Tritex Multigauge 5700 User manual

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page

simple . accurate . robust

www.tritexndt.com

Ultrasonic Thickness Gauge

Multigauge 5700

Datalogger

User Manual

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 1

Contents

1. Introduction 3

1.1. Multigauge 5700 Specification Table 3

2. Kit Contents 4

3. Getting Started 5

3.1. Quick Start Guide 5

3.2. Assembly 5

3.3. Batteries 6

3.4 Low Battery Warning 6

4. Probes 7

4.1. Introduction 7

4.2. Intelligent Probe Recognition (IPR) 7

4.3. Probe Selection Table 7

4.4. Probe Membranes 8

4.5. Changing the Membrane 9

4.6. Care of Probes 9

5. Getting to know your Multigauge 5700 10

5.1. Switching the Gauge On 11

5.2. Switching the Gauge Off 11

5.3. Automatic Shutoff 11

5.4. Automatic Display Dimming 11

5.5. Measurement Hold Feature 11

6. Navigating the Menus 12

6.1. Entering the Menus 12

6.2. Definition of Menu Items 13

6.3. iProbe 14

6.4. Setting the Calibration 16

6.5. Velocity Table ( approximate values) 17

6.6. Measuring 18

6.7. Setting the Units 18

6.8. Battery 18

6.9. Setting the Resolution 19

6.10. Coating Plus+ 19

6.11. About 5700 - Factory Reset 20

6.12. Setting the Time / Date 21

6.13. Enabling and disabling the Datalink 21

Tritex Sales 47 - Issue 1 - April 2014

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 2

7. Datalogging 22

7.1. Using the File Wizard 22

7.1.a Create a New File / New Template from Wizard 23

7.1.b Create a New File from Template 27

7.2. Selecting a Logfile 28

7.3. Logging 29

7.4. File Manager 30

8. Communicator Software 31

8.1. System Requirements & Installation 31

8.2. Quick Start Guide 32

8.3. Initial Setup and Use 34

8.3.1. Introduction 34

8.3.2. Measurement Tab 34

8.3.3. Datalogging Tab 36

8.3.4 Download Tab 42

8.3.5. Properties Tab 48

8.3.6. Diagnostics Tab 49

9. Using the Multigauge 5700 50

9.1. How Multiple Echo Works 50

9.2. Echo Strength Indicator 51

9.3. Precautions when Measuring 51

10. Help 53

10.1. Gauge fails to switch on 53

10.2. Difficult to obtain readings 53

10.3. Gauge displays up to three ascending bars 53

10.4. Standing readings are displayed when not measuring 53

10.5. Gauge measures correctly on steel test block

but not on material under test 54

10.6. Communication lost between gauge and PC / Laptop 54

11. General Information 55

10.1. Safety 55

11.2. RoHS 55

11.3. WEEE Disposal Instructions 55

11.4. RF Transceiver 56

11.5. Cleaning 56

11.6. Warranty 56

11.7. Service & Repair 57

12. Contact Information 58

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 3

Thank you for purchasing a Tritex Multigauge 5700 Datalogger. We are sure

that the gauge will give you many years of reliable use. To ensure that you can

gain maximum benefit from the gauge, please read this manual carefully.

The Multigauge 5700 Datalogger is a simple, robust ultrasonic thickness

gauge designed for most common thickness gauging applications. The easy to

use keypad allows operator interface, whilst the bright colour LCD display can

be used in all light conditions. The moulded soft rubber surround feels

comfortable, looks good and provides extra protection against knocks and

scrapes.

1.1. Multigauge 5700 Datalogger Specification Table

Sound Velocity Range From 1000 m/s to 8000 m/s (0.0394 in/µs to 0.3150 in/µs)

Single Crystal

Soft Faced Probe Options

Probe Measurement Range

Probe Sizes

Resolution 0.1 mm (0.005”) or 0.05 mm (0.002”)

Accuracy ± 0.1 mm (0.005”) or ± 0.05 mm (0.002”)

Display Multi character Colour LCD

Storage Capacity Up to 895 files, each file containing up to 100 records. Each

record contains up to 250 measurements.

