Triol TM01 User manual

2

Dear Customer!

Thank you for purchasing Triol TM01 Downhole Measuring System, the key to your

successful oil production strategy.

We are sure that our Downhole Measuring System technologies will allow you to

advance and maximize your production.

TM01 is complete with the following manuals:

Operation Manual Surface Equipment

Operation Manual TM01-10/11/18/20

Operation Manual TM01-05/15/25/28

Up-to-date technical documentation for TM01 can be downloaded here

https://triolcorp.eu/documents/ or using the QR-code.

Operation of the Triol Surface Equipment must be conducted by personnel

specially trained and authorized by the operator.

The manufacturer reserves the right to make circuital and design changes that are

not reflected in the operational documentation and do not impair the technical

specifications of the device.

3

Copyright © Triol Corporation Ltd. 1993-2020 All rights reserved.

No part of this publication may be reproduced or copied without prior

written permission from Triol Corporation Ltd.

All products and company names mentioned in this manual are trademarks

or registered trademarks of their respective holders.

The information contained herein is subject to change without prior notice

for improvement.

4

CONTENTS

List of abbreviation and warning indicators......................................................................................5

Triol blocks compatibility..................................................................................................................6

Safety requirements.........................................................................................................................7

Description.......................................................................................................................................9

Surface Card description..............................................................................................................9

Surface Board description...........................................................................................................13

Surface Panel description...........................................................................................................16

High-Voltage Choke IP56 description.........................................................................................19

High-Voltage Choke Flexible description....................................................................................20

Connection and configuration ........................................................................................................21

Triol Surface Card.......................................................................................................................21

Connection..............................................................................................................................21

Surface Card menu description...............................................................................................23

Starting up a Surface Card......................................................................................................26

Setting event log recording......................................................................................................26

Setting Wi-Fi............................................................................................................................27

Triol Surface Board.....................................................................................................................29

Connection..............................................................................................................................29

Surface Board testing..............................................................................................................30

Starting up a Surface Board....................................................................................................33

Data channel to the ACS (SCADA) .........................................................................................33

Triol Surface Panel.....................................................................................................................36

Connection..............................................................................................................................36

Surface panel testing...............................................................................................................37

Starting up a Surface Panel.....................................................................................................38

Setting event log recording......................................................................................................39

Setting up analog outputs (if included) ....................................................................................40

Configuring digital outputs (if included)....................................................................................40

Triol High-Voltage Choke............................................................................................................41

Connection..............................................................................................................................41

Installation of surface equipment on shelving..........................................................................43

Troubleshooting.............................................................................................................................46

Diagnostics flow charts...............................................................................................................46

Fuse replacement instructions for High-Voltage Choke..............................................................55

Storage ..........................................................................................................................................58

Periodical Maintenance..................................................................................................................58

APPENDIX A .................................................................................................................................59

APPENDIX B .................................................................................................................................63

APPENDIX C.................................................................................................................................68

APPENDIX D.................................................................................................................................71

APPENDIX E .................................................................................................................................80

APPENDIX F..................................................................................................................................83

APPENDIX G.................................................................................................................................84

APPENDIX H.................................................................................................................................85

5

List of abbreviation and warning indicators

Abbreviation:

TM01 –Downhole Measuring System

SB –Surface Board

SP –Surface Panel

SC –Surface Card

TM01-XXi –Downhole Intake Sensor

TM01-XXd –Downhole Discharge Sensor

HVC –High-Voltage Choke

ESM –Electric Submersible Motor

ESP –Electric Submersible Pump

OM –Operation Manual

0-SUT –Step-up Transformer zero point

GND –Ground

VSD –Variable Speed Drive

ACS –Automatic Control Station.

Indicators:

- Information to be considered.

- Attention! Caution or danger warnings.

6

Triol blocks compatibility

Surface unit

Downhole unit

Add. equipment

Board

Triol Surface Board ST

TM01-05

When connecting the

secondary winding of

the "Delta" transformer,

Triol High-Voltage

Choke IP56 or Triol

High-Voltage Choke

Flexible (without filter)

is used

TM01-09

TM01-10

TM01-15

TM01-20

TM01-25

TM01-28

Triol Surface Board LF

TM01-11

Triol Surface Board DG

TM01-12

Surface

Triol Surface Panel

TM01-05

TM01-09

TM01-10

TM01-15

TM01-20

TM01-25

TM01-28

Card

Triol Surface Card

TM01-05

Triol High-Voltage

Choke Flexible or Triol

TM01- Filter

TM01-09

TM01-10

TM01-15

TM01-20

TM01-25

TM01-28

7

When the supply voltage is applied to the VSD and the circuit breaker of the «0-

SUT» Downhole Measuring System of the VSD is on, a voltage of 100V or 200V

(SB DG) is supplied. Therefore, you must comply with the relevant electrical safety

requirements when installing the pumping unit.

