Tritech MicronNav User manual

MicronNav System

0656-SOM-00001-07 1 © Tritech International Ltd.

MicronNav System

Product Manual

0656-SOM-00001-07

MicronNav System

0656-SOM-00001-07 2 © Tritech International Ltd.

© Tritech International Ltd

The copyright in this document is the property of Tritech International Ltd. The document is supplied by Tritech International Ltd on

the understanding that it may not be copied, used, or disclosed to others except as authorised in writing by Tritech International Ltd.

Tritech International Ltd reserves the right to change, modify and update designs and specifications as part of their ongoing

product development programme.

All product names are trademarks of their respective companies.

MicronNav System

0656-SOM-00001-07 3 © Tritech International Ltd.

Table of Contents

Help & Support ........................................................................................................... 5

Warning Symbols ........................................................................................................ 6

1. Introduction ............................................................................................................. 7

2. Technical Specification ............................................................................................ 8

2.1. System ........................................................................................................ 8

2.2. Surface MicronNav100 Interface Hub ............................................................ 9

2.3. Surface USBL Dunking Transducer ............................................................. 10

2.4. Subsea Modem Head ................................................................................. 11

3. Installing the System ............................................................................................. 12

3.1. Preparation ................................................................................................ 12

3.1.1. Using the system with the Micron INS .............................................. 12

3.1.2. Mounting the Subsea Modem Head .................................................. 12

3.1.3. Mounting the Surface USBL Dunking Transducer .............................. 13

3.1.4. Electrical Connections to the Subsea Modem Head ........................... 15

3.1.5. Electrical Connection to the Surface USBL Dunking Transducer ......... 16

3.1.6. Electrical Connection to the Surface MicronNav100 Interface Hub ....... 16

3.1.7. External Computer Data Link Electrical Connections .......................... 16

3.2. Installation .................................................................................................. 17

3.2.1. System requirements ....................................................................... 17

3.2.2. Installing Seanet Pro ....................................................................... 17

3.2.3. Surface Hardware Installation and Configuration ................................ 19

3.2.4. Subsea Hardware Responder Configuration ...................................... 21

3.2.5. Subsea Hardware Transponder Configuration ................................... 28

3.2.6. Connecting optional third party GPS Receiver ................................... 29

3.2.7. Connecting optional third party High Accuracy Heading/Pitch/Roll

MRU Sensors ........................................................................................... 31

3.2.8. Data Input from an ROV .................................................................. 41

3.2.9. Connecting optional third party Video Camera ................................... 43

3.3. Remote Beacons ........................................................................................ 47

3.4. Dry System Check ..................................................................................... 50

3.4.1. Setting up the Application ................................................................ 50

3.4.2. Transducers and integral Heading/Pitch/Roll Sensor Check ................ 50

3.4.3. Optional third party GPS Comms Check ........................................... 52

3.4.4. Optional third party Heading & MRU Check ....................................... 52

3.4.5. Optional third party Video Check ...................................................... 53

3.5. Hardware Reset ......................................................................................... 53

4. Operation .............................................................................................................. 55

4.1. Mobilising the System ................................................................................. 55

4.1.1. Pre Dive Checks ............................................................................. 55

4.1.2. Deploying the USBL Head ............................................................... 55

4.1.3. Measuring the Installation Offsets ..................................................... 55

4.1.4. Creating a New Job (Using Wizard) .................................................. 56

4.1.5. Editing an Existing Job .................................................................... 62

4.1.6. Loading an Old Job ......................................................................... 63

4.1.7. Job Settings for Mobile or Fixed Platforms ........................................ 64

4.1.8. Applying a Geodetic Datum Shift to the reference co-ordinates ........... 70

4.1.9. Launching the Subsea Installation .................................................... 77

4.2. Operating the System ................................................................................. 78

4.2.1. User Controls .................................................................................. 78

4.2.2. The Readings Explained .................................................................. 79

4.2.3. User Features ................................................................................. 79

4.2.4. Other Controls ................................................................................. 84

4.3. Logging and Replay ................................................................................... 86

4.4. Shutting Down the System .......................................................................... 86

5. Maintenance ......................................................................................................... 87

MicronNav System

0656-SOM-00001-07 4 © Tritech International Ltd.

6. Adding and Using User Bitmap Charts ................................................................... 88

6.1. Adding a Chart ........................................................................................... 88

6.2. Editing a Chart ........................................................................................... 90

6.3. Deleting a Chart ......................................................................................... 91

6.4. Chart controls ............................................................................................ 91

6.5. Markers ..................................................................................................... 92

6.5.1. Overview ......................................................................................... 92

6.5.2. Creating and Laying a Marker .......................................................... 92

6.5.3. Saving the Markers .......................................................................... 93

6.5.4. Loading the Markers ........................................................................ 96

6.6. Other Chart Functions ................................................................................ 96

6.7. Load BSB Charts ..................................................................................... 100

7. Using the External Computer Data Link ................................................................ 105

7.1. Setting the RemV4 string output ................................................................ 105

7.2. List of Current String Formats ................................................................... 108

7.2.1. Proc XYZ ...................................................................................... 109

7.2.2. Raw XYZ ...................................................................................... 111

7.2.3. TP-2EC ......................................................................................... 113

7.2.4. Simrad HPR 300P ......................................................................... 114

7.2.5. Simrad HPR 410 ........................................................................... 115

7.2.6. NMEA $RATTM ............................................................................. 117

7.2.7. NMEA $GPGGA ............................................................................ 119

7.2.8. NMEA $GPGLL ............................................................................. 121

7.2.9. NMEA $GPRMC ............................................................................ 121

7.2.10. $PSIMSSB .................................................................................. 123

7.2.11. NMEA $GPDBT ........................................................................... 125

7.2.12. Notes .......................................................................................... 126

8. Using with Other Tritech Sonars .......................................................................... 127

9. Adding a Micron Echosounder ............................................................................. 128

10. Adding a Micron INS ......................................................................................... 130

11. Conversion Between MicronNav Responder and Transponder ............................. 131

11.1. Seanet Setup for Conversion .................................................................. 131

11.2. Conversion to Transponder ..................................................................... 133

11.2.1. Enabling the USBL Transducer Transponder Transmitter ................ 134

11.2.2. Configure Seanet Pro for Transponder Mode ................................. 134

11.3. Conversion to Responder ........................................................................ 136

11.3.1. Connect the Micron Sonar and Responder .................................... 137

11.3.2. Configure Seanet Pro Responder Mode ........................................ 139

Glossary ................................................................................................................. 142

MicronNav System

0656-SOM-00001-07 5 © Tritech International Ltd.

