INTERIOR14

SPRING SUSPENSION INSPECTION AND MAINTENANCE 15

Spring Suspension Inspection 15

Axle Clamps and Springs 16

Radius Rods 17

Rocker Bushings 17

Hangers 18

Spring Suspension Alignment 18

AIR-RIDE SUSPENSION INSPECTION AND MAINTENANCE 20

Air-Ride Suspension Inspection (Hendrickson HT Series, INTRAAX®,

Composilite™ and Ingersoll ISS Series) 20

Hendrickson Suspension Torque Requirements 21

II

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

Composilite™ Torque Requirements 22

ISS Series Torque Requirements 23

Air-Ride Suspension Alignment 24

Quick-Align Connection 24

Composilite™ Alignment 27

ISS Series Alignment 27

ISS Series SSA Alignment 29

HUB AND WHEEL INSTALLATION AND MAINTENANCE 32

Pilot Mount Wheels 32

Recommended Procedure for Replacing Studs 34

HYDRAULIC SYSTEM SERVICING 34

Tractor Hydraulic System Requirements 34

Pressure Filters 34

Hydraulic Cylinder Maintenance 35

Hydraulic Lines and Fittings 36

Hydraulic Fluid Recommendations 36

Hydraulic Valve Maintenance 36

GASOLINE ENGINE SERVICING 37

ANTI-LOCK BRAKE SYSTEM (ABS) 38

Ignition Power Activation 40

REAR IMPACT GUARD 40

OPERATING INSTRUCTIONS 41

COUPLING THE TRAILER 41

A NOTE ON AIR PRESSURE 43

LOADING THE TRAILER 43

ELECTRONIC SCALES 45

LIFT AXLE CONTROLS 45

Equalizing Lift Controls 45

AKAD2010 Lift Control 46

LSAS (Load Sensing Axle System) Lift Control 46

RA016SRA-32L Suspension Control 47

Regulating Lift Controls 50

HAC-USO/LSO Lift Control 50

AKAD2011 Lift Control 51

TIRE INFLATION SYSTEMS 52

TIREMAAX® PRO 52

DRIVE AND HYDRAULIC SYSTEMS 53

Supplying Power to the Electric Motor 53

OPERATING THE REAR DOOR(S) AND UNLOADING SYSTEM 54

Door and Conveyor System Component Identification 55

Lower Door Identification 55

Lower Door Component Identification 56

Upper Door Identification 56

Upper Door Component Identification 58

Unload Drive System Identification 61

Door and Conveyor Control Identification 62

GENERAL DOOR SAFETY 64

III

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

GENERAL CONVEYOR SAFETY 65

UNLOAD OPERATING PROCEDURES 66

Electric Motor-Driven Hydraulic System Operation 66

Gas Engine-Driven Hydraulic System Operation 66

Tractor-Driven PTO Hydraulic System Operation 67

Tractor-Driven PTO Wireless Remote Control Hydraulic System Operation 67

Combination Tractor-Driven PTO Hydraulic System and Gas Engine-Driven

and/or Electric Motor-Driven Hydraulic System Using Electric Motor-Driven

or Gas Engine-Driven Hydraulic System Operation 68

Combination Tractor-Driven PTO Hydraulic System and Gas Engine-Driven

and/or Electric Motor-Driven Hydraulic System Using Tractor-Driven PTO

Hydraulic System Operation 68

DOOR PROCEDURES 69

Lower Door Procedures 69

Manual Flip-Up Door 69

Hydraulic Operated Lower Door (Flip-Up or Slider) 70

Upper Door Procedures 72

Fold-Down Spud Door 72

Full-Swing Door 73

Top-Hinged Door 73

Fold-Down Extension (Sideboard) Door 77

OPERATING THE PNEUMATICALLY-ACTUATED FRONT WET SEAL 78

USING THE REMOVABLE TAIL FINS 79

TARP SYSTEMS 80

LADDER, WALKWAY AND CATWALK SAFETY 83

LADDER USE PROCEDURE 86

TRAILER MODIFICATIONS 88

REPORTING SAFETY DEFECTS 89

IV

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

LIMITATION OF WARRANTIES

Goods manufactured by Trinity Trailer Manufacturing, Incorporated (“Trinity Trailer”) are warranted to

be free from defects in workmanship or material under normal use and service for a period of One (1)

year to THE ORIGINAL OWNER or any remaining time on the warranty period for SUBSEQUENT

OWNERS.

This warranty is applicable if the owner has, as a minimum:

Properly maintained the trailer

Not overloaded the trailer (i.e. Exceeded the GVWR* or the GAWR*)

Not transported corrosive cargo

Adequately restrained the load

Loaded the trailer properly

The warranty period begins on the date the vehicle is delivered and ends at the expiration of the coverage

period.

THERE ARE NO WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, OR OTHER WARRANTIES, EXPRESSED OR IMPLIED, UNLESS

OTHERWISE EXPRESSLY SPECIFIED HEREIN.

Trinity Trailer’s sole obligation under this warranty is to repair or exchange, at its option, any such

goods manufactured which are found by Trinity Trailer to be defective in workmanship or materials.

Trinity Trailer reserves the right to require any products to be returned for inspection at the buyer’s

expense to our facility in Boise, Idaho. The foregoing shall be the sole and exclusive remedy for any

such defects, whether in contract, tort, warranty or otherwise.

In no event shall Trinity Trailer be liable for indirect, special, incidental or consequential damage in

connection with or arising out of the sale of goods or furnishing services.

The warranty herein does not apply to and Trinity Trailer makes no warranties, expressed or implied

with respect to:

Items manufactured by other parties

Items that have been modified by other parties

Goods which wear out and have to be replaced during the warranty period. These goods include

but are not limited to: tires, plastic liner, chains, flaps, tarp, light bulbs, electrical or hydraulic

receptacles, paint, brakes, linings, drums and return springs, equalizer, torque rod, camshaft

bushings, camshafts, slack adjusters, brake cylinder diaphragms, springs, slider pads, wheel

bearings, oil and oil seals, door seals, rim clamps and studs, gaskets and sealers, etc.

