Triogen TOG B2 Manual

Degrémont Technologies-Triogen

East Kilbride G75 0YF, Scotland

Tel: +44 (0) 135 522 0598

Fax: +44 (0) 135 557 0058

English Version - April 2011

Compact Ozone System

Installation & Operating

Instructions

1

CONTENTS INDEX

INFORMATION

GENERAL & TECHNICAL INFORMATION 2

ELECTRICAL INFORMATION 3

DESCRIPTION OF EQUIPMENT:

OZONE GENERATOR 4

AIR DRYER 4

VACUUM INDUCTION SYSTEM 5

CONTACT / DEGASSING SYSTEM 5

INSTALLATION OF EQUIPMENT:

BOOSTER PUMP & INJECTOR 6

WATER TRAP ASSEMBLY 6

OZONE GENERATOR 6

AIR DRYER 7

CONTACT / DEGASSING SYSTEM 8

OZONE GENERATOR MOUNTING DETAIL 9

DRYER MOUNTING DETAIL 9

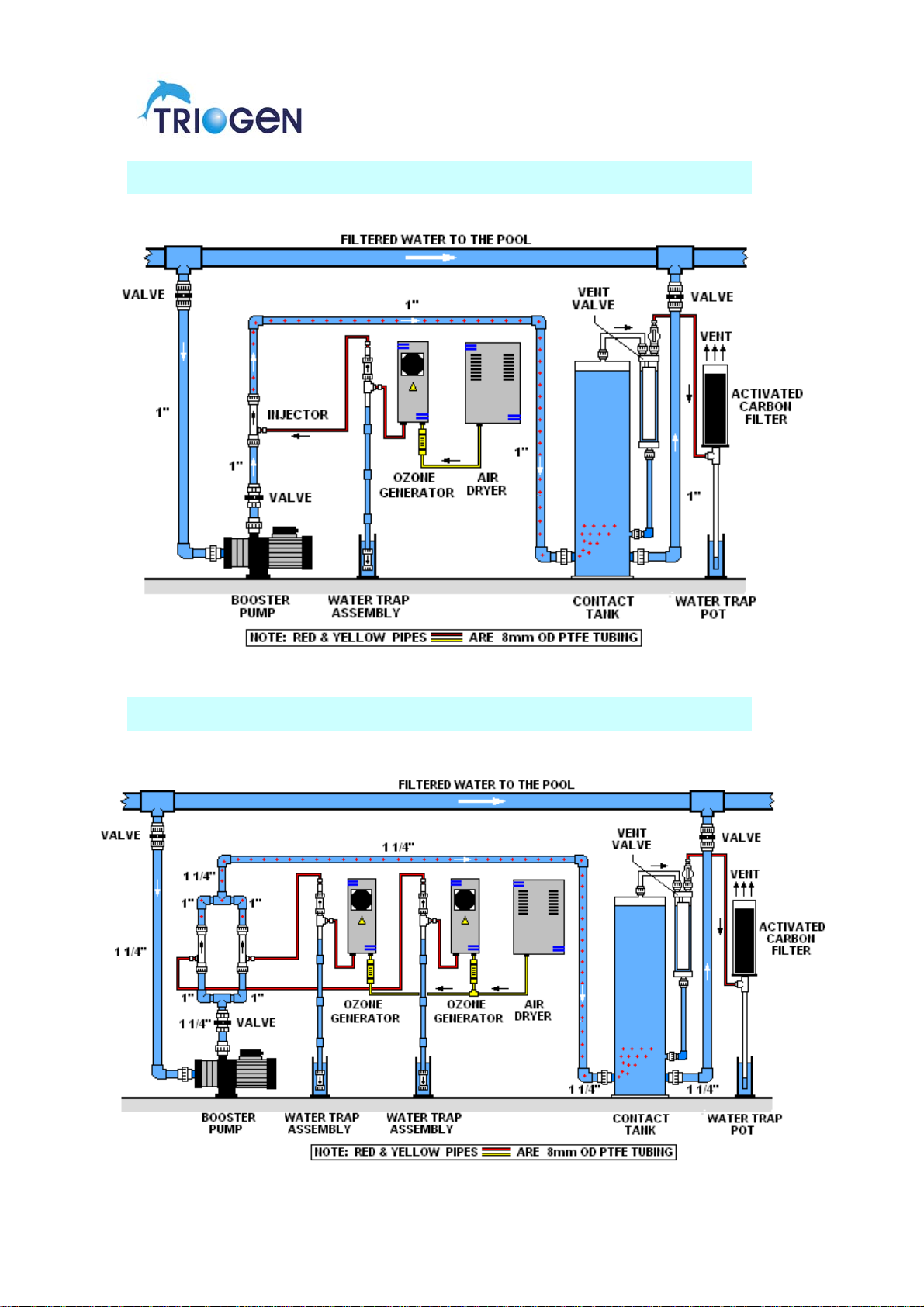

T2 INSTALLATION DIAGRAM 10

T2 INSTALLATION DIAGRAM (CONTACT) 10