Help & Support

First please read this manual thoroughly (particularly the Troubleshooting section, if present).

If a warranty is applicable, further details can be found in the Warranty Statement, 0080-

STF-00139, available upon request.

Tritech International Ltd can be contacted as follows:

Mail Tritech International Ltd

Peregrine Road

Westhill Business Park

Westhill, Aberdeenshire

AB32 6JL, UK

Telephone ++44(0)1224 744 111

Fax ++44(0)1224 741 771

Email [email protected]

Website www.tritech.co.uk

Prior to contacting Tritech International Ltd please ensure that the following is available:

1. The Serial Numbers of the product and any Tritech International Ltd equipment connected

directly or indirectly to it.

2. Software or firmware revision numbers.

3. A clear fault description.

4. Details of any remedial action implemented.

Contamination

If the product has been used in a contaminated or hazardous environment you

must de-contaminate the product and report any hazards prior to returning the

unit for repair. Under no circumstances should a product be returned that is

contaminated with radioactive material.

The name of the organisation which purchased the system is held on record at Tritech

International Ltd and details of new software or hardware packages will be announced at

regular intervals. This manual may not detail every aspect of operation and for the latest

revision of the manual please refer to www.tritech.co.uk

Tritech International Ltd can only undertake to provide software support of systems loaded

with the software in accordance with the instructions given in this manual. It is the customer's

responsibility to ensure the compatibility of any other package they choose to use.

MicronNav System

0656-SOM-00001-07 6 © Tritech International Ltd.

Warning Symbols

Throughout this manual the following symbols may be used where applicable to denote any

particular hazards or areas which should be given special attention:

Note

This symbol highlights anything which would be of particular interest to the reader

or provides extra information outside of the current topic.

Important

When this is shown there is potential to cause harm to the device due to

static discharge. The components should not be handled without appropriate

protection to prevent such a discharge occurring.

Caution

This highlights areas where extra care is needed to ensure that certain delicate

components are not damaged.

Warning

DANGER OF INJURY TO SELF OR OTHERS

Where this symbol is present there is a serious risk of injury or loss of life. Care

should be taken to follow the instructions correctly and also conduct a separate

Risk Assessment prior to commencing work.

MicronNav System

0656-SOM-00001-07 7 © Tritech International Ltd.

1. Introduction

The Tritech MicronNav system is an innovative Ultra Short Base Line (USBL) acoustic

tracking system designed for tracking or marking the position of underwater vehicles or

objects. The design of the system provides 180° hemispherical coverage from the surface

unit and 360° omni-directional coverage from the subsea unit enabling continuous reliable

tracking even in very shallow water. The size of the subsea unit is small enough to be fitted

to the smallest of observation class vehicles.

The system can be used stand-alone in Transponder mode in which case the subsea unit

only requires power, or it can be used with Tritech's range of imaging Sonars (Micron MKII

or MKIII, Super SeaKing and Gemini) in responder mode in which case the subsea unit is

powered by and communicated with through the Sonar Aux port. It is synchronised with the

Sonar to reduce the effect of acoustic interference on the sonar display. For compatibility

with other Tritech International Ltd Sonars see Chapter 8, Using with Other Tritech Sonars

The MicronNav system consists of a Seanet Pro application software package for installation

onto a suitable PC or laptop computer, a small surface MicronNav100 Interface Hub, a

lightweight surface USBL ‘Dunking’ Transducer (with integral magnetic compass and pitch/

roll sensor) and one or more small subsea MicronNav Modem heads.

Note

The Tritech SeaHub Surface Interface Module cannot be used in place of the

MicronNav100 Hub.

The Seanet Pro application software running on a PC or Laptop commands the subsea

MicronNav Modem head to transmit an acoustic ranging signal to the Surface USBL

Dunking Transducer. When operating in stand-alone Transponder mode this command is

sent acoustically via the USBL Dunking Transducer, and when combined with the Tritech

sonar and operating in Responder mode this command is sent electronically via the sonar

communications link.

The MicronNav acoustic ranging signal is detected by the USBL Dunking Transducer and

MicronNav100 Hub Interface module and the received signal information sent to the host

Seanet computer for calculation of range and bearing of the subsea head. USBL Dunking

Transducer pitch/roll and heading data from the integral pitch/roll sensors and magnetic

compass are also captured and sent to Seanet Pro for calculation of corrected position to

world axis.

If GPS positional data is available the range and bearing of the subsea head is synchronised

and the Seanet display updated with ships position and ROV position to true world position.

Provision is made to allow position information to be overlaid onto a user supplied bitmap

chart display of the local area if required.

The position fixing cycle is repeated dependent upon the selected update rate (0.5 – 10s).

MicronNav System

0656-SOM-00001-07 8 © Tritech International Ltd.

2. Technical Specification

2.1. System

Positioning Technology Spread Spectrum Acoustic Ultra Short Baseline (USBL) Range/

Bearing Tracking System. 20-28 kHz band. (Magnetic Compass

and Pitch/Roll Sensor built into Dunking transducer as standard)

Tracking Range 500m (1,640ft) typical Horizontal, 150m (492ft) typical Vertical.

Range is dependent on a variety of operating conditions:

• The presence of thermoclines

• The presence of acoustically reflecting surfaces within the

operating environment

• Ambient noise

• Salinity

• Volume reverberation

• Surface and seabed reflectivity

Range Accuracy +0.2 metre (7.87 inches) system timing accuracy – assuming

correct Velocity of Sound.

Bearing Accuracy +/-3 degrees (equates to better than +5% of slant range)

Position Update Rate 0.5 Seconds – 10 Seconds

Targets Tracked Maximum 1 Responder and 15 Transponders

Data Display Plan Position Indicator (PPI) display and optional user bitmap

chart display

Data Recording All Data recorded in standard Seanet Format for Replay or

Analysis

Surface Navigation NMEA 0183 GPS and Heading/Attitude Sensors supported.

Position of Surface vehicle displayable.

Technical Specification MicronNav System

0656-SOM-00001-07 9 © Tritech International Ltd.

2.2. Surface MicronNav100 Interface Hub

AC Power Supply 90V to 264V, 47Hz to 63Hz. IEC-320 C14 socket (for C13 cord),

20x5mm 2A Antisurge (T) fuse

DC Power Supply 12V to 36V, 2.1mm (0.08”) pin (positive centre).