*GVWR (Gross Vehicle Weight Rating)-The structural capability of the trailer when supported by the kingpin and axles

with the load uniformly distributed throughout the cargo space.

*GAWR (Gross Axle Weight Rating)-The structural capability of the lowest rated member of the running gear components-

suspension and spring system, hub, wheels and drums, rims, bearings, brakes, axles or tires.

V

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

IMPORTANT SAFETY INFORMATION

Before attempting to operate, load, unload or do anything with or to the trailer, YOU MUST

READ THIS MANUAL and become completely familiar with all of its operating instructions

and safety precautions.

To avoid serious injury or death, ALWAYS FOLLOW THESE PRECAUTIONS:

1. Do not allow unqualified, untrained or careless personnel to operate the trailer. Do not use

the trailer for a purpose for which it was not intended.

2. Each person at the user’s facility who may be involved with installing, operating, servicing,

inspecting, maintaining or repairing the trailer must read the complete operating

instructions and carefully study and understand the safety instructions. All actual and

potential operators should confirm their having done so in writing.

3. The trailer must be serviced and maintained only by authorized and properly trained

personnel. Such personnel must have undergone training by a factory-trained

representative concerning the proper and safe operation of the trailer. Only the

manufacturer or factory-trained technicians should carry out more than minor repairs.

4. Do not allow anyone who is not physically fit or mentally alert near the trailer or its

operating area. Be constantly alert to possible hazards on or around the trailer.

5. Keep a safe distance at all times from any moving parts, including the conveyor.

6. When unloading the trailer:

a. Long hair must be protected by headgear.

b. Do not wear loose apparel such as ties, scarves, etc.

c. Remove all wristwatches and jewelry.

d. Wear only approved industrial grade eye protection or a face guard to protect against flying

debris.

7. Do not allow tools or other loose objects to be placed on top of or around the trailer.

8. At the very first sign of any problem and before attempting any troubleshooting or

maintenance, the conveyor must be stopped.

9. Safety features must not be removed, dismantled, altered, put out of operation or relocated.

All guards and safety devices are to be re-fitted and in place after changeovers, servicing or

making repairs and before the trailer is used. All safety devices must be checked at regular

intervals for correct operation.

10. Do not remove safety signs or warning decals from the trailer. Product safety signs should

be periodically inspected and cleaned as necessary. Product safety signs should be

replaced when they are no longer legible at a normal viewing distance. Replacements are

available from Trinity Trailer Mfg., Inc.

11. Follow all workplace safety and accident prevention regulations applicable to the operation

of the trailer. Comply with local, state and/or federal environmental regulations, including

those governing airborne dust particles.

12. Designate a person to be responsible at any given time for installation, commissioning,

operating and repair of the trailer so the responsibility for safety will not be lost.

13. The trailer has been designed and built with original Trinity Trailer Mfg., Inc. parts only.

Only original Trinity Trailer Mfg., Inc. parts must be used for maintenance or repair. Use

of other parts will void your warranty.

14. Do not perform modifications to or reconstruction of the trailer without first getting written

approval from Trinity Trailer Mfg. Inc.

15. The cleanliness and tidiness of the trailer and its surrounding area must be ensured through

appropriate instructions, routine inspections and cleaning.

VI

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

WARNING SYMBOLS USED IN THIS MANUAL

Eagle Bridge™ trailers have inherent hazards associated with their use. We have made

efforts to minimize these risks through the use of engineering controls. There are certain

risks, however, which cannot be completely eliminated if the design is to remain

functional.

The following symbols and classifications of hazards are used in this manual and on the

safety labels on the trailer.

This is a safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!WARNING

!CAUTION

CAUTION

SAFETY LABELS

Your trailer had numerous safety labels affixed to it when it was built; they are shown

throughout this manual. It is important that these labels remain visible and legible throughout

the life of the trailer. To help ensure they are visible, the trailer should be cleaned regularly with

water and a mild detergent. Over time the condition and/or color of the labels may deteriorate

due to use of the trailer and the environment in which it is used. If the labels should become

illegible or lose their color, it is the owner’s responsibility to replace them. Contact our customer

service department at (800) 235-6577 to order replacements.

This indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

This indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury.

A caution statement used without the safety alert symbol

indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

1

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

INSPECTION, SERVICE AND MAINTENANCE

It is important that your Eagle Bridge™ trailer be inspected and serviced on a regular

basis to keep it in a safe and functional condition. Regular maintenance will also save

you money in costly repairs over time.

DAILY INSPECTION

A daily inspection of the following items should be performed before using the trailer:

•Bin and Support

Members

•Belt Return Slides

•Bolts and Fasteners

•Brake Adjustment

•Brake Pad Thickness

•Brake System

•Conveyor System

•Coupler Plate

•Fasteners

•Framework

•Hub Oil Level

•Hydraulic System

•Kingpin

•Ladders

•Lights and Wiring

•Mud Flaps

•Plastic Liner

•Pneumatic System

•Suspension System

•Tarp Hardware

•Tarps

•Tires

•Wheels

•Wheel Seals

PREVENTATIVE MAINTENANCE SCHEDULE

We recommend that you follow the general preventative maintenance schedule below.

The intervals given are for nominal operating conditions; service more frequently if the

trailer is used in an overly humid or dusty condition.

