RMG USM GT400 User manual

Operating Manual

Ultrasonic Flowmeter USM GT400

Issued:

07.05.2021

Version:

10

Firmware:

1.5

Contact

Manual USM GT400 · EN10 · May 2021

Manufacturer

Our customer service is available for technical queries:

Address

RMG Messtechnik GmbH

Otto-Hahn-Straße 5

D-35510 Butzbach

Telephone Switchboard

+49 6033 897 –0

Telephone Service

+49 6033 897 –0

Telephone Spare Parts

+49 6033 897 –173

Fax

+49 6033 897 –130

E-Mail

Original Document

The Ultrasonic Flowmeter USM GT400 OPERATING

INSTRUCTION 07.05.2021 is the original document.

This document may serve as a reference for translations into

other languages. Please use in case of any uncertainties the

German version as main reference.

Note

Unfortunately, paper is not updated automatically, whereas

technical development continuously advances. Therefore, we

reserve the right to make technical changes regarding the rep-

resentations and specifications of these operating instructions.

The latest version of this manual (and other devices) can be

downloaded at your convenience from our Internet homepage:

www.rmg.com

Date created

1/31/2014

…

4th revision date

02/12/2018

5th revision date

09/4/2018

6th revision date

11/18/2018

7th revision date

12/14/2019

8th revision date

02/19/2021

9th revision date

05/07/2021

Document version

and language

Document version

Ultrasonic Flowmeter USM GT400

manual de May 7th 2021

Language

EN

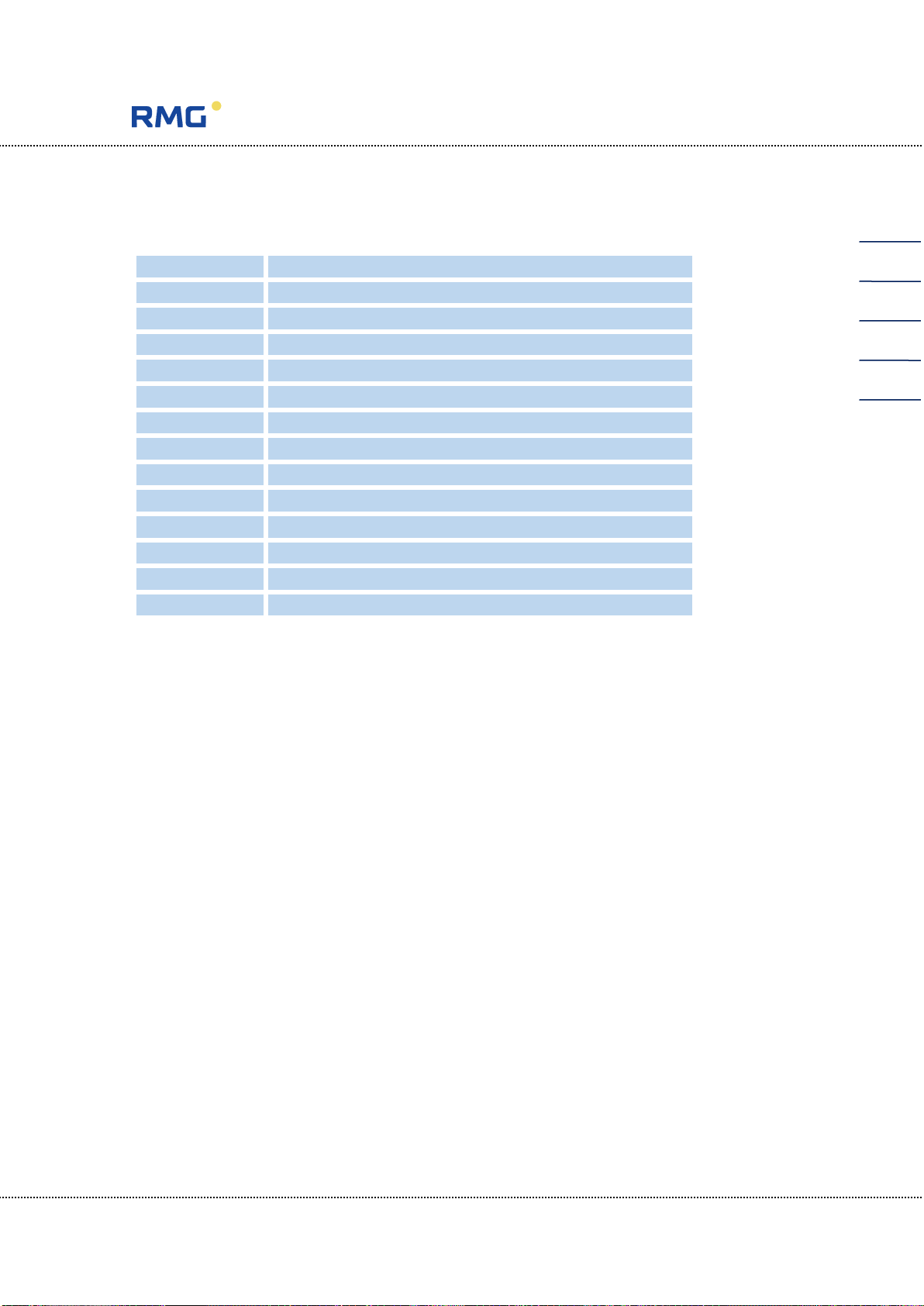

Contents

Manual USM GT400 · EN10 · May 2021

I

Content

1ABOUT THIS MANUAL......................................................................... 1

1.1 Objective of the manual.......................................................................................1

1.2 Specialized knowledge required .......................................................................2

1.2.1 Specialized knowledge required..........................................................................2

1.2.2 Abbreviations.......................................................................................................3

1.2.3 Layout of instructions ..........................................................................................4

1.2.4 Working with the device ......................................................................................5

1.2.5 Risk assessment and minimization...................................................................11

1.2.6 Validity of the manual........................................................................................13

1.2.7Transport...........................................................................................................14

1.2.8 Scope of delivery...............................................................................................16

1.2.9 Disposal of packaging material .........................................................................16

1.2.10 Storage..............................................................................................................16

1.3 Explosion-proof design.....................................................................................17

1.3.1 General information...........................................................................................17

1.4 Inspection and maintenance work..................................................................18