Power Consumption 4.8W from either source (with no external load)

DC Power Output (Port

D & AIF Port)

50W or 2A maximum current draw

Internal 20mm x 5mm 2A Quick Acting (F) fuse.

+33V if using AC, 1.5V less than the supply voltage if using DC.

Defaults to highest voltage if both are connected.

Supported Protocols USB2.0, RS232, RS422, RS485, ARCNET LAN.

Ports A, B and C DE-9 male connectors

RS232 (3 wire), RS485 (half duplex) on Ports A, B, C

RS232 (5 wire – RTS, CTD) on Port A

RS422 (full duplex differential) on Port B

ARCNET differential (analogue) LAN on Port C

Port D DIN-45322 Female Socket, screened with power & earth.

RS232 (3 wire), RS485 (half duplex)

ARCNET differential (analogue) LAN

AIF (ARCNET) Port DA-15 female connector

ARCNET differential (analogue) LAN

ARCNET TTL LAN (for backplane connection)

Optional support for “Port A” serial signals

Power output available

USB 2.0 480Mbps Ports One Type B on rear for PC connection.

Two Type A ports on front for auxiliary devices.

500mA over-current protected +5V on front ports.

Avoid USB hubs and cables exceeding 5m.

RAT Connection A single DE-9 female front panel connector for connection to a

“V2” Remote Access Terminal.

Transducer Connection DB-25 female port on rear panel for connecting the MicronNav

USBL Dunking Transducer.

Status Indicators 1 x Power/Status Indicator

4 x Communication Status Indicators (Red/Green)

11 x Communication Hardware Mode Indicators (Blue)

Dimensions Width: 232mm, Height: 52mm, Depth: 185mm

Weight 1.3Kg

Material Painted Aluminium, Matte Anthracite Textured Finish

IP Rating IP20 (no protection against water ingress).

Temperature Limits -10°C to 35°C (operation), -20°C to 50°C (storage)

Technical Specification MicronNav System

0656-SOM-00001-07 10 © Tritech International Ltd.

2.3. Surface USBL Dunking Transducer

Operating Beamwidth 180 degrees

Power requirement No external requirement – is supplied directly from

MicronNav100 Interface Hub

Comms requirement No external requirement – is connected directly to

MicronNav100 Interface Hub

Frequency of operation 20-28kHz Spread Spectrum

Depth Rating 10metres (32.8 feet)

Cable Length standard 10metres (32.8 feet) - other options available on

request

Maximum Cable Length 50metres (164 feet)

Maximum Diameter 110mm (4.33 inches) including mounting plate

Body Tube Diameter 75mm (2.95 inches)

Maximum Height 270mm (10.63 inches)

Weight in Air 1.96kg (3lbs 15oz)

Weight in Water 810g (1lb 12oz)

Material Mounting Flange: Marine Brass

Housing: Grey ABS

Transducer: Polyurethane

Operating Temperature -10°C to +35°C

Storage Temperature -20°C to +50°C

Technical Specification MicronNav System

0656-SOM-00001-07 11 © Tritech International Ltd.

2.4. Subsea Modem Head

Operating Beamwidth Omni directional Transducer

Power Requirement 12-48V DC

Note: Reverse and over-voltage protection are not provided to

the power supply.

Frequency 20-28kHz Spread Spectrum

Power Consumption Dependent on the system interrogation rate which is user

controlled (0.5, 1, 2, 5 or 10sec) for example at 1sec update the

average power consumption would be 175mW typical and at

0.5sec would be 350mW typical.

Main Port Type factory set to RS232

Note: Transient and over-voltage protection is applied to the

Comms ports but Comms ports are not DC isolated.

Main Port data rate factory set to 9600 baud (others available on request)

Aux Port Type factory set to RS232

Aux Port data rate factory set to 9600 baud (others available on request)

Depth Rating 750m (2,460ft)

Maximum Diameter 56mm (2.20 inches)

Maximum Height 76mm (2.99 inches)

Fixing Points 4 off M3 x 0.5 Tap 5.0 full thread

Weight in Air 210g (7.4oz)

Weight in Water 55g (1.9oz)

Material Housing: Anodised Aluminium

Transducer: Polyurethane

Operating Temperature -10°C to +40°C

Storage Temperature -20°C to +50°C

Caution

This specification refers to the Micron Nav Modem. The Micron Range (Sonar/

Seasprite, Echosounder, Micron Nav Modem) work on a voltage range of 12-48V

DC with the exception of the Micron Data Modem which uses 12-24V DC. If you

are unsure which product you are using either opt for a lower voltage or contact

Tritech International Ltd to discuss product options.

MicronNav System

0656-SOM-00001-07 12 © Tritech International Ltd.

3. Installing the System

3.1. Preparation

This section is intended to provide the user with sufficient information to allow for the

consideration and preparation of mounting brackets and wiring arrangements prior to receipt

of the system, final wiring however can only be completed once in receipt of the system as

interconnect leads are supplied with the system.

3.1.1. Using the system with the Micron INS

The Tritech Micron INS has been designed to be fully compatible with the MicronNav System

and can be integrated in a variety of ways.

For full details of how to install a Tritech Micron INS with the MicronNav please refer to

the Micron INS Product Manual (document reference: 0722-SOM-00001) alongside this

document.