AFTER THE FIRST 50 TO 100 MILES

•Check torque of cap nuts or flange nuts on each wheel

AFTER THE FIRST 1,000 MILES

•Check torque of suspension hardware

•Check alignment of suspension

AFTER THE FIRST 50 HOURS OF OPERATION

•Replace the hydraulic oil and filter

•Replace the oil in the planetary gearbox

2

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

EVERY 100 HOURS OF OPERATION

•Clean the spark arrester on the gasoline engine (if applicable)

EVERY 250 HOURS OF OPERATION

•Replace the hydraulic oil filter

EVERY 5,000 MILES OR ONCE A MONTH (WHICHEVER COMES FIRST)

•Wash trailer thoroughly with a mild detergent and water

•Check general structural condition for corrosion or cracks

•Inspect kingpin area

•Check clearances and torque of air-ride suspension system (if applicable)

•Visually check alignment of suspension

•Check condition of lights

•Check security of registration box and required paperwork

•Check wiring harness for cracking or chafing

•Check hydraulic and pneumatic lines for signs of leakage or wear

•Drain moisture from air reservoirs

•Check hinges on rear door(s) for signs of damage

•Lubricate hinges, latches and bearings (if applicable) on rear door(s)

•Inspect brake components for proper adjustment and for any sign of damage

•Check tires for excessive wear and proper inflation

•Check wheel nuts for proper torque

•Check wheel seals for leaks

•Check level of oil in axles

•Check conveyor system for excessive wear or damage

•Check condition of tarp system, if installed

•Check condition and security of mud flaps

•Check oil level in planetary gear on conveyor hydraulic and add if necessary

EVERY 15,000 MILES OR THREE MONTHS

All items listed above plus:

•Check all hardware; replace any which are damaged or missing; tighten any loose

bolts or nuts

•Clean grease off kingpin plate and inspect for excessive wear or cracks

•Measure alignment of suspension; adjust if out of allowable tolerance

•Inspect all welded connections and joints on suspensions

•Check for proper torque of all bolts and nuts on the suspension system

•Replace hub bearing lubricant

•Lubricate automatic slack adjusters

•Inspect brake drums, lining and shoes

3

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

•Test operation of brakes

•Inspect brake lines for wear or chafing

•Lubricate conveyor chains and front shaft bearings

•Check condition of front and rear chain sprockets and bearings for wear or damage

•Check lining of the trailer for cracks or damage; check floor lining for excessive wear

•Check condition of gladhand seals

•Lubricate the door seals

•Service gasoline engine in accordance with the manufacturer’s recommended

procedures (if applicable)

•Check aluminum sidewall extensions for damage or cracking (if applicable)

ONCE A YEAR

All items listed above plus:

•Drain and replace hydraulic fluid from reservoir

•Replace hydraulic oil and filter (or every 1,000 hours, whichever is first)

•Replace oil in the planetary gearbox (or every 1,000 hours, whichever is first)

•Lubricate landing legs

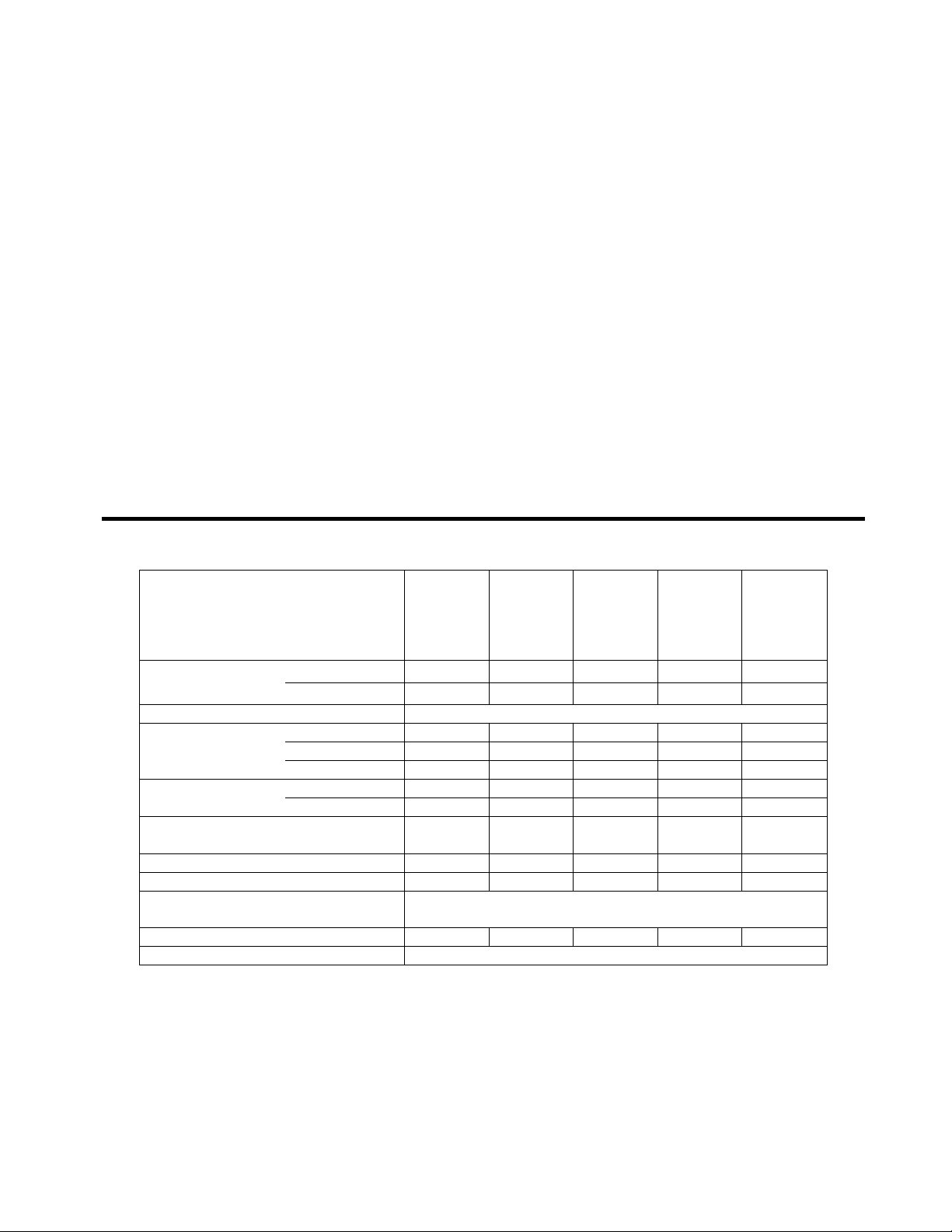

HONDA 20HP GASOLINE ENGINE MAINTENANCE SCHEDULE

Figure 1-Honda 20HP Gasoline Engine Maintenance Schedule

REGULAR SERVICE PERIOD (3)

Perform at every indicated month or

operating hour interval, whichever

comes first.

