GENERAL INFORMATION OA-3

installed equipment on the vehicle. The Payload Rating is

reduced if any accessories or other equipment is added to

the vehicle after final date of manufacture. The weight of

these items should be determined and deducted from the

Payload Rating.

The vehicle may also have a G WR (Gross ombina

tion Weight Rating). The G W (Gross ombination

Weight) is the total weight of the loaded tow vehicle (includ

ing passengers) and a loaded trailer.

The tires on the vehicle must be the proper size and

properly inflated for the load which you are carrying. The

vehicle ertification Label shows the originally equipped

tire size and recommended inflation pressures. For more

information on tires, refer to WHEELS AND TIRES (Sec.

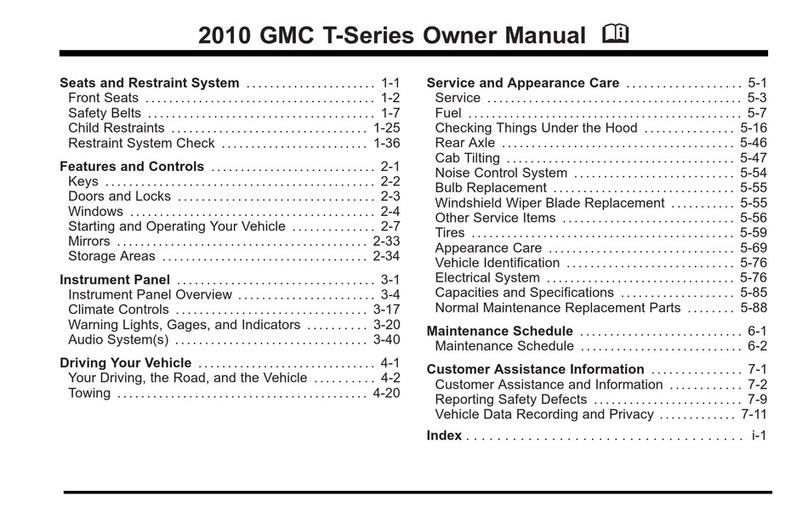

3E). MODEL REFERENCE

Refer to figures 5 and 6 to determine the vehicle model.

For R/V models, an “R” is a two-wheel drive vehicle and a

“V” is a four-wheel drive vehicle.

ENGINE IDENTIFICATION NUMBER

Refer to figure 7 to determine the location of the engine

I.D. number. Refer to figure 8 for engine, transmission, and

transfer case applications.

VEHICLE LIFTING PROCEDURES

CAUTION: To help avo d personal njury when a

veh cle s on a ho st,prov de add t onal support

for the veh cle at the oppos te end from wh ch

componets are be ng removed. Th s w ll reduce

the poss b l ty of the veh cle fall ng off the ho st.

For lifting a vehicle, various lift points are recommended.

Refer to figures 9 through 16.

When lifting the R vehicle with a hoist, the rear hoist

pads should be positioned under the rear spring front

hangers.

When lifting the V vehicle with a hoist, the front hoist

pads should be positioned under the frame, at the front

body mount. The rear hoist pads should be positioned

under the rear spring front hangers.

When lifting the front of the V vehicle with a floor jack,

position the jack pad at the center of the axle, not under the

front differential.

When lifting the P vehicle with a hoist, the rear hoist

pads should be positioned under the frame and inboard of

the rear spring front hangers.

When lifting the G vehicle with a hoist, the rear hoist

pads should be positioned under the rear spring forward

hangers.

Any time a vehicle is lifted with a vehicle jack or a floor

jack, the wheels at the opposite end of the lifted end should

be chocked. Also, jack stands should be used to provide

support. When supporting the vehicle with jack stands, the

jack stands should be placed under the frame, the front

suspension crossmember or the axle.

When removing major components of the vehicle while

the vehicle is on a hoist, the vehicle frame should be

chained to the hoist pads in order to prevent tip-off.

NOTICE: When jacking or lifting a vehicle, be

certain that the lift pads do not contact the cata

lytic converter, brake lines, brake cables, or fuel

lines. Such contact may result in damage or

unsatisfactory vehicle performance.

Pickup, Regular ab R-V MODELS hassis - ab, Bonus/ rew ab

Pickup, Bonus/ rew ab

hassis - ab, Regular ab

Surburban

L00301

Utility Vehicle

Jimmy (Blazer)

F gure 5 — R/V Models