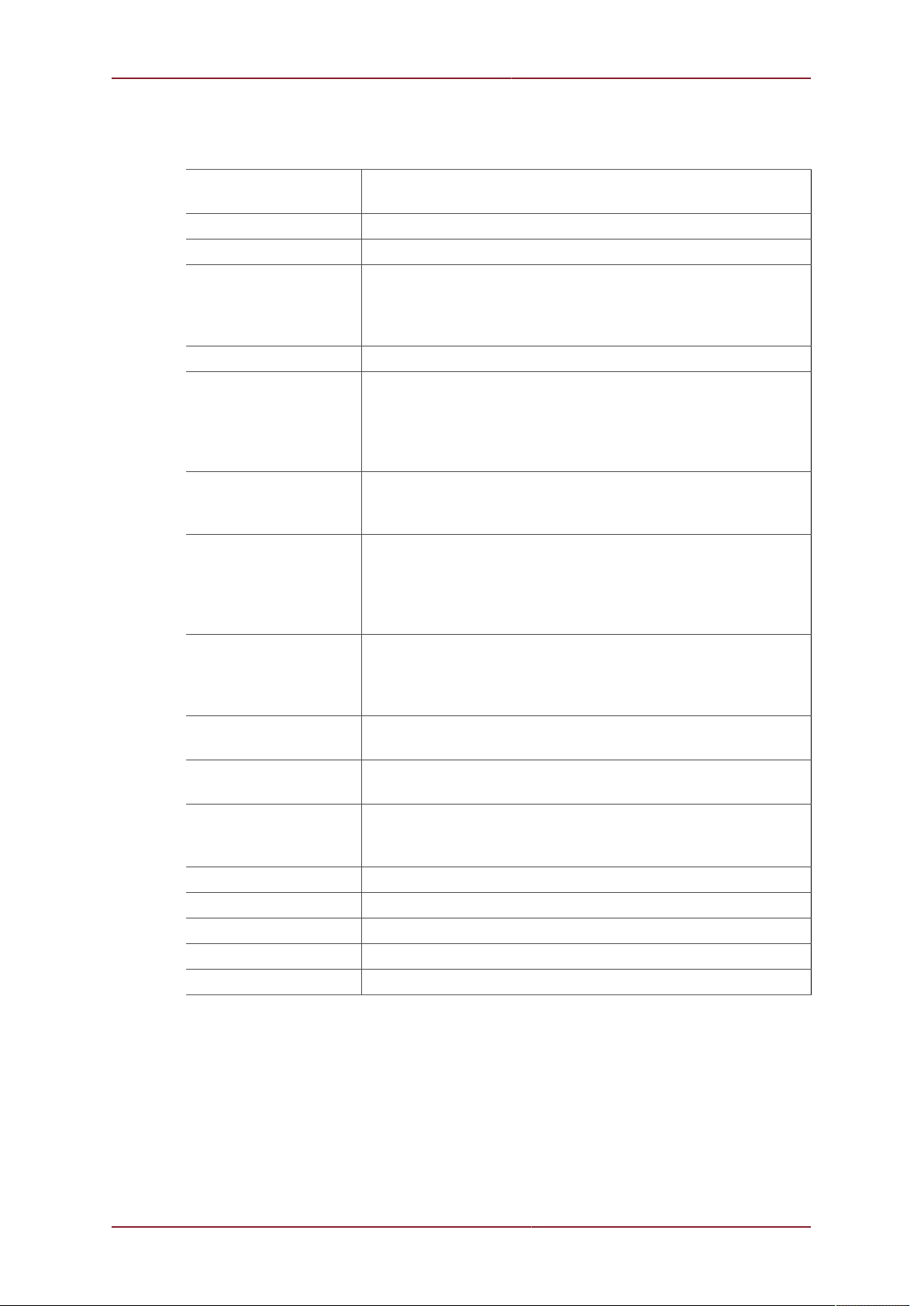

3.1.2. Mounting the Subsea Modem Head

The Subsea Modem Head should be mounted at the top of the ROV ensuring the transducer

is proud of the ROV fairing with a clear view from the transducer to the surface, also

remembering to ensure enough room is left to enable the cable connection to be made to the

Micron connectors. To assist with the mounting there are 4 off M3 x 0.5 tapped 5.0 deep full

thread fixing holes in the base of the unit (note: these are protected with plastic grub screws

when shipped from the factory and should be removed prior to using). An alternative method

of mounting the head is to gently grip with a 50mm diameter clamping mechanism around

the bottom part of the housing (in this case the plastic grub screws fitted to the fixing holes

should be left in place).

Caution

It is recommended that any fixing screws used should be of non-metallic material

to reduce the risk of corrosion around the fixing positions.

Installing the System MicronNav System

0656-SOM-00001-07 13 © Tritech International Ltd.

