Infinite Transtector ACINV Series User manual

Installation Manual

© 2020 Innite Electronics, Inc. Transtector is a registered trademark of Innite Electronics, Inc. | ACINV-M Rev. 1

ACINV Series 1RU Rack Mount Inverters

Installation Manual | ACINV Series 1RU Rack Mount Inverters

23

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

Contents

1. Features...........................................................................................................................................................4

1.1 Applications.............................................................................................................................................4

1.2 Specifications ..........................................................................................................................................5

1.3 Mechanical Drawings ..............................................................................................................................6

2. Introduction......................................................................................................................................................7

2.1 Front Panel Description...........................................................................................................................7

2.2 Rear Panel Description............................................................................................................................8

2.3 Installation ...............................................................................................................................................9

2.4 Quick Hook-up and Testing ...................................................................................................................11

2.5 Safety Grounding...................................................................................................................................12

2.6 Making DC Connections........................................................................................................................12

2.7 Alarm Connection..................................................................................................................................13

2.8 Inverter Operation..................................................................................................................................13

2.9 Cooling Fan Operation ..........................................................................................................................15

3. Maintenance..................................................................................................................................................15

4. Troubleshooting Guide...................................................................................................................................15

5. Important Safety Instructions.........................................................................................................................16

5.1 General Safety Precautions...................................................................................................................16

5.2 Precautions When Working with Batteries ............................................................................................16

6. DIP switch settings.........................................................................................................................................17

7. Communications Protocol & Remote ON/OFF Function ..............................................................................17

REV DESCRIPTION CHK’d & APPR’d / DATE

1 Initial Release DWR / 09-15-20

Product Support

Product support can be obtained using the following addresses and telephone numbers.

Phone: +1-208-635-6400

Web site – www.transtector.com

When contacting TRANSTECTOR, please be prepared to provide:

1. The product model number, spec number, S build number, and serial number

- see the equipment nameplate on the front panel

2. Your company’s name and address

3. Your name and title

4. The reason for the contact

5. If there is a problem with product operation:

• Is the problem intermittent or continuous?

• Whatrevisionisthermware?

• What actions were being performed prior to the appearance of the problem?

• What actions have been taken since the problem occurred?

Installation Manual | ACINV Series 1RU Rack Mount Inverters

45

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

1. Features

• R load Pure sine wave output (THD <3%)

• By-pass function (when externalAC source connected)

• Programmable output frequency, 50/60Hz (front panel DIP switch)

• RS232 Serial interface provides unit status

• Thermostatically controlled cooling fans

•Advanced microprocessor design

• Protection: Input Low Voltage, Input Overvoltage, Overload, Output Short Circuit, Over Temperature

1.1 Applications

Oceequipment–computers,printers,monitors,facsimilemachines,scanner.

ApplicationsshouldbelimitedonlytoITEandoceequipment.

1.2 Specications

MODEL NUMBER ACINV1-1KVA ACINV2-2KVA

100-120VAC Models

Inverter Section

Input Voltage Range 42-62VDC

Input Current (Max.) 22.8A 45.0A

Input Current (NL) 0.3A 0.45A

Output Power 1000VA @ ±0.85 PF

850W @ 1 PF 2kVA @ 0.85 PF

1700W @ 1 PF

Surge Rating 900W for 1 minute, 950W for 3 second,

1000W for 1 second 1870W for 1 minute, 2040W for 20 seconds

Eciency@FL 89% 90%

Output Voltage 100/110/115/120VAC ±3%

(switch selectable)

Output Frequency 50Hz or 60Hz ±0.05%

(switch selectable)

Peak Output Current 15A

Output Waveform Pure Sine Wave <3% THD (R Load)

Protection Output Overload - Output Short Circuit

Input Reverse Polarity (fuse) - Input Undervoltage - Input Overvoltage

Over Temperature

Digital Display OVP - UVP - OTP - OLP - VAC

AMP - WATT - VDC - TEMP - Hz

Control Port RS232C

Baud Rates - 2400, 4800, 9600, 19200 (switch selectable)

STS Section (By-Pass)

AC Input Range 90 - 130VAC (110VAC nominal)

Frequency 47 - 63Hz

Transfer Time 4 - 6ms

Alarm Relay Form-C dry contacts, indicates presence of AC Utility supply

(NOTE: Not suitable for direct connection to SELV circuits)

THE STS BY-PASS SECTION IS ONLY ACTIVE WHEN A UTILITY OR OTHER AC SOURCE IS CONNECTED.

