TRIOLIET TRIOTRAC JCB Tier4 1700 User manual

OPERATOR'S MANUAL

TRIOTRAC (JCB/FPT Tier 4/Stage IV)

self-propelled mixer

feeder

Order no. 92421/03 GB

Valid from 11-2018

Production series 12

Trioliet. Invents for you.

Contact

Trioliet BV

Kleibultweg 59

NL - 7575 BW Oldenzaal

PO Box 134

NL - 7570 AC Oldenzaal

F +31 (0) 541 57 21 25

T +31 (0) 541 57 21 21

Order no.: 92421GB

Version: 03.000

Date: November 2018

© Copyright, Trioliet BV.

All rights reserved. No part of this publication may be reproduced, stored in an automated database or

retrieval system, or published in any form or any way whatsoever, be it electronically, mechanically, by

means of printing, photocopying or recording, or by any other method without prior written permission

from the manufacturer.

1TRIOTRAC (JCB/FPT Tier 4/Stage IV)

TRIOTRAC (JCB/FPT Tier 4/Stage IV)

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 2

Table of contents

1 Introduction 4

2 TECHNICAL SPECIFICATIONS 6

2.1 Dimensions and weights 6

2.2 Vehicle data 7

2.3 Mixing chamber data 8

2.4 Silage cutting data 8

2.5 Discharge data 9

2.6 Weighing system data 9

2.7 Engine data 9

2.8 Hydraulic data 10

2.9 Cabin specifications and equipment 11

2.10 Lighting 11

2.11 Dashboard indicator lights 12

3 Intended use of the machine 14

3.1 Product liability 14

3.2 Explanation of warning symbols 14

4 Important safety measures 15

4.1 Mandatory safety instructions for the self-propelled machines. 15

4.2 Fire Hazard 17

4.3 Measures and advice in the event of emergencies 17

5 Operation of the machine 19

6 Putting the machine into operation 20

6.1 Delivery and Transport 20

6.2 Driving on Public Roads 20

6.3 Instructions for Driving the Machine 24

6.4 Using the Safety Belt 28

6.5 Starting and Switching off the diesel engine 28

6.6 Refuelling 28

6.7 Filling the DEF liquid 30

6.8 Isolator switch battery 31

6.9 Running the engine in 32

6.10 Recommended driving style 32

7 Operating the machine 33

7.1 Explanation of machine functions 33

7.2 Explanation of how to operate the display 38

7.3 Explanation of How to Operate the Machine Using the Joystick 60

7.4 Other Controls 69

7.5 Automix Speed Control 70

7.6 Optional auxiliary axle 71

8 Working with the machine 72

8.1 Entering the silage 72

3TRIOTRAC (JCB/FPT Tier 4/Stage IV)

8.2 Cutting and Loading 73

8.3 Mixing 79

8.4 Discharging 82

8.5 Blowing straw 84

8.6 Using magnet kits 85

9 Maintenance of the machine 88

9.1 Discharge and Transport Systems 92

9.2 Wheels and tyres 97

9.3 Checking the main cylinder 98

9.4 Mixing auger drive gearboxes 99

9.5 Maintaining the Powershift Gearbox and Wheel Axles 103

9.6 Hydraulic oil and filter elements 107

9.7 Checking the oil level and changing the oil in the pump splitter gearbox 110

9.8 Maintaining the Mixing Auger Drive 111

9.9 Maintenance of the cutting system 115

9.10 Lubricating 116

9.11 Chassis Fastening Bolts 121

9.12 Maintenance of Hydraulic Hoses 121

9.13 Maintenance of the JCB diesel engine 122

9.14 Maintenance of the FPT diesel engine 132

9.15 Cleaning and replacing cabin filters 146

9.16 Cleaning cooling package 147

9.17 Weighing computer 147

9.18 Maintenance by your dealer 147

10 Options and Accessories 148

10.1 Automatic lubrication system 148

10.2 Electric heating of the engine block, hydraulic oil and cabin 149

11 Troubleshooting list 150

11.1 Triotrac 150

11.2 Error Messages 155

12 Annexes 163

12.1 Hydraulic scheme (Version 501411/7) 164

12.2 Engine parts and sensors 167

12.3 Triotrac maintenance plan 171

12.4 Operating the Climate Control System 176

12.5 Fuse and Relay Overview 178

12.6 Overview of oil and filters to be used 184

12.7 Software Troubleshooting 186

13 CE declaration 187

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 4

1 Introduction

Congratulations on the purchase of your new

TRIOTRAC self-propelled mixer feeder

When delivering the unit, your dealer will have explained the controls, the mandatory safety

instructions and the maintenance procedures.

Before using your machine for the first time, we recommend that you carefully read this manual since

we cannot honour our guarantee in the event of operating errors or inexpert use of the machine.