T4 INSTALLATION DIAGRAM (CONTACT) 11

T8 INSTALLATION DIAGRAM (CONTACT) 11

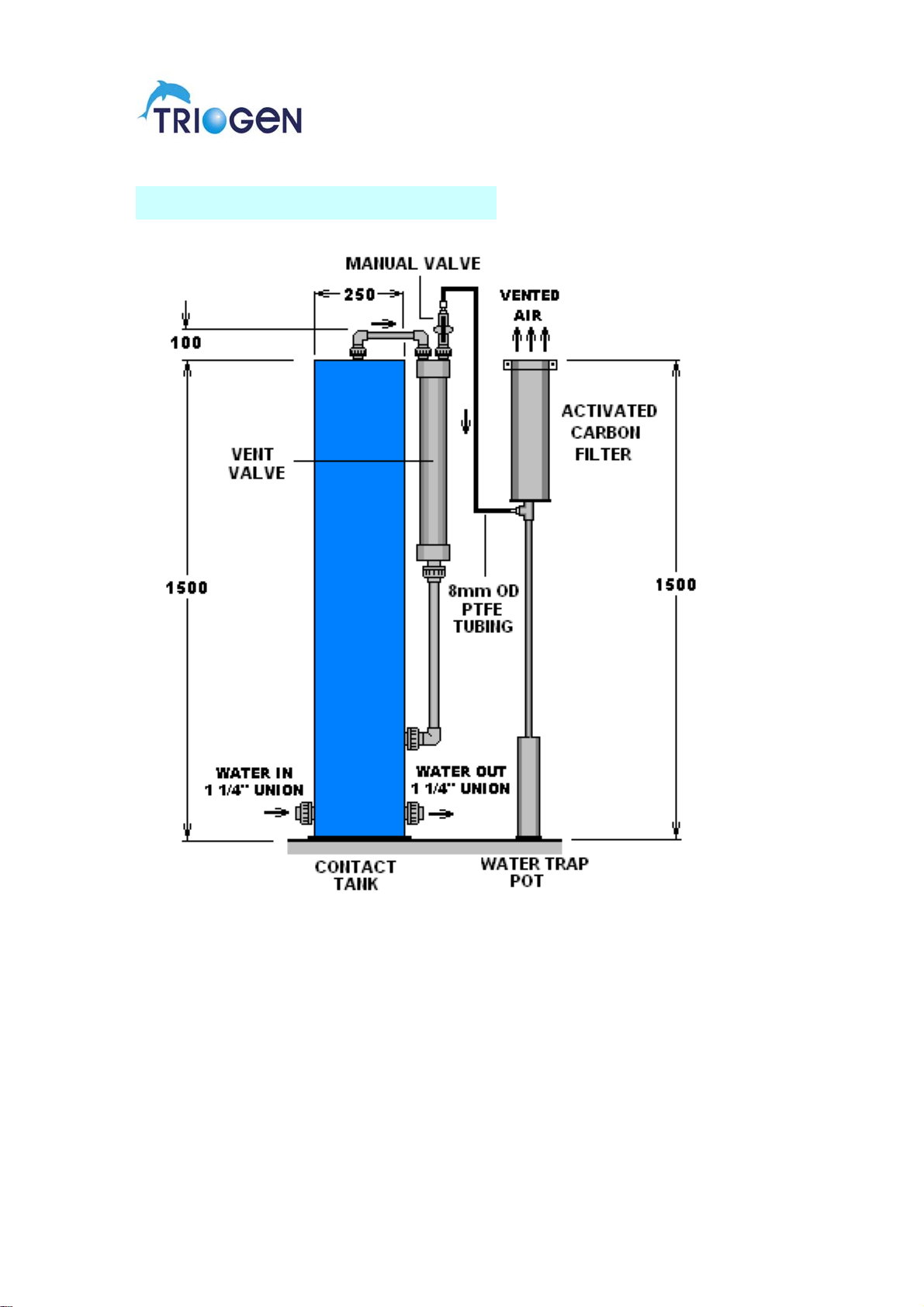

CONTACT DEGASSING DIAGRAM 12

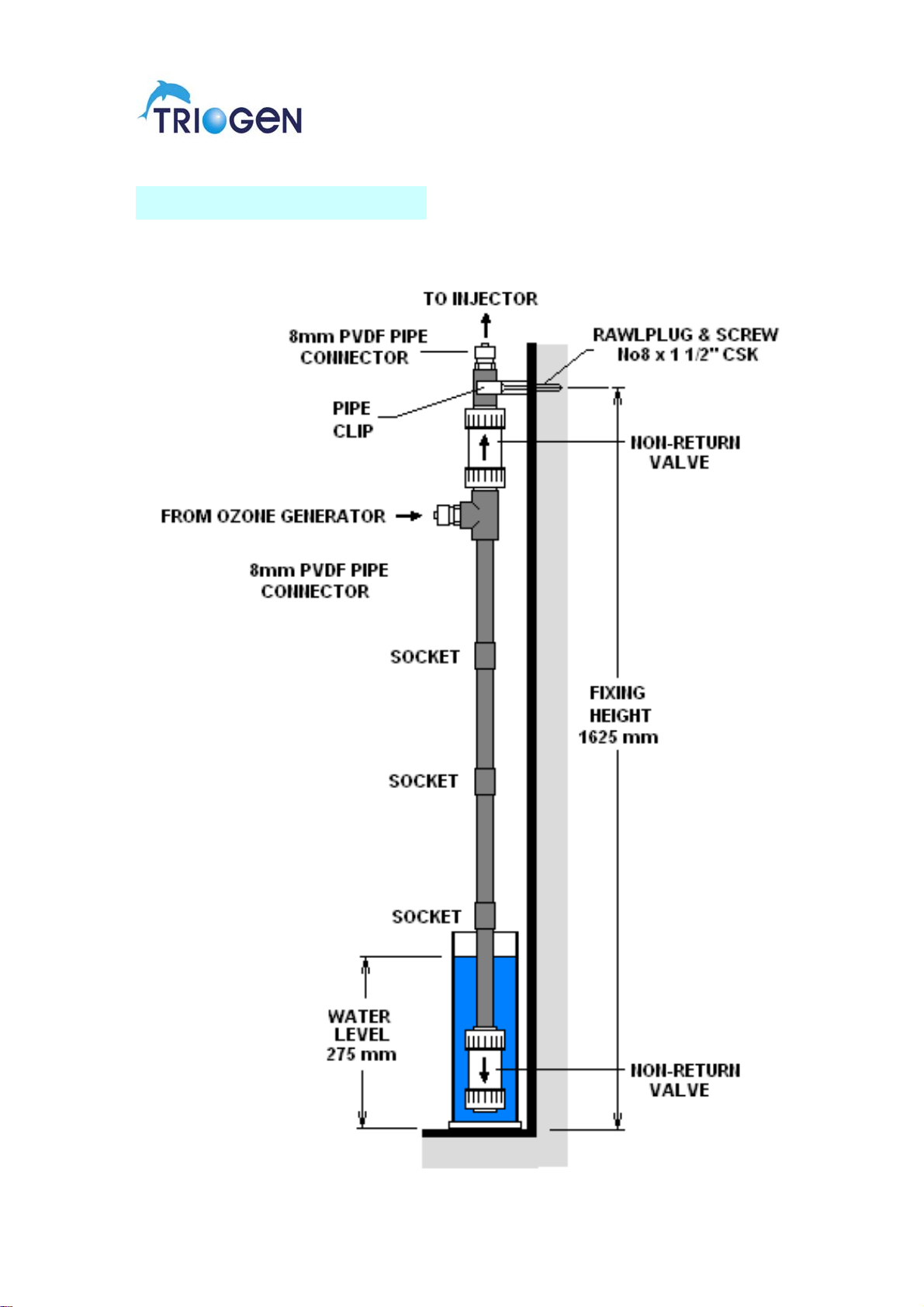

WATER TRAP DIAGRAM 13

ELECTRICAL INSTALLATION 14

MANUAL CONTROL 14

TIME CLOCK CONTROL 14

REDOX CONTROL 15

OPERATION OF EQUIPMENT:

STARTING THE OZONE SYSTEM 16

OPERATION & MAINTENANCE 17

SPARE PARTS:

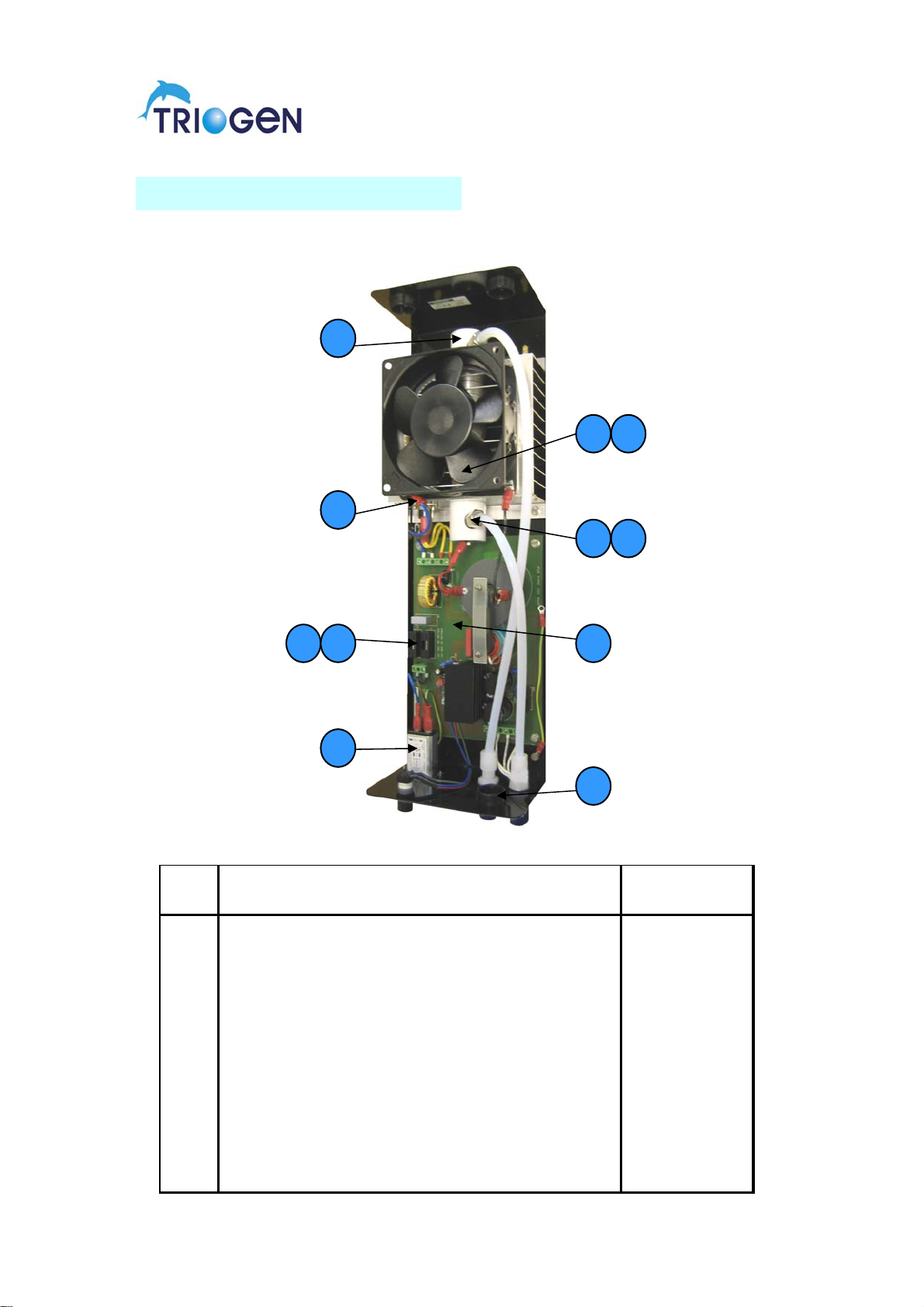

TOGB2 GENERATOR PARTS 18

TADB1 AIR DRYER PARTS 19

WARRANTY OF EQUIPMENT:

WARRANTY 20

2

GENERAL INFORMATION

T8 SYSTEM COMPRISES:

2 - OZONE GENERATOR TOG B2

1 - AIR DRYER TADB1

2 - INJECTOR

2 - WATER TRAP ASSEMBLY

2 - AIR FLOWMETER

2 - 8mm PTFE TUBING 3 METERS

1 - 8mm FESTO TEE-PIECE

TOG B2 TECHNICAL INFORMATION

OZONE OUTPUT (gm/hr) : 2.0

VOLTAGE (v/ph/hz) : 110-230/1/50-60

POWER (watts) : 120

DIMENSIONS (mm) : 440H x 155W x 110D

WEIGHT (kg) : 4.4

TAD B1 TECHNICAL INFORMATION

AIR OUTPUT (ltr/min) : 24

VOLTAGE (v/ph/hz) : 110-230/1/50-60

POWER (watts) : 60

DIMENSIONS (mm) : 440H x 305W x 110D

WEIGHT (kg) : 10.0

TDG A1 TECHNICAL INFORMATION

WATER FLOW (m3/hr) : 4.8 max

DIAMETER (mm) : 250

HEIGHT (mm) : 1600 overall

CONNECTIONS (mm) : 1” or 1 1/4” union

WEIGHT (kg) : 29 empty

CH2-50-1 TECHNICAL INFORMATION

WATER FLOW (m3/hr) : 2.4

PRESSURE (m head) : 28

VOLTAGE (v/ph/hz) : 110-230/1/50-60

POWER (watts) : 710

WEIGHT (kg) : 12.0

CH4-50-1 TECHNICAL INFORMATION

WATER FLOW (m3/hr) : 4.8

PRESSURE (m head) : 28

VOLTAGE (v/ph/hz) : 110-230/1/50-60

POWER (watts) : 1250

WEIGHT (kg) : 16.0

TECHNICAL INFORMATION

T4 SYSTEM COMPRISES:

1 - OZONE GENERATOR TOG B2

1 - AIR DRYER TADB1

1 - INJECTOR

1 - WATER TRAP ASSEMBLY

1 - AIR FLOWMETER

1 - 8mm PTFE TUBING 3 METRES

T2 SYSTEM COMPRISES:

1 - OZONE GENERATOR TOG B2

1 - INJECTOR

1 - WATER TRAP ASSEMBLY

1 - AIR FLOWMETER

1 - 8mm PTFE TUBING 3 METRES

TDG A1 SYSTEM COMPRISES:

1 - 250 DIA CONTACT TANK

1 - AUTOMATIC VENT VALVE

1 - CARBON DESTRUCT FILTER

1 - WATER TRAP POT

1 - 8mm PTFE TUBING 3 METRES

OPTIONAL EXTRAS:

INJECTOR BOOSTER PUMP CH2-50-1

(T2 & T4 SYSTEMS)

INJECTOR BOOSTER PUMP CH4-50-1

(T8 SYSTEM)

3

ELECTRICAL INFORMATION

SYMBOLS:

The lightning flash with arrowhead symbol is to alert the user to

the presence of uninsulated “dangerous voltage” within the

product enclosure that may be of sufficient magnitude to

constitute risk of electric shock to persons.

The warning label is to instruct service personnel to disconnec

t

the mains supply before removing the front cover.

CAUTION: To reduce the risk of fire or electric shock, do not expose this

unit to excessive temperatures, rain or moisture.

Always disconnect this unit from the supply when not in use fo

r

lengthy periods.

IMPORTANT: Servicing should only be done by qualified personnel. No user

-

serviceable parts inside.

MAINS OPERATION:

The wires in the lead are coloured in accordance with the

following wiring codes:

BROWN…………………LIVE

BLUE…………………….NEUTRAL

YELLOW/GREEN………EARTH

The wires in the mains lead must be connected to the terminals

in the plug as follows:

BROWN WIRE…………L OR RED

BLUE WIRE……………N OR BLACK

YELLOW/GREEN……..E OR EARTH

The plug should be fitted with a 3 amp fuse

NOTE: THIS UNIT MUST BE EARTHED.

INTERNAL FUSES:

The following fuses are fitted within the equipment:

OZONE GENERATOR

220 – 240V-2 No. 1A TYPE (T) – 20mm

110 – 120V-2 No. 2A TYPE (T) – 20mm

AIR DRYER

220 – 240V No. 1.6A TYPE (T) – 20mm

110 – 120V No. 3A TYPE (T) – 20mm

DESCRIPTION OF EQUIPMENT

Triogen compact air dryers are fully automatic desiccant dryers which are

electronically controlled for reliability and ease of use.

The dryer contains two desiccant columns with integral heater elements, two

three-port solenoid valves, an air pump for purging moisture from the

columns, all of which are controlled by a programmable relay.

When one column is drying the air, the other column automatically heats up

and the small purge pump passes air in reverse flow through the column to

drive out the moisture retained within the desiccant material. After a pre-set

period of time, the heater and pump are switched off to allow time for the

column to cool down prior to it going on stream to allow regeneration of the

other column.

This process is continuous unless the unit is switched off. Automatic cycling

of the air dryer columns is controlled by a no-maintenance programmable

relay ensuring no loss of cycling sequence when the unit is switched off.

AIR DRYER

4

Triogen compact ozone generators comprise three main components – a

high voltage, high frequency power board driving a ceramic corona discharge

module which is air cooled by an integral cooling fan.

Normal atmospheric air can be used as the feed gas, or pre-dried air supplied

by a Triogen compact air dryer, either of which is drawn through the ozone

generator under vacuum which is created by a water driven venturi injector.

When the unit is switched on, an electrical corona discharge is formed within

the module by the power being supplied from the board. This reforms the

oxygen molecules (O2) present in the feed gas into ozone (O3) as the air

passes through the module.

As heat is produced by the generation of the corona discharge, it is

necessary to cool the module during operation. This is achieved by the use of

an integral cooling fan fitted within the ozone generator.

The high voltage, high frequency power board incorporates full overload and

short circuit protection. In addition a thermostat is fitted to the module which

will isolate the power in the event of a cooling fan failure causing the module

to overheat.

The ozone generator is fitted with an output control knob, located on the

underside of the unit adjacent to the pipe connectors, which electrically varies

the ozone output between 50% and 100% of the rated output of the unit.

OZONE GENERATOR

THE VACUUM INDUCTION SYSTEM

THE CONTACT / DEGASSING SYSTEM

An optional contact / degassing system is available which virtually eliminates

the air bubbles present in the ozonised water stream thereby avoiding air

entering the pool through the water inlet system.

The system comprises of a contact tank fitted with an external combined

level control and venting valve which vents the excess air and any ozone gas

present to an ozone gas destruct unit which destroys any ozone gas before

venting to the atmosphere.

The ozone gas destruct unit consists of a wall mounted container which is

filled with activated carbon through which the vented air from the degasser

unit is passed.

Any excess ozone gas present reacts with the carbon and is converted back

to oxygen before being released to the atmosphere.

It is strongly recommended that a degassing system is adopted as

entrained air entering the pool can be visually unacceptable and could

have a bleaching effect on pool liners or covers.