24.0

56 A/F

Ø50

66

Ø49

Ø56

76

16

26

24.0

4 OFF M3 x 0.5

4.5

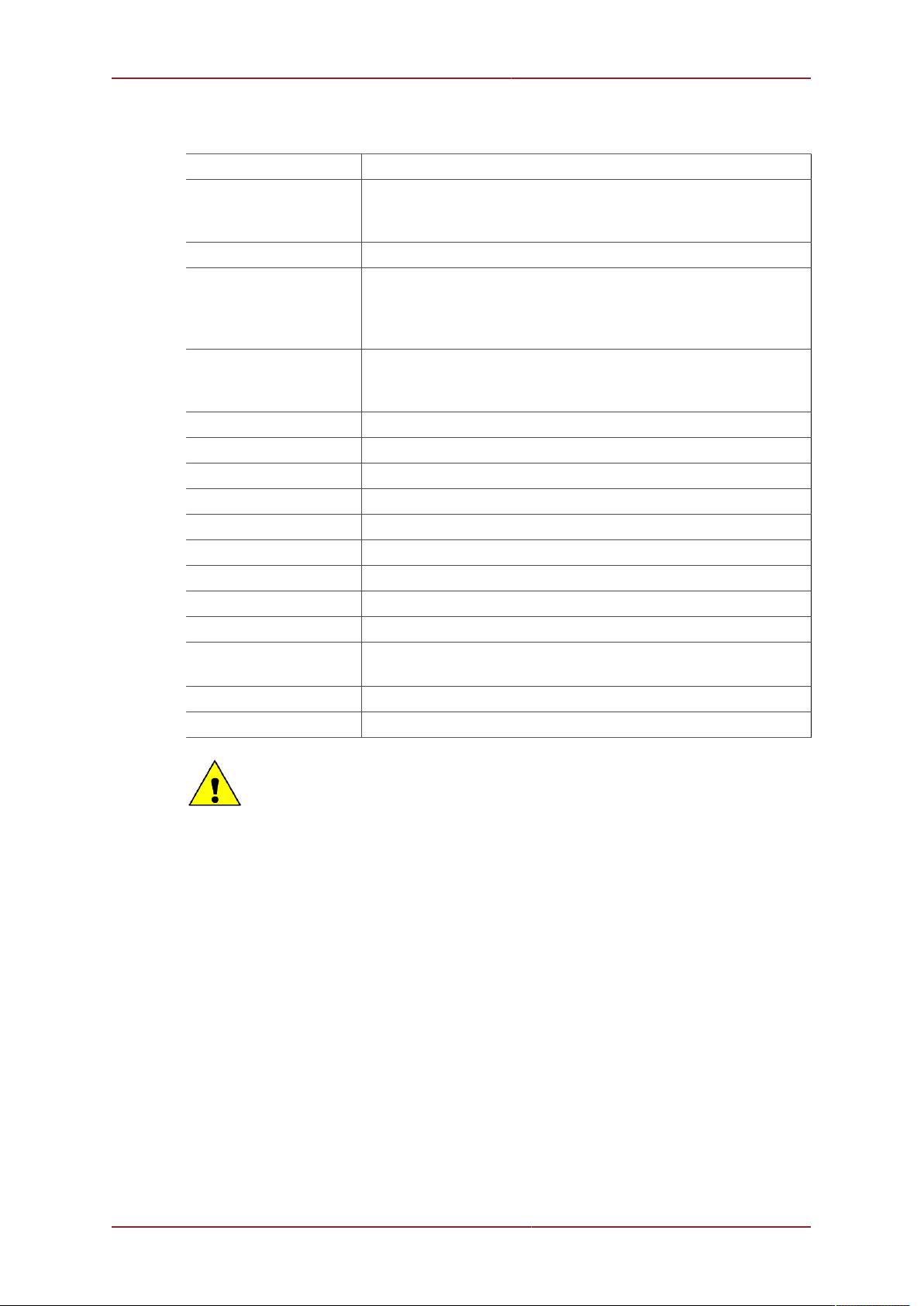

3.1.3. Mounting the Surface USBL Dunking Transducer

The USBL Dunking Transducer should be mounted from the fixed platform/dockside or

mobile platform/vessel such that the transducer head is at least 1m to 2m below the surface

of the water and at least 1m to 2m away from the dock wall or vessel, if operating from a

vessel it may be difficult to achieve 1m to 2m clearance from the side so in this case lower

the head deeper to ensure a clearance of 1m to 2m below the bottom of the hull.

Caution

The depth of the head must not exceed 10m. Also, when installing on a vessel it

is important to ensure the head is mounted clear of any propellers or thrusters.

The USBL Dunking Transducer contains an integral Magnetic Heading and Pitch/Roll Sensor

that enables the MicronNav Seanet application software running on the surface computer

to make corrections to world axis, this is particularly effective when operating from a non-

magnetic mobile platform/vessel or fixed dockside.

When operating from a steel hull vessel the integral sensor will be affected by magnetic

interference from the vessel and it is recommended in this type of installation that an external

Ships Compass & Motion Reference Unit (MRU) is used to provide the Heading and Pitch/

Roll information, details of how to connect and use an external Compass & MRU sensor can

be found in Section 3.2.7, “Connecting optional third party High Accuracy Heading/Pitch/Roll

MRU Sensors”.

Installing the System MicronNav System

0656-SOM-00001-07 14 © Tritech International Ltd.

The USBL Dunking Transducer is supplied with a short mounting pole (0.5m long) that will

screw into the 22mm diameter coupling on the top of the USBL Head mounting flange and

provide a clamping point for attaching to the users installation. The mounting flange coupling

is a standard 22mm water pipe fitting (UK) enabling a standard 22mm diameter copper water

pipe to be used as a mounting pole fitting directly to the head.

An alternative method of mounting the head is to fabricate a dedicated mounting bracket

and fasten to the USBL mounting flange. It is recommended however that a non-magnetic

material is used for the fixing so as not to affect the integral Magnetic Heading and Pitch/

Roll sensor, if the user wishes to use stainless steel for the fabrication some Duplex Alloys

such as FerraliumSD40 are particularly good but are rather exotic, stainless steel 316 (typical

material used for sub-sea housings) however has little effect on the compass readings and

could be used as an alternative.

Caution

When operating from a vessel consideration should be given to the speed the

vessel is likely to be travelling and the resultant force/pressure the USBL Dunking

Transducer mounting arrangement will need to withstand.

The yellow line indicates the front of

transducer head. This should be positioned

facing in the required forward position to

ensure correct representation on the PPI

display when set to “Ships Head Up”. If

operating from a fixed platform/dockside this

would normally be facing away from the

platform/dockside and if operating from a

mobile platform this would normally align with

the front of the vessel.

Installing the System MicronNav System

0656-SOM-00001-07 15 © Tritech International Ltd.

Ø 26.6 THRU ALL

1 1/8" - 14 UNS THRU ALL

33.0

40.05 TYP

20.0 TYP

3 x Ø 6.5 THRU ALL

4 x Ø 6.5 THRU ALL

15.0

46.25 23.13 TYP

20.0 TYP

Ø 110.0

71.0

Ø 33.0

16.0

3.1.4. Electrical Connections to the Subsea Modem Head

Responder Mode

In Responder mode there is no direct connection from the ROV to the sub-sea Modem head

- in this configuration the ROV connects to the Tritech Sonar head (Main port) using the cable

supplied with the Sonar, and the MicronNav sub-sea Modem head (Main port) connects to

the (Auxiliary port) of the Sonar using the Double Ended Interconnect cable supplied with

the MicronNav system.

Transponder Mode

In Transponder mode the MicronNav subsea Modem head only requires power supply

connections - this can be from the ROV, a stand-alone underwater battery pack or from the

Auxiliary port of any of the Tritech subsea heads.

12

643

5

Face View

Connector

Pin Wire Colour Function

1 Yellow not connected

2 Blue not connected

3 Red Supply +

4 Black Supply Ground

5 Green not connected

6 cable sheath Earth/Screen

Installing the System MicronNav System

0656-SOM-00001-07 16 © Tritech International Ltd.

3.1.5. Electrical Connection to the Surface USBL Dunking Transducer

The USBL Dunking Transducer is supplied complete with underwater cable moulded directly

onto the head and a DB-25 connector at the dry side for connection directly into the USBL

connector on the rear of the MicronNav100 Interface Hub.

3.1.6. Electrical Connection to the Surface MicronNav100 Interface Hub

The surface MicronNav100 Interface Hub requires power from a 90 to 264V AC supply 47

to 63Hz, or a 12 to 36V DC supply - power consumption from either source will be typically

4.8W (with no additional external device load).

Communications from the MicronNav100 Interface Hub to the Subsea head (if being used

with Micron/SeaSprite Sonar) is via a DE-9 socket which connects to Port B plug on the rear

of the unit.