ITEM

Each

Use

First

Month or

20 Hrs

Every 6

Months

or

100 Hrs

Every

Year

Or

300 Hrs

Every 2

Years or

500 Hrs

Engine Oil

Check Level

ο

Change

ο

ο

Engine Oil Filter

Replace

Every 200 Hrs

Air Cleaner

Check

ο

Clean

ο (1)

Replace

ο *

Spark Plug

Check/Adjust

ο

Replace

ο

Spark Arrester

(Applicable Types)

Clean

ο

Idle Speed

Check/Adjust

ο (2)

Valve Clearance

Check/Adjust

ο (2)

Combustion

Chamber

Clean

After Every 1000 Hrs (2)

Fuel Filter

Replace

ο (2)

Fuel Tube

Check

Every 2 Years (Replace if necessary) (2)

*Replace the paper filter element only.

(1) Service more frequently when used in dusty areas.

(2) These items should be serviced by your Honda servicing dealer, unless you have the proper tools and are mechanically

proficient. Refer to the Honda shop manual for service procedures.

(3) For commercial use, log hours of operation to determine proper maintenance intervals.

4

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

FIFTH WHEEL AREA INSPECTION

The fifth wheel area must be kept clean and free of dirt and foreign materials. This

includes the area between the kingpin plate and the body of the trailer where the

conveyor chains and flaps travel. Buildup of snow, ice or other foreign materials can

cause binding or other serious damage if allowed to remain in this area. Any binding can

place excess stress on the front shaft, which can result in any of the following:

•The shaft to bend or break

•The bearings or adjustment mechanisms to be damaged

•The chain to stretch excessively, resulting in premature failure

Daily inspect the kingpin and kingpin plate for the following:

•Wear, cracks or other damage

•Damaged or missing parts

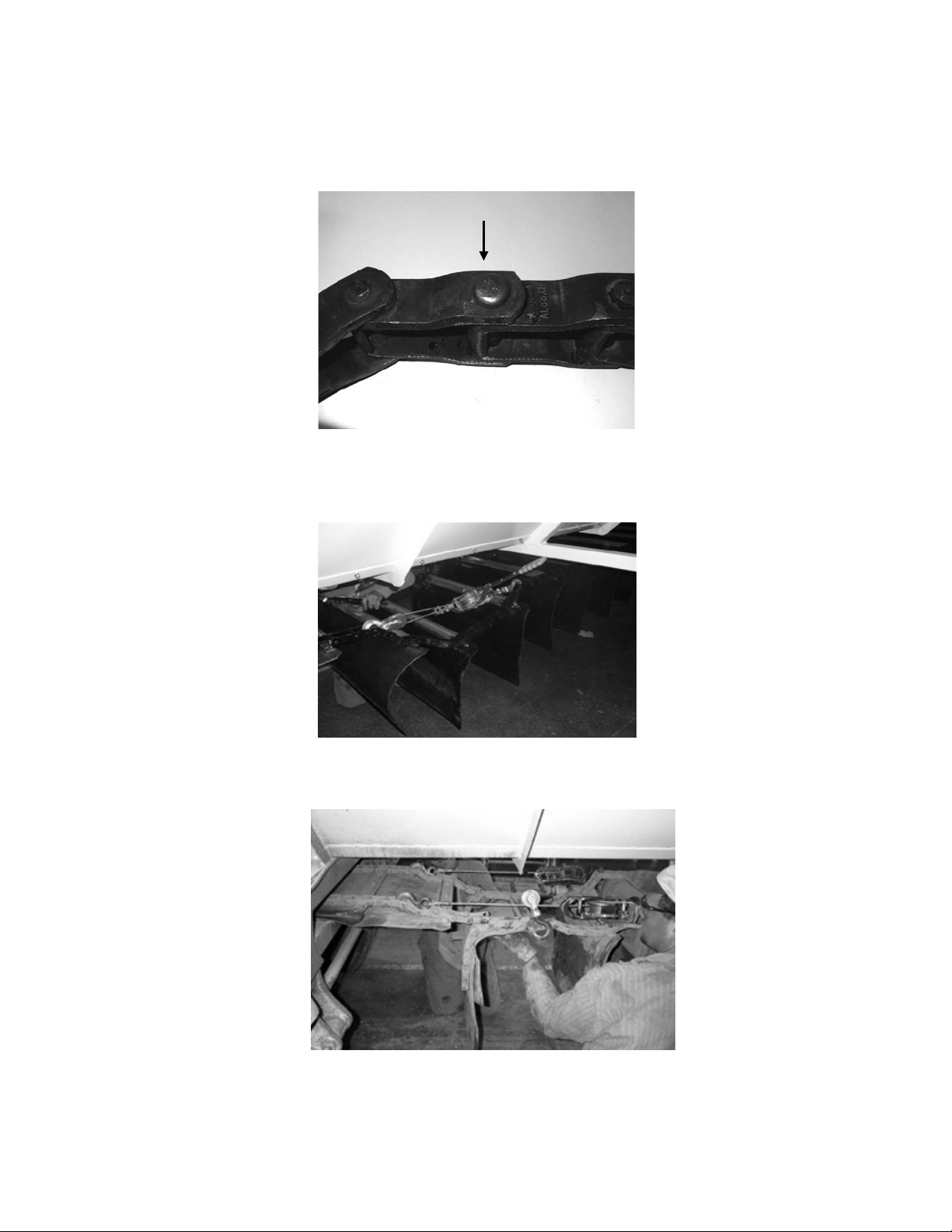

•Bent belt return slides (Figure 2); these can be bent during normal operation and must

be straightened before use

Keep the fifth wheel plate lubricated in accordance with the tractor manufacturer’s

recommendations.