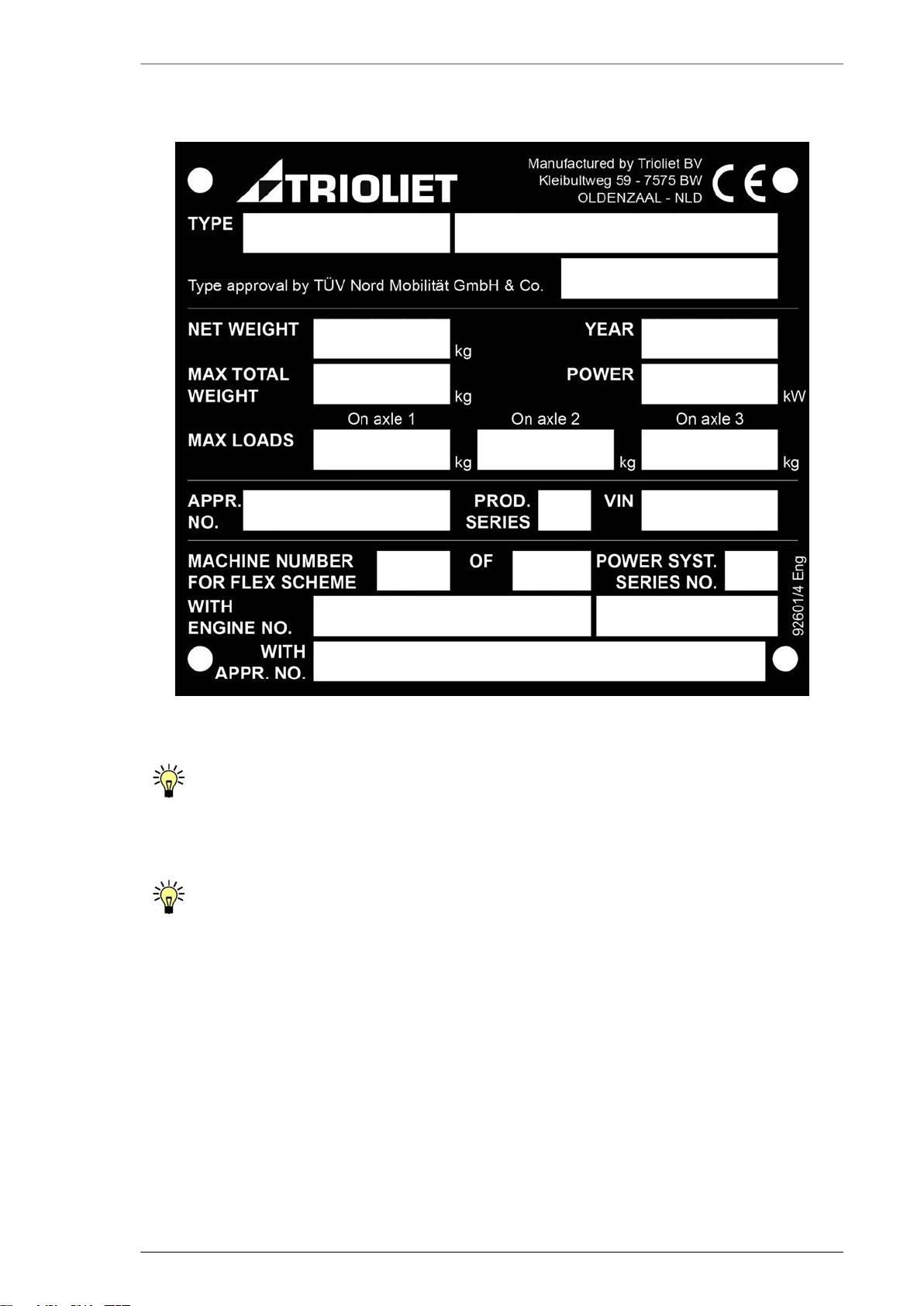

The type plate is located at the front right of the

machine on the mudguard inside the engine

compartment. The cross conveyor unit also

has its own type plate intended for our internal

administration.

Fig. 1

Introduction

5TRIOTRAC (JCB/FPT Tier 4/Stage IV)

Enter the production serial number and machine number PIN (VIN) below.

Please always give the machine and production serial number when ordering parts.

Note. The manufacturer will always strive to improve its products and reserves the right to

make modifications without any obligation in respect of previously supplied machines. All

illustrations and details provided in this Operator's manual are subject to change without

prior notice.

Note. The illustrations and details provided are as precise as possible but are not binding

because of possible changes in the interim.