1.4.1 General information...........................................................................................18

2QUICK GUIDE....................................................................................... 20

2.1 Mechanical connection......................................................................................21

2.1.1 Connection flanges............................................................................................21

2.1.2 Inlet / outlet piping .............................................................................................21

2.1.3 Joining pressure connections............................................................................21

2.2 Electrical connection .........................................................................................22

2.3 Start up..................................................................................................................22

2.4 Earthing.................................................................................................................23

2.5 Parameter setting................................................................................................24

3DEVICE OVERVIEW............................................................................ 25

3.1 Main components................................................................................................25

3.2 Ultrasonic electronics........................................................................................27

3.3 Arrangement of the ultrasonic transducers .................................................31

4FUNCTIONAL PRINCIPLE –ULTRASONIC-FLOW

MEASUREMENT.................................................................................. 32

Contents

Manual USM GT400 · EN10 · May 2021

II

4.1 General description............................................................................................33

4.2 Correction of the base line...............................................................................37

4.2.1 Base line correction via polynomial................................................................... 38

4.2.2 Correction via a piecewise linearization............................................................ 39

4.3 Diagnostic function Speed of Sound............................................................. 40

4.3.1 Standard method of SoS calculation................................................................. 40

4.3.2 SoS calculation via gas components ................................................................ 40

4.3.3 Extended SoS calculation................................................................................. 41

4.4 Import of gas composition data...................................................................... 42

4.4.1 Option 4: Data input on fixed defaults............................................................... 43

4.4.2 Data input on fixed defaults for air .................................................................... 43

4.4.3 Data input via RMGBus .................................................................................... 45

4.4.4 Data via Modbus (USM GT400 is SLAVE) ....................................................... 46

4.4.5 Import of data via Modbus (USM GT400 is Master).......................................... 47

4.5 Batch mode..........................................................................................................52

