TriTeq MicroIQ UT User manual

FOR OFFICE FURNITURE, STORAGE CABINETS, LOCKERS, SAFES, VAULTS, SECURED ENCLOSURES

R

O

TriTeq Lock and Security

701 Gullo Ave

Elk Grove Village, IL 60007

Phone: (847) 640-7002

Toll Free:(888) 603-5625

Email: marketing@triteqlock.com

www.microiqlock.com

Haworth

© Copyright 2014 TriTeq Lock and Security. All rights reserved061515 - Rev. 5

1

1

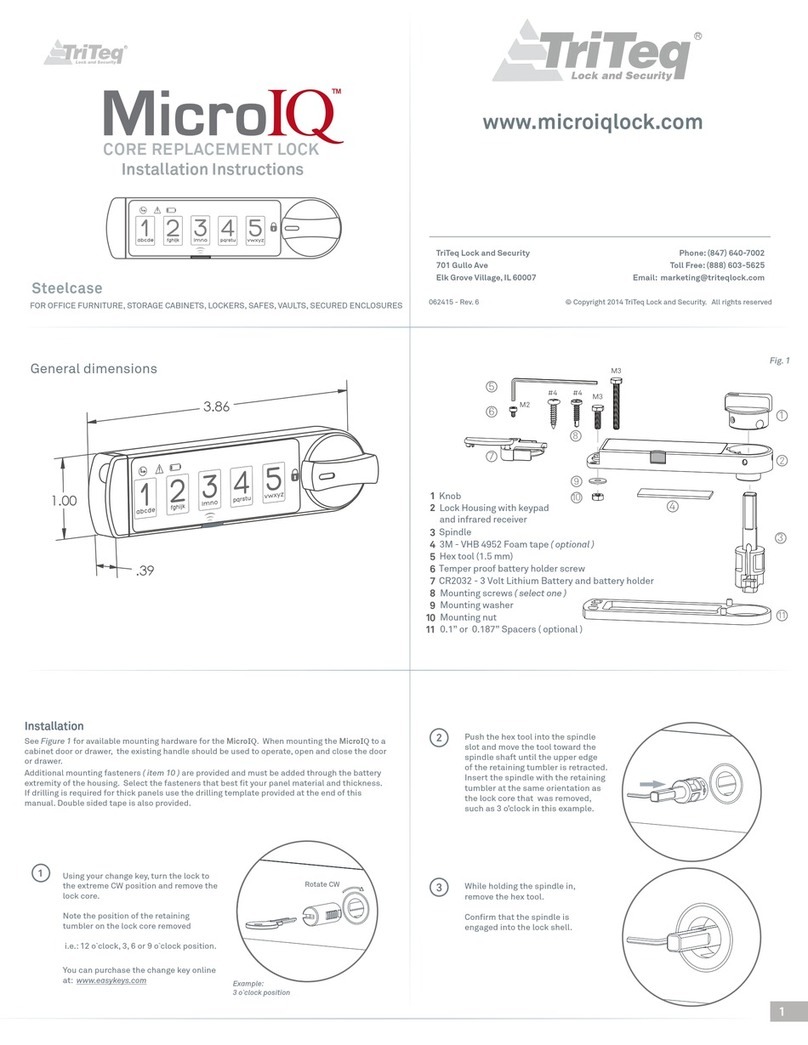

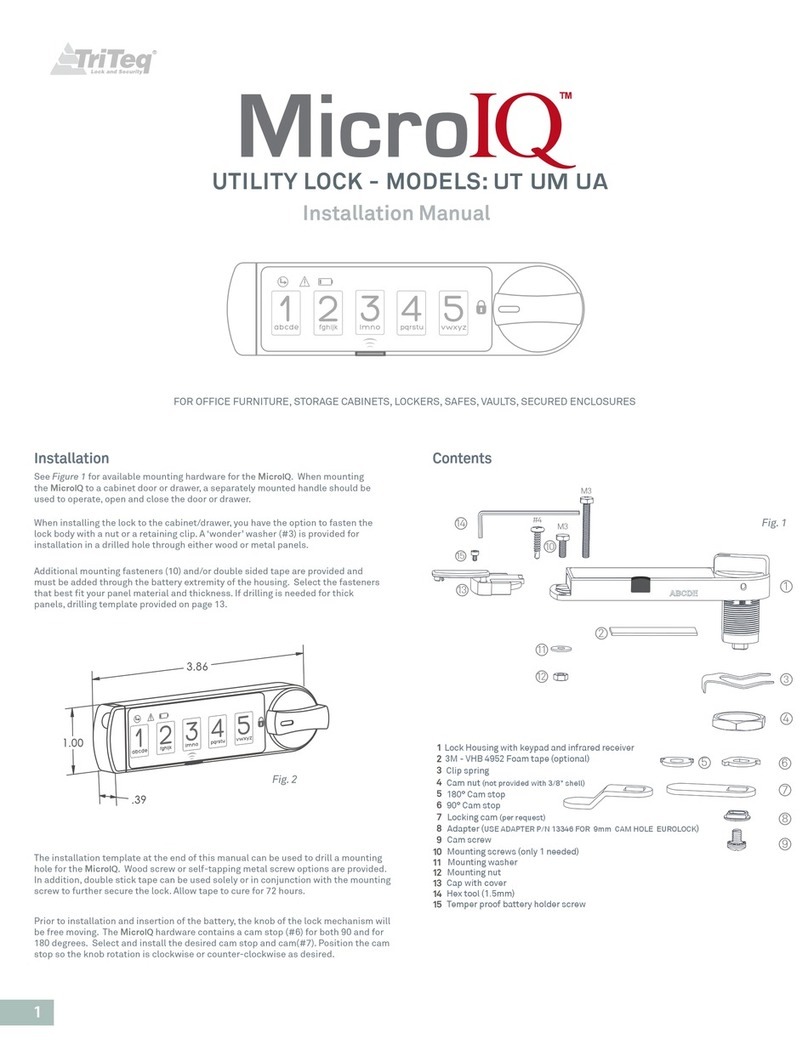

.39

1.00

3.86

General dimensions

Lock Housing with keypad

and infrared receiver

CR2032 - 3 Volt Lithium Battery and battery holder

1

2

3

4

5

6

7

8

9

10

11

12

13

Spindle spacer

Spindle

Knob

Mounting screws ( select one )

Mounting nut

Mounting washer

0.1” or 0.187” Lock spacers ( optional )

Cam stop

Hex tool (1.5 mm)

Temper proof battery holder screw

3M - VHB 4952 Foam tape (optional)

1

11

12

2

4

3

5

6

7

8

9

Fig. 1

10

13

M3

M3

M2

#4

#4

Installation Instructions

CORE REPLACEMENT LOCK

R

O

TM

MODELS:

UT CT ST

4

See Figure 1 for available mounting hardware for the MicroIQ. When mounting the MicroIQ to a

cabinet door or drawer, the existing handle or a separately mounted handle should be used to

operate, open and close the door or drawer.

Installation

Additional mounting fasteners (item 10) are provided and must be added through the battery

extremity of the housing. Select the fastener that best fits your panel material and thickness.

If drilling is required, use the drilling template provided at the end of this manual.

Double sided tape is also provided.

Using your change key, remove the

existing lock core.

Note the position of the retaining

tumbler on the lock core removed

i.e.: 12 o`clock, 3, 6 or 9 o`clock position.

Example:

12 o`clock position

1

Insert the spindle with the retaining tumbler

in the same orientation as the original lock

core retaining tumbler.

Push the spindle into the lock shell until fully

seated.

3

Insert the provided hex tool into the spindle

as shown.

Move the hex tool towards the arrow

indicated on the spindle until the retaining

tumbler is retracted.

2

3

You can purchase the change key online

at: www.easykeys.com

10

8

Remove the hex tool and confirm that the

spindle is captured into the shell by retaining

the tumbler.

The spindle is inserted properly when it can

not be removed from the housing.

4

Insert the knob. Exercise the knob and verify

that the spindle is engaged and operates

your locking mechanism as intended.

Remove the knob from the spindle with the

mechanism in the locked position.

5

Remove the knob and insert the provided

spindle spacer. Align the spline of the

spindle spacer with one valley from your

lock shell.

6

7The MicroIQ can be mounted to the cabinet with

the enclosed screw or double stick tape or both.