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 6

2 TECHNICAL SPECIFICATIONS

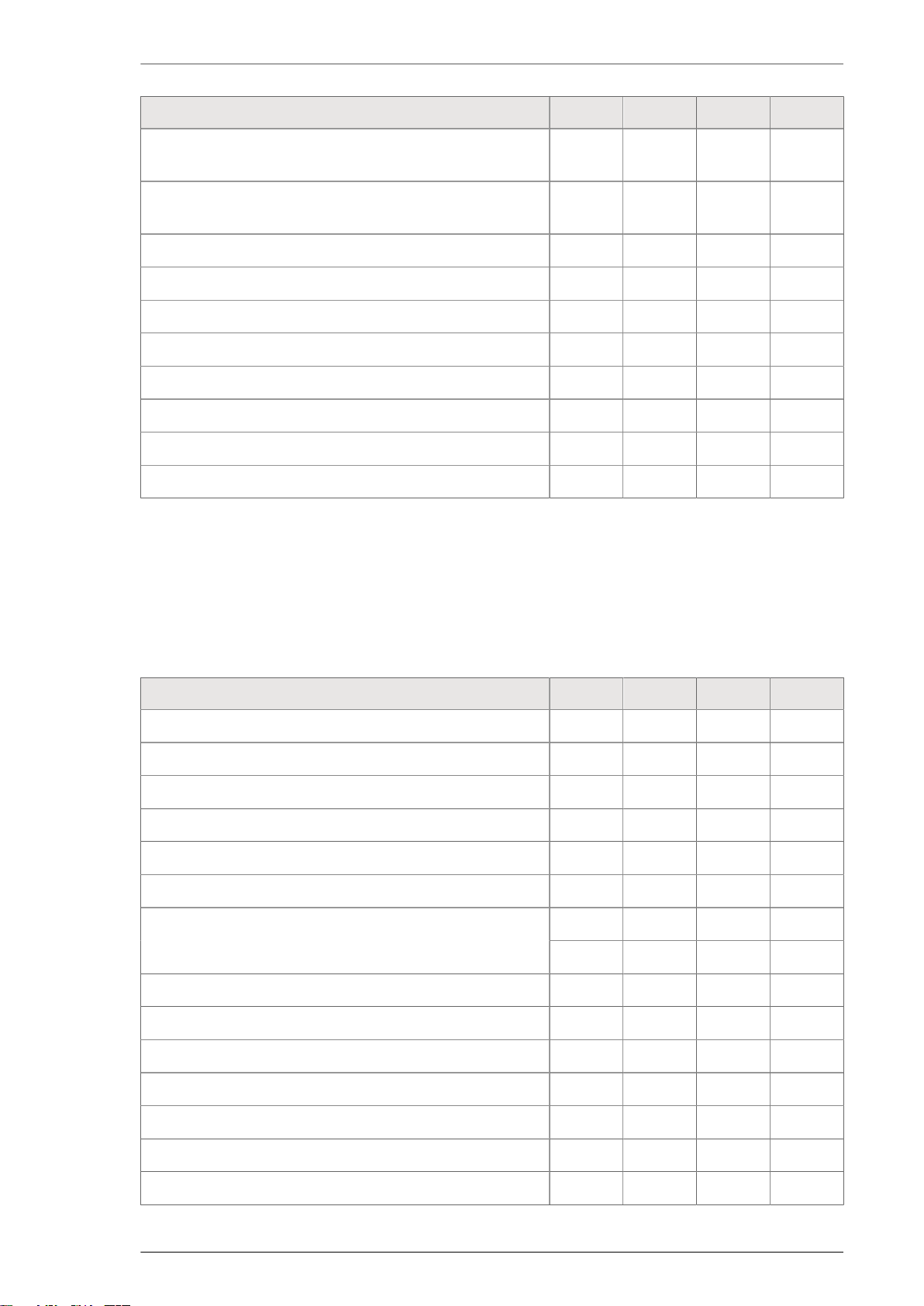

2.1 Dimensions and weights

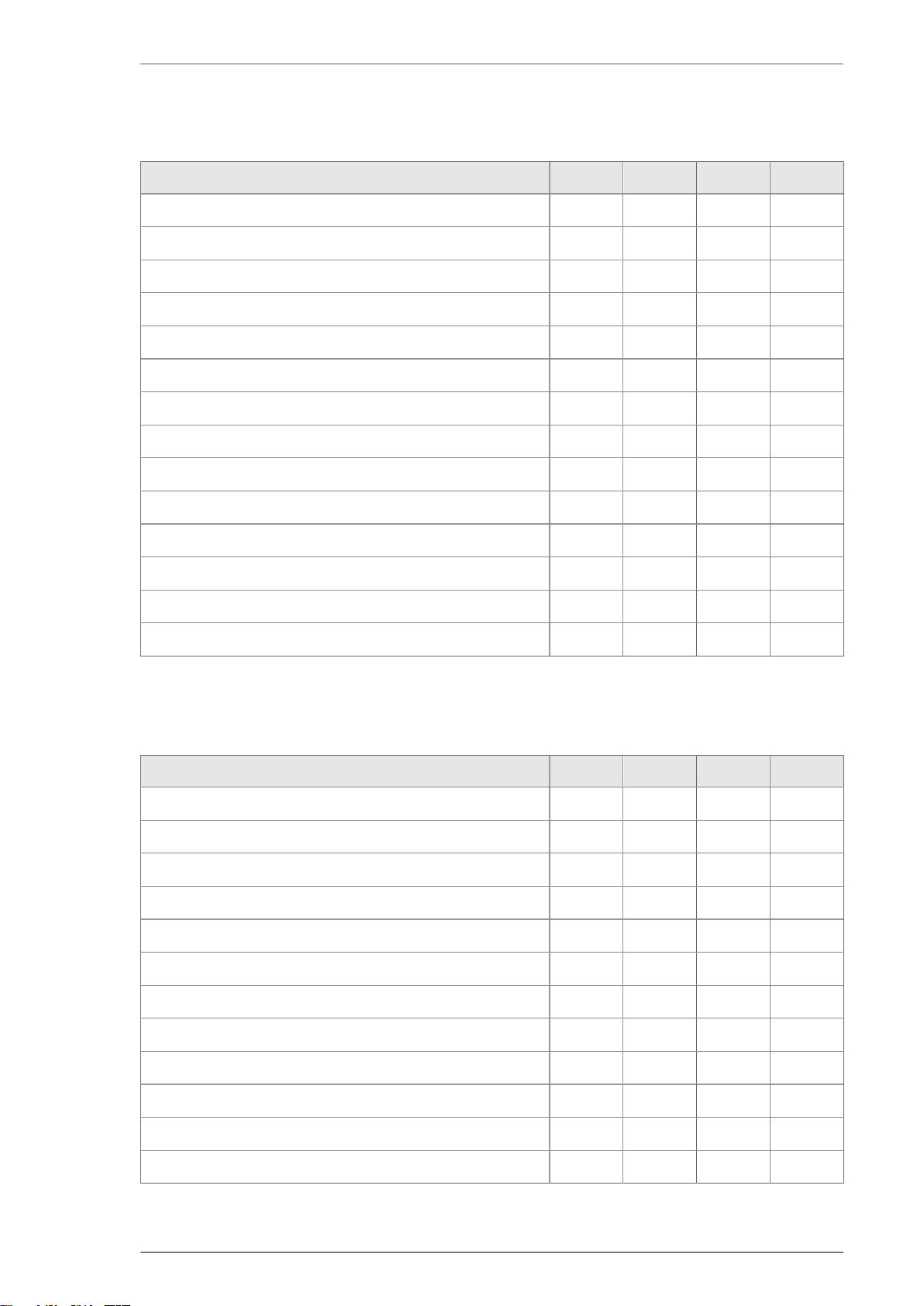

Specifications [ ] 1700 2000 2400

Length [m] 9.70 10.20 10.25

Width [m] 2.44 2.44 2.44

Height (excl. rotating light) [m] 2.93 2.93 3.27

Height when driving on public roads for TÜV-approved

machines

[m] 3.13 3.13 3.27

Turning radius (outside radius) with 4-wheel steering [m] 7 7 7

Tare weight (two axles) ** [kg] 16,000 16,400 16,900

Tare weight (with optional auxiliary axle, three axles) ** [kg] 17,100 17,500 18,000