4.6 Signal damping ................................................................................................... 52

5SAFETY.................................................................................................. 53

5.1 Intended use ........................................................................................................54

5.2 Layout of instructions .......................................................................................55

5.3 Qualification of the personnel......................................................................... 56

5.4 Safety instructions............................................................................................. 57

5.4.1 Hazards during transporting.............................................................................. 58

5.4.2 Hazards during installation................................................................................ 58

5.4.3 Hazards during start up..................................................................................... 60

5.4.4Hazards during cleaning ................................................................................... 61

5.4.5 Hazards during maintenance and repairs......................................................... 61

5.4.6 Hazards during operation.................................................................................. 62

5.4.7 Hazards for operation in potentially explosive environments............................ 63

5.5 Responsibilities of the operator......................................................................64

6TRANSPORT AND STORAGE.......................................................... 65

6.1 Transport.............................................................................................................. 66

6.1.1 Scope of supply ................................................................................................ 66

6.1.2 Transporting the device .................................................................................... 67

6.1.3Unpacking the device........................................................................................ 67

6.1.4 Disposal of packaging material......................................................................... 70

6.1.5 Prior to installation ............................................................................................ 70

6.1.6 Removing the transporting locks....................................................................... 71

Contents

Manual USM GT400 · EN10 · May 2021

III

6.2 Packing the device for transportation............................................................73

6.3 Storage ..................................................................................................................79

6.3.1 Packing the device for storage..........................................................................79

6.3.2 Checking the device after storage.....................................................................80

7CONSTRUCTION AND PLANNING.................................................. 81

7.1 Connection flanges.............................................................................................81

7.2 Seals.......................................................................................................................82

7.2.1 Flat seal.............................................................................................................83

7.2.2 Grooved gaskets...............................................................................................84

7.2.3 Spiral seals........................................................................................................85

7.3 Screws...................................................................................................................87

7.4 Installation possibilities ....................................................................................88

7.4.1 Dependency on the gas flow direction ..............................................................88

7.4.2 Two devices series connected (Face to Face)..................................................91

7.5 Flow computer.....................................................................................................93

8INSTALLATION.................................................................................... 95

8.1 Assembly work preparations ...........................................................................96

8.2 Installation of the device...................................................................................99

8.2.1 Mounting the inlet and outlet piping...................................................................99

8.2.2 Installation of the connection box....................................................................101

8.3 Connecting the device electrically............................................................... 103

8.3.1 Connecting the power supply..........................................................................108

8.3.2 Digital interfaces of USM-GT400.....................................................................108

8.3.3 Connecting the computer for RMGViewUSM.....................................................110

8.3.4 Connecting the flow computer.........................................................................110

8.3.5 Connection of external DSfG-Device-F via Modbus........................................113

8.3.6 Interface converter ..........................................................................................124

8.3.7 Connecting the device to earth........................................................................126

8.4 Installing the pressure connection.............................................................. 128

8.5 Outdoor installation......................................................................................... 130

9START UP ........................................................................................... 132

9.1 Comparing meter parameters....................................................................... 132

9.2 Checking functions of the USM.................................................................... 132

9.3 Reading out speed of sound......................................................................... 133

Contents

Manual USM GT400 · EN10 · May 2021

IV

10 OPERATION........................................................................................ 134

10.1 Measuring values and parameters............................................................135

10.1.1 Input protection for parameters....................................................................... 135

10.1.2 Parameter and measuring values with variable units ..................................... 135

10.1.3 Calibration and Service Switch ....................................................................... 136

10.1.4 Interfaces to converters and controllers.......................................................... 136

10.1.5 Interface for service and parameterization...................................................... 137

10.1.6 Adaptation of the DZU protocol to ERZ 2400 ................................................. 138

10.2 Calling up and changing the parameters via the ultrasonic electronics

139

10.2.1 Calling up the value of a parameter................................................................ 140

10.2.2 Entering data................................................................................................... 141