1/8” diameter hole

for metal

3/32” diameter

hole for wood

The installation template at the end of this

manual can be used to drill the mounting hole

for the MicroIQ. A wood screw and a

self-tapping metal screw are provided.

3/32” diameter

hole for wood

8

The spacers are available in chrome and black finish. To select your preffered

finish, add the letter “C” for chrome or “B” for black to the end of the part

number. (e.g.: 13081-00-C )

If the lock shell has a non-removable finish cup or a collar/bezel that would

restrict the MicroIQ from being inserted flush to the cabinet, use an

appropriate lock spacer in between the MicroIQ and the cabinet. Spacers of

0.1” ( P/N: 13081-00 ) and 0.187” ( P/N: 13081-10 ) are available from TriTeq.

Mount as shown on page 8.

Remove the backing from the foam tape (underneath the lock body) and insert

the MicroIQ in the desired orientation until it is flush with the face of your panel.

Allow tape to cure for 72 hours.

Select appropriate mounting screw. If a lock spacer is required, a mounting

screw must be used.

Spindle

Spacer

Lock

Spacer

Bezel

912

13

11

OPTIONAL:

If your locking mechanism does not have a

rotational stop, insert one of the provided

cam stops to match the desired rotation.

Insert the knob at LOCKED position and

rotatate to verify that the cam stop was

positioned correctly.

Confirm that your mechanism is locked

when the knob points to the lock icon

If your locking mechanism requires the knob to

rotate CW from “locked” to “unlocked”, rotate your

knob only 45°. Using the hex tool, fasten the knob to

the spindle from the indicated location.

If your locking mechanism requires the knob to rotate CCW from “locked”

to “unlocked”, rotate your knob only 45° and using the hex tool, fasten the

knob to the spindle from the indicated location.

6

1

5

9

7

11 12

After installing the lock to the mounting surface, the battery and holder can be inserted

into the lock. The cover for the battery holder also serves to lock the holder into the lock

housing. The battery cover must be in the fully open position before inserting the holder.

The battery holder screw cannot be protruding from the bottom of the battery holder. It

must be flush with the holder so the holder can be inserted.

Check that the battery is properly inserted into the holder. The “+” surface of the

battery should be Inserted into the holder against the surface of the holder marked

with the “+” symbol. Insert the battery holder into the lock with the holder cover in the

fully open position and with the battery holder screw flush to the bottom of the holder

until the holder is fully seated. Next, use the hex tool to fasten the battery holder

screw into the lock body. Last, swing the battery holder cover to the closed position,

push in and fully seat the cover into the battery holder until it is flush to the lock body.

If the battery is inserted while the knob is locked, you should hear the lock mechanism

click and the unit will lock. If the battery is inserted while the knob is unlocked, after

turning the knob to the locked position you should hear the lock mechanism click and

the unit will lock. If the unit will not lock after inserting the battery, enter the factory

code, move the knob to the unlocked position, and move the knob to the locked

position and you should hear the lock mechanism click and the unit will lock. If the

unit still does not lock, replace the battery.

Battery

1 2

3 4

Battery

Holder

Battery

Cover

LIFT

UPWARD

SWING OVER

AND SNAP THE

COVER DOWN

Hex

Tool

Battery

Cover

Screw

Liability Limits:

Operating Temperature: 0 - +50 C

Storage temperature: -10 - +70 C

Operating Moisture: 20% - 80% Rh (without condensation)

Replacement Battery: 3 volt lithium CR2032

Battery Life: 5 years or more ( calculated at 20 uses per day )

This is a limited warranty and in lieu of all other warranties (including the

implied warranties of merchantability and fitness of use) and under no

circumstances shall TriTeq Lock & Security or Hudson Lock, LLC be liable for

any incidental or consequential damages or losses.

To clean the MicroIQ surface, apply a non-acid based cleaner to a clean cotton

cloth. Do not spray cleaner directly on the MicroIQ. Wipe down the keypad and

housing surface of excess cleaner.

TriTeq Limited Warranty:

TriTeq offers a one year limited warranty on all products to be free from

manufacturing defects in materials and workmanship. This limited

warranty does not cover battery, lost combinations or damages caused by

improper mounting, operation or unreasonable use.