Maximum technical loading weight at 40 km/h, two

axles **

[kg] 4,000 3,600 3,100

Maximum technical loading weight at <10 km/h, two

axles **

[kg] 12,000 11,600 11,100

Maximum technical loading weight at 40 km/h, three

axles **

[kg] 9,900 9,500 9,000

Maximum technical loading weight at <10 km/h, three

axles **

[kg] 16,900 16,500 16,000

Maximum total weight at 40 km/h (NL), two axles * [kg] 20,700 20,700 20,700

Maximum loading weight (public road NL), two axles* [kg] 4,900 4,200 3,900

Maximum total weight at 40 km/h (NL), three axles * [kg] 28,000 28,000 28,000

Maximum loading weight (public road NL), three axles* [kg] 11,100 10,400 10,100

Maximum legal total weight at 40 km/h (DE), two axles [kg] 18,000 18,000 18,000

Maximum legal loading weight (public road DE), two

axles

[kg] 2,200 1,500 1,200

Maximum legal total weight at 40 km/h (DE), three

axles

[kg] 25,000 25,000 25,000

Maximum legal loading weight (public road DE), three

axles

[kg] 8,100 7,400 7,100

Maximum legal total weight at 40 km/h (FR), two axles [kg] 19,000 19,000 19,000

Maximum legal loading weight (public road FR), two

axles

[kg] 3,200 2,500 2,200

TECHNICAL SPECIFICATIONS

7TRIOTRAC (JCB/FPT Tier 4/Stage IV)

Specifications [ ] 1700 2000 2400

Maximum legal total weight at 40 km/h (FR), three

axles

[kg] 26,000 26,000 26,000

Maximum legal loading weight (public road FR), three

axles

[kg] 9,100 8,400 8,100

Ground clearance at lowest point (unloaded) [mm] 340 340 340

Ground clearance at centre of chassis (unloaded) [mm] 375 375 375

Wheelbase [m] 5.25 5.25 5.25

Track width at front [m] 2.38 2.38 2.38

Track width at rear [m] 2.38 2.38 2.38

Suspension travel front (empty/loaded) [mm] 35 40 40

Front suspension travel (left/right) [mm] 250 250 250

Suspension travel rear (empty/loaded) [mm] 35 40 40

*

**

Technical maximum.

Machines with FPT engines are the basis weights, machines with JCB engines have a 150 kg lower tare weight.

2.2 Vehicle data

Specifications [ ] 1700 2000 2400

4-wheel steering - s s s

Four-wheel drive - s s s

Limited slip differential - s s s

Max. speed in working mode [km/h] 20 20 20

Max. speed in transport mode [km/h] 40 40 40

Max. speed in reverse [km/h] 20 20 20

[km/h] 1.8 1.8 1.8Min. speed (discharging)