NORMAL OPERATION , WITH OR WITHOUT A UTILITY OR OTHER AC SOURCE IS ‘ON-LINE’ , WITH THE INVERT-

ER DELIVERING REGULATED AC TO THE OUTLETS.

General

Temperature Range -20°C to +60°C Operating

-30°C to +70°C Storage

Safety UL60950-1 (Listed - E130645)

EMC FCC Class B

Dimensions 16.1”(d) x 19”(w) x 1.73”(h)

408.7mm(d) x 484.0mm(w) x 44.0mm(h)

Mounting 19” rack-mount, 1RU high

Weight 16.5lbs / 7.5Kg

Installation Manual | ACINV Series 1RU Rack Mount Inverters

67

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

SINEWAVE

INVERTER

1.26”

(32.0mm) 1.73”

(44.0mm)

1.12”

(28.5mm)

16.4”

(416.8mm)

3.94”

(100.0mm)

1.1”

(28.0mm)

1.30”

(33.0mm)

1.30”

(33.0mm)

3.78”

(86.8mm)

1.1”

(28.0mm)

3.42”

(86.8mm)

7.17”

(182.0mm)

2.48”

(63.0mm)

1.57”

(40.0mm)

1.26”

(32.0mm) 1.73”

(44.0mm)

0.12” (3.0mm)

0.12” (3.0mm)

19.06” (484.0mm)

18.31” (465.0mm)

19.06” (484.0mm)

18.31” (465.0mm)

TOP VIEW

REAR VIEW

(as seen from back)

SIDE VIEW

FRONT VIEW

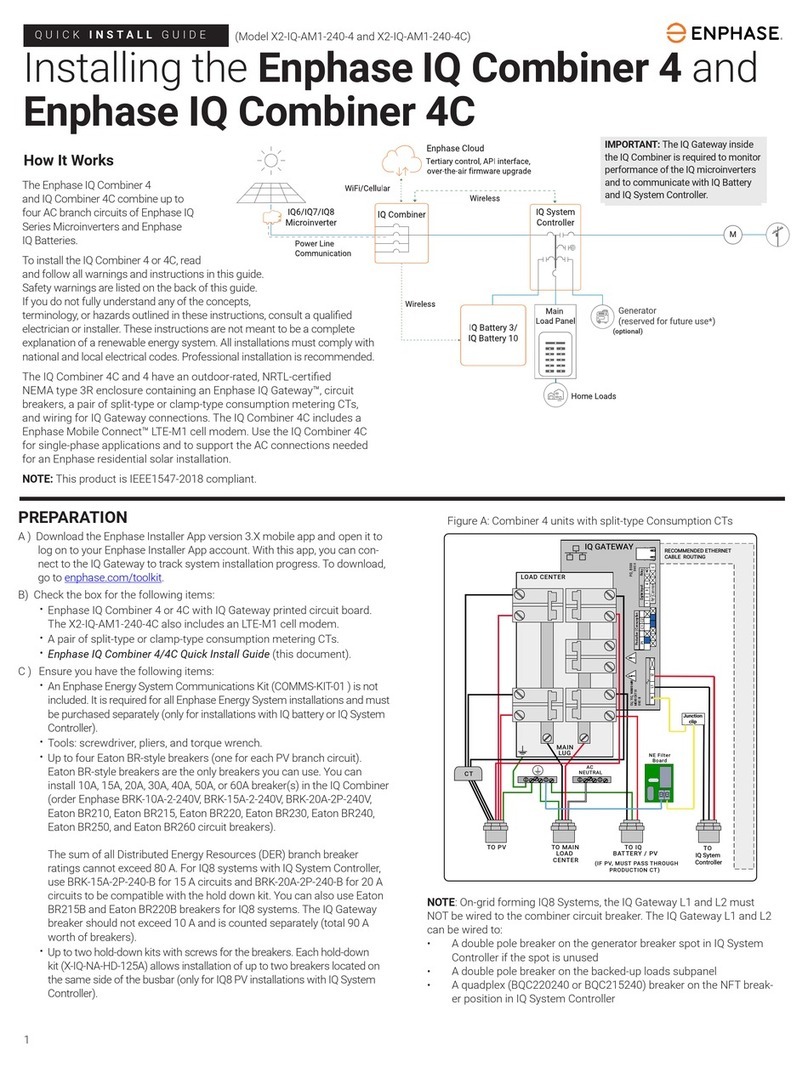

1.3 Mechanical Drawings 2. Introduction

ACINV Series is an advanced range of pure sine wave output power inverters employing microprocessor technology.