Cleaning and Care:

ATTENTION:

Battery life may vary with battery brand and environmental conditions.

Mounting Template

3.150

.75

1.00

Measure before drilling.

If the length of the segment is dierent from 1.00"

the template dimensions will be scaled accordingly

1/8” diameter hole for metal

3/32” diameter hole for wood

This manual suits for next models

2

Other TriTeq Lock manuals

Popular Lock manuals by other brands

Assa Abloy

Assa Abloy Lockwood Optimum manual

Stock Loks

Stock Loks C8714 instruction sheet

LEHMANN

LEHMANN Dial Lock 61 operating instructions

Gantner

Gantner GAT Lock 6010 F installation instructions

Assa Abloy

Assa Abloy Yale SIMPLICITY Mounting instructions

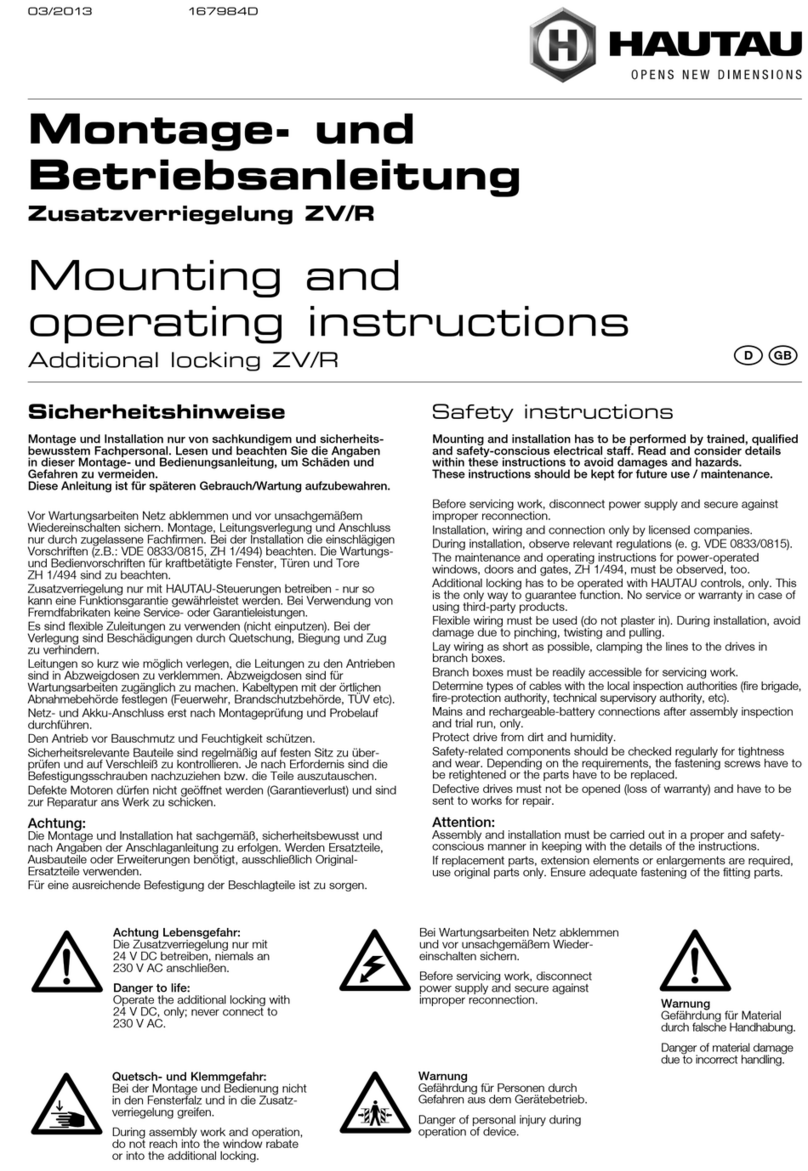

HAUTAU

HAUTAU ZV/R Mounting and operating instructions

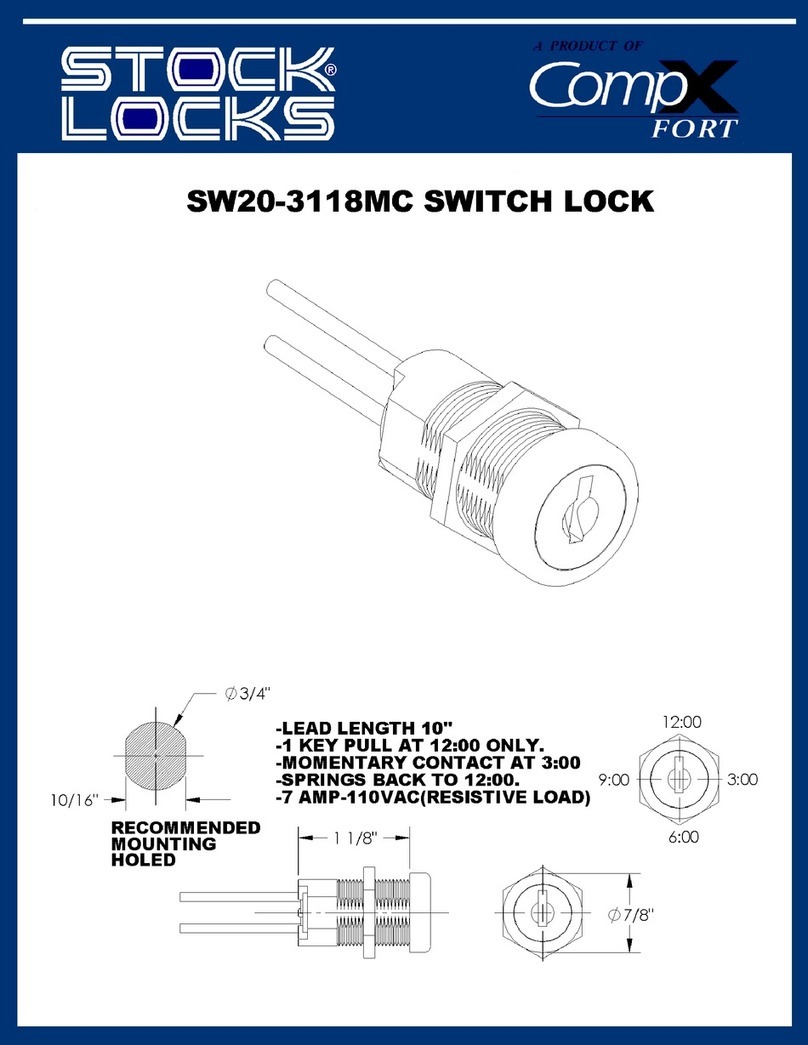