5

The ozone induction system is comprised of an air to water venturi injector

which is driven by a water booster pump.

The booster pump takes its supply from the filtered water return pipe to the

pool and increases the pressure of the water that then passes through the

venturi injector. The design of the injector then uses this pressure to induce a

vacuum at the side connection of the unit which is connected to the ozone

generator via a water trap assembly.

It is the creation of this vacuum that draws the air through the ozone

generator and then into the injector where the ozone gas then mixes with the

water stream.

The amount of suction created by the injector can be controlled by varying

the water flow from the booster pump by adjusting the valve fitted in the

pump discharge line. Alteration of the airflow through the generator also

controls the amount of ozone gas produced.

6

INSTALLATION OF EQUIPMENT

The installation of the equipment should only be carried out by engineers who

are trained in fitting standard pool filtration equipment.

BOOSTER PUMP & INJECTOR

The injector booster pump suction pipe should be installed as close as possible

to the main pool water return line.

The pump MUST be installed in such a manner that it has flooded suction at all

times as failure to do so will result in a premature failure of the pump seals.

The pipework should be sized to suit the suction and discharge of the pump used

and incorporate isolation valves at both take-off connections to the main pool

water return line and also between the booster pump discharge and the injector.

The injector can be mounted either in a horizontal or vertical position. It is

normally mounted directly above the booster pump discharge valve.

WATER TRAP ASSEMBLY

A

water trap assembly, as shown in the typical installation diagrams, MUST

always be used to ensure that water cannot pass from the injector to the ozone

generator when the water booster pump is stopped.

The water trap assembly should be wall mounted as close as possible to the

injector at a distance not exceeding 3 metres and at the height indicated.

A

fter mounting, the injector suction should be connected to the top connection o

f

the water trap assembly utilising the flexible tubing supplied. The tubing should

be clipped to the wall at 300mm centres to prevent the tubing from kinking unde

r

it’s own weight, particularly at the top connection to the water trap.

OZONE GENERATOR

The ozone generator should be wall mounted as close as possible to the wate

r

trap assembly at a distance not exceeding 3 metres and a minimum height o

f

1.65 metres above floor level.

The ozone generator MUST only be wall mounted utilising the two screw fixings

included with the unit.

When the position of the ozone generator has been ascertained, the two holes

centres should be marked and drilled in accordance with the fixing centres of the

unit. Insert the plastic rawlplugs into the drilled holes and then insert the

roundhead screws until the screw head is protruding 3mm above the surface.

The ozone generator is then hung on the screw fixings utilising the keyhole slots

on the rear of the unit.

7

OZONE GENERATOR (CONT’D)

A

fter mounting, the ozone generator air outlet should be connected to the side

connection of the water trap assembly utilising the 8mm O.D. flexible tubing

supplied with the unit and supported at 300mm centres to prevent the tubing from

kinking under it’s own weight, particularly at the side connection to the water trap.

The air flowmeter included with the ozone generator should be connected to the

air inlet of the ozoniser utilising a 25mm long piece of the 8mm O.D. flexible

tubing supplied.

When selecting a location for the ozoniser, the following instructions should be

adhered to:

The ozone generator should not be located in a position that subjects the

equipment to rain or moisture.

The ozone generator should not be located in the vicinity of any chemical storage

tanks that are likely to emit chemical fumes.

The ozone generator should not be located in the vicinity of any other equipment

that emits heat. The unit operates with fan-assisted cooling and therefore an

y

obstruction of ventilation or excessive heat will cause damage and shorten the

life of the equipment.

If the ozone generator is being installed in an unheated outdoor plantroom fo

r

use with a seasonal outdoor pool, then the unit should be removed at the end o

f

the season and stored indoors until required.

The ozone generator produces high voltage electricity, therefore never remove

the outer cover while the unit is connected to the mains power supply.

AIR DRYER

The air dryer should be wall mounted adjacent to the ozone generator at the

same height, leaving an air gap of 50mm between the units. The units should

only be mounted side by side and never above or below each other.

The air dryer MUST only be wall mounted utilising the two screw fixings included

with the unit.

When the position of the air dryer has been ascertained, the two hole centres

should be marked and drilled in accordance with the fixing centres on the unit.

Insert the plastic rawlplugs into the drilled holes and then insert the roundhead

screws until the screw head is protruding 3mm above the surface. The air drye

r

is then hung on the screw fixings utilising the keyhole slots on the rear of the unit.

8

AIR DRYER (CONT’D)

Under no circumstances should the air dryer cover be removed and the unit

screwed tightly to the wall as the wall fixing method described above is to allo

w

easy removal of the unit should it be required.

It should be noted that the air dryer utilises heat to regenerate the desiccant

material and therefore contact with the outer casing should be avoided when the

unit s in operation.

It should also be noted that the unit emits steam during its regeneration cycle and

therefore it should be located away from any other equipment which may be

affected by condensation.