For optimum performance and life expectancy they must be installed and used properly.

Please read the instructions in this manual BEFORE installing the unit and switching it on.

2.1 Front Panel Description

SINEWAVE

INVERTER

ON/OFF

SWITCH

PROGRAMMING

DIP SWITCHES LEDs & DISPLAY

FUNCTION

SELECTOR

2.1.1 ON/OFF Switch

Switches the inverter electronics ON and OFF. Should be in the OFF position during installation.

2.1.2 Function Selector, LEDs & Display

When the function selector is sequentially pushed the display shows the reading associated with the actual

parameter indicated by the top row of LEDs in the sequence:

VAC - AMP - WATT - VDC - TEMP - Hz

In the event of a fault condition this will be indicated on the display. See section 2.8.

The ONLINE LED indicates that a Utility or other external AC source is connected to the unit.

The BYPASS LED indicates that the unit is shutdown and the Utility or otherAC source has been switched

to the outlet sockets.

IMPORTANT NOTE: In the event of a DC supply failure or if the ON/OFF switch is set to the OFF

position all LEDs and the display will be switched o. If a Utility or other AC source is connected to

the unit this will automatically be fed to the outlet sockets, unless the AC Mains Breaker mounted

on the rear panel is switched o.

2.1.3 DIP Switches

The DIP switches are used to set output frequency, RS232 baud rate and output voltage setting. See

sections 7.1 and 7.2 for full details.

Installation Manual | ACINV Series 1RU Rack Mount Inverters

89

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

2.2 Rear Panel Description

AC MAINS

ALARM RELAY

RS232

AC MAINS INPUT

FG N L

AC MAINS

BREAKER

CHASSIS

GROUND DC INPUT

NEGATIVE DC INPUT

POSITIVE AC OUTLETS

2 x NEMA 5-15

115VAC OUTPUT MODELS

AC OUTLETS

2 x IEC60320-C13

AC MAINS

ALARM RELAY

RS232

AC MAINS INPUT

FG N L

AC MAINS

BREAKER

CHASSIS

GROUND

DC INPUT

NEGATIVE

DC INPUT

POSITIVE

230VAC OUTPUT MODELS

2.2.1 AC Outlets

120VACoutputmodels(-Nsux)arettedasstandardwith2xNEMA5-15outletsockets,ratedat12A

maximum each.

Electrical Hazard.

Contact with water can cause electric shock.

2.2.2 Ventilation openings.

Donotobstruct.Allowatleast3”(~75mm)forclearairow.

2.2.3 ACmainsbreaker.Thisbreakermustbeoperatedbyqualiedpersonnelonly.itmustbeswitchedonto

allow the utility AC to be fed to the outlet sockets when the unit is on bypass.

2.2.4 Alarm connector: This connector MUST NOT be connected to SELV circuits.

NO means: Normally Open

NC means: Normally Close

COM means: Common.

The alarm indicates that an external AC source is available for by-pass purposes.

When the inverter is switched on and an AC supply is available to the by-pass circuit, NC and COM are

shorted.

When the inverter is switched on and there is no AC supply available to the by-pass circuit, NO and COM

are shorted.

Whentheinverterisswitchedo,NCandCOMareshorted.

See section 2.7 for details about using this function.

2.2.5 DC Input Terminals.

Used to connect to a -48V battery or other suitable DC source.

[+] must be connected to the positive terminal of the battery or DC source.

[-] must be connected to the negative terminal of the battery or DC source.

WARNING: Reverse polarity connection will blow an internal fuse and may also damage the unit

beyond repair. Pay particular attention when connecting to a -48V battery system. In such event the

unit will have to be returned to TRANSTECTOR for repair if possible and any remaining warranty

will be void.

-48V SYSTEM

AC MAINS

BATT RET

+12V or +24V SYSTEM

(+24V shown as example)

AC MAINS

RET BATT

20~32VDC

2.2.6 RS232 connector, 9-way D-type.

This connector allows for connection to a PC serial port and various status information obtained.

See section 8 for more details.

2.2.7 Frame Ground.

Connect to the frame ground of the cabinet or rack in which the unit is installed using 8AWG wire.

WARNING!

Operation of this inverter without a proper ground

connection may result in an electrical safety hazard.

2.3 Installation

WARNING!

Shock Hazard. Before proceeding further, carefully check that

the unit is NOT connected to any batteries and that all wiring is

disconnected from any electrical sources.