[m/s] 0.5 0.5 0.5

German TÜV/French DRIRE 20 km/h - o o o

German TÜV/French DRIRE 25 km/h - o o o

German TÜV/French DRIRE 40 km/h - o o o

Cruise control - s s s

Maximum speed when entering the silage pit [km/h] 5 5 5

At speeds above 20 km/h, two-wheel front steering - s s s

Max. incline in working mode [%] 30 30 30

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 8

Specifications [ ] 1700 2000 2400

Max. incline in transport mode [%] 14 14 14

Max. upslope angle in working mode [%] 18 18 18

Door sill to shed L = 1000 mm, H = 330 mm - s s s

Multi-disc brake (internal) as service brake - s s s

Disc brake on output Powershift shaft as parking brake - s s s

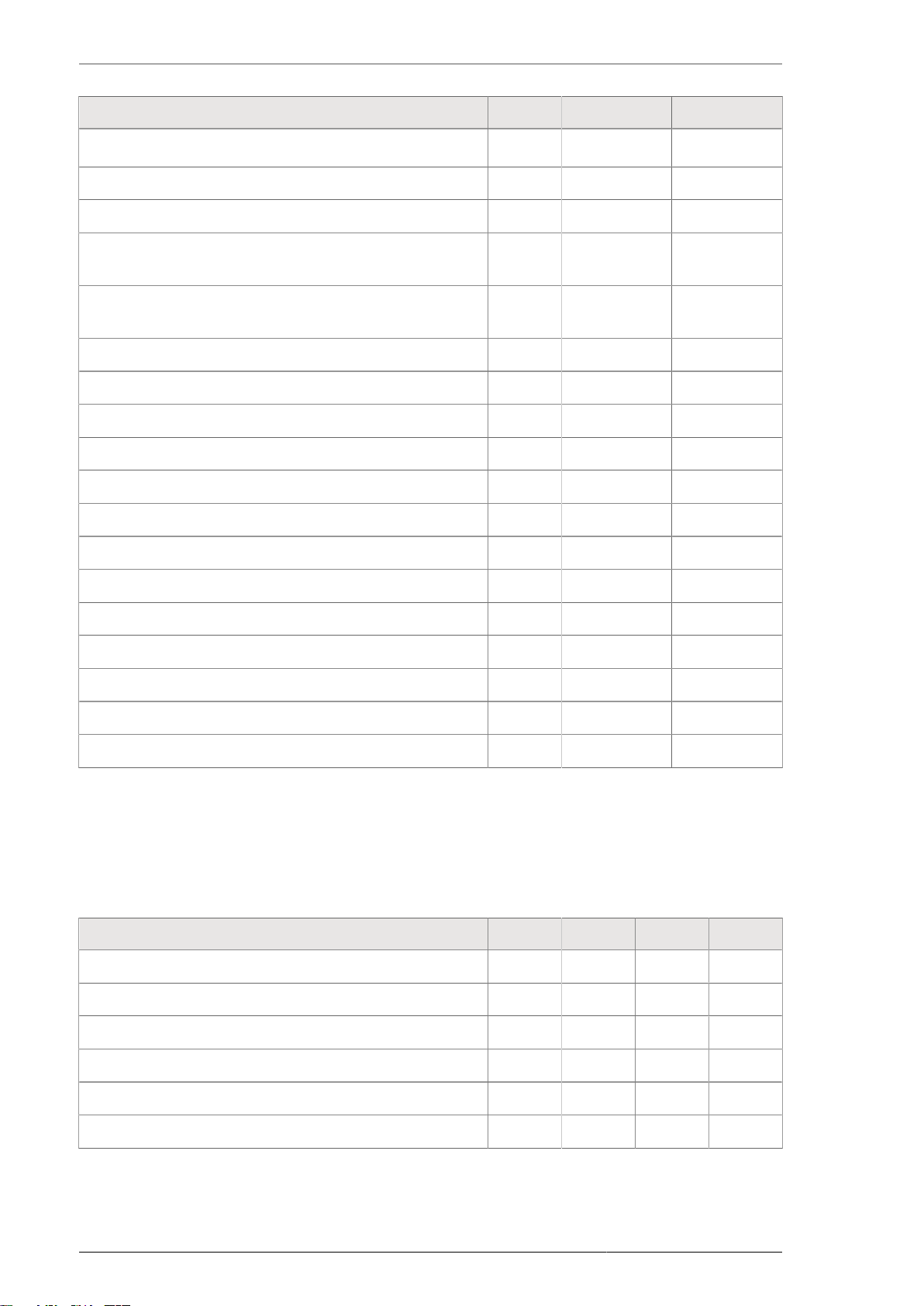

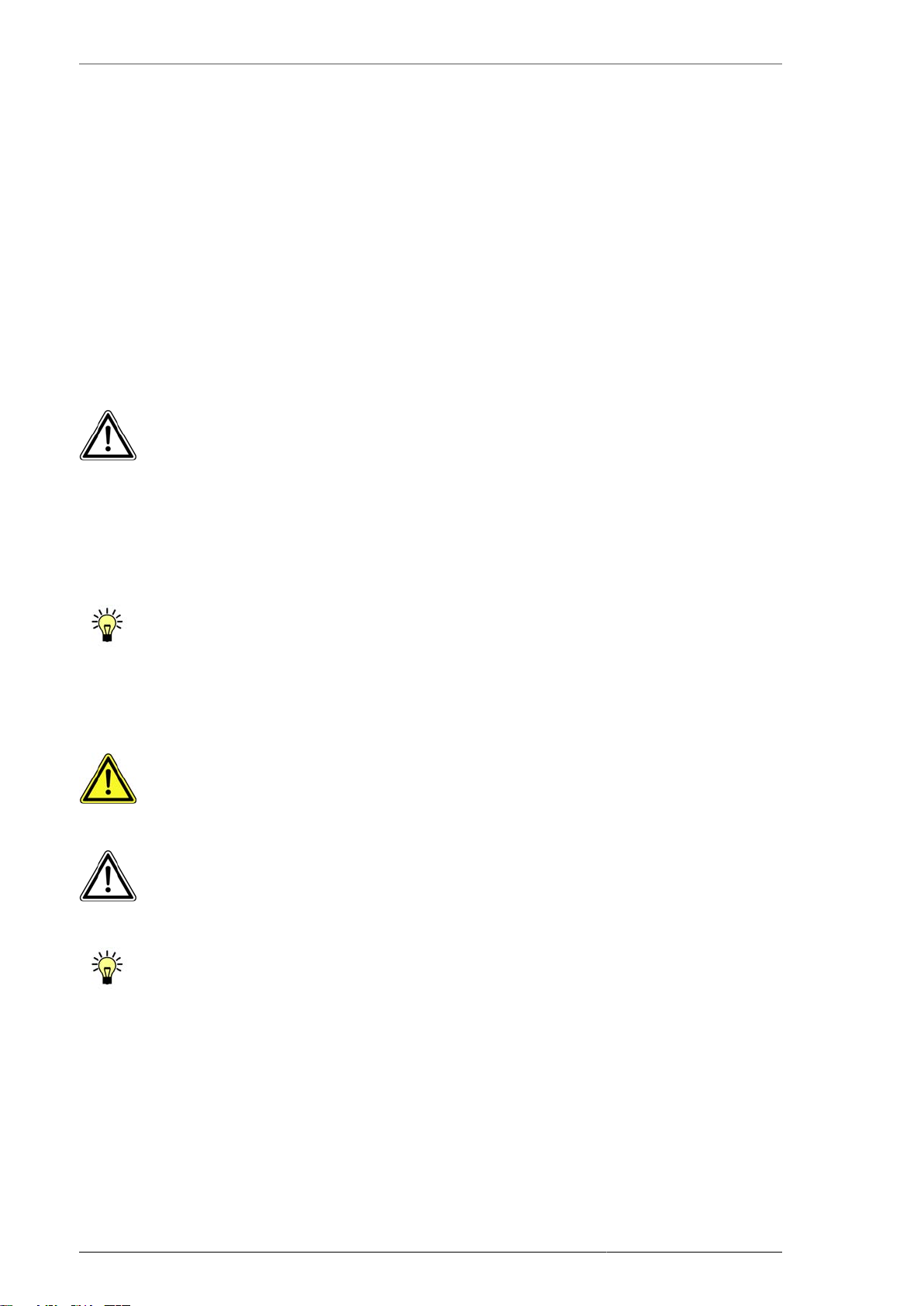

2.3 Mixing chamber data

Specifications [ ] 1700 2000 2400

Capacity [m3]17 20 24

Wall thickness [mm] 8 8 8

Bottom thickness [mm] 10 10 10

Wear strip thickness [mm] 12 12 12

Auger pitch [mm] 450 450 450

Auger blade thickness [mm] 15 15 15

Auger wing thickness [mm] 18 18 18

Diameter of mixing chamber [mm] 2200 2440 2440

Number of mixing augers - 2 2 2

Auger speed continuously variable in mixing mode [rpm] 0-35 0-35 0-35

2.4 Silage cutting data

Specifications [ ] 1700 2000 2400

Max. silage cutting height [m] 6.0 6.0 6.0

Silage cutting width [m] 1.85 1.85 1.85

Silage cutting depth [m] 0.35 0.35 0.35

[m3/

min]