Data Transmission RF Transceiver, 2.4GHz

Batteries 3 x disposable AA alkaline batteries or rechargeable NiMH /

NiCD

Battery Life 20 Hours continuous use using alkaline batteries

Gauge Dimensions 147 mm x 90 mm x 28 mm (5.75” X 3.5” X 1”)

Gauge Weight 325 g (11.5 ounces) including batteries

Environmental Case rated to IP65. RoHS and WEEE compliant

Operating Temperature -10°C to +50°C (14°F to 122°F)

Storage Temperature -10°C to +60°C (14°F to 140°F)

2.25 MHz 3.5 MHz 5 MHz

3 - 250 mm

(0.120” to 10”)

2 - 150 mm

(0.080” to 6”)

1 - 50 mm

(0.040” to 2”)

13 mm (0.5”) &

19 mm (0.75”) 13 mm (0.5”) 6 mm (0.25”) &

13 mm (0.5”)

1. Introduction

The Tritex Multigauge 5600 has been manufactured to comply with

British Standard BS EN 15317:2007, which covers the characterisation

and verification of ultrasonic thickness measuring equipment.

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 4

Key:

1 - Test Block - The 15 mm test block is used to test the performance

and serviceability of the gauge.

Membrane Key - Used to remove the membrane retaining ring. See

page 9 for further details.

Batteries - 3 X AA disposable batteries.

Membranes - See page 9 for fitting instructions. Pack of 10

supplied.

2 - Ultrasonic Gel - 150 ml.

3 - Gauge Body - See page 10 for further details.

4 - Membrane Oil - 15 ml.

5 - Probe Cable - 1.5m long. Longer or shorter cables can be ordered.

6 - Manual, calibration certificate and 3 year warranty certificate.

7 - Neck Strap - Used with optional leather case.

8 - Probe - See page 7 for further details.

9 - RF Transceiver - Link between gauge and PC / Laptop

2. Kit Contents

1

2

3

4

6

7

8

5

9

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 5

3. Getting Started

3.1. Quick Start Guide

Following is a quick start guide to help you get a feel for the gauge without

reading the entire manual. For a more detailed explanation of each of these

steps please read the full manual.

1 Unscrew the probe knurled ring and apply a few drops of

membrane oil to the face of the probe. (Pg 9)

2 Screw the knurled ring back onto the probe ensuring no air has

been trapped and the membrane is flat to the probe face. (Pg 9)

3 Connect the probe, cable and gauge together. (Pg 5)

4 Turn the gauge on using the ‘ON/OFF’ switch. (Pg 11)

5 If the ‘Home’ screen is displayed, navigate using the arrows to the

‘Measuring’ screen option and press the key. (Pg 18)

6 Apply a small amount of ultrasonic gel to the surface being

measured.

7 Place the probe onto the ultrasonic gel / test piece.

8 A measurement will be displayed.

3.2. Assembly

To assemble the gauge for use:

i. Attach the probe to the probe cable by pushing the cable Lemo

plug into the socket on the probe.

ii. Connect the other end to the gauge Lemo socket.

Note: To remove the connectors, simply pull back on the connector collars to

release the plug from the socket. Do not force or twist under any

circumstances.

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 6

Datalink

RF

Enabled

Measuring

mm

Battery

4.4V

Select File

Logfiles

4

Time/Date

09:15:10

11.05.14

000001

Logfile

Logging

3.3. Batteries

The Multigauge 5700 uses 1.5Vdc ‘AA’ alkaline disposable batteries supplied

with the kit. NiMH and NiCD rechargeable batteries can also be used. Insert

the batteries into the battery compartment as shown below, ensuring the

batteries are inserted the correct way round:

WARNING: If the gauge is to be left unused for an extended period of time

then the batteries must be removed prior to storage.

Warning:Do not mix rechargeable and disposable batteries in the gauge.

3.4. Low Battery Warning

When the batteries become low, the battery symbol in the right of the display

in measurement mode and in the top right on the ‘Home’ screen will indicate a

decrease in battery power. It will change from green to orange as an advanced

warning, and to red when the battery level is critical.

When the batteries become very low it is advisable to replace them. Otherwise

after a short time the gauge will turn off automatically.

Positive

Terminals (+)

+ ++

Battery Indicator

Measuring mm

5915 m/s

2.25 MHz 13mm

AUTO

HOLD

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 7

4. Probes

4.1. Introduction

All probes used with Tritex Multigauges are single crystal soft faced probes.

The table below identifies the different probe options and which probe is the

most suitable for different applications. All probes are colour coded to help

identify their frequency.

The single crystal means that measurements are taken using a straight path of

ultrasound, giving perfect linearity throughout the measuring range. The

probes are not affected by V-beam error.