Do not connect the output sockets to an incoming AC source.

This power inverter should be installed in a restricted access location such as a Telecommunications room or IT room,

whereaccessislimitedtoserviceandotherqualiedpersonnelandwhichcanonlybeenteredbyuseofatoollockor

key which is controlled by the authority that is responsible for the location. Bare parts of any terminals that present a

hazardous energy level shall be located or guarded so that unintentional bridging by conductive materials that might be

present is unlikely. Areadily accessible disconnect device shall be incorporated in the building installation wiring prior to

connection to the inverter. These locations should additionally meet the following requirements:

Installation Manual | ACINV Series 1RU Rack Mount Inverters

10 11

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

2.3.1 Dry - Do not allow water to drip or splash on the inverter.

2.3.2 Elevated OperatingAmbient - if the inverter is installed in a closed or multi-unit rack assembly the operating

ambient temperature of the rack environment may be greater than the room ambient. consideration should

be given to installing the inverter in an environment compatible with the maximum ambient temperature of

60°C.

2.3.3 Safe-Donotinstalltheinverterinabatterycompartmentorotherareaswhereammablefumesmayexist,

such as fuel storage areas or engine compartments.

2.3.4 ReducedAirow-Installationoftheinverterinarackshouldbesuchthattheamountofairowrequiredfor

safe operation is not compromised.

2.3.5 Dust Free - Do not install the inverter in a dusty environment as dust and other particles such as wood

shavings,lingscanbepulledintotheunitwhenthecoolingfansareoperating.

2.3.6 Close to Batteries - Avoid excessive cable lengths but do not install the inverter in the same compartment

as the batteries. Use the recommended wire lengths and sizes (see section 2.6). Also, do not mount the

inverter where it will be exposed to gasses produced by the battery as these gasses are highly corrosive

and prolonged exposure will damage the inverter.

2.3.7 Mechanical Loading - Mounting of inverter in the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

2.3.8 Circuit Overload - Consideration should be given to the connection of the inverter to the supply circuit and

theeectthatoverloadingofthesecircuitsmighthaveonovercurrentprotectiondevicesandsupplywiring.

Appropriate consideration of equipment nameplate ratings should be used when addressing this concern.

2.3.9 Reliable Earthing - Reliable earthing of rack-mounted equipment should be maintained. Particular attention

should be given to supply connections other than direct connections to the branch circuit (e.g. use of power

strips).

2.3.10 The unit shall be connected directly to the DC supply system earthing electrode conductor or to a bonding

jumper from an earthing terminal bar or bus to which the DC supply system earthing electrode is connected.

2.3.11 The unit shall be located in the same immediate area (such as adjacent cabinets) as any other equipment

that has a connection between the earthed conductor of the same DC supply circuit and the earthing

conductor, and also the point of earthing of the DC system.The DC system shall not be earthed elsewhere.

2.3.12 The DC supply source must be located within the same premises as the unit.

2.3.13 Switching or disconnecting devices shall not be in the earthed circuit conductor between the DC source and

the point of connection of the earthing electrode conductor.

2.3.14 This unit is intended for connection to a branch circuit with maximum 20A fuse protection.

2.3.15 PleaseconrmthattheACinputbreakerissettotheOFFpositionbeforeconnecting/disconnectingtheAC

power. Do not touch theAC INPUT terminals other than with properly insulated tools so as to avoid electric

shock.Ensurethattheprotectivecoverhasbeencorrectlyttedafterinstallationorwhenanymaintenance

has taken place.

2.3.16 Protection in PRIMARY CIRCUITS against over currents, short circuits and earth faults shall be provided,

either as an integral part of the unit or as part of the building installation.

2.3.17 Aluminium conductors must not be used for protective earthing connections.

2.3.18 For supply connections, use wires suitable for at least 105°C since, from test results, cable temperatures

may exceed 90°C.

2.4 Quick Hook-up and Testing

2.4.1 Unpack and inspect the power inverter. If any damage is visible do not proceed any further. Contact

TRANSTECTOR Customer Service immediately

Ensure that the power switch and the AC input breaker are in the OFF position.

2.4.2 Connect the cables to the power input terminals on the rear panel of the power inverter.

The red terminal is positive [+] and black terminal is negative [-].

Insert the cables into the terminals and tighten the Allen nut to clamp the wires securely.

WARNING!

You may observe a spark when you make this connection since

currentmayowtochargecapacitorsinthepowerinverter.

Donotmakethisconnectioninthepresenceofammablefumes.