ATTENTION! Filter capacitors retain life-threatening charge. Before working with

the downhole measuring system, make sure that capacitors are de-energized.

Safety requirements

The safety requirements for the control, operation, maintenance and repair of the system must

comply with the Occupational Health and Safety Management Systems (BS OHSAS 18001:2007),

Safety Rules for Operation of Customers’ Electrical Installations, Rules for Safety in the Oil and

Gas Industry, and Inter-industry Rules on Labor Safety.

All actions for installation, assembly, dismantling, operation, and Downhole Measuring System

maintenance must be performed in accordance with applicable local and electrical codes.

Inappropriate installation and operation of the Downhole Measuring System may result in personal

injury or equipment damage. When installing, maintaining, and repairing, it is important to monitor

lack of voltage at the input and output terminals and wires.

Before starting work with the Downhole Measuring System, employees must:

·be specially trained and examined in labor protection issues

·attend a preliminary medical examination (when hired for work) and periodic health

examinations (during the entire labor activity)

·have an electrical safety qualification.

When connecting to the power supply line, special attention must be paid to ensuring reliable

grounding of board/panel casing.

Grounding resistance must meet the local and national requirements.

When performing any work with the Downhole Measuring System, security measures

must be taken:

·disconnect power to the VSD

·disconnect power to the SB, SC, and SP

Figure 1 - Surface Panel power switch

ATTENTION! Installation of telemetry must be carried out when the ESM and

VSD power supplies are completely switched off.

8

Safety recommendation

The Downhole Measuring System must be installed, adjusted, and serviced by qualified

electrical maintenance personnel. Improper installation or operation may cause injury to personnel

or damage to equipment. The Downhole Measuring System must be installed and grounded in

accordance with local and national electrical codes. There is a high level of voltage in the drive’s

cabinet. Extreme care must be taken to ensure all power sources are disconnected before

starting installation, maintenance, and repair jobs. Once repairs are completed, the Downhole

Measuring System connections must be re-established.

Personal Protective Equipment (PPE)

The basic personal protective equipment (PPE) required for field service includes, but is not

limited to, steel toe shoes, safety glasses and a hard hat. If electrical configuration or

maintenance is performed on potentially energized circuits, personal protective equipment is

required to minimize the danger of electrical shock, arc flash and/or arc blast. The level of PPE

required can vary based upon the electrical energy available at the installation site. If any doubt

exists, consult and employ the recommendations published in the National Fire Protection Code,

NFPA-70E. Always be aware of, and conform to, the applicable local fire and electrical safety

regulations.

Safety Procedures

Work inside the cabinets must be performed with the power off. Isolate energy source(s)

and use proper Lock Out/Tag Out (LOTO) procedures and personal protective equipment (PPE)

to ensure personnel safety. The panel/board also contains stored sources of energy in the form of

capacitors. Allow sufficient time after power is removed for those capacitors to discharge to a

safe level below 50VDC.

9

Description

Surface Card description

Surface Card (IP20 enclosure) is designed for inside the VSD installation.

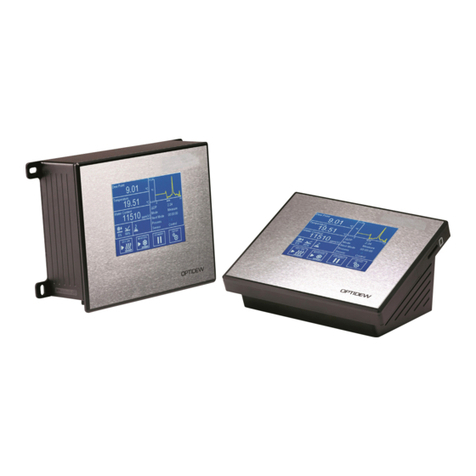

Figure 2 –Surface Card

Surface Card specification with all parameters, operating conditions, and overall dimensions:

Table 1 –Surface Card specification

Input/Output parameters

Rated voltage

24VDC +10, -20%

Power consumption, not more than

50W

Duration mode

Long

Operating voltage in the communication circuit

with submersible unit (if the insulation of Step-up

–cable ESM system is in operation condition)

