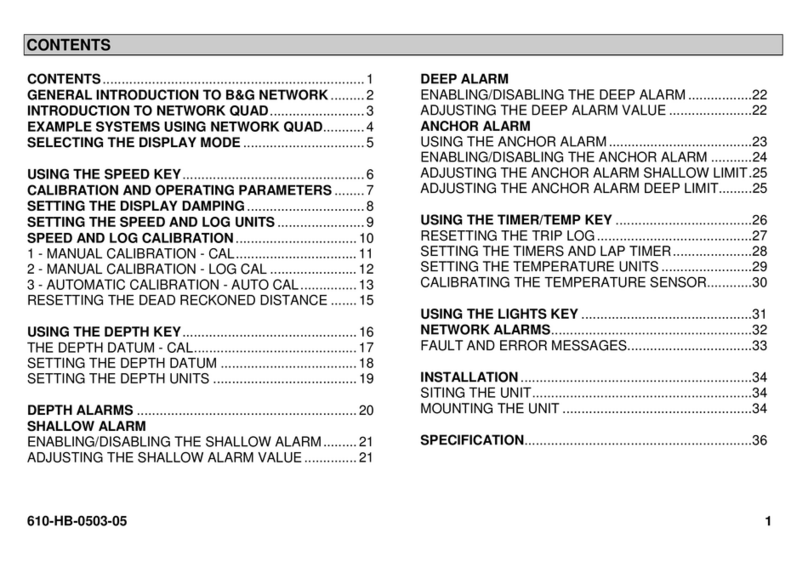

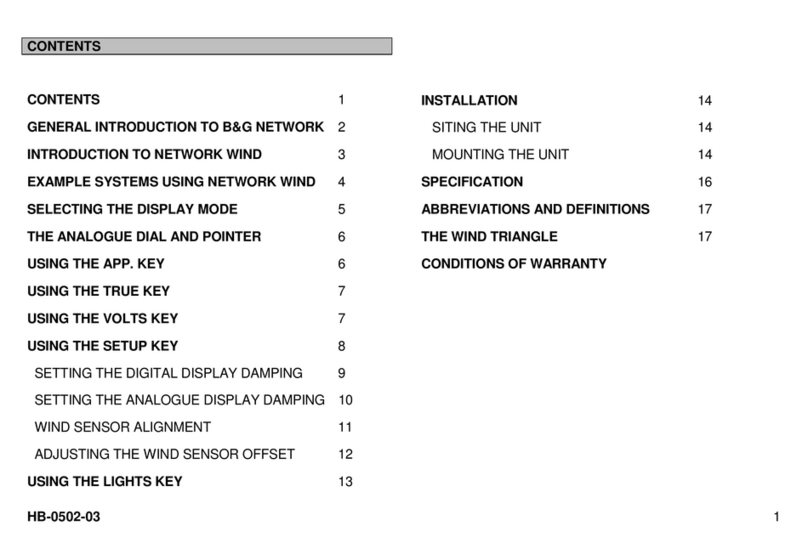

index

hydraulic drive pump installation examples 26

single station system example 26

dual station system example 26

dual station system with bypass example 27

dual station pressurisedsystem example 27

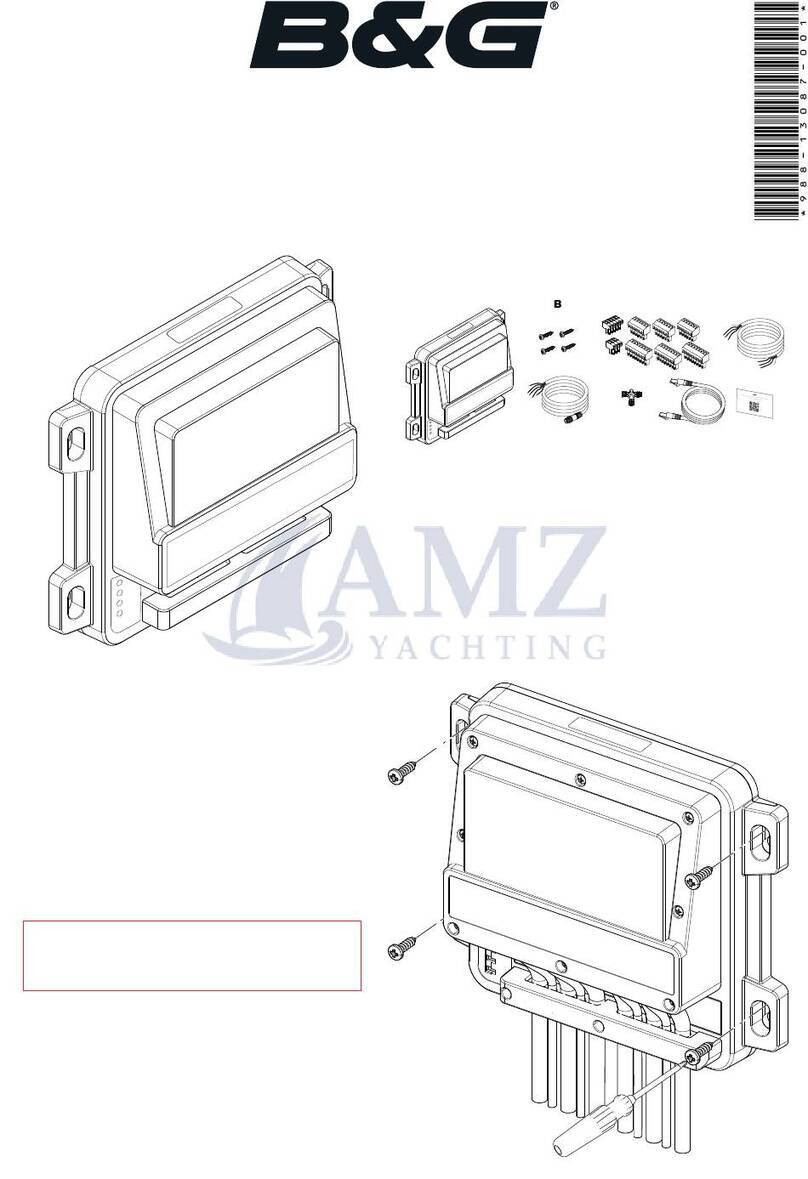

advanced control processor unit (acp) 28

description 28

siting the acp 28

mounting procedure 28

cable and connection information 29

emc compliance 29

general wiring notes 29