Figure 2-Belt Return Slides

Belt Return Slides

5

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

ADJUSTING AND LUBRICATING

THE CONVEYOR SYSTEM

CONVEYOR CHAIN ADJUSTMENT

It is normal for the chain to "stretch" as it is used. The amount of "stretch" will be greater

when the chain is new as the pins get seated against the barrel of the chain. It is important

to keep the chain adjusted to prolong the life of the chain. The chain should be operated

within the two pointers on the chain adjustment gauge (Figure 3), which is located on the

roadside of the trailer between the front of the suspension and the center of the trailer.

Figure 3 - Chain Adjustment Gauge

Jam Nut

Adjuster Bolt

Figure 4 - Chain Adjustment Assembly

6

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

ADJUSTING THE CHAIN

1. Loosen the jam nut in the chain adjustment assembly (Figure 4).

2. Tighten the adjuster bolt, alternating sides so that one side of the shaft does exceed

1/4" ahead of the opposite side, until the chain is between the two pointers on the

chain adjustment gauge (Figure 3).

3. If the chain adjustment assembly is out of adjustment and the chain is not within the

two pointers, you will have to remove some chain links. (Procedure to follow)

4. Measure the distance from front of trailer to the shaft on each side and adjust so that

there is no more than 1/8" difference.

5. Tighten the jam nut.

REMOVING CHAIN LINKS

1. Rotate the conveyor until there is a master pin 3 - 5 feet in front of the suspension.

The master pin can be identified by the head of the pin (Figure 5).

2. Loosen the jam nut in the chain adjustment assembly (Figure 4).

3. Loosen the adjuster bolt, alternating sides so that one side of shaft does not exceed

1/4" behind the opposite side, until the sprocket teeth are just in front of the trailer

floor.

4. Verify that the shaft can rotate without the sprockets hitting the trailer floor.

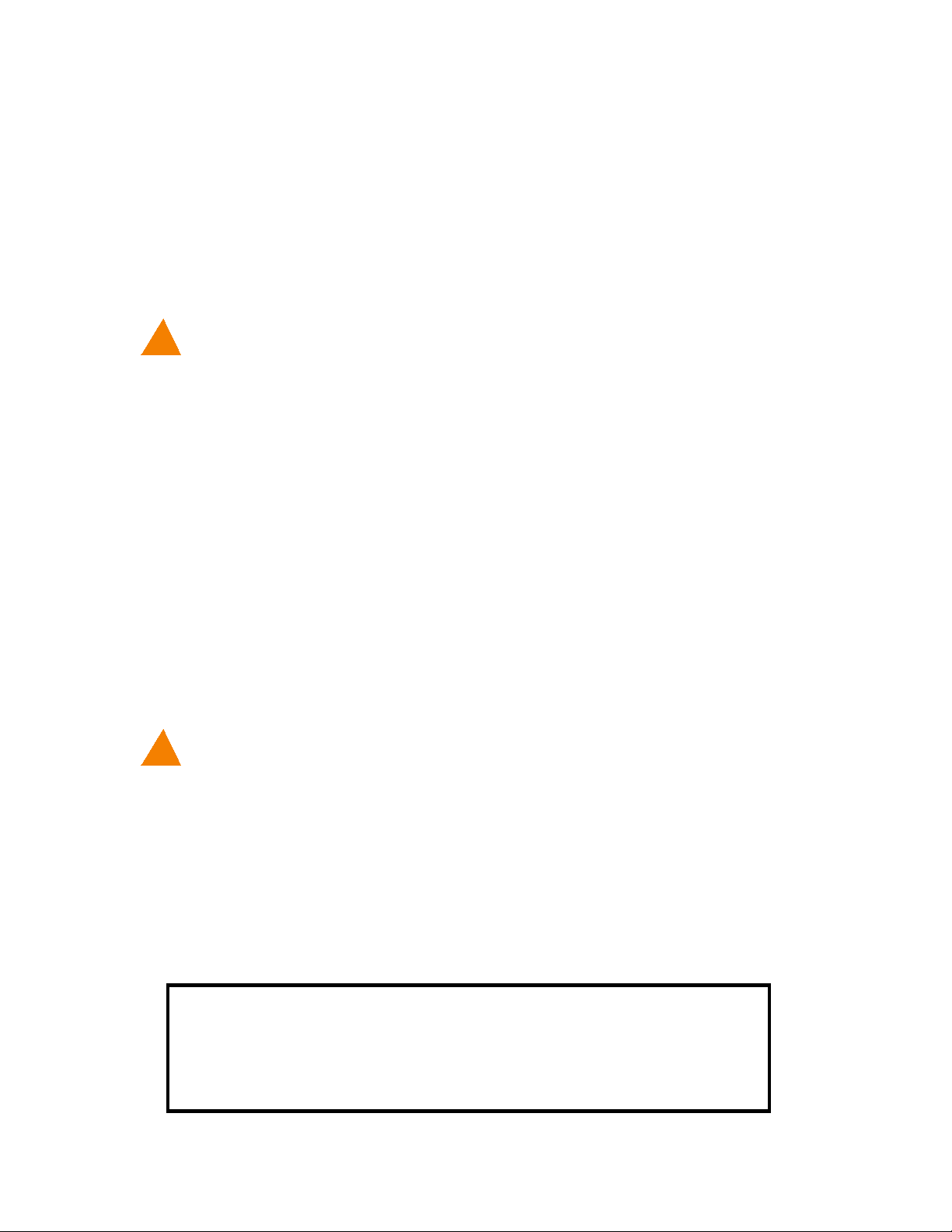

5. In front of the suspension connect a Come-Along into the chain links of each chain

with the master pin centered between the connection points.