10.2.3 Changing the parameters of protection E and S............................................. 144

10.3 Parameterize the USM interface.................................................................149

10.3.1 Interface 0....................................................................................................... 149

10.3.2 Interface 1....................................................................................................... 150

10.3.3 Interface 2....................................................................................................... 150

10.4 Modbus communication in detail ..............................................................161

10.4.1 Codes supported............................................................................................. 161

10.4.2 Data types....................................................................................................... 161

10.5 Configuration of the current output..........................................................163

10.6 List of the measurement values and parameters.................................163

11 MAINTENANCE.................................................................................. 164

11.1 Maintenance schedule .................................................................................165

11.2 Checking the device for leaks....................................................................165

11.3 Checking the device for any signs of damage.......................................166

11.4 Changing the battery....................................................................................166

11.5 Changing the transducer.............................................................................166

11.6 Changing the ultrasonic electronics.........................................................167

11.7 Cleaning the device ......................................................................................167

11.8 Check the official seal..................................................................................168

11.9 Decommissioning and disposal ................................................................168

12 ALARM AND WARNING MESSAGES ........................................... 170

12.1 Alarm messages............................................................................................171

12.2 Warning messages........................................................................................172

Contents

Manual USM GT400 · EN10 · May 2021

V

12.3 Notes................................................................................................................ 175

12.4 Troubleshooting............................................................................................ 175

13 TECHNICAL SPECIFICATIONS...................................................... 177

13.1 Performance data.......................................................................................... 178

13.2 Approved gas types..................................................................................... 180

13.2.1 Suitability and safety for natural gas containing H2 ........................................180

13.3 Approved measuring range according to MID....................................... 181

13.4 Type plate....................................................................................................... 182

13.4.1 Type plate ATEX / IECEx................................................................................183

13.4.2 Type plate NEC (CSA) ....................................................................................184

13.5 Weights and dimensions ............................................................................ 184

13.5.1 NEC (CSA)......................................................................................................185

13.5.2 ATEX / IECEx..................................................................................................186

13.6 Inner diameter of connecting spool pieces............................................ 189

13.7 Official seal diagram .................................................................................... 192

13.7.1 Type plate........................................................................................................192

13.7.2 Ultrasonic electronics......................................................................................193

13.7.3 Ultrasonic gas meter .......................................................................................195

13.8 Transducer types.......................................................................................... 197

14 SPARE PARTS AND ACCESSORIES ........................................... 199

15 LISTS OF PARAMETERS AND MEASURED VALUES.............. 201

16 USM GT400 APPROVAL.................................................................. 246

16.1 Metrological approvals................................................................................ 246

16.2 Pressure devices approval......................................................................... 246

16.3 Electromagnetic compatibility................................................................... 246

16.4 Explosion protection approval.................................................................. 246

16.5 Standards, directives and guidelines ...................................................... 247

17 USM GT400 GLOSSARY.................................................................. 249

18 USM GT400 ATTACHMENT............................................................. 250

Contents

Manual USM GT400 · EN10 · May 2021

VI

1 About this manual

Manual USM GT400 · EN10 · May 2021

1

1 About this manual

Content

1.1 Objective of the manual 1

1.2 Specialized knowledge required 2

1.2.1 Specialized knowledge required 2

1.2.2 Abbreviations 3

1.2.3 Layout of instructions 4

1.2.4 Working with the device 5

1.2.5 Risk assessment and minimization 11

1.2.6 Validity of the manual 13

1.2.7 Transport 14

1.2.8 Scope of delivery 16

1.2.9 Disposal of packaging material 16

1.2.10 Storage 16

1.3 Explosion-proof design 17

1.3.1 General information 17

1.4 Inspection and maintenance work 18

1.4.1 General information 18

1.1 Objective of the manual

In this chapter you will be given information on this manual.

The manual provides you with the information that is designed for trouble-free and

safe operation.

The ultrasonic gas meter is state of the art and conceived and manufactured ac-

cording to the recognized safety standards and guidelines.