all rudder drives –heavy duty power cables 30

linear drives –clutch/valvecables 30

acp unit terminal details 30

wire colour coding and abbreviations 30

wiring connections 31

clutch voltage selection 31

acp dip switch location 32

h1000 and alarm connections 33

hand-held, mob and joystick 34

hydraulic ram drive connections 35

ram solenoid wiring details 36

hydraulic pump connections 37

continuous drive connections 38

direct paddle input connection 39

linear feedback connection 40

non-b&g paddle connection 41

gyro stabilized compass connection 42

furuno ad10 heading connection 43

optional accessories 44

hand-held controller 44

description 44

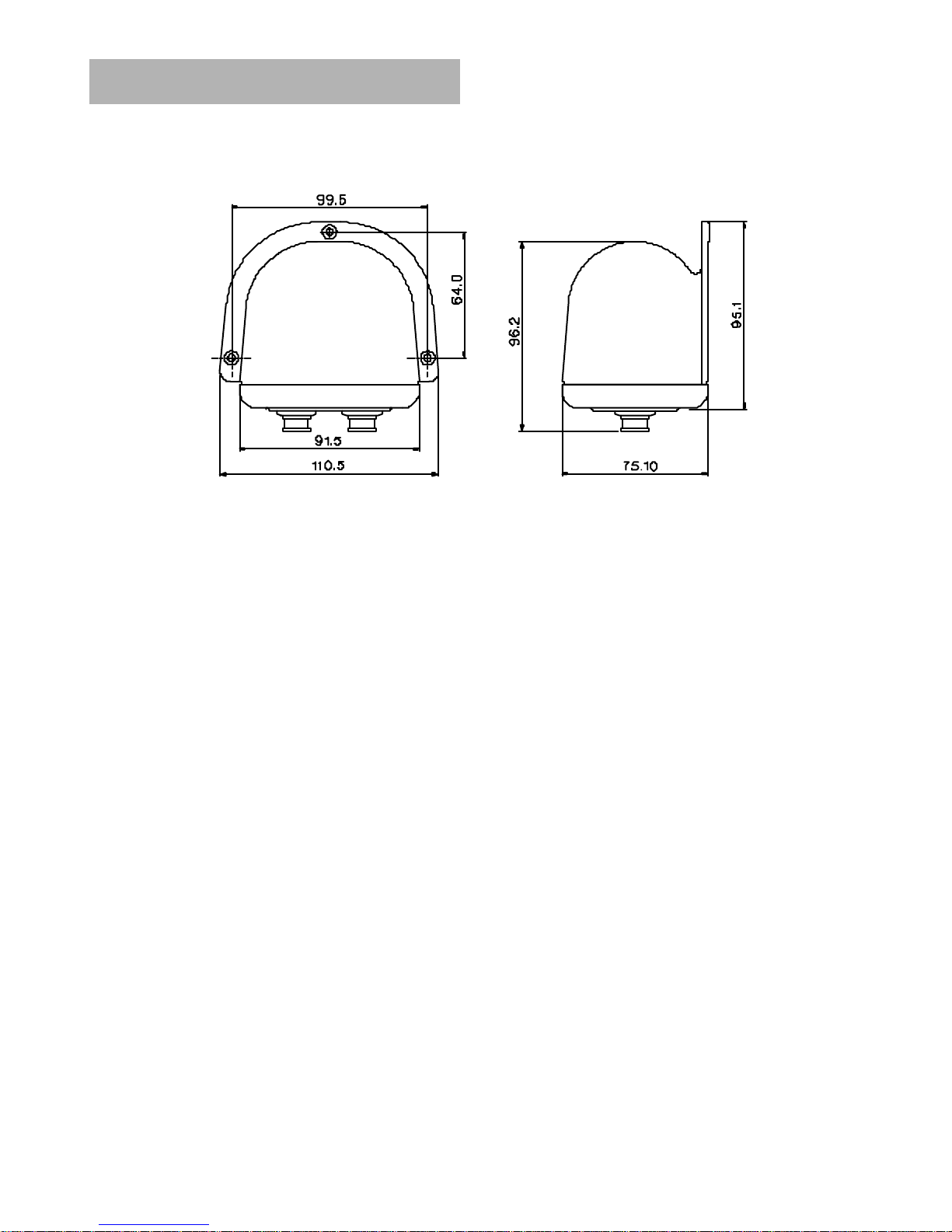

siting the hand-held unit 44

mounting procedure 44

man overboard button (mob) 45

description 45

siting the man overboard alarm button 45

mounting procedure 45

acp joystick 46

description 46

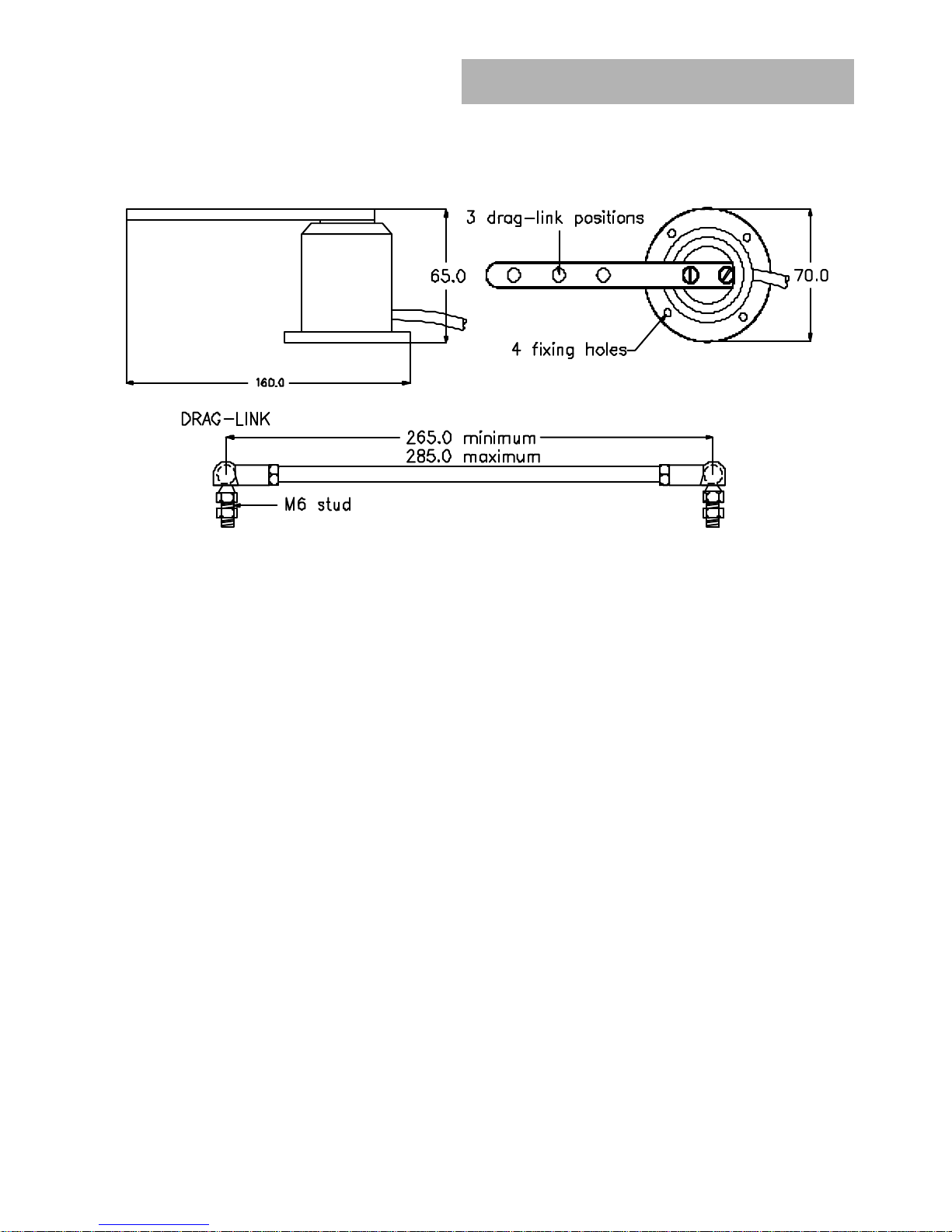

siting the joystick 46

mounting procedure 46