4.2. Intelligent Probe Recognition (IPR)

All probes have IPR (Intelligent Probe Recognition). IPR transmits data from

the probe to the gauge so that it is instantly recognised. This includes data

such as the probe serial number, frequency, size and the unique signature of

the probe. The gauge uses this information to automatically adjust settings to

achieve the best performance. When a probe is connected, the display will

show ‘IPR Probe connected: 2¼ MHz 13mm’.

If a probe is connected that does not have IPR, the gauge will prompt the user

to select the correct setting from a list of probe options.

See ‘iProbe’ on page 14 for further details.

4.3. Probe Selection Table

Frequency 2.25 MHz 3.5 MHz 5 MHz

Measuring Range 3 - 250 mm

(0.120” to 10”)

2 - 150 mm

(0.080” to 6”)

1 - 50 mm

(0.040” to 2”)

Colour Yellow Green Blue

Diameters Available 13 mm (0.5”) &

19 mm (0.75”) 13 mm (0.5”) 6 mm (0.25”) &

13 mm (0.5”)

Suitable for Most thickness

gauging applications.

Works particularly well

on heavy corrosion,

especially the 19 mm

probe.

Will measure relatively

thin metal which is

corroded. Normally

used only if measuring

down to 2 mm is of

importance.

Ideal for measuring

thin metal in relatively

good condition. Not

advisable to use as

the main probe.

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 8

4.4. Probe Membranes

All probes are fitted with protective membranes to help prolong the life of the

probe. The membranes also provide a flexible interface which acts as an aid

when working on rough surfaces. Membrane wear should be monitored and

checked at regular intervals.

Normal Temperature Membranes

Standard membranes allow measurements to be taken on hot surfaces up to a

maximum of 70°C (158°F).

High Temperature Membranes

Teflon™ membranes are available for measurements on hotter surfaces. In

this case measurements can be taken on surfaces up to 150°C (302°F). Care

should be taken that the probe does not overheat. The probe should be

allowed to cool down in between each measurement. A high temperature

ultrasonic gel is advised for this application.

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 9

Knurled Ring (1)

Membrane (2)

Retaining Ring (3)

Probe (4)

Lemo

Connector

Membrane

Key (5)

Membrane

Oil (6)

Membrane

Oil

www.tritexndt.com

4.5. Changing the Membrane

i Unscrew the knurled ring (1) from the probe (4).

ii Using the membrane key (5), remove the retaining ring (3) from

inside the knurled ring (1).

iii Push the old membrane (2) out from the front.

iv Fit a new membrane (2) from the back and push it down until it

locates in the groove on the inside front edge.

v Refit the retaining ring (3) and secure it in place using the

membrane key (5).

vi Place a few drops of membrane oil (6) onto the face of the probe

(4). Do not use too much.

vii Screw the knurled ring (1) back onto the probe (4) whilst applying

pressure on the membrane (2) with the thumb to expel any air

from behind the membrane.

Note: Do not apply too much membrane oil underneath the membrane. Once

fitted, the membrane should be flat with no air bubbles trapped behind.

Warning: Never use a probe without a membrane fitted.

4.6. Care of Probes

All probes should be treated with respect. When taking measurements, they

should not be scraped or dragged along the surface. Although the membranes

will protect the probe against everyday wear and tear, they will not protect

against rough treatment and misuse.

Warning: Never try to repair a probe or try to remove scratches from the face

of the probe. This may result in further damage. Always return it to Tritex NDT

for investigation and possible repair.

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 10

datalogger

5700

Probe Cable

Connector

Back

Battery

Compartment

5. Getting to know your Multigauge 5700

Front

Up Selection (5)

ON/OFF Button (3)

Down Selection (9)

OK / Enter (4)

Menu (8)

Colour LCD Display

Top

Right Selection (7)Left Selection (2)

Option Key 2 (6)Option Key 1 (1)

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 11

5.1. Switching the Gauge On

i To switch the gauge on, press the ‘ON/OFF’ switch (3).

ii After booting up, the gauge will display the ‘Home’ screen if a

probe is connected as follows:

Note 1:If no probe is connected when the gauge is turned on the display will

show ‘No Probe connected’. See page 15 for further details.

Note 2: If a probe other than a Tritex probe is attached before switching on

then the gauge will display a list of probe options once ‘OK’ has been selected

See page 14 for further details.