100V

Design and control connections

Enclosure, not lower than

IP20

Display

LCD 3.5”, 320x240

Wired communication interface

RS-485, RS-232, USB com

Wireless communication port

Wi-Fi

Environmental conditions

Ambient temperature

from -20°С (-4°F) to +85°С (185°F)

Relative air humidity at + 25°C, without

condensation

100%

Altitude, not more than

3281ft (1000m)

Overall dimensions and weight

Overall dimensions, not more than

150mm (5.90in) x 120mm (4.70in) х

70mm (2.75 in)

Weight, not more than

0.7kg (1.54lbs)

10

Description of the elements of the Surface Card:

Power –Surface Card powered

Sensor –communication available / no communication with downhole sensor

R ins –insulation resistance / current leakmeasurement

Alarm –alarm triggering

Display–display of current parameters

USB com –service port

USB host –reading log file

Keyboard –navigate the Surface Cardmenu

There are indicators and various signs on the Surface Card, the description of which are

given below.

Figure 3 –Surface Card (front view)

11

Description of the elements of the block Surface Card:

1. Interface port (RS-232, RS-485)

2. Dout port (Dout1, Dout2)

3. Supply port (24VDC)

4. Output port (supply downhole sensor)

Figure 4 –Surface Card (bottom view)

To switch on Surface Card, it is necessary to supply power to the unit. Table 2 shows

the possible status indications on the Surface Card.

12

Table 2 - Description of LED indicators on the Surface Card

LED

Status

Description

Power

ON

24VDC power applied

OFF

no 24 VDC power applied

Sensor

ON

(green)

there is no communication failure with downhole

sensor

ON

(red)

there is communication failure with downhole sensor

R ins

ON

insulation resistance/current leak measurements

OFF

data transmission from downhole sensor

Alarm

ON

Digital output has triggered. The value of one of

the set parameters has gone beyond the minimum

or maximum.

OFF

Digital outputs are disabled. Parameter values did not

go beyond the minimum and maximum.

13

Surface Board description

The Triol Surface Board ST, LF, DG (IP20 enclosure) is designed for inside the VSD

installation. The Surface Board offers RS-485 and RS-232 Modbus ports as standard.

Figure 5 - Surface Board

Surface Board specification with all parameters, operating conditions, and overall

dimensions:

Table 3 –Surface Board ST, LF, DG specification

Input/Output parameters

Rated voltage*

220V (±20%), 110V (±10%)

Frequency

50/60Hz (±2%)

Power consumption, not more than**

40W

Duration mode

Long

Operating voltage in the communication circuit

with submersible unit (if the insulation of Step-

up –cable ESM system is in operation

condition)***

100V

Design and control connections

Enclosure, not lower than

IP20

Display

None

Physical interface

RS-485/232 Modbus RTU

Environmental conditions

Ambient temperature

from -60°С (-76°F) to +85°С (185°F)

Relative air humidity at +25°C, without

condensation

100%

Altitude, not more than

3281ft (1000m)

Overall dimensions and weight

Overall dimensions, not more than

216mm (8.5in) x 240mm (9.45in) х

142mm (5.6in)

Weight****, not more than

4kg (8.8lbs)

*

Surface Board DG rated voltage is 220V (±20%)

** Surface Board DG power consumption is not more than 100W

*** Operating voltage in the communication circuit is 200V

**** Surface Board DG weight is not more than 6kg (13.23lbs)

14

Description of the elements of the Surface Board:

Heating –heating work

R ins. –insulation resistancemeasurement

Sensor –SB works with downhole sensor

Power –SB powered

GND –ground

0-SUT –cable for connecting intake sensor through the transformer wye point

110/220V–input voltage Surface Board ~ 110 ... 220V AC (for SB DG –220V)

RS-485 –RS-485 communication interface

RS-232, RS-485 –RS-232 communication interface and RS-485 interface

contacts are duplicated

There are indicators and various signs on the Surface Board, the description of which are

given below.

Figure 6 –Surface Board

To switch on the SB, it is necessary to supply power to the unit. Table 4 shows the

possible status indications on the SB.

15

Table 4 - Description of LED indicators on the Surface Board

LED

Status

Description

R ins.

ON

When power is applied to the SB, all LEDs

are turned on for 5 seconds. Checking the health of

LEDs

Sensor

ON

Power

ON

R ins.

OFF

The SB is not powered or the power

supply in the SB is faulty

Sensor

OFF

Power

OFF

R ins.

ON

The SB measures insulation resistance

Sensor

OFF

Power

ON

R ins.

OFF

The SB powers the downhole sensor

The downhole sensor measures and transfers data to

the SB

Sensor

ON

Power

ON

R ins.