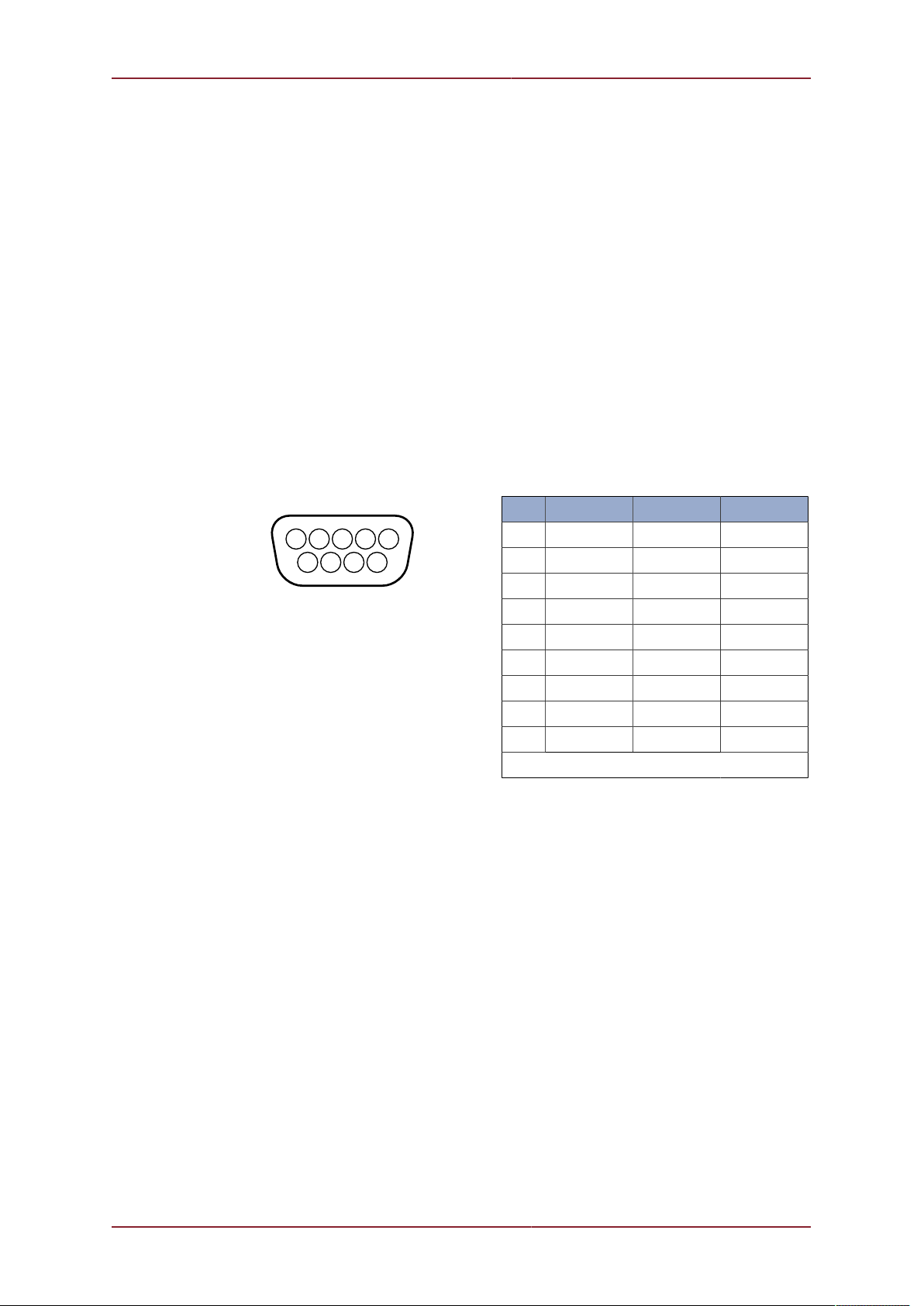

Connections to the DE-9 socket on Port B are as follows:-

45

12

8

6

3

7 9

Pin RS232 RS422 RS485

1 ‡ ‡ ‡

2 RX TX.A TX/RX.A

3 TX TX.B TX/RX.B

4 ‡ ‡ ‡

5 GROUND GROUND GROUND

6 ‡ ‡ ‡

7 ‡ RX.B ‡

8 ‡ RX.A ‡

9 ‡ ‡ ‡

‡ = connected for handshaking only.

Communications from the MicronNav100 Interface Hub to the computer running the

MicronNav Seanet application software is via a USB Type-A to Type-B cable supplied with

the system, connection is to the rear of the unit.

3.1.7. External Computer Data Link Electrical Connections

If the MicronNav data is required by a third party software package running on an external PC

then connection from the Surface MicronNav100 Interface Hub to the external PC is made

via one of the four serial interface connectors located at the rear of the unit, Port A, B, C or

D. (Note: If the system is being used in Responder mode Port B will be used for the Sonar

communications and will not available for this).

If ports A, B or C are to be used for external communications a DE-9 socket should be wired

as above, if port D socket is to be used a DIN-45322 (6 pin) plug is required and should be

wired as follows:

Installing the System MicronNav System

0656-SOM-00001-07 17 © Tritech International Ltd.

4

1

3

2

6

5

Pin RS232 RS485

1 RX TX/RX-A

2 TX TX/RX-B

3 ‡ ‡

4 ‡ ‡

5 GROUND GROUND

6 ‡ ‡

‡ = connected for handshaking only.

Warning

The 6 pin DIN-45322 connector Port D has a live 24V supply output on pin 3

referenced to 0V on pin 4.

3.2. Installation

3.2.1. System requirements

Seanet Pro has the following system requirements:

Minimum Recommended

Processor 2GHz 2GHz dual core

RAM 1GB 2GB

Graphics 3D hardware accelerated graphics card.

Display 1280x1024 (32bit colour) 1600x1200 (32bit colour)

Disk space Install is 20MB, greater than 160GB recommended for log files

Networking 100Mbit·s-1 (fast Ethernet) 1000Mbit·s-1 (Gigabit Ethernet)

Software Windows XP 32bit Windows 7 32 or 64bit

It is highly recommended that your system specifications are checked against these

requirements prior to attempting installation of Seanet Pro.

3.2.2. Installing Seanet Pro

Seanet Pro is supplied on a CD-ROM which has been designed to auto-run upon

disc insertion. The latest commercial release of software is always available from

www.tritech.co.uk.

Once loaded, the main menu of the CD will be shown on screen.

Installing the System MicronNav System

0656-SOM-00001-07 18 © Tritech International Ltd.

Click on the Seanet Pro button and the following screen will display all the appropriate

software packages for installation.

Click on the appropriate installation option and then follow the onscreen prompts and

instructions.

•Seanet Pro using AIF Card - select this option if you are using a SCUv4, or PC

equiped with a PCI AIF card.

