TriTeq MicroIQ UM User manual

.39

1.00

3.86

Fig. 2

The installation template at the end of this manual can be used to drill a mounting

hole for the MicroIQ. Wood screw or self-tapping metal screw options are provided.

In addition, double stick tape can be used solely or in conjunction with the mounting

screw to further secure the lock. Allow tape to cure for 72 hours.

Prior to installation and insertion of the battery, the knob of the lock mechanism will

be free moving. The MicroIQ hardware contains a cam stop (#6) for both 90 and for

180 degrees. Select and install the desired cam stop and cam(#7). Position the cam

stop so the knob rotation is clockwise or counter-clockwise as desired.

1

Contents

1

R

O

TM

UTILITY LOCK - MODELS: UT UM UA

Installation Manual

FOR OFFICE FURNITURE, STORAGE CABINETS, LOCKERS, SAFES, VAULTS, SECURED ENCLOSURES

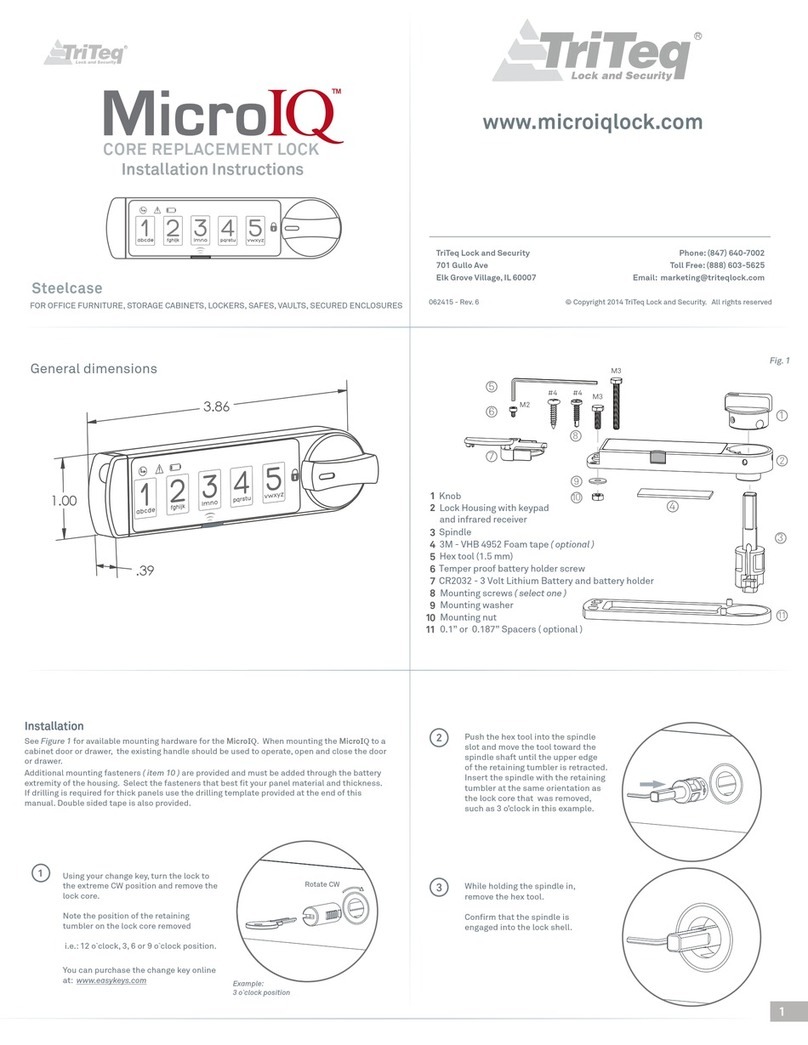

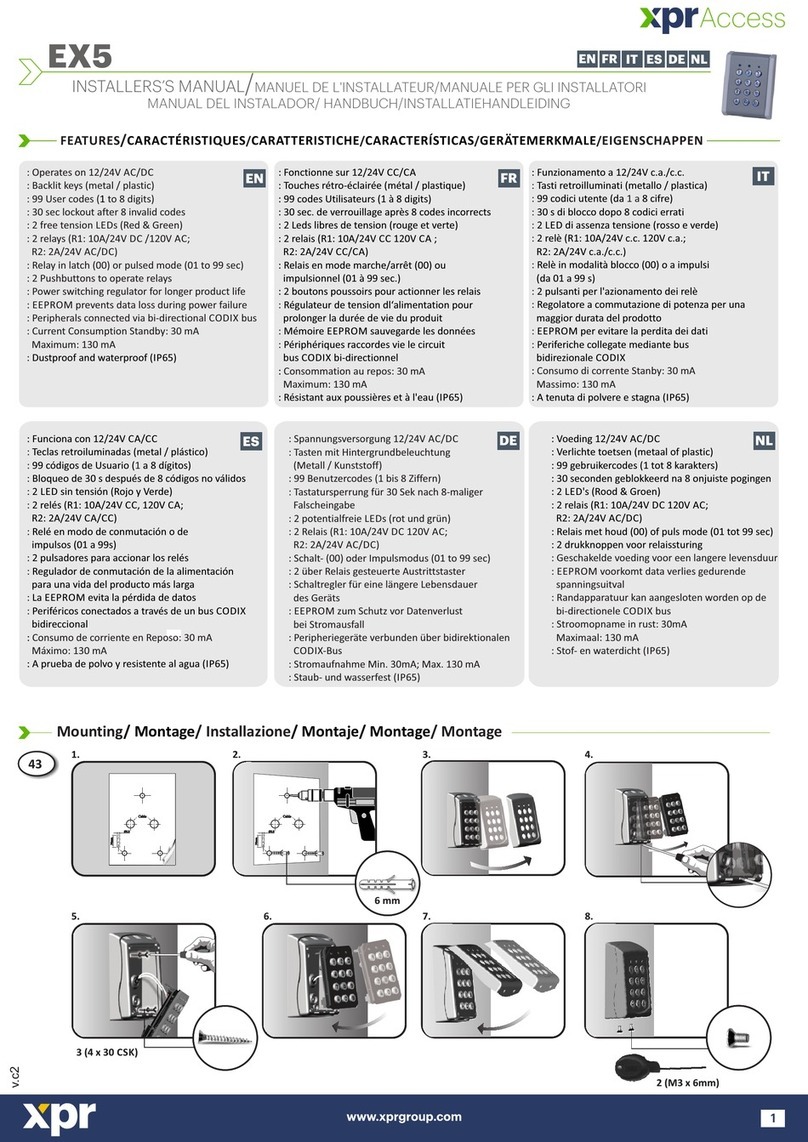

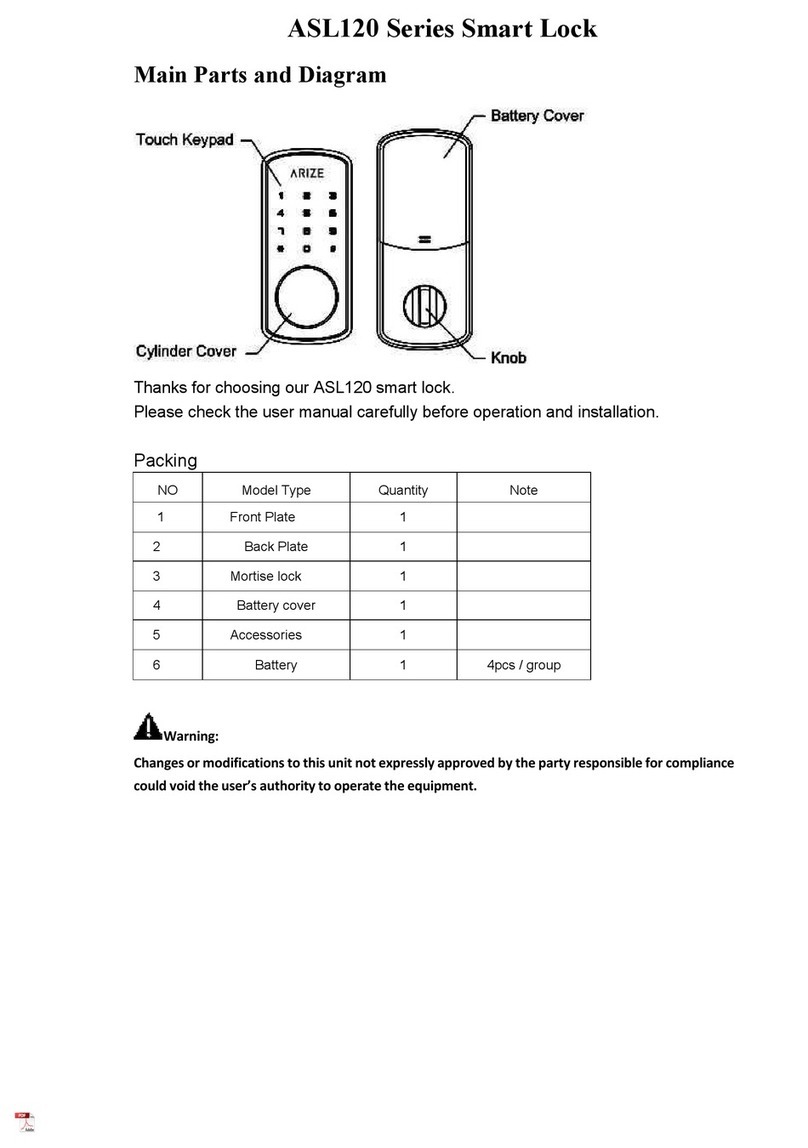

See Figure 1 for available mounting hardware for the MicroIQ. When mounting

the MicroIQ to a cabinet door or drawer, a separately mounted handle should be

used to operate, open and close the door or drawer.