6. Pull up all of the slack chain (Figure 6).

7. Grind the weld off of the master pins.

8. Drive out the pin using a punch.

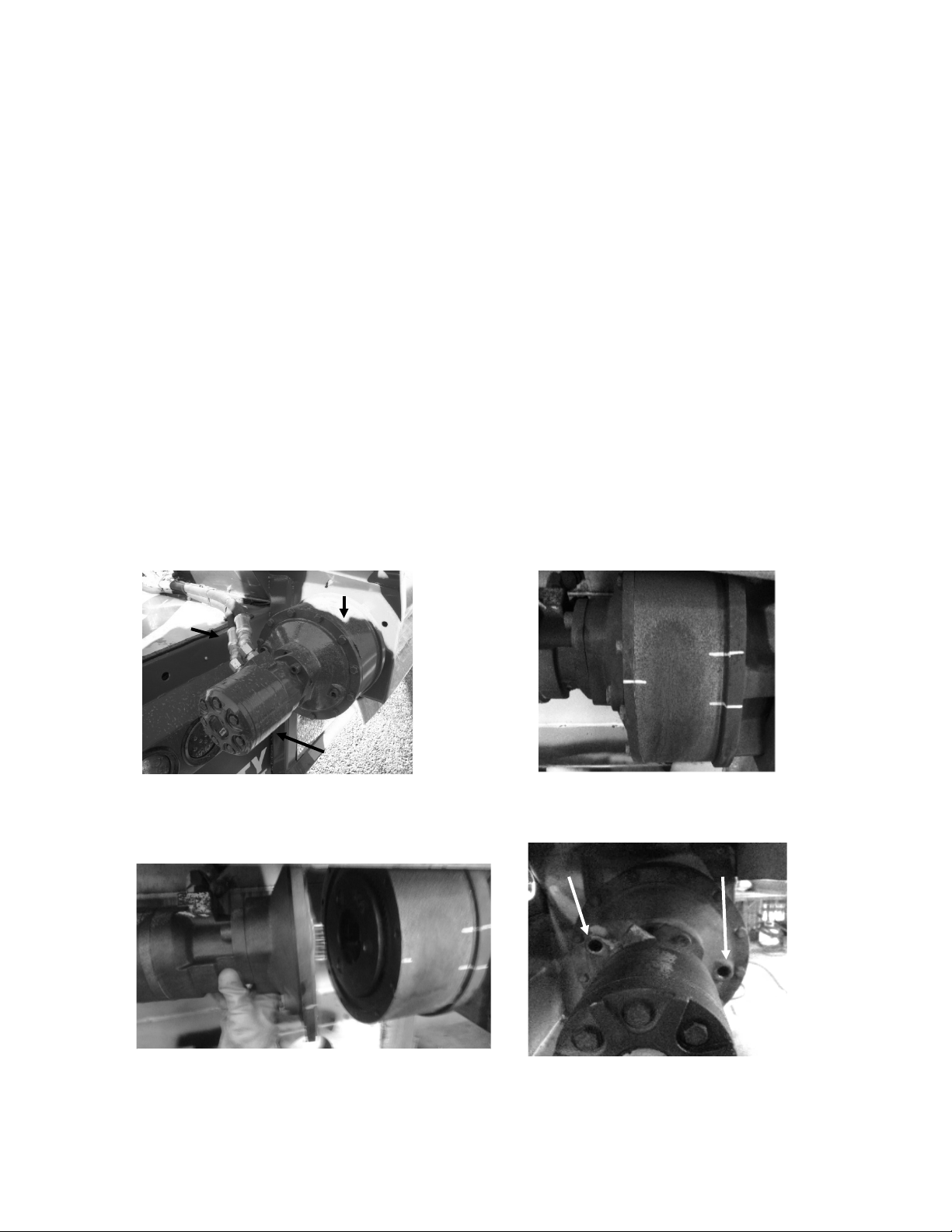

9. Pull up the slack to determine how much of the chain to remove (Figure 7). You may

have to remove links from both sides of the split. You should remove links so that

you do not have more than 5 links between flaps.

10. Grind off the head of the pin you need to remove (Figure 8).

11. Drive out the pin using a punch.

12. Connect the chain using a new pin and cotter pin.

13. Weld the chain pins using the following procedure.

14. Remove the Come-Along from each chain.

15. Adjust the chain using the previous procedure.

WELDING CHAIN PINS

The pin must be secure and should not be able to freely rotate within the link as this can

cause accelerated wear and result in failure of the pin.

1. Place the ground clamp from the welder on the chain itself near the link to be welded.

Placing the ground on the body of the trailer will not allow enough current to pass

through the link to obtain a sufficient weld.

2. Weld the pin on the "trailing" edge of the pin. Weld between the pin and the link, not

just the pin and the cotter pin (Figure 9).

7

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

3. No weld is required on the opposite side of the chain where the head of the pin meets

the link (Figure 5).

.

Master Pin

Figure 5 - Master Pin Identification

Figure 6 - Using Come-Along To Pull Up Chain Slack

Figure 7 - Determine How Much Chain To Remove

8

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

CONVEYOR CHAIN LUBRICATION

The conveyor chain must be inspected regularly and lubricated using a high quality oil.

Do not use grease. Any type of lubricant may be used depending on products hauled and

individual preference. A good general purpose lubricant is chain and cable fluid, which

has penetrating qualities as well as dust repellent. Use Table 1 to determine which grade

of lubricant to use based upon the operating temperature.

Table 1-Chain Lubricant Guide

Temperature

(Degree °F)

Recommended

Lubricant

-20 to 20

SAE 10

20 to 40

SAE 20

40 to 100

SAE 30

100 to 120

SAE 40

120 to 140

SAE 50

Figure 8 - Chain Pin With Head Ground Off

Figure 9 - Properly Welded Pin

9

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

How often the chains need lubrication is dependent upon the amount of use and the type

of product carried.

•Under daily use or in harsh environments, daily inspection is required. Lubricate as

needed.

•Under all other uses, weekly inspection should be sufficient. Lubricate as needed.

•If a food-grade lubricant is used, you may need to apply it more often. It is your

responsibility to determine how often lubrication is required.

!WARNING

Remember, proper lubrication can extend chain life, reduce down time and save you

money.

BEARINGS AND SPROCKETS

The bearings on the front and rear conveyor shafts must be inspected and lubricated at

regular intervals using an NLGI Grade 2 general-purpose grease. As with chain

lubrication, the amount of lubrication is dependent upon the amount of use.