COMPX

COMPX SW20-3118MC Dimensional drawing

PROMIX

PROMIX SM101 operating manual

Kaba Mauer

Kaba Mauer 82021 Code-Combi K operating instructions

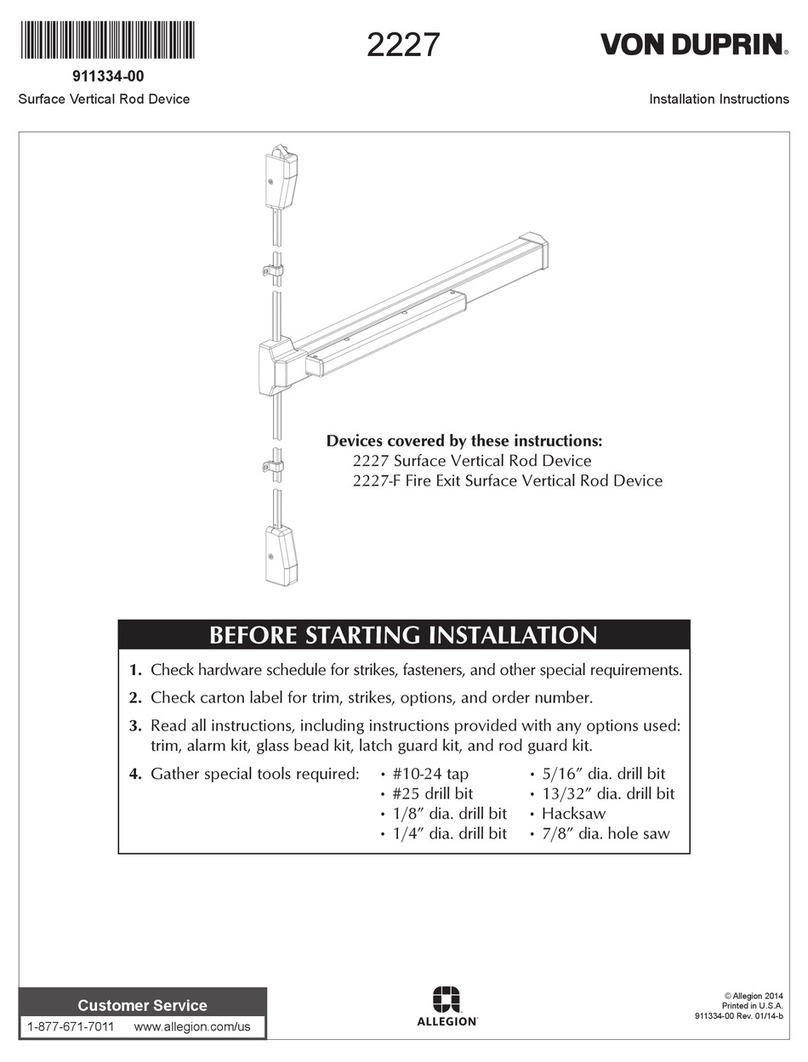

Von Duprin

Von Duprin 2227 Series installation instructions

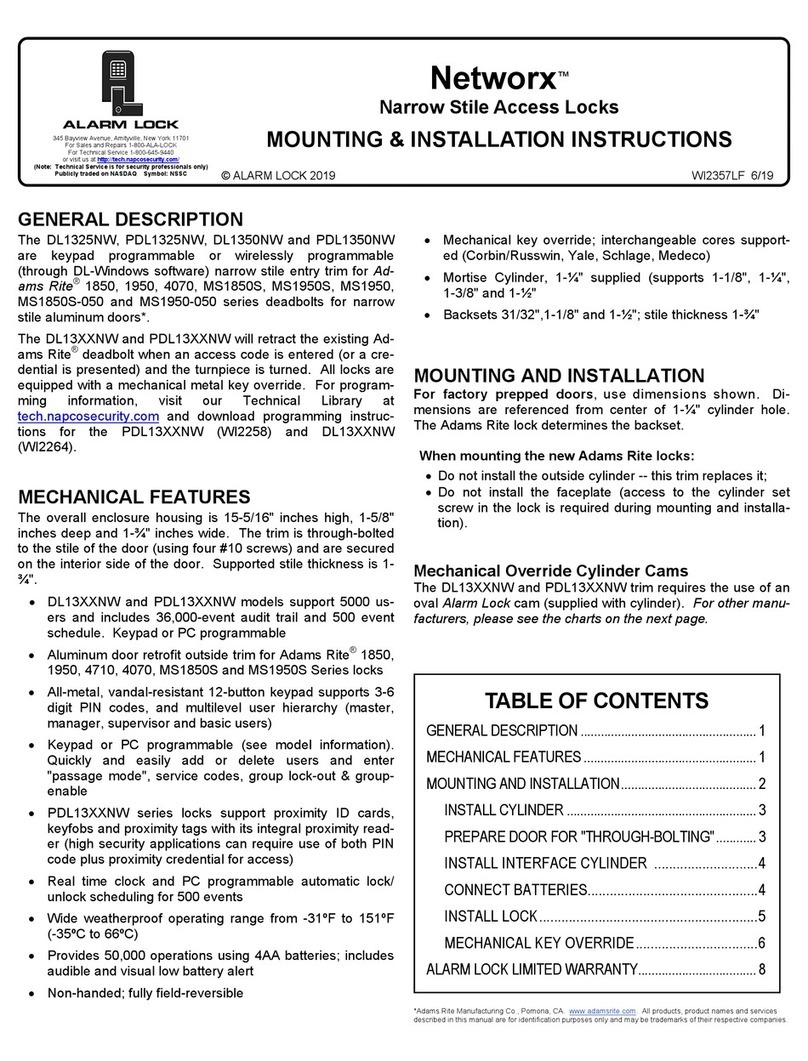

Alarm Lock

Alarm Lock Networx DL1325NW Mounting Installation Instructions

FingerTec

FingerTec Keylock 8800 user guide