Explosionorremayresult.

WARNING!

Make sure all the DC connections are tight (torque to 9-10 ft-lbs,

11.7-13Nm). Loose connections will overheat and could result in

a potential hazard.

2.4.3 If connecting to a utility or other AC supply make the L, N and FG connections after placing the supplied

safetycoverovertheACsupplycable.SeegureAbelow.

NotethatitwillbenecessarytoremovethetwoscrewsxingtheACinputconnectorinplaceandreplace

themwiththetwohexnutpillarssuppliedwiththesafetycoverbeforeitcanbetted.SeegureBbelow.

WARNING!

Connect to the utility supply only after the safety cover has

been installed.

AC Supply

Installation Manual | ACINV Series 1RU Rack Mount Inverters

12 13

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

2.4.4 Before proceeding further, carefully check that the cables you have just connected to the negative terminal

of inverter are connected to the negative DC power source.

CAUTION!

Reverse polarity connection will blow a fuse in inverter and may

permanently damage the inverter.

Damage caused by reversing polarity connection is not covered

by our warranty.

2.4.5 Set the power switch to the ON position. After a moment you will hear three beeps. At the same time,

the display scrolls the word “TRANSTECTOR” twice. After that, you will hear a continuous sound from

internal alarm. When theAC output voltage shows on the display the unit will have completed the start-up

sequence.

2.4.6 Set the power switch to the OFF position. The unit should shut down completely.

2.4.7 To accurately measure the true output R.M.S. voltage of inverter connect to one of the outlet sockets and

then set the power switch to ON. Voltage will appear at the output sockets after the start-up sequence is

completed.

2.5 Safety Grounding

During the AC wiring installation, AC input and output ground wires are connected to the inverter. The AC input ground

wire must be connected to the incoming ground from your AC utility source.

The AC output ground wire should go to the grounding point for your loads (for example, a distribution panel of bus

chassis).

2.5.1 Neutral Grounding - 120V models only.

The neutral conductor of the AC output circuit of the Inverter is connected to the safety ground during

inverter operation. This conforms to national electrical code requirements that separately derived AC

sources (such as inverters and generators) which have their neutral conductors tied to ground in the same

way that the neutral conductor from the utility is tied to ground at the GFCI breaker panel. When AC utility

power is connected and the inverter is in bypass mode, this connection (neutral of the Inverter’s AC output

to input safety ground) is not present so that the utility neutral is only connected to ground at your breaker

panel, as required.

2.6 Making DC Connections

Follow this procedure to connect the battery cables or those from another DC source to the DC input terminals on the

Inverter.Your cables should be as short as possible (ideally, less than 10 feet / 3 meters) and large enough to handle the

required Current in accordance with the electrical codes or regulations applicable to your installation.

Cables that are not an adequate gauge (too narrow) or are too long will cause decreased inverter performance such as

poor surge capability and frequent low input voltage warnings and shutdowns.

These low input voltage warnings are due to DC voltage drop across the cables from the inverter to the batteries / other

DC source.

The longer and narrower these cables, the greater the voltage drop.

WARNING!

The installation of a fuse must be on the positive cable.

Failure to place a fuse on [+] cables running between the

inverter and battery or other DC source may cause damage

to the inverter and will void the warranty.

Connections must not be made when the DC source is live.

Increasing your DC cable size will help to improve the situation.

TRANSTECTOR recommends the following cables for optimum inverter performance.

Model NUMBER

1kVA models Wire

Size1 In-line

Fuse Model NUMBER

2kVA models Wire

Size1 In-line

Fuse

ACINV1-1KVA #6AWG 40A ACINV2-2KVA #2AWG 70A

Notes:

1. Use only high quality copper wiring and keep cable length from 3-6 feet (~1-2m).

2. The maximum wire size that the black and red input connectors can accept directly is #2AWG.

Thesemodelsaresuppliedwithtwotypesofadaptorforuseindierentapplications.Onetype

MUSTbettedintotheconnectorstoallowforthegreaterwiresizerequired.

A suitable breaker, at the DC source, for isolation and overload protection is recommend.

2.7 Alarm Connection

It is important to note that the electronic circuits associated with this function are directly connected within the

AC output circuits of the inverter and that for this reason the relay contact connections that are provided on the

rear panel mounted wire clamp connector MUST be considered to be at a non-SELV potential and all necessary

precautions to protect the operator from electric shock hazard must be taken.

These relay contacts must not be connected directly to any SELV or other safety connected circuit and any

cables or wiring used for such connections must be double insulated.