•Under daily use, daily inspection is required. Lubricate as needed.

•Under all other uses, weekly inspection should be sufficient. Lubricate as needed.

•Inspect sprockets for excessive wear or damage.

!WARNING

PLANETARY GEARBOX

When using the planetary gearbox under normal temperature ranges between 0-120 °F,

the gearbox is to be half full of SAE 80/90 oil. Use the lower of the two plugs to check

the level of the oil. Oil is to be changed after the first 50 hours of operation with

subsequent changes every 1000 hours or yearly, whichever comes first.

Attempting to lubricate the chains while they are in motion

can result in serious bodily injury or death. Stay clear of the

chains while they are in motion. Position the chains and

completely disable the hydraulic system before doing any

maintenance.

Attempting to lubricate the bearings while the shaft is

rotating can result in serious bodily injury or death. Stay

clear of the bearings while they are rotating. Completely

disable the hydraulic system before doing any maintenance

on the bearings.

NOTE

There is absolutely no warranty, expressed or implied, on the chain or

drive system if the system is not maintained properly, is misused or is

overloaded. This includes, but is not limited to the hauling of corrosive

materials such as fertilizer, sludge, brewer’s mash or corn gluten.

10

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

CHANGING PLANETARY OIL

The following are basic instructions for changing the oil in the planetary. For more

detailed instructions see the Planetary Disassembly procedure or the Planetary Service

Manual found on the CD provided with this manual.

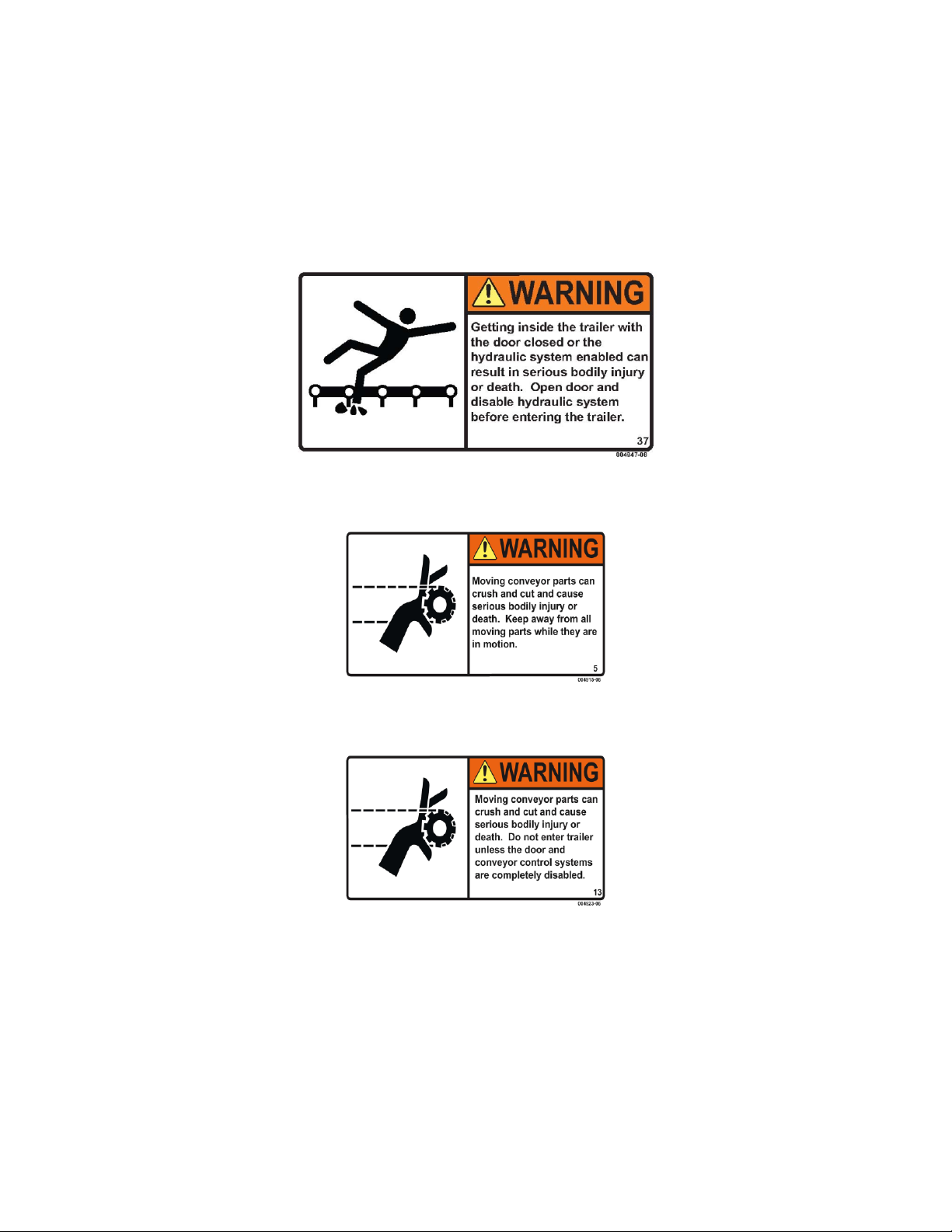

1. Label and remove the hydraulic lines from the hydraulic motor (Figure 10).

2. Mark position of the planetary cover and ring gear for reassembly (Figure 11).

3. Remove the cover with motor attached (Figure 12).

4. Remove all gear sets.

5. Remove the ring gear.

6. Clean and inspect all gears for chipped, cracked, pitted, or rusty teeth.

7. Apply a small bead of silicone to all sealing surfaces.

8. Install ring gear.

9. Install all gear sets.

10. Install cover and torque all bolts to 45 lb-ft.

11. Remove the fill and full plugs from the cover (Figure 13).

12. Add SAE 80/90 gear oil through the fill hole until oil comes out of full hole.

13. Reinstall plugs into cover.

14. Reconnect the hydraulic lines to the hydraulic motor.

FULL

Figure 10 - Planetary

Hydraulic

Lines

Planetary

Hydraulic

Motor

Figure 11 - Planetary Position Marking

Figure 12 - Planetary Cover Removal

Figure 13 - Planetary Plugs

FILL

FULL

11

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

LUBRICATION OF THE DOOR(S)

Door hinges and bearings must be lubricated regularly, especially if the trailer has been

operated or stored for an extended period of time in a humid or wet environment.

