Trocen TC-6832 User manual

TC-

6832 Montion controller

Operation manual of main

6832 Montion controller

Operation manual of main

Vibration knife motion

controller series

6832 Montion controller

Operation manual of main

board

Vibration knife motion

controller series

RV 1.4

WWW.AWC608.COM

C

opyright notice

Shenzhen TROCEN automation technology co., LTD. (hereinafter

referred to as TROCEN) reserves the right to modify the products

and product specifications in this manual without prior notice.

TROCEN

shall not

incidental or consequential loss or liability caused by improper use

of this manual or product.

TROCEN has the patent right, copyright and other intellectual

property rights of the product and its software. With

authorization, the product and its related parts shall not be copied,

manufactured, processed or used directly or indirectly.

Machines in motion are dangerous. It is the

responsibility of the user to design effective error

handling and safety protec

use of the machine. We shall not be liable for any

incidental or consequential damages.

Contact us

Shenzhen TROCEN automation technology co., LTD.

Address: 1st floor, building 4, zhiheng industrial park, nanshan

district, shenzh

en city, guangdong province

TEL:0755-

27958262

FAX:0755-

27447913

EMAIL:

qiancheng@sztrocen.com

WEB:

www.sztrocen.com/www. awc608.com

Foreword

Motion controller user manual

opyright notice

Shenzhen TROCEN automation technology co., LTD. (hereinafter

referred to as TROCEN) reserves the right to modify the products

and product specifications in this manual without prior notice.

shall not

be liable for any direct, indirect, special,

incidental or consequential loss or liability caused by improper use

of this manual or product.

TROCEN has the patent right, copyright and other intellectual

property rights of the product and its software. With

authorization, the product and its related parts shall not be copied,

manufactured, processed or used directly or indirectly.

Machines in motion are dangerous. It is the

responsibility of the user to design effective error

handling and safety protec

tion mechanisms during the

use of the machine. We shall not be liable for any

incidental or consequential damages.

Shenzhen TROCEN automation technology co., LTD.

Address: 1st floor, building 4, zhiheng industrial park, nanshan

en city, guangdong province

27958262

27447913

-608

qiancheng@sztrocen.com

www.sztrocen.com/www. awc608.com

TC-6832

Motion controller user manual

1

Shenzhen TROCEN automation technology co., LTD. (hereinafter

referred to as TROCEN) reserves the right to modify the products

and product specifications in this manual without prior notice.

be liable for any direct, indirect, special,

incidental or consequential loss or liability caused by improper use

TROCEN has the patent right, copyright and other intellectual

property rights of the product and its software. With

out

authorization, the product and its related parts shall not be copied,

Machines in motion are dangerous. It is the

responsibility of the user to design effective error

tion mechanisms during the

use of the machine. We shall not be liable for any

Shenzhen TROCEN automation technology co., LTD.

Address: 1st floor, building 4, zhiheng industrial park, nanshan

WWW.AWC608.COM

Thank you for choosing gancheng motion controller.

In order to repay our customers, we will provide you with

motion controller, perfect after

support to help you complete the production of the equipment.

More information on TROCEN products

The company's website is

You can learn

more about the company and products on our

website, including: company profile, product introduction, technical

support and the latest product release.

You can also contact us at 0755

about the company and its products.

Techni

cal support and after

You can obtain our technical support and after

through the following ways:

Email:

qiancheng@sztrocen.com

TEL:0755-

27958262

To: floor 1, building 4, zhiheng industrial park, nanshan district,

shenzhen city, g

uangdong province

Shenzhen TROCEN automation technology co. LTD

Zip code:518100

Application

The user can understand the basic operation of the tc

card by reading this operation instruction.

Use object

This specification is suitable for

Motion controller user manual

Thank you for choosing gancheng motion controller.

In order to repay our customers, we will provide you with

motion controller, perfect after

-

sales service and efficient technical

support to help you complete the production of the equipment.

More information on TROCEN products

The company's website is

www.sztrocen.com/www. awc608.com.

more about the company and products on our

website, including: company profile, product introduction, technical

support and the latest product release.