3.6 3.6 3.6Net maximum silage cutting speed with maize

[kg/s] 42 42 42

[kg] 25 25 25Silage cutting precision

[m3]0.1 0.1 0.1

Width of remaining silage compared to silo wall [mm] 150 150 150

Transport time from silage to mixing chamber

(elevation time)

[s] 2.5 2.5 2.5

TECHNICAL SPECIFICATIONS

9TRIOTRAC (JCB/FPT Tier 4/Stage IV)

Specifications [ ] 1700 2000 2400

Belt speed elevating conveyor [m/s] 0-2.5 0-2.5 0-2.5

Min. number of cutting cycles per round/square bale - 5 5 5

Loading arm with 1 cylinder - s s s

Cutting motion independent of downward cutting speed - s s s

Cutting curve correction - s s s

2.5 Discharge data

Specifications [ ] 1700 2000 2400

Front discharge (cabin, rear) - s s s

Rear discharge - o o o

Discharge slide - o o o

Discharge height (upper side belt) [mm] 1000 1000 1000

Maximum discharge speed (maize) [m3/

min]

666

Minimum total discharge time [min] 2:50 3:20 4:00

Discharge opening width [mm] 1280 1280 1280

Discharge opening height [mm] 640 640 640

Auger speed continuously variable in discharge mode [rpm] 0-45 0-45 0-45

2.6 Weighing system data

Specifications [ ] 1700 2000 2400

Number of weighing bars - 4 4 4

Programmable Digistar TST 7600 weighing computer - s s s

2.7 Engine data

Specifications [ ] JCB FPT

Standard nominal power [kW] 129 187

Number of cylinders - 4 6

Boring [mm] 106x135 104x132

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 10

Specifications [ ] JCB FPT

Cylinder capacity [cm3]4765 6728

Weight (net engine block) [kg] 496 530

Tier/Stage emission standard - 4/IV 4/IV

Specific fuel consumption (FLRS) [g/

kWh]

210 202

Max. torque at rpm [Nm/

rpm]

690/1500 1160/1500

Cooling circuit capacity (ASTM D6210) [l] 25 35

Oil quantity min. level [l] 11.5 8

Oil quantity max. level [l] 14 12

After-treatment system - EGR+SCR HI-eSCR *

Urea (DEF) reservoir capacity [l] 16 30

Dynamo capacity [A] 100 90

Cyclone filter - s s

Fuel tank capacity (standard) [l] 275 275

Cleanfix radiator cleaning blower - s s

Consumption per load (1700-2400) [l] 10.5 12

Starter motor voltage [V] 24 24

Engine control module voltage/sensors [V] 12 24

Airco compressor voltage [V] 24 24

* DOC+SCR+CUC

2.8 Hydraulic data

Specifications [ ] 1700 2000 2400

Hydraulic drive pump [l/min] 216 216 216

Hydraulic mixer pump [l/min] 216 216 216

Hydraulic pump for auxiliary hydraulics [l/min] 255 255 255

Hydraulic drive motor [cc] 85 85 85

Hydraulic mixer motor [cc] 85 85 85

Oil tank capacity [l] 85 85 85

TECHNICAL SPECIFICATIONS

11 TRIOTRAC (JCB/FPT Tier 4/Stage IV)

2.9 Cabin specifications and equipment

Specifications [ ] 1700 2000 2400

Minimum step height [cm] 45 45 45

Heated outside mirrors - s s s

Electrically adjustable mirrors - s s s

Provision for hands-free telephone - s s s

FM radio/Mp3/WMA/USB/Bluetooth - s s s

Cabin heating by engine coolant/climate control - s s s

Rear-view camera - s s s

Extra camera - o o o

Interior lighting - s s s

Windscreen wipers, front - s s s

Windscreen wiper, rear - s s s

Screen washers, front and rear - s s s

Windscreen wiper, right with washer - s s s

Airco - s s s

2.10 Lighting

Specifications [ ] 1700 2000 2400

Working lamps, front (2x) - s s s

Working lamps, rear (2x) - s s s

Working lamps, discharge opening (2x) - s s s

Adjustable working lamps with cutting area (1x) - s s s

Working lamp on mixing chamber (cabin, rear) (1x) - s s s

Sidelights/dipped-beam headlamps/large light, front - s s s

Direction-indicator lamps, front - s s s

Direction-indicator lamps, rear - s s s

Rear position (side) lamps - s s s

Brake lights, rear - s s s

Fog lamps, rear - s s s

Reversing light - s s s

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 12

Specifications [ ] 1700 2000 2400

End outline marker lights - s s s

Side marker lights - s s s

Rotating light - o o o

2.11 Dashboard indicator lights

Specifications [ ] 1700 2000 2400

Engine oil pressure - s s s

Engine oil filter - s s s

Engine oil level - s s s

Engine temperature - s s s

Fuel level - s s s

Air filter - s s s

Status SCR system - s s s

Status regeneration SCR system - s s s

Ignition - s s s

DEF level - s s s

Indication water in fuel - s s s

Glow plug - s s s

Battery (rechargeable) - s s s

Main-beam headlamp - s s s

Dipped-beam headlamps (general lighting) - s s s

Direction-indicator lamps - s s s

Working lamps - s s s

Fog lamps. - s s s

Emergency brake pressure/pressure emergency brake

circuit

- s s s

Automatic or manual transmission - s s s

Cold start/assisted hill start - s s s

Cutting mode/transport mode (low/high) - s s s

Driving direction (forward, neutral and reverse) - s s s

Hydraulic oil level - s s s

TECHNICAL SPECIFICATIONS

13 TRIOTRAC (JCB/FPT Tier 4/Stage IV)

Specifications [ ] 1700 2000 2400

Hydraulic oil temperature - s s s

Augers (off, mixing mode, discharge mode or rpm) - s s s

Four-wheel drive indicator light - s s s

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 14

3 Intended use of the machine

The machine may be used only for:

– Cutting and loading the cut silage into the mixing chamber.