Installation

When installing the lock to the cabinet/drawer, you have the option to fasten the

lock body with a nut or a retaining clip. A ‘wonder’ washer (#3) is provided for

installation in a drilled hole through either wood or metal panels.

Additional mounting fasteners (10) and/or double sided tape are provided and

must be added through the battery extremity of the housing. Select the fasteners

that best fit your panel material and thickness. If drilling is needed for thick

panels, drilling template provided on page 13.

14

1

13

11

2

Fig. 1

10

15

#4

M3

M3

Lock Housing with keypad and infrared receiver

Cap with cover

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Locking cam (per request)

Clip spring

Cam nut (not provided with 3/8” shell)

Cam screw

Mounting screws (only 1 needed)

Mounting nut

Mounting washer

180° Cam stop

90° Cam stop

Adapter (USE ADAPTER P/N 13346 FOR 9mm CAM HOLE EUROLOCK)

Hex tool (1.5mm)

Temper proof battery holder screw

3M - VHB 4952 Foam tape (optional)

12

4

3

5

6

7

8

9

Operation

1-2-3-4-5 keypad buttons: For entering and programming lock codes.

Program button: Initiate the lock programming mode by pressing the front thin edge of the black button inward toward the mounting surface the MicroIQ is mounted to.

Infrared Receiver:

The Infrared Receiver will receive a signal from an electronic TriTeq key-fob when

it is pointed at the receiver located behind the Program button. The Program

button is slightly opaque so the key-fob signal will penetrate the button.

Knob:

To move the lock mechanism 90 or 180 degrees clockwise or counterclockwise from

the locked and unlocked states.

The Green and Red LED’s will flash and illuminate to indicate operating conditions

per the descriptions below.

The Yellow LED will flash 5 times after the lock is operated to signify the

battery level is low and should be replaced.