•Seanet Pro using RS232 - select this option if you are using a SeaHub, MicronNav

Hub, PC or Laptop with either hardware COM Ports or USB converters.

•Hammerhead - this option installs a modified version for use with the Super SeaKing

Hammerhead sonar.

•Dumplog - this option installs an additional software package for post-processing data files.

Installing the System MicronNav System

0656-SOM-00001-07 19 © Tritech International Ltd.

•Task Scheduler - this option installs an additional software package to automate the

recording of logfiles with Seanet Pro.

•Sonar Image Tiler - this option installs an additional software package that can mosaic

sonar imagery from Seanet Pro onto background images.

Note

Do not attempt to remove the CD-ROM from your computer during the installation

process.

3.2.3. Surface Hardware Installation and Configuration

Caution

The power should be turned off before making a connection between the sonar

head and surface controller (SCU or SeaHub).

Carefully unpack the system from the transit case and uncoil the USBL cable, the

MicronNav100 Hub is located underneath the lift out section containing the Subsea Modem

Head and cable assemblies.

If the supplied mounting pole is to be utilised fit it to the standard plumbing fitting on the brass

mounting plate on top of the USBL Head and connect the USBL Head cable connector to the

DB-25 socket on the rear panel of the MicronNav100 Hub.

Note

It is recommended to wait until after the system has been fully configured and

the Dry System check completed before fitting the USBL Dunking Transducer to

the desired mounting arrangement.

Connect the computer USB port on the rear panel of the MicronNav100 Hub to a USB 2.0

port on the User computer with the supplied USB cable assembly.

Connect power to the MicronNav100 Hub and switch on. The indicator LEDs on the front of

the unit will flash and the ports will auto-install on the computer - this will take a minute or so

to complete and you may be prompted to re-boot the computer.

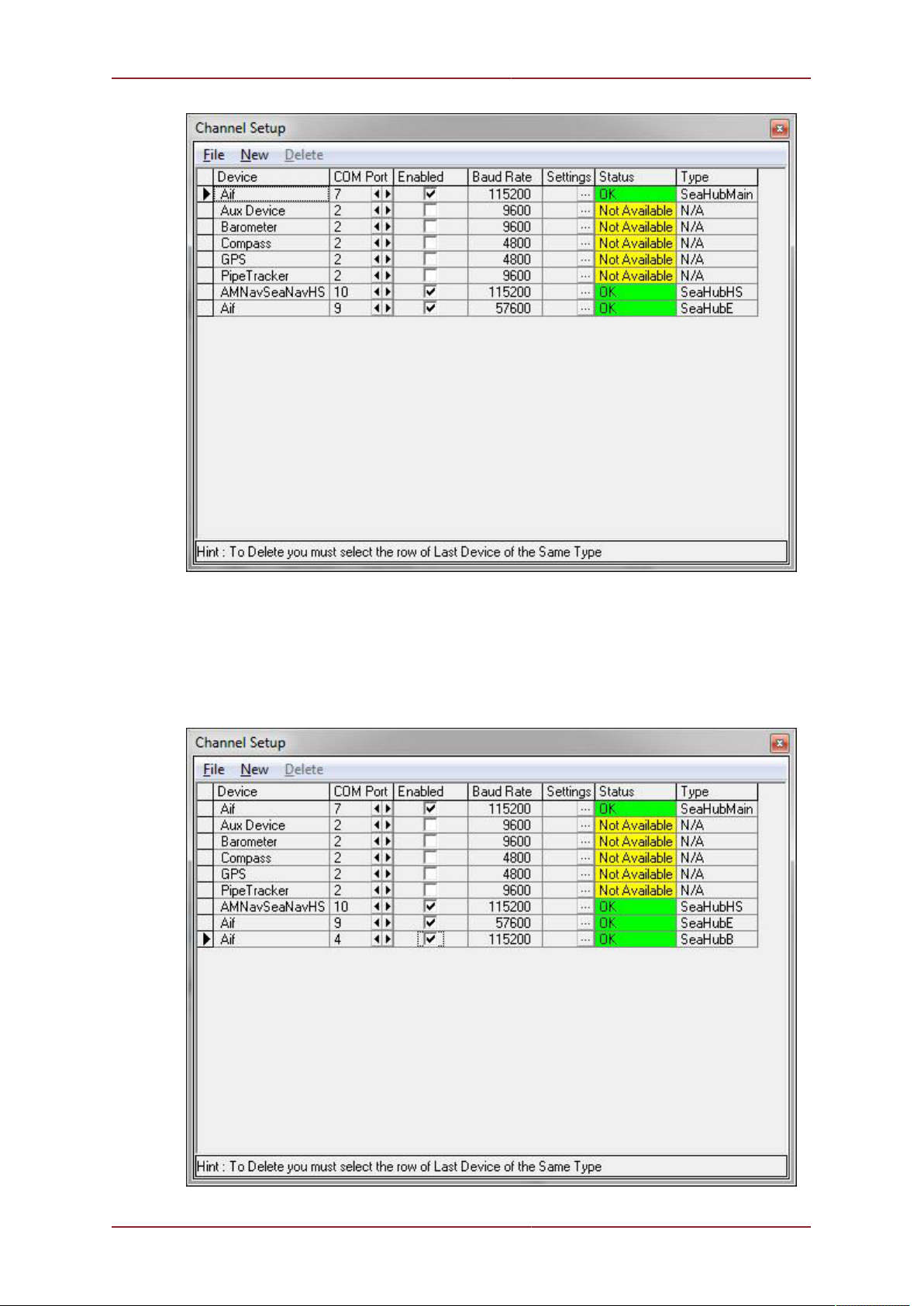

The Seanet software must now be configured for the MicronNav100 Hub – click the Seanet

Setup icon on the desktop to run the Seanet setup program, select Utilities from the top

menu bar of the Seanet Setup window followed by Com Setup from the sub-menu to open

the Channel Setup page, a dialog box will be opened notifying detection of the SeaHub

on one of the COM ports and you will be asked to confirm Auto Enable of an Aif device - this

should be confirmed by selecting YES. The Channel Setup page will then automatically add

and enable the ports that are required as shown below.

Note

Port numbers may differ on different computers dependent on Windows setup.

Installing the System MicronNav System

0656-SOM-00001-07 20 © Tritech International Ltd.

Now add a port for the Micron or SeaSprite Sonar connection for use when Responder mode

operation is required. This is done by selecting New from the menu bar followed by Aif from

the sub-menu. The new Aif device must now be configured to Port B by adjusting the COM

Port number with the spin edit button until the Type=”SeaHubB” as shown below, click the

check box to enable and close the ‘Channel Setup’ page by clicking the ‘X’ at the top right

of the window.

