Fitting the engine & Transmission

Torque Converter.

Step One

Fit the pre-drilled eng /

transmission plate to the

chassis slide rails.

Mount the engine on top

of the plate using the pre-set holes.

Using 4x M8 x 65 hex ( up from the underside of the frame)

2x 3/8” washers per bolt (against the underside of the rails),

4x M8 washers on the top of the engine foot followed by

4x M8 nylocks. (Tighten the nylocks then back them off

enough to allow the engine to move forward to tension the

chain).

Step Two

Assemble the idle shaft

from the left hand side :

1. Collar (grub screws removed & kept safe).

2. 12 tooth sprocket with 3/16” key cut to size (14mm).

3. Collar.

4. Collar.

5. Driven pulley (With the spring boss facing left & 3/16” x

21/4” long key inserted) & collar.

All the keys must be a good tap fit.

Step Three

Mount the two box section

risers to the plate forward of

the engine (Leave a small gap

for the left hand inspection

side cover to slide between the

frame & the riser).

Using 4x M8 x 140 bolts, 3/8” penny washers (2 together

on the underside of the slide rail)

4x M8 nylocks, loosely bolt the idle shaft

bearings on top, with the bearing grub

screw bosses facing inwards. (Remove

bearing grub screws & keep in a safe

container for later use). As the risers are

mounted to the chassis sliders, the idle

shaft assembly can be introduced into the

bearings.

Step Four

When aligned the idle shaft bearing

bosses need to be secured to the idle

shaft.

This is done by using a drill bit just

smaller than the grub screw hole in the

bearing & drilling through the hole into the shaft by 1-2mm.

(Be sure the shaft is centralized in the bearings, & make sure the

risers are fully tightened before drilling).

The grub screws are then refitted to the bearings (remove any

swarf first) & through into the shaft preventing any sideways

movement.

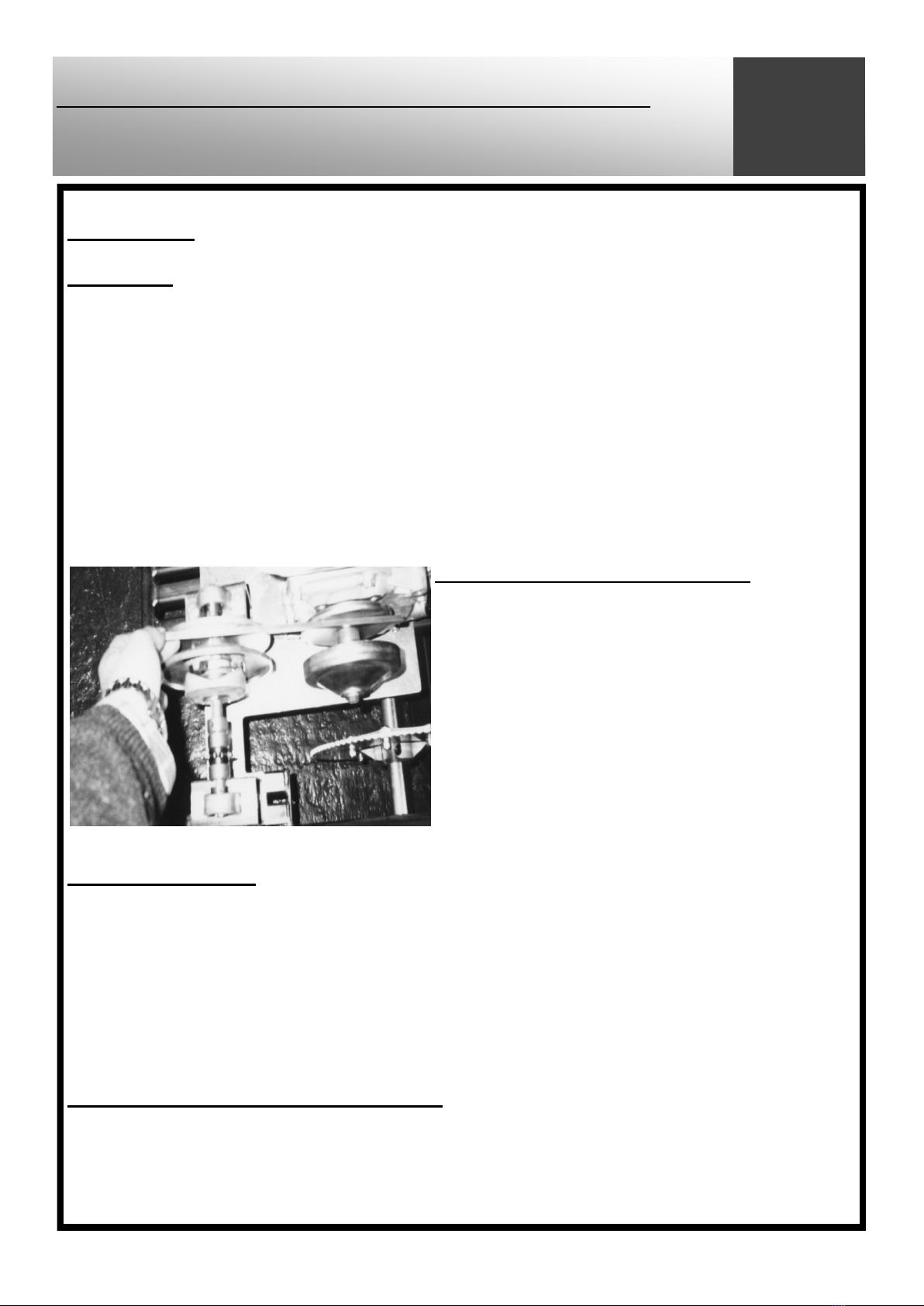

Step Five

Assemble to the very lightly greased

engine output shaft, the driver flat

pulley half tight up to the shaft

shoulder. (Driver fixed sheave #12).

Then tighten the engine down.

Tighten down the two idle shaft bearings & risers checking

alignment. Move the R.H.S collar up to the flat side of the

driven pulley (Driven fixed face #1) & using a straight edge

align the flat working faces of the

two pulleys up.

(This is important to enable the

belt run in line, otherwise rapid

belt wear & dragging will occur).

Step Six

With the R.H.S shaft collar tight up against the pulley, hold the

collar in position & push away the pulley.

Making sure the collar does not move drill through the grub screw

hole into the shaft 1-2mm.

N.B Do not drill into the key way slot or near it).

Fit the grub screw,

(remove any swarf from the

hole first) & check the pulley

alignment.