2.8 Inverter Operation

To operate the power inverter, turn it on using the ON/OFF switch on the front panel. The power inverter is now

ready to deliver AC power to your loads.

If you are operating several loads from the power inverter, turn them on separately after the inverter has been

turned on. This will ensure that the power inverter does not have to deliver the starting currents for all the loads

at once.

CAUTION!

EXTERNAL SURFACES GET HOT.

During the period of the unit running, the case may become very

warm. Please do not touch the side marked. “ ” directly.

Installation Manual | ACINV Series 1RU Rack Mount Inverters

14 15

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

2.8.1 Controls and indicators:

TheON/OFFswitchturnsthecontrolcircuitinthepowerinverteronando.

2.8.2 Output Voltage Indication

When the VDC LED is lit the display shows the Output Voltage

WhentheunitisrstswitchedontheVACLEDislitandtheOutputVoltageisdisplayedasdescribed

above.

Selection of the following parameters is achieved by pressing the Function Selector button to the right of

the display sequentially.

2.8.3 Output Current Indicator

When the AMP LED is lit the display shows the Output Current

2.8.4 Output Watts Indicator

When the WATTS LED is lit the display shows the Output Power in Watts

2.8.5 Input DC Voltage Indicator

When the VDC LED is lit the display shows the DC Input Voltage

2.8.6 Temperature Indicator

When the TEMP LED is lit the display shows the internal Operating Temperature

2.8.7 Output Frequency AC Indicator

When the Hz LED is lit the display shows the Output Frequency

The following table details the accuracy of measurement of the above mentioned display reading.

Function VAC AMP WATT VDC TEMP Hz

Range 100-120V 0-10A 0-1KW

or

0-2kW 42-62V 0-120°C 50Hz

or

60Hz

Accuracy ± 1% 1% ± 0.5A ± 3% ± 2% ± 1% ± 0.5%

These inverters are designed to operate from the following input voltage ranges:

42.0 to 62.0VDC

High and low DC input voltage conditions are handled per the following table and described in

more detail below:

Model

Type DC input OVP

shut-down DC input OVP

alarm DC input UVP

shut-down DC input UVP

alarm

48VDC 62.0VDC 61.0VDC 43.0VDC 42.0VDC

2.8.8 Over voltage protection indicator: (OVP)

When OVP is indicated on the display the unit has shut itself down due to the input voltage exceeding the

limits shown above.

2.8.9 Under voltage protection indicator: (UVP)

When UVP is indicated on the display the unit has shut itself down due to the input voltage falling below the

limits shown above.

2.8.10 Over temp protection indicator: (OTP)

When OTP is indicated on the display the unit has shut itself down because it has become overheated.

The unit may overheat because it has been operated at power levels above its rating, or because it has

been installed in a location which does not allow it to dissipate heat properly. The unit will automatically

restartonceithascooledo.

2.8.11 Overload protection indicator: (OLP)

When OLP is indicated on the display one of two conditions has occurred as follows:

a) For an overload condition approximately 110-120% of the WATTS rating of the unit and lasting up to

around 1 minute, an audible alarm will sound and the unit will continue to deliver power directly to the load.

If the overload condition continues the unit shuts itself down.

b) For a larger overload condition the unit shuts itself down immediately.

In both cases it is necessary to restart the unit once the overload has been removed.

In all of the above cases, if an AC utility supply is connected and the AC input breaker switched ON the load will be

automatically be transferred to the utility supply.

2.9 Cooling Fan Operation

The cooling fan management system monitors both the output power and internal temperature of the unit.

Thefanswillnotnormallyruniftheoutputpowerislessthan300W,unlesstheinternaltemperatureexceedsrecommended

norms.

In the event that the ventilation openings are obstructed the unit will enter over temperature protection mode (OTP) and

the cooling fan will continue to operate in order to reduce the internal temperature to a safe operating level. Once this

has been achieved the unit will turn on automatically.

3. Maintenance

ACINV Series inverters require only minimal maintenance for reliable operation.

The exterior of the unit should be cleaned down periodically with a dry cloth to prevent accumulation of dust and dirt,

paying particular attention to the ventilation openings.

Also,theDCinputterminalconnectionsshouldbecheckedtoensurethattheyaresucientlytight.

4. Troubleshooting Guide

WARNING!

Do not open or disassemble the inverter.Attempting to service

theunityourselfmayresultinariskofelectricalshockorre.