5.2. Switching the Gauge Off

To switch the gauge off, press and release the ‘ON/OFF’ switch (3)

5.3. Automatic Shutoff

The gauge will automatically shut off after 8 minutes of inactivity to save

battery power.

5.4. Automatic Display Dimming

The display will dim automatically after 30 seconds to preserve the battery

power. Pressing any key or the commencement of measurements will return

the display to its normal brightness.

5.5. Measurement Hold Feature

To hold a measurement, press the ‘Option Key 1’ (1) button whilst a

measurement is displayed. The display will hold the measurement and flash

‘Holding’ in the top right corner.

To resume measuring, press the ‘Option Key 1’ (1) button which is labelled

‘Resume’

Datalink

RF

Enabled

Measuring

mm

Battery

4.4V

Select File

Logfiles

4

Time/Date

09:15:10

11.05.14

000001

Logfile

Logging

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 12

6. Navigating the Menus

6.1. Entering the Menus

i Press and release the ‘Menu’ button (8).

ii The ‘Home’ screen will be displayed.

iii To navigate the menus use the ‘Arrow’ buttons (2,5,7 & 9).

iv To select a menu item, press ‘OK’ (4).

v To see additional menu items, navigate left and right from the

‘Home’ screen using the left (2) and right (7) arrow key.

vi The following shows the complete menu:

Datalink

RF

Enabled

Measuring

mm

Battery

4.4V

Select File

Logfiles

4

Time/Date

09:15:10

11.05.14

000001

Logfile

Logging

Datalink

RF

Enabled

5700

Gauge

About

Measuring

mm

Battery

4.4V

Units

V3.51b

mm

Resolution

mm

0.1

iPROBE

2¼ MHz

13mm

5915

m/s

Calibration Select File

Logfiles

4

Time/Date

09:15:10

11.05.14

000001

Logfile

Logging

File

Manager

File

Wizard

Coating

CP+

Plus

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 13

6.2. Definition of Menu Items

To enter the menu at any time, press the ‘Menu’ (8) key.

Coating Plus+ - Allows measurements to be taken through extremely thick

coatings up to 20mm, depending on the type of coating. In

normal mode the gauge can still ignore up to 6mm of coating.

Calibration - All materials have varying velocity of sound properties and this

section allows the gauge to be calibrated for the different

materials that the gauge can measure.

File Manager - Allows editing of stored logfiles and templates.

File Wizard - Allows the creation of new logfiles and logfiles from

templates. Also the creation of new templates.

Logging - Shows the measurements being stored.

Select File - Allows the selection of file to which measurements are to be

added.

Measuring - Displays the measurements being taken by the gauge.

Time / Date - Displays the current time and date.

Battery - Displays the remaining battery life. The green changes to

amber when the battery is getting low and then changes to red

when the batteries are critically low.

Data Link - Shows when the RF datalink is enabled or disabled. Disabling

the datalink when not in use will conserve battery life. It only

needs to be enabled when transferring files.

5700

Gauge

About

Units

V3.51b

mm

Resolution

mm

0.1

iPROBE

2¼ MHz

13mm

Datalink

RF

Enabled

Measuring

mm

Battery

4.4V

Select File

Logfiles

4

Time/Date

09:15:10

11.05.14

000001

Logfile

Logging

5915

m/s

Calibration

File

Manager

File

Wizard

Coating

CP+

Plus

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 14

iProbe - Shows that an iProbe has been connected. The probes are

automatically recognised by the gauge and all the relevant

probe data is transferred to the gauge to perfectly match the

probe to the gauge for optimum performance.

About 5700 - Displays the software and firmware versions and includes a

facility to reset the gauge to factory settings.

Units - The measurements can be displayed in metric or imperial.

Resolution - The measurements can be displayed to a resolution of

0.05mm or 0.1mm.

6.3. iProbe

There are three different modes for probe selection: automatic, manual and no

probe connected.

Automatic - When a Tritex probe is connected, the gauge will automatically

identify the probe type and set the gauge accordingly. All the relevant probe

data is transferred to the gauge to perfectly match the probe to the gauge for

optimum performance.

The following screen will appear prompting confirmation of the probe. Press

‘OK’ (4) to continue.

The selected probe will then be displayed at the bottom right of the screen in

measurement mode.