Blink

Insulation resistance less than 10kΩ. A delay of 20

seconds to the next measurement without powering

the downhole sensor

Sensor

OFF

Power

ON

R ins.

OFF

Processing a reset command for the downhole

sensor.

The downhole sensor constant power mode is on, or

in the included Rins test mode

Sensor

Blink

Power

ON

The Surface Board transmits data via RS-232 and RS-485 interfaces. The SB is a slave device

that responds to master requests, for example, the board responds to requests from the ACS

(SCADA).

Interface settings and register map are in Appendix B of Modbus map.

16

Surface Panel description

The Triol Surface Panel (IP56 enclosure) shows information on the display for operators to

read and process data in real time relating to the fluid parameters and parameters of the submersible

equipment. The SP offers an RS-485 Modbus port as standard. Digital and analog I/O are optional.

Figure 7 - Surface Panel

Surface Panel specification with all parameters, operating conditions, and overall

dimensions:

Table 5 –Surface Panel specification

Input / Output parameters

Rated voltage

220V (±20%), 110V (±10%)

Frequency

50/60Hz (±2%)

Power consumption, not more than

300W

Duration mode

Long

Operating voltage in the circuit with

submersible unit (if the insulation of Step-up is

an ESM cable)

100V

Design and control connections

Enclosure, not lower than

IP56

Display

LCD 20x4 Symbols

Physical interface

RS-485/232 Modbus RTU

Environmental conditions

Ambient temperature

from -40°С (-40°F) to +75°С

(167°F)

Relative air humidity at +25°C,

without condensation

100%

Altitude, not higher than

3281ft (1000m)

Overall dimensions and weight

Overall dimensions, not more than

230mm (9.05in) x 460mm

(18.11in) х 505mm (19.88in)

Weight, not more than

30kg (66.1lbs)

17

There are indicators and various signs on the SP, the description of which are given below.

The layout of the SP controls is shown in figures 8 and 9.

Figure 8 –Surface Panel (front view)

18

Description of the elements of the Surface Panel:

1. USB –connector for external flash media

2. RS-485 –DB9 connector for RS-485 communication

3. Heating –SP heating works

4. R ins. –insulation resistance measurement

5. Sensor –SP works with downhole sensor

6. Power –SP is powered

7. Power ON/OFF –circuit breaker QF1

8. Control buttons –scroll through menus and adjust settings

9. LCD –screen for displaying information and setting parameters

10.Operation –connection established, there is no error

11.Error –there is an error

12.Alarm –there is no connection to TM01

13.GND –grounding

14.Network –power connection

15.0-SUT –connection to the transformer wye point

16.RS-232/ RS-485 –Phoenix terminal (XT3) for RS-485 and RS-232

communication

17.Extreme inclusion of a Surface Panel

Figure 9 –Surface Panel (bottom view)

To switch on the Surface Panel, it is necessary to supply power of 110-220V and turn on

the QF1 circuit breaker according to the wiring diagram.

The Surface Panel can exchange data with the upper level via an RS-485 interface using

one of the following protocols: Triol, TriolAK, and Transfer. Description of the protocols are

presented in Appendix C.

19

High-Voltage Choke IP56 description

Triol High-Voltage Choke IP56 provides a zero “wye” point when the transformer is connected

in «delta» mode.

Figure 10 High-Voltage Choke

High-Voltage Choke specification with all parameters, operating conditions, and overall

dimensions:

Table 6 –High-Voltage Choke specification

Input / Output parameters

Maximum voltage of power circuits

5000V

High-Voltage Choke current saturation, not less

than

70mA

Maximum choke power circuit current

160mA

Phase inductance, not less than

140H

Duration mode

Long

Design and control connections

Enclosure, not lower than

IP56

Number of safety interlocks

3

Environmental conditions

Ambient temperature

from -20°С (-4°F) to +60°С

(140°F)

Relative air humidity at +25°C,

without condensation

100%

Altitude, not higher than

3281ft (1000m)

Overall dimensions and weight

Overall dimensions, not more than

229mm (9.02in) x 460mm

(18.11in) х 501.5mm (19.7in)

Weight, not more than

35kg (77.1lbs)

20

High-Voltage Choke Flexible description

Triol High-Voltage Choke Flexible (IP56, IP65, IP00) provides a zero “wye” point when the

transformer is connected in «delta» mode.

