Page 2

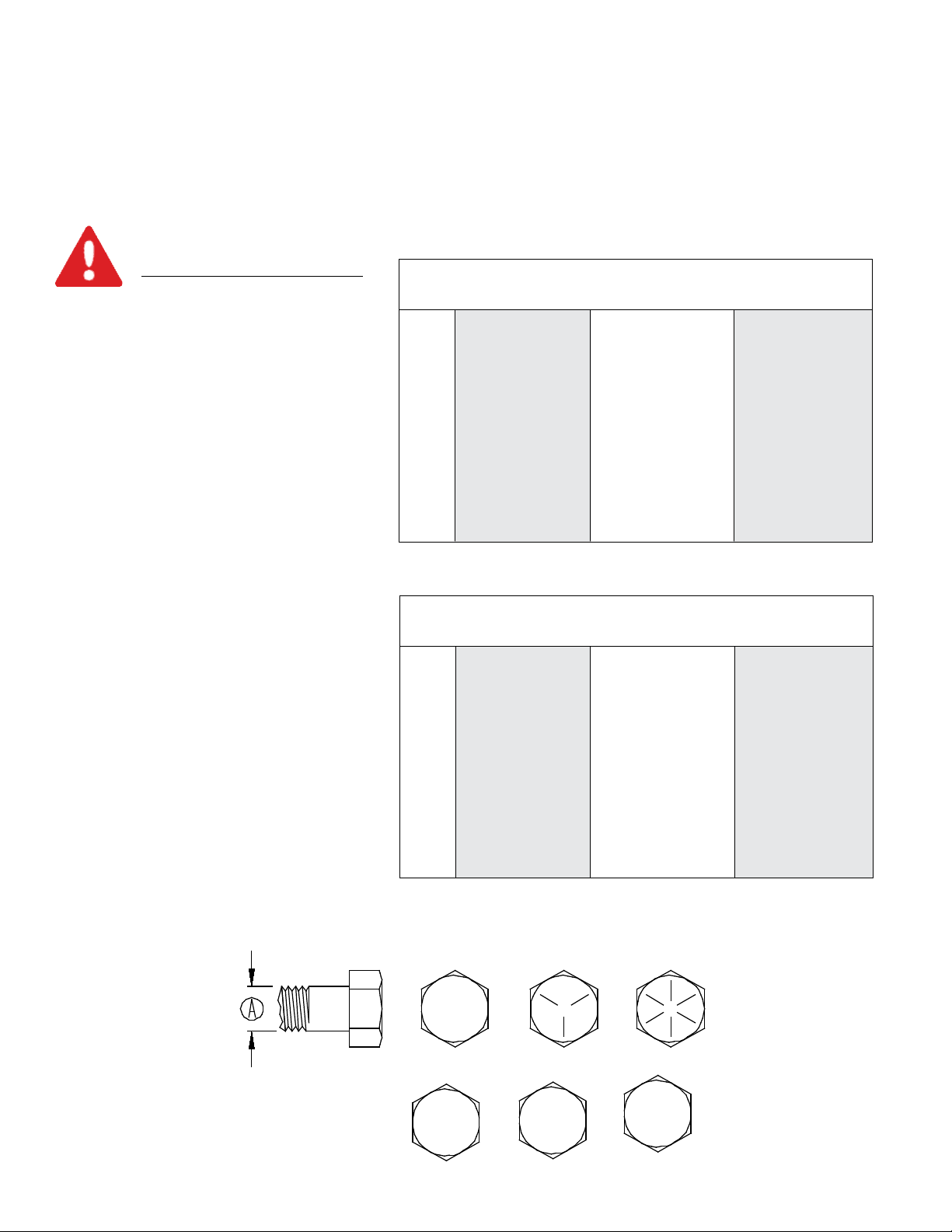

GENERAL INFORMATION

1. Unless otherwise specified, high-strength (grade5)

(3 radial-line head markings) hex head bolts are used

throughout assembly of this piece of equipment.

2. Whenever terms “LEFT” and “RIGHT” are used in this

manual it means from a position behind wagon box and

facing forward.

3. When placing a parts order, refer to this manual for

proper part numbers and place order by PART NO. and

DESCRIPTION.

4. Read assembly instructions carefully. Study

assembly procedures and all illustrations before you begin

assembly. Note which parts are used in each step. This

unit must be assembled in proper sequence or complica-

tions will result.

WARNING: TO AVOID PERSONAL INJURY OR DEATH, OBSERVE FOLLOWING

INSTRUCTIONS:

Never overload mixer. Rating of gear or rating of tires, whichever is less.

Ensure that anybody present is clear before applying power to any machinery used in conjunc-

tion with wagon box or when moving box.

Never allow anyone in, near, or on mixing chamber during mixing, transporting, or unloading

of feed.

Thank you for purchasing a Turbo-Max Mixer Truck. We feel you have made a wise choice and hope you are completely satis-

fi e d with your new piece of equipment. Your new Turbo-Max Mixer Truck is a durable, efficient and easy to use unit. Proper

care and use will result in many years of service.

INTRODUCTION

Table of Contents

General Information ............................................................................................................ 2

Safety , Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Safety Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Lighting and Marking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Sign Care. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tire Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

During Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Following Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........................................................ . . . . . . . . . . . . . . . . . . . . . . . 7

Highway and Transport Operations....................................................................................7-8

Performing Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bolt Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mixer Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Mixer Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Inspections and Adjustments ............................................................................................. 13

Lubrication Schedule.......................................................................................................... 14

Decal Location ................................................................................................................... 15

Oilbath Assembly ............................................................................................................... 16

Reel & Auger Assembly...................................................................................................... 17

Final Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Discharge Breakdown

Slide Tray. . . . . . . ............. . . . . . . . .............. . . . . . . . ......... . . . . . . . ............. . . . . . . . ............. . . . . ............. . . . . 21

Slide Tray (used on serial #) ......................................................................................... 21

Hydraulic Breakdown

Electric Selector Valve for Slide Tray......... ............................. .............. ......................... 22

Switchbox Assembly

Toggle Switch Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Joystick Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Driveline Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29