Probe change:

iPR Probe connected:

2¼ MHz 13mm

OK

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 15

Manual - When a suitable probe other than a Tritex probe is fitted, the gauge

will automatically detect this and display the following screen:

This is a prompt to select the correct setting for the probe that has been

connected. Press ‘OK’ (4) and then use the ‘Up’ (5) and ‘Down’ (9) arrow

buttons to select from the following displayed list:

Press ‘Option Key 2’ (6) to save the selection. The selected probe will be

displayed at the bottom of the screen in measurement mode.

The above menu can also be displayed by selecting ‘iProbe’ from the ‘Home’

screen menu.

Note: This feature only shows in the menu if a compatible probe other than a

Tritex probe with IPR is fitted.

SAVE

QUIT

Select Probe:

2 ¼ MHz 13mm

2 ¼ MHz 19mm

3 ½ MHz 13mm

5 MHz 13mm

5 MHz 6mm

Probe change:

Unrecognised Probe :

OK

!

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 16

No Probe - If no probe is connected when the gauge is turned on, or if a probe

is disconnected, the screen will display the following:

Either connect a suitable probe or simply press the ‘OK’ (4) button to enter

the ‘Home’ screen. This will allow navigation of the menus without a probe

fitted. Once ‘OK’ has been selected, the display will show ‘No Probe!’ on

the ‘Home’ screen and at the bottom right of the screen in measurement

mode.

6.4. Setting the Calibration

The gauge should be calibrated to the type of material that is being measured.

This is because all materials have different velocity of sound properties.

There are two methods of changing the calibration. Either adjust the velocity of

sound setting according to the metal being measured, or adjust the the gauge

to a known thickness of metal.

Gauges are supplied with the calibration set to mild steel at approximately

5900 m/s (0.2323 in/µs). This may vary according to the properties of the

supplied 15 mm test block material.

Note: The calibration does not need to be reset each time the gauge is used.

The last setting will be remembered.

Calibrating the Velocity of Sound

iNavigate to ‘Calibration’ on the ‘Home’ screen using the ‘Arrow’

keys (2,5,7 & 9). Use the Definition of Menu Items on pg 13 as a

guide.

ii Press ‘OK’ (4).

iii Use the ‘Left’ (2) and ‘Right’ (7) buttons to adjust the velocity of

sound to the the required new velocity.

iv Press ‘Option Key 2’ (6), the gauge will save the new calibration

and return to the ‘Home’ screen.

Probe change:

No Probe connected:

OK

!

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 17

Calibrating to a Known Thickness

iNavigate to ‘Calibration’ on the ‘Home’ screen using the ‘Arrow’

keys (2,5,7 & 9). Use the Definition of Menu Items on pg 13 as a

guide.

ii Press ‘OK’ (4).

iii Place the probe on a piece of material of a known thickness such

as the test block supplied with the kit.

iv Adjust the measurement displayed to the known thickness

using the ‘Left’ (2) and ‘Right’ (7) buttons.

v Press ‘Option Key 2’ (6), the gauge will save the new calibration

and return to the ‘Home’ screen.

6.5. Velocity Table (approximate values)

The given values are in certain cases strongly dependent on the alloy, heat

treatment, manufacturing and processing and are therefore only approximate

standard values. They are given here as a guide only.

Reference: Mathies, Klaus (1998), Thickness Measurement with Ultrasound, Berlin: German Society of

Nondestructive Testing.

Material Velocity -

m/s

Velocity -

in/µs

Aluminium

Rolled

Duraluminium

6200 -6360

6420

6320

0.2441 - 0.2504

0.2528

0.2488

Bronze (5%P) 3531 0.1390

Copper 3666 - 4760 0.1443 - 0.1874

Glass, Plate 5766 0.2270

Inconel, Forged 7820 0.3079

Lead 2050 - 2400 0.0807 - 0.0945

Steel, Mild

Supplied Test Block

5890 - 5960

5900 approx.

0.2319 - 0.2346

0.2323 approx.

Steel, Stainless

10 Cr Ni 18 8, ann

5530 - 5790

5530

0.2177 - 0.2280

0.2177

Steel, Tool

C105 Annealed

C105 Hardened

5490 - 5960

5854

0.2339 - 0.2346

0.2305

Tin 3210 - 3320 0.1264 - 0.1307

Titanium 5823 - 6260 0.2293 - 0.2465

Zinc 3890 - 4210 0.1531 - 0.1657

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 18

6.6. Measuring

In ‘Measuring’ mode, the following screen will be displayed:

See Chapter 9, page 50 for further details.