However, risks may arise during use that can be easily avoided by observing this

manual.

For this reason, you may only use the device as intended and in technically sound

condition.

If the ultrasonic gas meter is not used for its intended purpose, warranty claims will

be void.

1 About this manual

Manual USM GT400 · EN10 · May 2021

2

1.2 Specialized knowledge required

This manual provides information that is necessary for fault-free and safe opera-

tion.

The Ultrasonic Flowmeter USM GT400 was designed and produced according to

the state of the art and generally recognized safety standards and directives. How-

ever, its use can entail dangers that are avoidable by complying with this manual.

The device must only be used as intended and in technically sound condition.

Vorsicht

Unintended use voids all warranty claims and the Ultrasonic Flowmeter

USM GT400 can also lose its approvals.

1.2.1 Specialized knowledge required

Persons working with or on the device must have the following knowledge:

•training / education for working in potentially explosive environments.

•the ability to correctly assess dangers and risks when using the device. Possi-

ble dangers are, e.g., components under pressure or the result of incorrect in-

stallation.

•recognize dangers that could be caused by the used flow medium.

•training / education by RMG for working with gas measuring instruments.

•education / instruction in all country-specific standards and directives to be ob-

served for work that is to be carried out on the device.

Further information can be found under:

Chapter 5.3, „Qualification of the personnel“ on page 56

1 About this manual

Manual USM GT400 · EN10 · May 2021

3

1.2.2 Abbreviations

The following abbreviations are used:

AGC

Automatic Gain Control

ca.

circa, approximately

as app.

as applicable

max.

maximum

MC

Measurement Canada

MID

Measurement Instruments Directive

min.

minimum

SNR

Signal to Noise Ratio

SoS

Speed of Sound

TD

Transducer (ultrasonic transmitter and receiver)

TNG

Transducer of a certain production type.

USE

Ultrasonic electronics

USM

Ultrasonic gas meter

e.g.

For example

1 About this manual

Manual USM GT400 · EN10 · May 2021

4

1.2.3 Layout of instructions

The following notices are used:

Danger

This warning notice informs you of imminently threatening dangers that

can arise due to misuse/operator error. If these situations are not avoided,

death or severe injuries can occur.

Warning

This warning notice informs you of potentially dangerous situations that

can arise due to misuse/operator error. If these situations are not avoided,

minor injuries can occur.

Caution

This notice informs you of potentially dangerous situations that can arise

due to misuse/operator error. If these situations are not avoided, damage

to the device or nearby property can occur.

Note

This notice provides you with helpful tips to make your work easier. This

notice also provides you with further information about the device or the

work process in order to prevent operator error.

1 About this manual

Manual USM GT400 · EN10 · May 2021

5

1.2.4 Working with the device

1.2.4.1 Safety instructions Danger, Warning, Caution and Note

Danger

All of the following safety notices must be observed!

Disregard of the safety notices can result in danger to the life and limb or

environmental and property damage.

Bear in mind that the safety warnings in this manual and on the device cannot

cover all potentially dangerous situations, because the interaction of various condi-

tions can be impossible to foresee. Merely following the instructions may not suf-

fice for correct operation. Always remain attentive and consider potential conse-

quences.

•Read this operating manual and especially the following safety notices care-

fully before working with the device for the first time.

•Warnings are provided in the operating manual for unavoidable residual

risks for users, third parties, equipment, or other property. The safety in-

structions used in this manual do not refer to unavoidable residual risks.

•Only operate the device in fault-free condition and in observance of the op-

erating manual.

•Compliance with local statutory accident prevention, installation and assem-

bly regulations is also mandatory.

Caution

All notices in the manual must be observed.

Use of the gas chromatograph PGC 9300 is only permitted in accordance

with the specifications in the operating manual.

RMG assumes no liability for damages arising due to disregard of the op-

erating manual.

1 About this manual

Manual USM GT400 · EN10 · May 2021

6

Danger

Service and maintenance tasks or repairs that are not described in the op-

erating manual must not be carried out without prior consultation with the

manufacturer.