The contact / degassing tank should be installed in the pipeline between the

injector and the return connection on the main pool water line ensuring that the

direction arrow on the unit is in line with the direction of flow.

On T2 and T4 systems, 1” uPVC should be used.

On T8 systems, 1 ¼” uPVC should be used.

T

he activated carbon filter pot should now be installed in a suitable position at a

maximum height of 1500mm from the top of the filter pot to floor level. The 3/8 “

uPVC pipes supplied should be assembled and then connected to the top T-

piece assembly. The non-return valve supplied as a loose item should then be

connected to the bottom of the 3/8” pipe ensuring that the flow arrow on the valve

is pointing in the direction shown on the installation diagrams.

T

he assembly should then be positioned into the bottom water trap pot and then

secured to the wall at the height shown on the installation diagrams. The bottom

non-return valve should not touch the bottom of the pot as this will restrict its

operation.

T

he activated carbon filter unit should then be charged with the materials

supplied.

First empty the contents of the gravel into the filter, followed by the activated

carbon. The materials supplied should fit exactly into the filter container. The

activated carbon will, over a period of time, degenerate through usage. When the

carbon level falls to approximately 25mm from the top of the container the

activated carbon must be topped up.

T

he level control vent valve should be connected to the filter unit using the 8mm

O.D. tubing supplied. Ensure that the tubing is firmly fixed to the wall surface,

thus avoiding any kinks developing in the system.

Fill the water trap pot to with water to 25mm from the top.

N

OTE: It is the responsibility of the user to ensure that the correct level o

f

activated carbon is maintained. Spare activated carbon can be purchased in 2k

g

p

acks from Triogen or an appointed agent.

CONTACT / DEGASSING SYSTEM

9

AIR DRYER WALL MOUNTING DETAIL

OZONE GENERATOR WALL MOUNTING DETAIL

10

T2 INSTALLATION DIAGRAM (NO CONTACT / DEGASSER)

T2 INSTALLATION DIAGRAM WITH CONTACT / DEGASSER

11

T4 INSTALLATION DIAGRAM WITH CONTACT / DEGASSER

T8 INSTALLATION DIAGRAM WITH CONTACT / DEGASSER

12

CONTACT DEGASSING SYSTEM

NOTE: THE UNIT IS SUPPLIED WITH 1 1/4” - 1” REDUCERS FOR THE WATER

CONNECTIONS TO ALLOW THE USE OF 1” PIPING

Should the plantroom be below the level of the pool, the system must run

on a 24 hour cycle, as the head of water created could cause a leak through

the vent valve and find its way into the plantroom via the waterpot. If the

plant has to be closed down for any reason, close the ½ “ compact manual

valve provided. If the plantroom is above the pool level these precautions

need not apply.

Note! The automatic level control valve is not a 100% shut off valve.

13

WATER TRAP ASSEMBLY

14

ELECTRICAL INSTALLATION

The electrical installation of the equipment should only be carried out by trained

personnel.

The ozone generator and dryer should be fitted with mains plugs in accordance with

the electrical safety instructions.

The mains socket into which the units are to be connected should be of the wall

mounted SWITCHED mains outlet type. The socket must be earthed.

The mains outlet socket can take its electrical feed from various sources, depending

on the method of control.

The injector booster pump should be electrically installed in line with manufacturers

recommendations and should be interlocked with the main circulation pump.

T2 ozone systems require a single outlet switched wall socket.

T4 ozone system requires a double outlet switched wall socket.

T8 ozone system requires a triple outlet switched wall socket.

The number of outlets above do not accommodate the injector booster pump supply

as this would normally be incorporated in the main filtration control panel or from a

separate pump starter unit.

NOTE: UNDER NO CIRCUMSTANCES SHOULD THE GENERATOR OR THE AI

R

DRYER BE HARD WIRED DIRECTLY TO A POWER SUPPLY. IF THIS IS DONE,

THE WARRANTY OF THE UNITS ARE IMMEDIATELY INVALID.

NOTE: UNDER NO CIRCUMSTANCES SHOULD THE GENERATOR OR THE AI

R

DRYER BE WIRED DIRECTLY INTO A FILTRATION CONTROL PANEL O

R

SIMILAR – THEY MUST BE WIRED AS INSTRUCTED ABOVE.

The reason for the above is to ensure that the units can be easily removed either fo

r

winter storage or servicing.

MANUAL CONTROL

If the ozone generator is to be manually controlled, the feed to the mains socket

should be directly from the main filtration control panel and interlocked with the

main circulating pump starter to ensure that the ozone system stops if the main

circulation system stops.

The switch on the mains outlet socket can then be used to stop and start the

ozone system manually as long as the circulating system is operational.

TIME CLOCK CONTROL

If the ozone system is to operate under time clock control together with othe

r

items of equipment, then the ozone system and booster pump should be fed from

the master control panel controlling all other equipment, again via a switched wall

socket into which the ozone generator (and air dryer) are plugged.