Green

Proceed

LED

Red

Error

LED

Yellow

Low battery

LED

Knob

in locked

position

Location to

point the

key-fob

Battery

holder

with cover

Keypad

Fig. 5

Program

button

Push thin

front edge

inward

Press

Here

R

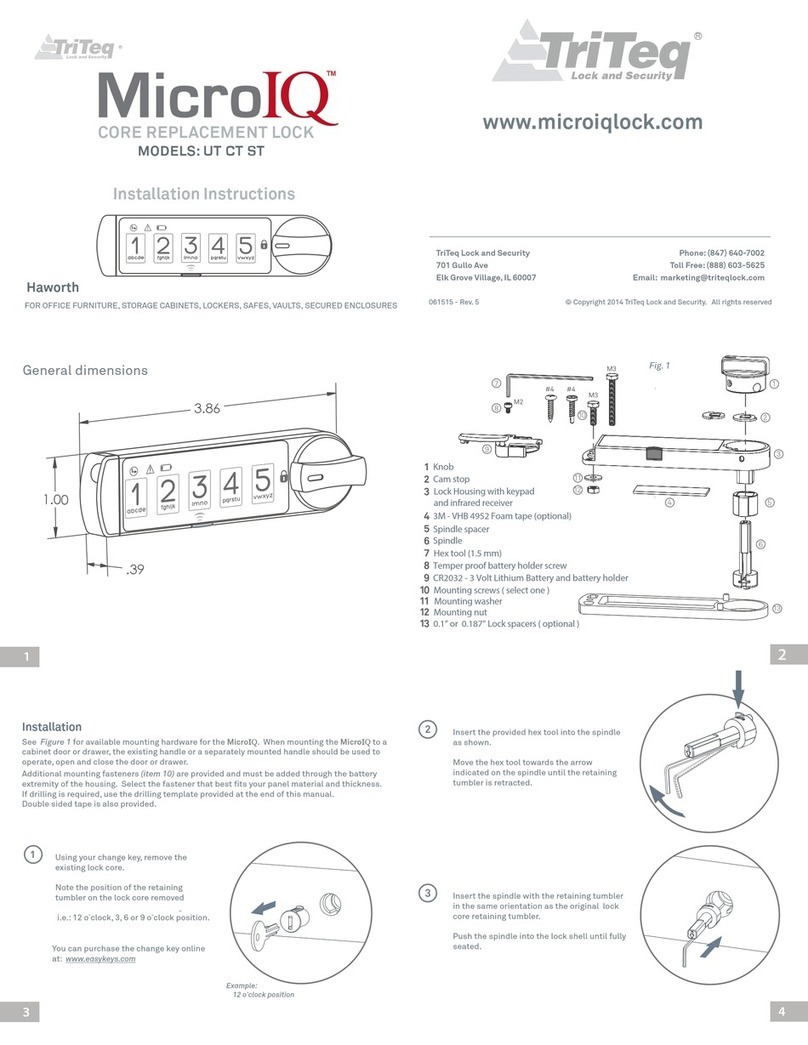

The mounting screw for the Lock Housing must be installed before

installing the MicroIQ battery.

1

2

Battery

If mounted on sheet metal :

If mounted to wood panel with

threaded insert:

Select appropriate mounting screw. If a lock

spacer is required, a mounting screw must be

#4 Sx.375 sheet-metal screw

M3 x25mm (1”) screw

In addition, the double stick tape can

be used solely or in conjunction with

the mounting screw to further secure

the lock. Allow tape to cure for 72 hours.

Fig. 3

2 3

56

Battery

Holder

Battery

Cover

LIFT

UPWARD

1

4

Battery

Holder

Battery

Strip

(optional)

Battery

Strip

(optional)

SWING OVER

AND SNAP THE

COVER DOWN

PULL SRTIP

BEFORE USING

Hex

Tool

Screw

Battery

Strip

(optional)

Battery

Strip

(optional)

NOTE: If the assembled lock is going to be transported or

shipped, it is required that the battery assembly includes the

battery strip. If the lock is being set up for use, the battery

strip is not needed (skip step 1 and 6).

Rotate the knob to the unlocked position

Insert the battery strip into the housing.

Insert the battery holder assembly (battery, holder, and

cover) into the lock housing making sure the cover is

open. If the assembly is not fully seated, make sure the

battery holder screw is flush with the bottom of the

assembly and that it is not interfering with the fit.

Insert the provided M2 screw in the battery holder.

Use the hex tool to attach the battery assembly to the

lock housing.

Swing the battery cover closed and snap in place.

If transporting/shipping the lock assembly, the battery

strip must be removed prior to use. Remove by pulling

the strip out of the housing.

1

2

3

4

5

6

7

Liability Limits:

Operating Temperature: 0 - +50 C

Storage temperature: -10 - +70 C

Operating Moisture: 20% - 80% Rh

(without condensation)

Replacement Battery: 3 volt lithium CR2032

This is a limited warranty and in lieu of all other warranties (including the implied warranties

of merchantability and fitness of use) and under no circumstances shall TriTeq Lock & Security

or Hudson Lock, LLC be liable for any incidental or consequential damages or losses.

To clean the MicroIQ surface, apply a non-acid based cleaner to a clean cotton cloth. Do not spray

cleaner directly on the MicroIQ. Wipe down the keypad and housing surface of excess cleaner.

TriTeq Limited Warranty:

TriTeq offers a one year limited warranty all products to be free from manufacturing defects

in materials and workmanship. This limited warranty does not cover battery, lost combinations

or damages caused by improper mounting, improper or unreasonable use.

Care and Cleaning:

TriTeq Lock and Security

701 Gullo Ave

Elk Grove Village, IL

60007

Phone: (847) 640-7002

Toll Free: (888) 603-5625

Email: marketing@triteqlock.com

Battery Life: 3 to 5 years typical or 50,000 operations

ATTENTION: Battery life may vary with battery brand

and environmental conditions.

© Copyright 2014 TriTeq Lock and Security. All rights reserved

13018 - Rev. 3 S-L

Mounting Template

3.150

.75

1.00 Measure before drilling.

If the length of the segment is dierent from 1.00"

the template dimensions will be scaled accordingly

As an option, the lock can be operated with the one blue remote key-fob and up to two black remote User key-fobs.

For further instructions about programming and operating the MicroIQ, please refer to the“MicroIQ Programming” manual or

watch the videos on our website, www.MicroIQLock.com

1

3

When entering the Factory code, the Supervisor code or User code,

you should hear a ‘click’ sound, the green LED will light up turn the

knob to unlocked position.

To unlock MicroIQ using a code:

Turn the knob from the unlocked position to the locked position,

listen for the lock mechanism to operate by hearing a “click”

sound, confirm the knob is locked.

To re-lock MicroIQ:

1/8” diameter hole for metal

3/32” diameter hole for wood

Other manuals for MicroIQ UM

1

This manual suits for next models

2

Other TriTeq Lock manuals