Figure 11 High-Voltage Choke Flexible

High-Voltage Choke specification with all parameters, operating conditions, and overall

dimensions:

Table 7 –High-Voltage Choke Flexible specification

Input / Output parameters

Maximum voltage of power circuits

5000V

High-Voltage Choke current saturation, not less

than

70mA

Maximum choke power circuit current

160mA

Phase inductance, not less than

140H

Duration mode

Long

Design and control connections

Enclosure, not lower than

IP56/IP65

Number of safety interlocks

3

Environmental conditions

Ambient temperature

from -20°С (-4°F) to +60°С (140°F)

Relative air humidity at +25°C,

without condensation

100%

Altitude, not higher than

3281ft (1000m)

Overall dimensions and weight

Overall dimensions IP56, not more than

Overall dimensions IP65, not more than

327mm (12.8in) x 375mm

(14.8in) х 156mm (6.1in)

327mm (12.8in) x 375mm

(14.8in) х 156mm (6.1in)

Weight IP56, not more than

Weight IP65, not more than

24kg (52.9lbs)

22kg (48.5lbs)

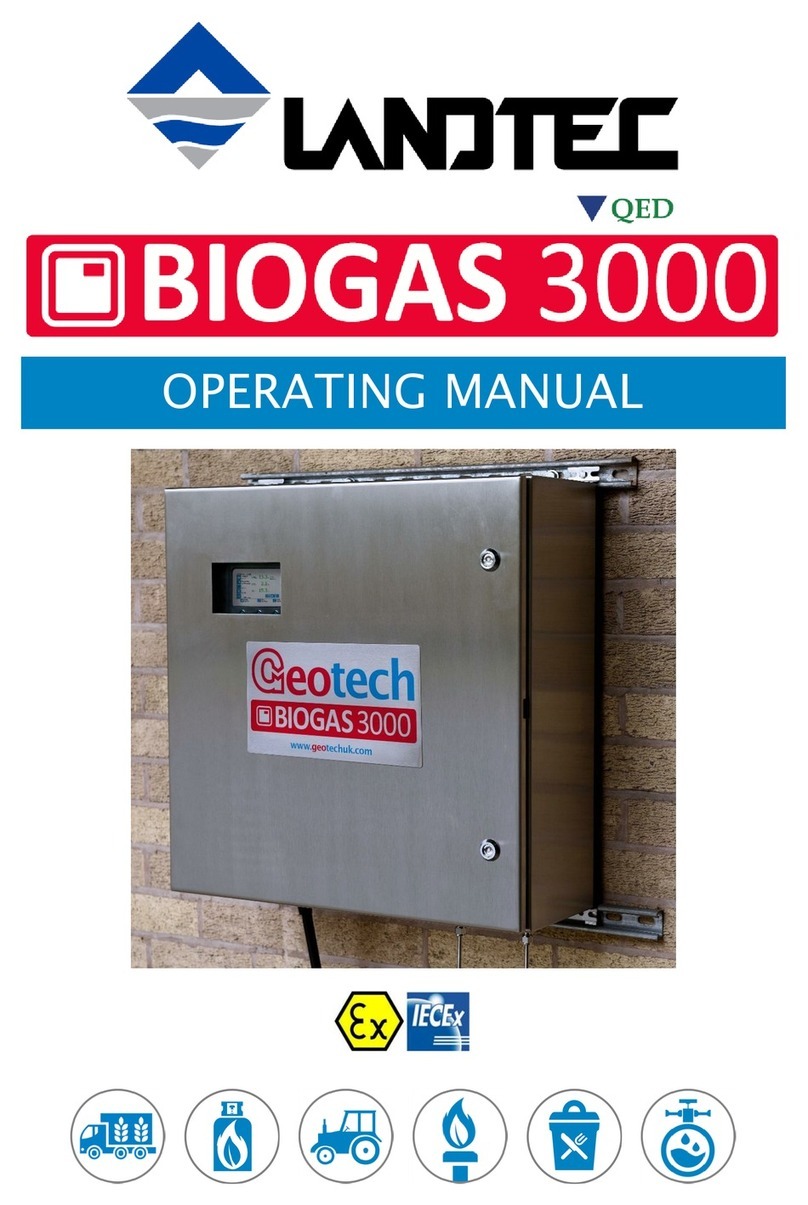

Table of contents

Popular Measuring Instrument manuals by other brands

Winland Electronics

Winland Electronics TempAlert MTA-1 quick start guide

ABB

ABB C11 user manual

GW Instek

GW Instek GLA-1016 user manual

Union Instruments

Union Instruments INCA4003 Translation of the original operating instructions

KATA

KATA DGM-1500 Turva manual

Vanguard Instruments

Vanguard Instruments Auto-Ohm 10 user manual