Also, the warranty will be void in the event that any seals have

been broken or tampered with.

ACINV Series inverters are designed to comply with all relevant EMI Regulations so long as they have been correctly

installed. If incorrectly installed interference with other electronic equipment in close proximity may occur.

Installation Manual | ACINV Series 1RU Rack Mount Inverters

16 17

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

• Make sure that the chassis ground lug at the rear of the unit is solidly connected to the ground system of the rack or

cabinet in which it is installed.

• Keep the cables between the battery or other DC source and the unit as short as possible and twist them together

about 2 to 3 twists per foot. This will minimise radiated interference from the cables.

Problem and Symptoms Possible Cause Solution

Low output voltage

(120V : 95-105VAC) Incorrect type of voltmeter Use true RMS meter (See section 2.4.7)

Display indicates OLP Overload condition Reduce load

No output voltage

Input voltage fault Low / High input voltage Recharge battery, check connections.

No output voltage

Display indicates OTP

Load <500W (1kVA unit)

Load <1000W (2kVA unit)

Thermal shutdown Ensure ventilation openings are clean and

not obstructed.

Improve ventilation.

Reduce ambient temperature.

No output voltage

Display indicates OLP Short circuit or wiring error

Excessive load

Check AC wiring for short circuit or

improper polarity (L and N reversed)

Remove load

If none of the above solves the problem please contact customer support, see inside front cover.

5. Important Safety Instructions

WARNING!

Before installing and using this inverter, be sure to read these

safety instructions.

Keep them in a safe place for future reference.

5.1 General Safety Precautions

5.1.1 Do not expose the Inverter to rain, snow, spray or dust. To reduce risk of hazard, do not cover or obstruct

the ventilation openings. Do not install the Inverter in a zero-clearance compartment as overheating may

result.

5.1.2 Toavoidariskofreandelectronicshock.Makesurethatexistingwiringisingoodelectricalcondition;and

that wire size is not undersized. Do not operate the Inverter with damaged or substandard wiring.

5.1.3 Thisequipmentcontainscomponentswhichcanproducearcsorsparks.Topreventreorexplosiondonot

installincompartmentscontainingbatteriesorammablematerialsorinlocationswhererequireignition

protected equipment.

This includes any space containing gasoline-powered machinery, fuel tanks, or joints, ttings, or other

connection between components of the fuel system.

5.2 Precautions When Working with Batteries

5.2.1 Ensure the installer is familiar with the material safety data sheet from the manufacturer of the batteries

concerning safe use and medical treatment.

5.2.2 NEVERsmokeorallowasparkorameinthevicinityofbatteries.

5.2.3 Do not drop a metal tool on the battery. The resulting sparks or short-circuit on the battery or other electrical

part may cause an explosion.

5.2.4 Removepersonalmetalitemssuchasrings,bracelets,necklaces,andwatcheswhenworkingwithbatteries.

Lead-acid batteries produces a short-circuit current high enough to weld a ring or the like to metal, causing

severe burn.

6. DIP switch settings

ThefollowtablesdenethevarioussettingsoftheDIPswitchesmountedattheleftsideofthefrontpaneloftheInverter.

Note that when changes are made to these settings it is necessary to recycle the power to the Inverter to allow

the internal microprocessor to read the new settings.

S1 FREQ. (Hz) S2 S3 BAUD RATE S4 S5 VOLTAGE OUTPUT

ON 60 * OFF OFF 2400 OFF OFF 100VAC

OFF 50 OFF ON 4800 * OFF ON 110VAC

---- ---- ON OFF 9600 ON OFF 115VAC *

---- ---- ON ON 19200 ON ON 120VAC

* default setting as shipped.

7. Communications Protocol & Remote ON/OFF Function

ACINV series inverters can communicate their status to a computer via an RS232 connection by sending a single ‘Status

Inquiry’ Telnet command from the computer as follows.

UsingaTerminalprogrammesuchasHyperterminalcreateaprolewiththefollowingparameters:

Baud rate: to match setting on unit (default 2400)

Data bits: 8

Parity: none

Stop bits: 1

Flow control: none

From the properties tab (in Hyperterminal) settings and then ASCII and make sure that all boxes are checked with the

exception of ‘Force incoming data to 7-bit ASCII.

Makesuretheproleissavedforfutureuse.