Changes to the device are not permitted.

The technical specifications must be observed and followed for safe oper-

ation (see chapter 13: Technical specifications).

Performance limits must not be exceeded.

Please only use screws, bolts, nuts and seals or parts with comparable

characteristic values for installing the meter in the pipeline. (see chapter 7

Construction and Planning)

For safe operation, the device must only be used in the scope of the in-

tended use. (see chapter 5.1 Intended use).

1.2.4.2 Dangers during commissioning

Initial commissioning

The initial commissioning must only be carried out

by specially trained personnel (training by RMG) or

RMG service personnel.

Note

An acceptance test certificate and corresponding test report must be cre-

ated for the commissioning.

These, the operating manual and the CE Declaration of Conformity must

be stored so that they are always readily available. In the process, the en-

tire documentation, including the conformity declarations and certificates

must be checked for completeness.

As far as possible, all sharp edges on the device have been removed. Nev-

ertheless, personal protective equipment must be used for all work, which

must be provided by the operator.

1 About this manual

Manual USM GT400 · EN10 · May 2021

7

Danger

This symbol is used in the manual as a warning of the dan-

ger of explosion; observe the instructions following the

symbol.

With the danger of explosion, the following must be observed, in particular:

•Install the device as specified in the operating manual. If the device is not

installed as specified in the operating manual, there may be a risk that other

connected devices do not have adequate explosion protection.

The explosion protection is lost!

•Inadequately qualified persons working on the equipment are unable to cor-

rectly estimate dangers. Explosions can be triggered. Only work on the

equipment if you have the appropriate qualifications.

•Components can be damaged if you do not use suitable tools and materi-

als. Use tools that are recommended for the respective work in the operat-

ing manual.

Mechanical installation

Mechanical installation must only be performed by ap-

propriately qualified technicians.

Electrical installation

Installation on electrical components must only be car-

ried out by qualified electricians.

Mechanical and/or elec-

trical installation

These qualified personnel require training specifically for

work in explosion-prone areas. Qualified personnel are

persons who have training / education in accordance

with DIN VDE 0105, IEC 364 or comparable stand-

ards.

Danger

Connection of pressurized pipelines must only be carried out by trained

qualified personnel.

1 About this manual

Manual USM GT400 · EN10 · May 2021

8

Danger

The installation and removal of the USM GT400 may only take place in a

depressurized state and in an explosion-free atmosphere. During the in-

stallation process, the descriptions in the operating instructions must be

observed.

In general, it is recommended to carry out an exchange only in consulta-

tion with RMG Service.

After working on pressure-bearing components, the tightness must be

checked.

All of the above points also apply to repair and maintenance work and gen-

erally when the meter has to be opened.

Flange fastening elements, screw plugs, screw connections and check

valves as well as pressure extraction screw connections, valves and pro-

tective tubes must not be loosened during operation.

1 About this manual

Manual USM GT400 · EN10 · May 2021

9

1.2.4.3 Dangers during maintenance and repair

Operating personnel

The operating personnel use and operate the device in

the scope of the intended use.

Maintenance personnel

Work on the device must only be carried out by qualified

personnel who can carry out the respective tasks on the

basis of their technical training, experience and familiar-

ity with the applicable standards and requirements.

These qualified personnel are familiar with the applica-

ble statutory regulations for accident prevention and can

independently recognize and avoid potential dangers.

Maintenance and clean-

ing

Maintenance and cleaning must only be performed by

appropriately qualified technicians.

Danger

Inadequately qualified persons working on the equipment are unable to

correctly estimate dangers. Explosions can be triggered. If work on live

equipment must be conducted in explosion-prone areas, sparks that are

created can trigger an explosion.

Only work on the equipment if you have the appropriate training and quali-

fications.

Danger

The device can be damaged if it is not cleaned as specified in the operat-

ing manual. Only clean the device as specified in the operating manual.

If you do not use the appropriate tool, components may be damaged. The

explosion protection becomes invalid.