6.7. Setting the Units

Either metric (mm) or imperial (inch) units can be selected.

iNavigate to ‘Units’ on the ‘Home’ screen using the ‘Arrow’ keys

(2,5,7 & 9). Use the Definition of Menu Items on pg 13 as a guide.

ii Press ‘OK’ (4).

iii Use the ‘Up’ (5) and ‘Down’ (9) buttons to select the required

units.

iv Press ‘Option Key 2’ (6), the gauge will save the new units and

return to the ‘Home’ screen.

v Pressing the ‘Option Key 1’ (1) will quit the units setup and return

to the ‘Home’ screen.

6.8. Battery

The battery voltage is displayed in the ‘Home’ screen. See Chapter 3, page 6

for further details regarding batteries.

Measuring mm

5915 m/s

2.25 MHz 13mm

AUTO

HOLD

15.0

SAVE

QUIT

Select Units:

mm

inch

change Measuring Units:

ü

Tritex Multigauge 5700 Datalogger Ultrasonic Thickness Gauge www.tritexndt.com

Page 19

6.9. Setting the Resolution

Either 0.1 mm (0.002”) or 0.05 mm (0.005”) resolution can be selected.

iNavigate to ‘Resolution’ on the ‘Home’ screen using the ‘Arrow’

keys (2,5,7 & 9). Use the Definition of Menu Items on pg 13 as a

guide.

ii Press ‘OK’ (4).

iii Use the ‘Up’ (5) and ‘Down’ (9) buttons to select the required

resolution between ‘0.05’ and ‘0.1’ (metric) or ‘0.005’ and 0.002’

(imperial).

iv Press ‘Option Key 2’ (6), the gauge will save the new resolution

and return to the ‘Home’ screen.

v Pressing the ‘Option Key 1’ (1) will quit the resolution setup and

return to the ‘Home’ screen.

6.10. Coating Plus+

Coating Plus+mode is used to measure metal thickness when thick coatings

up to 20 mm exist. Normal measurement mode will ignore coatings up to

approximately 6 mm. In both modes, the actual thickness of coating that can

be ignored depends on the type of coating.

Note: Coating Plus+mode should not be left on for all measurements. The

gauge will achieve a better performance on standard coatings with this

function turned off.

SAVE

QUIT

Select Resolution:

ü

0.1 mm

0.05 mm

change Reading Resolution:

Table of contents

Popular Data Logger manuals by other brands

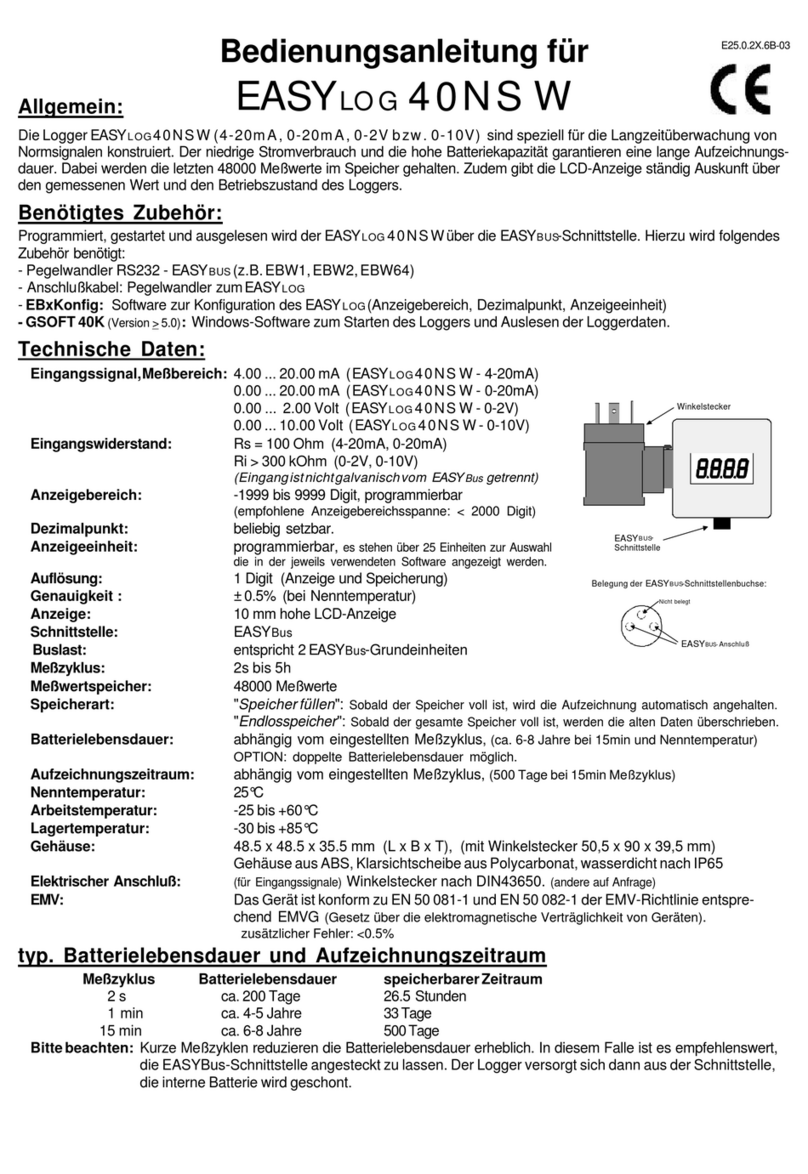

GREISINGER

GREISINGER EASYLog 40NS W operating manual

National Instruments

National Instruments myDAQ 195509D-01L USER GUIDE AND SPECIFICATIONS

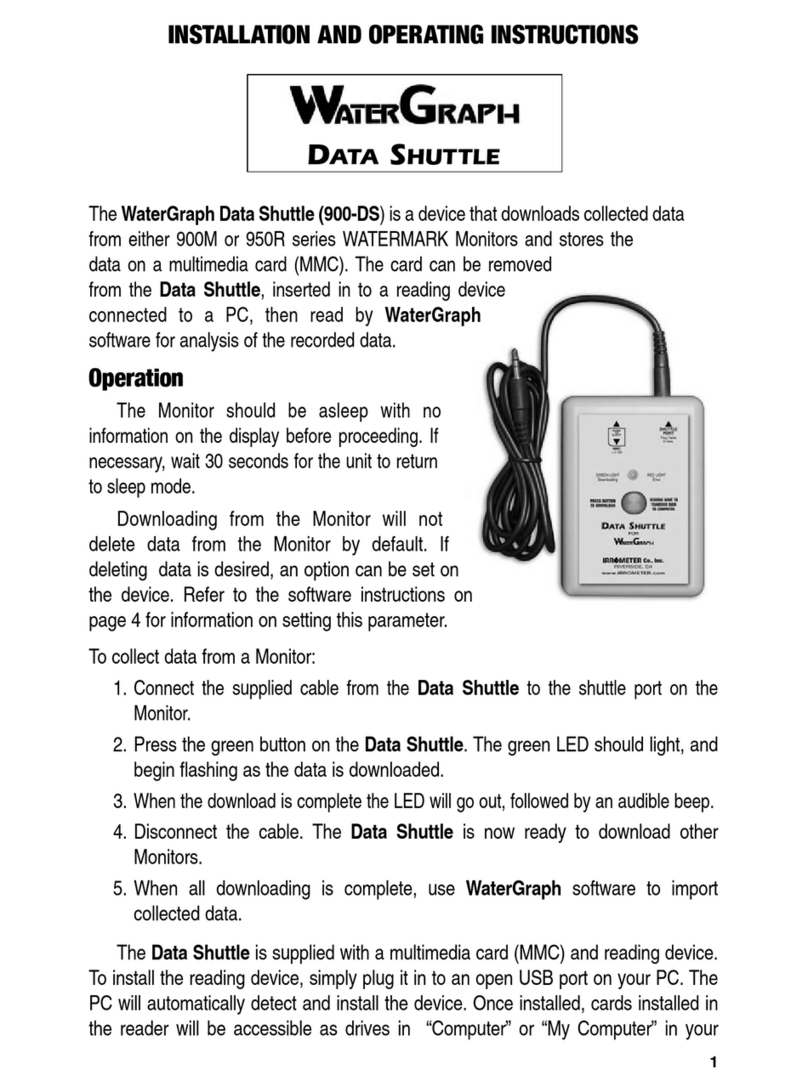

IRROMETER

IRROMETER WaterGraph Data Shuttle Installation and operating instructions

ADLINK Technology

ADLINK Technology DAQ-2010 user guide

T&D

T&D RTR-53 user manual

DENT Instruments

DENT Instruments ELITEpro XC Operator's guide