– Mixing the loaded silage.

– Transporting and discharging the mixed silage.

The machine is solely equipped for farmyard use. When driving on public roads, you must comply

with the current national (traffic) regulations and any roadworthiness inspections (TÜV, DRÉAL, etc.).

3.1 Product liability

Attention! Under no circumstances may the machine be used for any purpose other than

the above-mentioned intended use without the manufacturer's prior written consent Should

this occur, then the product liability and possibly your warranty lapse.

Unauthorised modifications to the machine will cause all product liability and responsibility to lapse

and any resulting damage shall never qualify for compensation under the warranty.

While using the machine for its designated purpose, the manufacturer’s user and mandatory safety

instructions must be observed.

Note. References to "right" and "left" are to be understood to mean from the perspective of

the direction of travel (direction of transport) of the machine.

3.2 Explanation of warning symbols

Danger! When you see this symbol and this sign, there is an acute risk to life and health of

man and animal.

Attention! This sign indicates there is a risk of damage to machine(s), feed, buildings and so

forth, as well as potential financial and/or legal issues (warranty, liability, and so forth).

Note. This indicates a comment intended to help make work easier, better and safer.

Important safety measures

15 TRIOTRAC (JCB/FPT Tier 4/Stage IV)

4 Important safety measures

Attention! Please read this Operator's Manual carefully before using the machine.

■ The machine should be operated by only one person.

■ Make sure that you are familiar with all systems, controls and indicators and their functions before

you use them. Once it is running it will be too late.

■ The machine may be operated only by people who are familiar with the prescribed operating,

maintenance and the mandatory safety instructions.

■ You, as its owner, are responsible for the safe use and maintenance of the machine. Read the

safety instructions and warnings carefully and make sure you understand them. Instruct any

employee or colleague in the safe operation and use of the machine. Repeat this instruction every

year.

■ Before every use, check the machine with respect to operational and road safety. In addition to

the specific instructions in this Operator's Manual, please also observe the generally applicable

rules with regard to safety and the accident prevention!

■ The user should wear close-fitting clothes. Avoid wearing loose-fitting clothing.

4.1 Mandatory safety instructions for the self-

propelled machines.

1. In Europe, motor vehicles with a total weight exceeding 7,500 kg may be operated only by people

aged 18 years or older, who hold an EC driving licence with category C entitlement.

2. Starting, operating or test-running must never take place in an enclosed space, in view of the risk

of inhaling exhaust gases (Article 69 of the Agricultural Safety Decree).

3. Drivers must operate the machine from the driver's seat and there must not be any other people

and/or animals within reach of the machine. This has been safeguarded by means of a seat

switch. If the seat switch has not been activated, virtually none of the functions can be used.

4. Always observe the machine's intended use. Never transport people, animals or goods other

than silage material with the machine. Never use the machine or any part of the machine (cutting

board) as a hoisting or lifting tool.

5. Never enter the area between the machine and silage when the engine is running.

6. Always lower the loading platform to the ground and the cabin to its lowest position before exiting

the machine. Place the cutting board in its lowest position, level with the front of the loading

platform and apply the parking brake. Always park the machine on a dry and stable surface.

7. Turn the ignition key to the off position and remove it from the ignition after operating the machine.

Close the cabin.

8. If the controls of the machine are not responding, always immediately turn off the ignition

and apply the parking brake in order to prevent the machine from making any unintended or

unexpected manoeuvres.

9. The signs and stickers on the machine provide important information for its safe operation;

complying with this information will increase your safety! Keep them in legible condition. If they

become damaged, order replacements from your dealer (see spare parts list).

10. Hydraulic lines should be checked for damage at least once per year by an expert (dealer).

Damaged hoses must be replaced immediately with hoses of equal quality. You should never

attempt to stop an oil leak by hand when the motor is running. The oil may penetrate the skin and

cause blood poisoning. The maximum oil pressure may be as high as 450 bar.

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 16

11. The machine should be operated only if the safety devices are completely intact and in working

condition! The safety devices prevent access to hazard areas. They must, therefore, be kept in

good condition. They are there for your safety and the safety of others!

12. It is forbidden to disable, short-circuit or bypass any safety devices present on the machine. If you

do so, all product liability lapses!

13. When driving on public roads, make sure that the machine is in Transport Mode and that the

loading arm, cutting board and cabin are in safe positions. Make sure the mixer feeder is

equipped with such lighting and reflectors as required by law.

14. Cleaning, maintenance and repair work and resolving failures may be carried out only when the

engine is switched off and the hydraulic system is depressurised. Do not leave the machine alone

unless the it has come to a complete standstill, the engine has been switched off, the isolator

switch has been turned off, the parking brake applied and the ignition key removed.

15. Always adjust your travelling speed to suit the ground and weather conditions! Do not make any

sudden turns when driving up or down hills, or when driving across a slope! When driving around

bends, bear in mind the long length/width (turning circle) and large mass (inertia) of the machine!

16. Take the maximum permissible axle load and the maximum permissible total weight of the

machine into consideration!

17. Never enter the mixing chamber under any circumstances. During maintenance and repair work

in the mixing chamber, the motor must be stopped and the ignition key removed from the ignition

lock.

18. No one is permitted to be in the vicinity of the mixer feeder while it is entering the silage. Do not

allow anyone else or any animals to be present in the direct vicinity of the machine while it is

cutting, collecting or elevating the forage.

19. Lower the front of the machine and the loading arm fully when carrying out any maintenance or

repair work. Maintain a safe distance when lowering the loading arm and the machine. Where the

nature of the work requires the machine or loading arm to remain raised, measures must be taken

to ensure they are effectively supported.