15

REDOX CONTROL

Redox control is normally only adopted for spa bath applications where accurate

dosing monitoring is required due to the high turnover rate of the spa water and

fluctuating bather loads.

The normal method adopted when ozone is to be used in conjunction with

bromine is to combine the ozone system with a commercial brominator fitted with

an electrical solenoid valve on its outlet. When the redox controller reaches the

low set point, the ozone generator, booster pump and solenoid valve on the

brominator are energised automatically and continue to run until the redo

x

controller reaches the high set point when they are switched off.

The ozone system can also be used for redox controlled applications in

conjunction with standard chlorine dosing equipment but under these conditions,

the ozone system normally runs continuously.

IN ALL CASES, THE OZONISER MUST BE PLUGGED INTO A SWITCHED

OUTLET SOCKET WHICH IS FED FROM ANY OF THE ABOVE SOURCES

AND INCORPORATES PROPER EARTHING CONNECTIONS.

16

STARTING THE OZONE SYSTEM

The start-up of the ozone system will depend largely on how the system has

been installed but the following checks should be carried out:

1. Check that the water trap pot and the degasser drain pot, if fitted, have

been filled with water to a level of 25mm from the top of the pots and

that all interconnecting tubing is correctly installed.

2. If the system is fitted with the optional degasser system, check that the

activated carbon filter pot has been charged with gravel and activated

carbon.

3. Disconnect the flexible tubing between the water trap assembly and the

ozone generator.

4. With the main circulation system running, open both system isolating

valves to the flood system, check the system for any signs of wate

r

leakage and also that the check valve assembly within the water trap

unit has stopped any backflow of water from the injector.

5. Start the booster pump to ensure that suction is achieved at the side

connection of the water trap assembly. The booster pump should be

stopped and re-started several times to ensure that the ball check valve

incorporated in the water trap assembly seals properly and stops any

water backflow from the injector. Once this has been checked, then the

suction connection to the ozone generator can be remade.

6. Switch on the ozone generator (and air dryer) and then re-start the

booster pump. Air should now be drawn through the ozone system.

7. Check the airflow through the ozone generator and set to 12 litres/min.

utilising the booster pump discharge valve to control the air flow through

the ozone generator.

8. If the system is fitted with the degasser system, check that the

automatic air release valve is venting the column properly and

maintaining a near static water level within the column.

9. Check that there is no smell of ozone from the area of the activated

carbon filter pot. If there is, turn off the ozone generator, air dryer i

f

fitted, and booster pump and carry out the checks in 1 and 2.

10. Check that the system operates correctly under time clock or redo

x

control if fitted and that if the main circulating pump stops, the ozone

system stops.

11. Check that the booster pump always maintains a flooded suction afte

r

the main circulating pump has been switched off.

17

OPERATION & MAINTENANCE

It should be noted that the noise emitted by the generator may fluctuate as the

output is varied but this will stabilise within a few minutes as the temperature o

f

the inner electrode increases or decreases in accordance with the amount o

f

power supplied to the ozone module.

The ozone system has been designed for either periodic or continuous running

with the minimum of maintenance and supervision but the following

checks should be carried out at a minimum of once per week.

Check that ozone generator and air dryer indicator lights are illuminated when

the system should be in operation.

Check the level of water in the water trap pot and top up as required to the

correct level of 25mm from the top of the pot.

Check that the correct airflow is being drawn through the ozone generator and

adjust if necessary.

Check that the injector booster pump is operating correctly.

On systems fitted with the optional degasser system, it is necessary to check the

activated carbon in the activated carbon filter pot which will degenerate

through usage. When the carbon level falls to approximately 25mm from

the top of the container the system must be topped up.

Note: It is the responsibility of the user to ensure that the correct level of

activated carbon is maintained. Spare activated carbon can be purchased

in 2kg packs from Triogen or your local distributor.

Maximum output of the generator is attained when the control knob is set to

position 10. The airflow through the generator should be maintained at the

recommended 10-12 litres/minute, irrespective of the setting used for the

variable output.

18

TOG B2 GENERATOR PARTS

ITEM PART BIN

No. DESCRIPTION REF.

1 TOG B2A POWERBOARD ETR0042

2 FAN 230V 120mm INPUT VERSION FAN0009

3 FAN 110V 120mm INPUT VERSION FAN0001

4 OZONE MODULE END CAP MPP0089

5 MALE ADAPTOR UNION 8mm - 1/8" ST.ST. MPM0072

6 UNION SEAL RING 1/8" FES0034

7 PANEL MOUNTED UNION 8mm x 8mm PVDF PPF0209

8 MODULE THERMOSTAT 70oC EMC0181

9 MAINS POWER FILTER SOCKET EMC0104

10 FUSE 5 x 20 1 AMP TYPE T 230V ECA0119

11 FUSE 5 x 20 2 AMP TYPE T 110V ECA0106

1

2 3

4

5 6

7

8

9

10 11

This manual suits for next models

4

Table of contents