Corrosion can lead to the failure of door hinges if they are not maintained properly. As a

general rule with the rear doors, as with the entire trailer, “if it moves, lubricate it.” Use a

NLGI Grade 2 general-purpose grease on all shafts and grease zerks.

The seals on most doors should have silicone grease or spray-on lubricant applied to them

once every three months. This will help them last longer and will help them provide a

better seal. During cold, damp weather or under heavy use, apply the grease more

frequently.

CARE OF THE PLASTIC LINER

HIGH MOLECULAR WEIGHT (HWM) AND

ULTRA-HIGH MOLECULAR WEIGHT (UHMW) LINER

The plastic liner under the chain (and on the slopes, if applicable) must be inspected for

damage and wear. Replace the liner if it is worn through at any spot. If any foreign

material should become lodged between the liner and the body of the trailer, remove it by

blowing or vacuuming it out.

!

CAUTION

!WARNING

Use eye protection when using air to blow material from

underneath the liner to help prevent injuries from flying

particles.

Getting inside the trailer with the door(s) closed or the

hydraulic system energized can result in serious injury or

death. Open door(s) and disable all hydraulic systems

before entering the trailer.

12

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

COATING CARE AND CORROSION PREVENTION

Your Eagle Bridge™ trailer is coated with a high-performance polyurethane paint. This

paint is designed to give you durable performance in the rugged environments

encountered by your trailer.

The best way to preserve the finish on your trailer and help prevent corrosion is to wash it

regularly, especially after it has been used around road salt or other ice melting agents,

road oil or tar, or any other potentially corrosive material. Use warm water with a mild

detergent and allow the trailer to air dry. Use of abrasive or caustic cleaning agents will

void the paint warranty. Hauling corrosive products such as salts and fertilizers will also

void the paint warranty.

Small nicks or chips in the paint can occur with normal use. Any chips or scratches in

the finish should be repaired with matching touch-up paint. This is especially important

for carbon steel trailers, as even small areas of bare metal can corrode quickly. The cost

of repairing any chips is the responsibility of the owner.

Removal or disrepair of mud flaps on either the tractor or the trailer will void the paint

warranty. Frequent use of the trailer on gravel roads will also void the warranty.

If your trailer has aluminum wheels, you should clean them regularly with mild detergent

and water to prevent corrosion. Use a non-abrasive, non-acidic cleanser to remove heavy

build-up when necessary. Do not use abrasive metal polishes or scouring pads.

STAINLESS STEEL BODIES

Trailers with stainless steel bodies require the same care as painted trailers. Regular

washings to remove road grime and remnant corrosive material will help maintain the

finish and help prevent corrosion. Use warm water with a mild detergent and allow the

trailer to air dry. Use of abrasive cleaning agents will dull and scratch the finish. Use of

carbon steel utensils will result in surface contamination.

It is particularly important to rinse off the trailer after hauling any material containing

chlorides as prolonged contact with chlorides may dull the finish and leave it subject to

pitting.

Carbon contamination of stainless steel will cause localized rust spots. The breakdown of

the carbon on the surface of stainless steel does not affect the structural integrity of the

trailer.

13

©2014-2015 Trinity Trailer Mfg., Inc.

Jun 2014 Rev

CLEANING THE INTERIOR

If product accumulates underneath the chain and flaps, it can usually be removed by

lifting each flap and vacuuming, sweeping or blowing the material out. Under no

circumstances should you get into the trailer with the conveyor system running or

enabled (Figure 14). For your safety, completely disable the hydraulic system

before entering the trailer (Figures 15 and 16).

Figure 14 - Entry into Trailer Decal

Figure 15 - Moving Conveyor Parts Decal

Figure 16 - Moving Conveyor Parts Decal

14

©2014-2015 Trinity Trailer Mfg., Inc.

Table of contents

Popular Utility Vehicle manuals by other brands

Toro

Toro Workman GTX Operator's manual

Humbaur

Humbaur 1000 Series operating instructions

Taylor-Dunn

Taylor-Dunn C0-014-32 Operation, t roubleshooting and replacement parts manual

Clam

Clam POLAR TRAILER LG 1300 manual

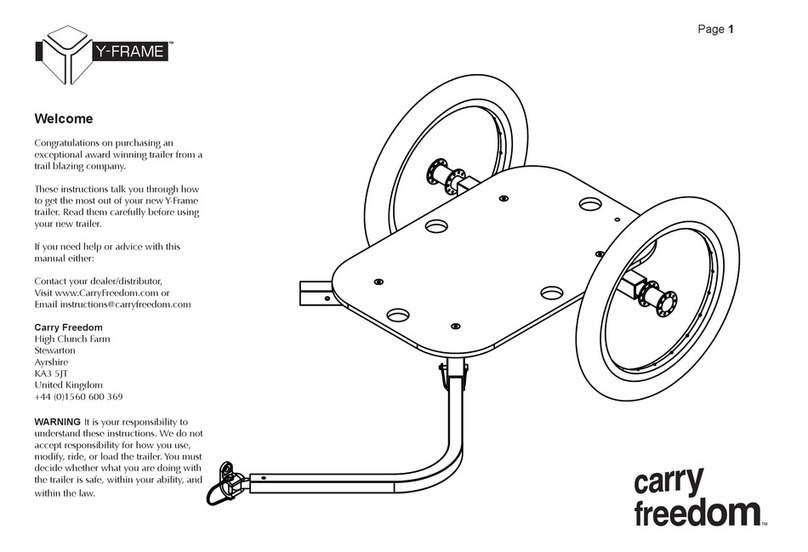

Carry Freedom

Carry Freedom Y-Frame instructions

Sodi

Sodi mini 950 User maintenance guide