20. Never walk or stand under the raised loading arm under any circumstances. If this is necessary

for carrying out certain duties, the loading arm and cutting unit must be effectively supported.

21. Never stand on the cross conveyor belt or elevating conveyor at the front of the machine.

22. Do not allow the engine to run at high speed in an unloaded state.

23. The turbo compressor works at very high temperatures. Allow the turbo compressor first to cool

down before carrying out any maintenance work.

24. Contact with the hot surfaces can cause burns. The engine and machine parts are hot when

the vehicle is working. Allow the engine and machine parts to cool down before carrying out any

maintenance work on the vehicle.

25. Fuel is flammable, never approach the fuel system with a naked flame. Immediately turn the

engine off if you suspect a fuel leak. It is forbidden to smoke while refuelling or when the fuel

system is being worked on. Never fill the fuel tank when the engine is running. Wipe away any

spilled fuel, otherwise there is a risk of fire breaking out. Fire could break out and people might be

injured if you ignore this precaution.

26. Always drive with the recommended tyre pressure.

27. Make sure that the raised cutting board does not come into contact with overhead electric cables.

Always jump out of the machine if contact is or has been made.

28. The maximum authorised speed on public roads in the Netherlands is 40 km/h. The machine

must be fitted with statutory lighting and reflectors and 40 km/h stickers must be clearly visible

on it. In most European countries, the machine must bear a number plate and have a permit for

driving on public roads.

Important safety measures

17 TRIOTRAC (JCB/FPT Tier 4/Stage IV)

4.2 Fire Hazard

Attention! Although the utmost care and attention is taken to minimise fire hazards, the risk

of fire through a short-circuit in combination with oil and fuel or the burning of feed residue

can never be fully excluded.

■ The Stage IV engine exhaust system gets very hot. Remove feed residue regularly, particularly

around the engine, and clean the machine in accordance with the instructions.

■ Replace damaged cables and cable shielding immediately.

■ Combat rodents.

■ Keep the supplied fire extinguisher in good working order and have it inspected regularly by an

approved body.

■ Always take out fire insurance for the machine, the place where it is stored and its contents.

4.3 Measures and advice in the event of emergencies

What to do in the event of an emergency

In the event of an accident, always notify the fire brigade or first-aid specialists immediately. Follow the

instructions below in an emergency, while waiting for the arrival of the first-aid specialists.

What to do in the event of a fire

Extinguish the fire using the fire extinguishers present and in the manner indicated by the fire brigade

(fire fighting equipment for certain machines and tools is required under current safety legislation).

Burns

■ Extinguish any flames on the clothing of a person by:

– throwing water over them;

– using a powder extinguisher, making sure not to aim at the person's face;

– with fire blankets or by rolling the person over the ground.

■ Try not to remove any clothing that might be stuck to the skin.

■ In the case of burns, immediately remove all clothing soaked by the hot liquid.

■ Cover the burns with a emergency burn kit or with a sterile bandage.

Carbon monoxide (CO) poisoning

Carbon monoxide from the engine exhaust is odourless and is dangerous because it causes poisoning

and, combined with air, forms an explosive mixture. In enclosed spaces carbon monoxide is extremely

dangerous because it can reach critical concentrations in a very short time. When a person who has

been poisoned has to be assisted in an enclosed space:

■ Immediately ventilate the space to reduce the gas concentration.

■ When you enter the space, hold your breath, do not light flames, do not turn on any lights or use

electrical appliances or telephone to prevent an explosion.

■ Drag the poisoned person outside into the fresh air or to a well ventilated space. Lay the person

down on his side if he is unconscious.

DEF first aid

After swallowing large amounts of DEF (Diesel Exhaust Gas Fluid, also called AdBlue), consult a

doctor immediately. Do not induce vomiting unless instructed by medical personnel to do so. Never

administer anything by mouth to someone who is unconscious.

92421/03 GB

TRIOTRAC (JCB/FPT Tier 4/Stage IV) 18

Avoid prolonged or repeated contact of DEF fluid with the skin (hands, arms or face) and clothing.

Wear chemical resistant gloves, overalls and approved safety goggles while working with the fluid.

Immediately flush eyes with plenty of clean water in event of contact. Consult a doctor if irritated.

Always wash your hands and arms thoroughly after working with this product before eating, drinking,

smoking or going to the toilet. DEF is corrosive to some metals, such as copper and copper alloys.

Make sure DEF does not come into contact with electrical connections.

Only use approved storage and delivery systems. DEF solution is very polluting for surface water and

groundwater. DEF cannot be removed by oil separators; therefore it is important to prevent spillage

and contamination. Keep the liquid in a sealed container in a separate, approved and marked area

with a maximum temperature of 30°C.

Electric shock

There is no risk of electrocution from the 12 V or 24 V electrical installation of the engine; but, in the

event of a short-circuit, for example caused by an overheated metal tool, there is a risk of burns. In

these circumstances, do the following:

■ Always turn off the main switch.

■ Remove the object that caused the short circuit using something that provides sufficient thermal

insulation.

Injuries and fractures

Given the large number of possible circumstances and the specific nature of the actions to be

performed, the intervention of a medical team is always required.

■ In the case of bleeding, hold the edges of the wound together until help arrives.

■ If there is any suspicion of a fracture, do not move the injured part of the body. Move the person

only if absolutely necessary.

Caustic burns

Caustic burns are caused by contact with extremely acid or alkaline substances from batteries; in

these circumstances, do as follows:

■ Remove the clothing soaked with the caustic liquid.

■ Wash the area with a lot of running water. Avoid any parts that have not been in contact with the

liquid.

If battery acid, lubricants or diesel come into contact with the eyes:

■ Flush eyes with water for at least 20 minutes.

■ Keep the eyelids open so that the eyeball is well flushed.

■ Move the eye in all directions to promote flushing.

This manual suits for next models

5

Table of contents