•Only clean the device with a slightly damp cloth!

1 About this manual

Manual USM GT400 · EN10 · May 2021

10

Danger

The USM GT400 must only be used as intended! (Chapter 5.1).

Danger

Prevent use of the USM GT400 as a potential climbing aid or use of attach-

ments of the USM GT400 as potential handles.

1.2.4.4 Qualifikation of the user

Notice

In general, the following is recommended for all persons working with or on

the USM GT400:

•Training / education for work in explosion-prone areas.

•The capacity to be able to correctly estimate dangers and risks when work-

ing with the gas USM GT400 and all connected devices. Possible dangers

include components that are under pressure and consequences of incor-

rect installation.

•Recognition of dangers that can arise from the flow medium that is used.

•Training / education by RMG for work with gas measuring devices.

•Education / instruction in all national standards and directives to be com-

plied with for the work to be carried out on the USM GT^^400 analytical

computer.

1 About this manual

Manual USM GT400 · EN10 · May 2021

11

1.2.5 Risk assessment and minimization

According to assessment by qualified employees of RMG, the USM GT 400 is

subject to risks during its use. Risks can also arise due to high pressures and oc-

casionally due to pressures that are too low. Work outside of the permissible tem-

perature range can also lead to dangers. Impermissible current and voltage values

can trigger explosions in explosion-prone areas. The risk assessment requires an

emptying and ventilation of the pipeline for connection of a USM GT 400. Then

and only then it is assured that there is not an explosion-prone gas mixture in the

pipeline. Naturally, work must only be carried out by trained personnel (see chap-

ter 5.3Qualification of the personnel) who are also trained to recognize suitable

tools and use them exclusively. These risks were summarized alongside develop-

ment and measures were taken to minimize these risks.

Measures for risk minimization:

- All pressurized parts are designed in accordance with AD 2000 rules and regu-

lations, Pressure Equipment Directive, Annex 1

- The complete pressure design has been inspected by TÜV Hessen

- All pressurized parts have been manufactured with a material certificate; there

is an uninterrupted change of batch tracing of pressurized components

- The mechanical properties of all relevant pressurized components have been

subjected to tension tests, notch impact bending tests and hardness tests

- Non-destructive testing was also carried out: X-ray and ultrasonic inspection of

the meter housing for defective points in material, surface crack testing with

magnetic powder and a color penetration process

- Strength tests for components were conducted at 1.5 times the nominal pres-

sure for the pressure testing; the leak testing for the assembly was conducted

at 1.1. times the nominal pressure. Certificates were issued for successfully

passed tests.

- The maximum operating pressure and the permissible temperature range are

specified on the type plate of the device. Operation of the device is only permit-

ted within these specified ranges.

1 About this manual

Manual USM GT400 · EN10 · May 2021

12

Danger

The following applies for work in explosion-prone areas (all zones):

- Only tools that are approved for Ex Zone 1 are permitted for mainte-

nance and repair tasks. Components can be damaged if you do not

use suitable tools.

The explosion protection is lost.

- Otherwise, work must only be carried out when there is not an ex-

plosive atmosphere.

- The risk of ignition due to impact or friction must be avoided.

- The wiring from and installation of the gas chromatograph PGC 9300

in explosion-prone areas must only be carried out by trained person-

nel in accordance with EN60079-14 and in observance of national

regulations.

- Qualified persons must satisfy the definitions in accordance with

DIN EN 0105 or IEC 364 or directly comparable standards.

- Only trained and instructed personnel are permitted. Work on the

measuring system must only be carried out by qualified persons and

inspected by responsible qualified supervisors.

- Qualified persons have been authorized by the person responsible

for safety of personnel to carrying out such work on the basis of

their training, experience or instruction and familiarity with applica-

ble standards, provisions, accident prevention regulations and sys-

tem conditions. It is essential that these persons are able to recog-

nize and avoid potential dangers in good time.

Other manuals for USM GT400

1

Table of contents

Other RMG Measuring Instrument manuals