At the computer type: Q1<cr>

The inverter will respond as follows:

INV INV data stream, (MMM.M NNN.N PPP.P QQQ RR.R S.SS TT.T b7b6b5b4b3b2b1b0<cr>

Installation Manual | ACINV Series 1RU Rack Mount Inverters Installation Manual | ACINV Series 1RU Rack Mount Inverters

18 19

+1 (208) 635-6400 | www.transtector.com +1 (208) 635-6400 | www.transtector.com

This document is believed to be correct at time of publication and TRANSTECTOR accepts no responsibility for consequences

from printing errors or inaccuracies. Specications are subject to change without notice.

INVERTERdata stream :

Thereshouldbeaspacecharacterbetweeneveryeldislistasfollowed:

a. Start byte : (

b. I/P voltage : MMM.M------------------------------(SPEC)

M is an integer number ranging from 0 to 9.

The unit is Volts.

c. I/P fault voltage : NNN.N------------------------------(SPEC)

N is an integer number ranging from 0 to 9.

The unit is Volts.

d. O/P voltage : PPP.P

P is an integer number ranging form 0 to 9.

The unit is Volts.

e. O/P current : QQQ

QQQ is a percent of maximum current, not an absolute value.

f. I/P frequency : RR.R

R is an integer number ranging from 0 to 9.

The unit is Hz.

g. DC voltage : SS.S or S.SS

S is an integer number ranging from 0 to 9.

The unit is Volts.

h. Temperature : TT.T

T is an integer number ranging form 0 to 9.

The unit is degrees centigrade.

i. INVERTER Status : <U>-----------------------(SPEC)

<U> is one byte of binary information such as <b7b6b5b4b3b2b1b0>.

Where bn is an ASCII character ‘0’ or ‘1’.

INVERTER status: Bit Description

7 1 : Utility Fail (Immediate)

6 1 : Battery Low

5 SPEC

4 SPEC

3 SPEC

2 SPEC

1 SPEC

0 SPEC

j. Stop Byte : <cr>

Example : Computer : Q1<cr>

INVERTER Response : (208.4 140.0 208.4 034 59.9 54.2 35.0 00110000<cr>

Means : AC I/P voltage is 208.4V.-------------------------(SPEC)

AC I/P fault voltage is 140.0V.------------------(SPEC)

AC O/P voltage is 208.4V.

AC O/P current is 34%.

AC O/P frequency is 59.9 HZ.

DC I/P voltage is 54.2V.

Temperature is 35.0 degrees centigrade.

RS232 Hardware connection.

Note that only a 3 wire RS232 cable may be used otherwise damage may occur to the Inverter and/or the PC.

PC

GND

5

3

2

5

3

2

GND

TXD TX

RXD RX

INVERTER

About Transtector Systems:

Transtector Systems, an Infinite Electronics brand, leads the industry with a comprehensive product portfolio

and specialized expertise in consulting, design and manufacturing of AC, DC, data and signal surge protection,

communications power cabinets, and EMP protection.

Transtector provides valuable end-to-end power and signal integrity solutions for markets that include

telecommunications, medical imaging, transportation, energy, security and the military. Our goal is to support the urgent

surge-protection requirements of our customers with responsive customer service, technical support and a wide-range of

quality AC, DC and data line surge protection products in-stock and available for same-day shipping.

Contact us at +1 208 635 6400 or online at www.transtector.com.

About Infinite Electronics:

Infinite Electronics is a leading global supplier of electronic components serving the urgent needs of engineers through

a family of highly recognized and trusted brands. Our portfolio brands are specialists within their respective product set,

offering broad inventories of engineering-grade product, paired with expert technical support and same day shipping.

Over 100,000 customers across a diverse set of markets rely upon Infinite Electronics to stock and reliably ship urgently

needed products every day.

This manual suits for next models

2

Table of contents

Popular Inverter manuals by other brands

Generac Power Systems

Generac Power Systems APS 6.0 Operating & installation manual

ABB

ABB UNO-DM-TL-PLUS-US product manual

Chicago Electric

Chicago Electric 95519 Assembly and operation instructions

Moso

Moso SF8KTL manual

SunSynk

SunSynk 8K-SG04LP3 Installer manual

Parker

Parker DN-6 Series Installation, operation and maintenance manual

Toshiba

Toshiba TOSVERT VF-S9 instruction manual

Deye

Deye SUN-8K-G05-LV user manual

Generac Power Systems

Generac Power Systems 7 kW NG Installation and owner's manual

Briggs & Stratton

Briggs & Stratton 10000 Watt Operator's manual

INVT

INVT Goodrive10 Series Operation manual

Mastervolt

Mastervolt Sunmaster XS4300 User and installation manual