Table of contents

Other Tritech Marine Equipment manuals

Popular Marine Equipment manuals by other brands

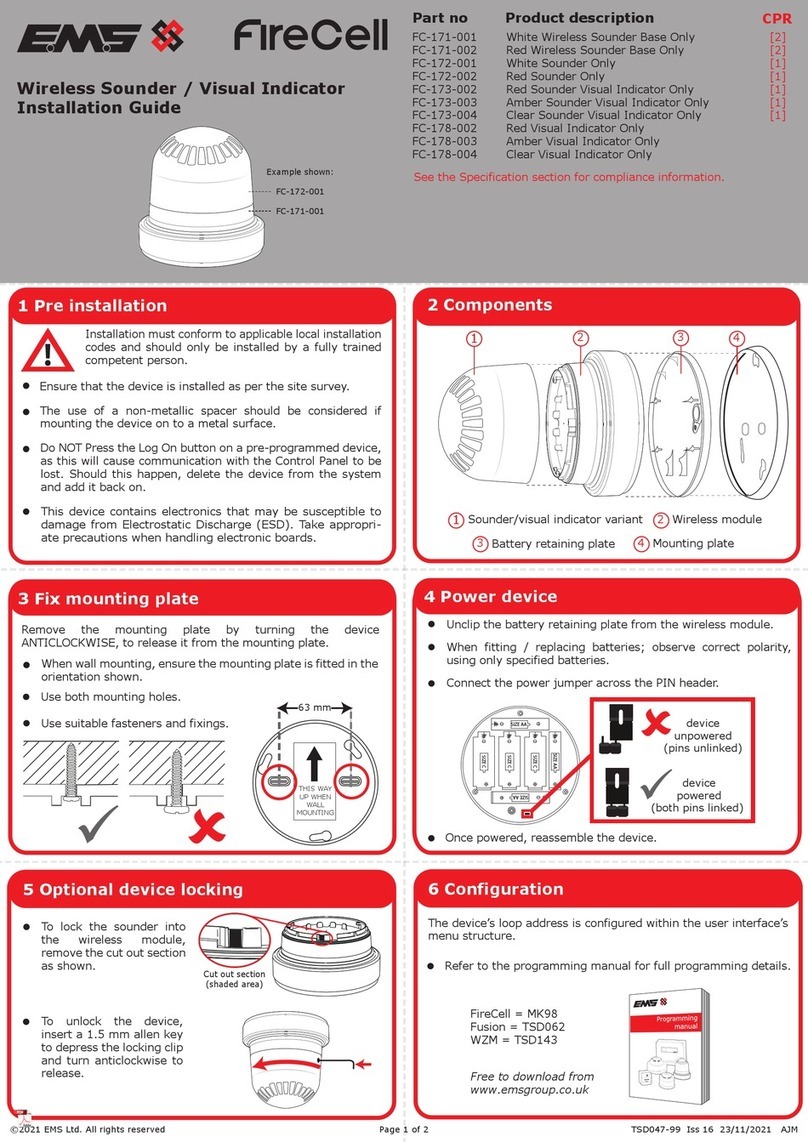

EMS

EMS FireCell FC-171-001 installation guide

Raymarine

Raymarine ST40 Quick reference guide

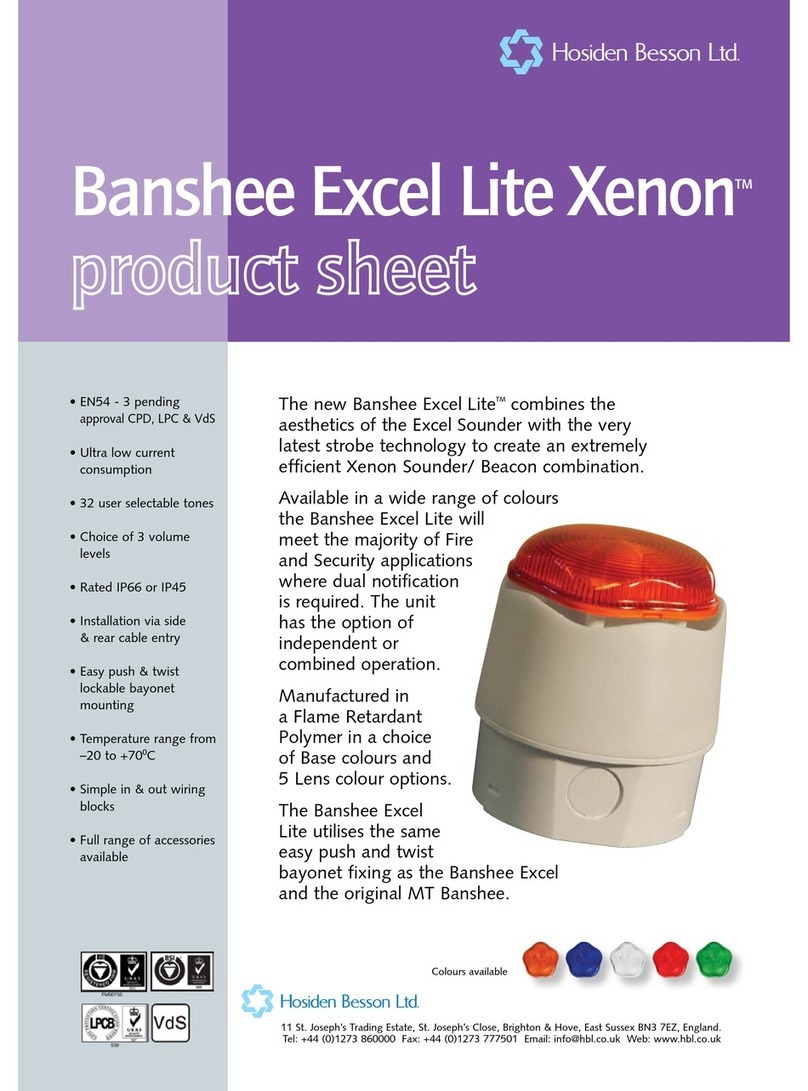

Hosiden Besson

Hosiden Besson Banshee Excel Lite Xenon Product sheet

Beijer Electronics

Beijer Electronics X2 marine 15 - B2 HB manual

Risco

Risco WL S52 Installation and programming instructions

Furuno

Furuno IF-7000 Operator's manual