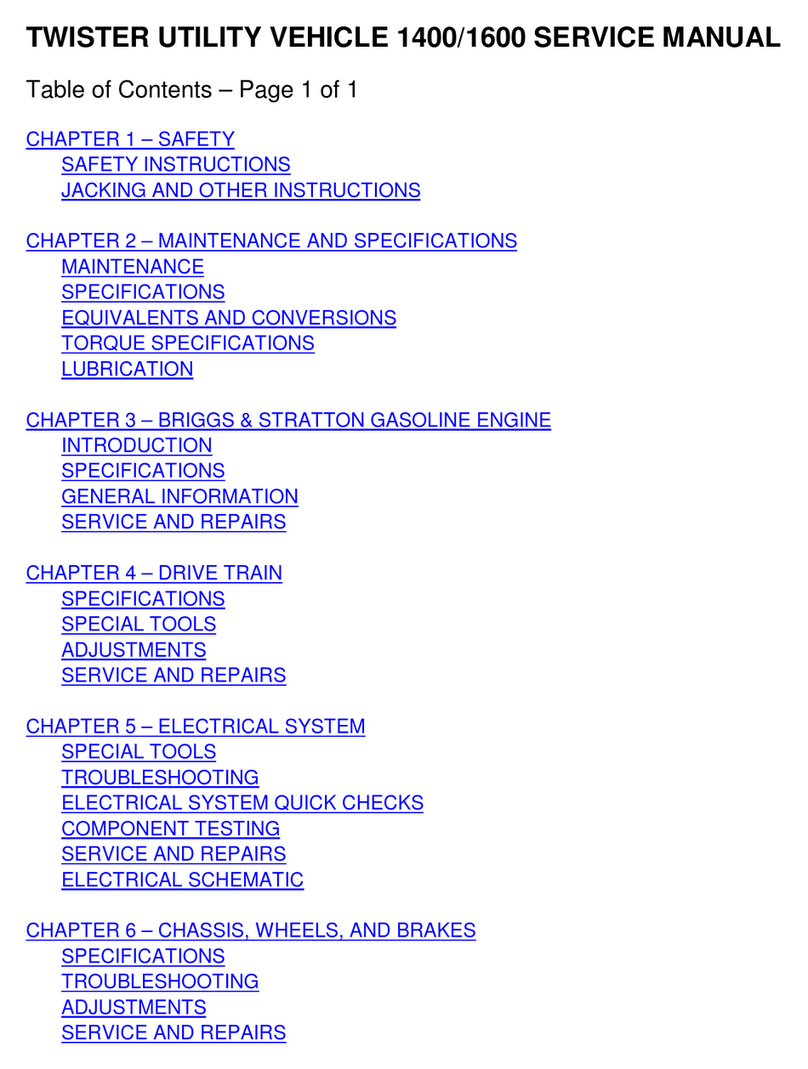

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

Supervisor’sResponsibilities.................................4

BeforeOperating.................................................4

Operation.............................................................5

Maintenance.........................................................6

SoundPressure.....................................................6

Vibration..............................................................6

SoundLevelCertication.....................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................13

1CheckingtheFluidLevels................................13

ProductOverview......................................................14

Controls.............................................................14

Specications.....................................................17

Attachments/Accessories...................................17

Operation...................................................................18

CheckingtheEngineOilLevel............................18

AddingFuel.......................................................19

CheckingtheCoolantLevel................................20

CheckingtheTransaxle/HydraulicFluid

Level..............................................................20

CheckingtheHighFlowHydraulicFluid(If

soequipped)...................................................21

CheckingtheFrontDifferentialOilLevel

(FourWheelDriveModelsOnly)....................21

CheckingtheTorqueoftheWheel

Nuts...............................................................22

CheckingtheTirePressure.................................22

CheckingtheBrakeFluid....................................22

Pre–startingChecks............................................23

StartingtheEngine.............................................23

DrivingtheVehicle.............................................23

StoppingtheVehicle...........................................24

StoppingtheEngine...........................................24

NewVehicleBreak–in........................................24

CheckingtheInterlockSystem............................24

OperatingCharacteristics...................................25

Passengers..........................................................25

Speed.................................................................26

Turning..............................................................26

Braking..............................................................26

TipOvers...........................................................26

Hills...................................................................27

LoadingandDumping........................................27

FourWheelDrive(FourWheelDriveModels

Only)..............................................................28

TransportingtheVehicle.....................................28

TowingtheVehicle.............................................28

TowingaTrailerwiththeVehicle.........................29

Maintenance...............................................................30

RecommendedMaintenanceSchedule(s)................30

ServiceIntervalChart.........................................31

HeavyDutyOperation.......................................32

PremaintenanceProcedures....................................32

RemovingtheFullBed.......................................32

InstallingtheFullBed.........................................32

JackingtheVehicle..............................................33

RemovingtheHood...........................................33

Lubrication.............................................................34

GreasingBearingsandBushings.........................34

EngineMaintenance...............................................37

ServicingtheAirCleaner....................................37

ChangingtheEngineOilAndFilter....................37

FuelSystemMaintenance.......................................38

FuelLinesandConnections................................38

ServicingtheWaterSeparator/Fuel

Filter..............................................................38

ElectricalSystemMaintenance................................39

Fuses..................................................................39

JumpStartingtheVehicle....................................40

ServicingtheBattery...........................................40

DriveSystemMaintenance.....................................41

ChangingtheFrontDifferentialOil(Four

WheelDriveModelsOnly).............................41

InspectingtheConstantVelocityBoot(Four

WheelDriveModelsOnly).............................41

AdjustingtheShiftCables...................................42

AdjustingtheHigh–LowCable...........................42

InspectingtheTires............................................42

CheckingtheFrontWheelAlignment.................42

CoolingSystemMaintenance..................................43

RemovingDebrisfromtheCooling

System............................................................43

ChangingEngineCoolant...................................44

BrakeMaintenance.................................................45

AdjustingtheParkingBrake................................45

AdjustingtheBrakePedal...................................45

BeltMaintenance....................................................46

AdjustingBelts...................................................46

ControlsSystemMaintenance.................................46

AdjustingtheAcceleratorPedal..........................46

AdjustingtheClutchPedal..................................47

ConvertingtheSpeedometer..............................47

HydraulicSystemMaintenance...............................48

ChangingtheHydraulicFluidandCleaning

theStrainer.....................................................48

ReplacingtheHydraulicFilter.............................48

ChangingtheHighFlowHydraulicOiland

Filter(Ifsoequipped).....................................49

Storage.......................................................................50

Schematics.................................................................51

3