You can also contact us at 0755

-

27958262 for more information

about the company and its products.

cal support and after

-

sales service

You can obtain our technical support and after

-

sales service

through the following ways:

qiancheng@sztrocen.com

27958262

To: floor 1, building 4, zhiheng industrial park, nanshan district,

uangdong province

Shenzhen TROCEN automation technology co. LTD

The user can understand the basic operation of the tc

-

6832 control

card by reading this operation instruction.

This specification is suitable for

engineers who have a certain

TC-6832

Motion controller user manual

2

In order to repay our customers, we will provide you with

first-class

sales service and efficient technical

support to help you complete the production of the equipment.

www.sztrocen.com/www. awc608.com.

more about the company and products on our

website, including: company profile, product introduction, technical

27958262 for more information

sales service

sales service

To: floor 1, building 4, zhiheng industrial park, nanshan district,

6832 control

engineers who have a certain

WWW.AWC608.COM

understanding of mechanical automation operation such as

vibrating knife.

Main content

The basic operation and use of TC

detail.

Related Documents

《TroCutCAD I

nstructions

1.2

Explanation of terms and abbreviations

1.3 Open box

................................

1.4

Panel appearance

1.5

Panel appearance and size drawing

1.5.1

Baseplate appearance and port

1.5.2 Port Instruction

1.5.2.1

Baseplate power port

1.

Product Introduction

1.1

system introduction

Tc-

6832 motion controller is a vibration cutting motion control

system developed by shenzhen TROCEN

co., LTD. TC -

6832 motion controller based on TC

original function, for the touch screen, increase the spindle cutting

indentation, V groove cutting, the press pulley, and other functions,

support double head, three h

the technological requirements, higher requirements for equipment

Motion controller user manual

understanding of mechanical automation operation such as

The basic operation and use of TC

-

6832 panel are introduced in

Related Documents

nstructions

》

Catalogue

Explanation of terms and abbreviations

................................

................................

................................

................................

Panel appearance

................................................................

........................

Panel appearance and size drawing

................................

.........................

Baseplate appearance and port

................................

1.5.2 Port Instruction

................................

................................

Baseplate power port

................................

................................

Product Introduction

system introduction

6832 motion controller is a vibration cutting motion control

system developed by shenzhen TROCEN

automation technology

6832 motion controller based on TC

-

6828 pro the

original function, for the touch screen, increase the spindle cutting

indentation, V groove cutting, the press pulley, and other functions,

support double head, three h

ead at the same time, the main meet

the technological requirements, higher requirements for equipment

TC-6832

Motion controller user manual

3

understanding of mechanical automation operation such as

6832 panel are introduced in

................................

.................... 5

................................

........ 5

........................

7

.........................

9

................................

...................... 9

................................

................. 10

................................

.. 10

6832 motion controller is a vibration cutting motion control

automation technology

6828 pro the

original function, for the touch screen, increase the spindle cutting

indentation, V groove cutting, the press pulley, and other functions,

ead at the same time, the main meet

the technological requirements, higher requirements for equipment

WWW.AWC608.COM

function more complex blade cutting production requirements and

develop a high-

end type vibration knife cutting motion controller.

The system is used by t

controller of the lower computer, which can greatly improve the

production efficiency and reduce the production cost.

The upper computer software of this system, namely TroCutCAD

software, has the following charac

friendly interface

operation

Support

CorelDraw

software

SupportAI

UD6 etc

formatted file

Simple drawing function

Automatic layout and path optimizatio

The motion controller of the lower plane of this system has the

following characteristics:

high-

speed DSP master control chip, faster operation

speed, more advanced motion algorithm, better effect

7 inch TFT LCD touch screen, more intuitive interface,

e

asier operation

all-

optical coupling isolates external electromagnetic

interference, making the system more stable and

reliable

Motion controller user manual

function more complex blade cutting production requirements and

end type vibration knife cutting motion controller.

The system is used by t

he upper computer software with the motion

controller of the lower computer, which can greatly improve the

production efficiency and reduce the production cost.

The upper computer software of this system, namely TroCutCAD

software, has the following charac

teristics:

friendly interface

,powerful ,

Intuitive and convenient

operation

CorelDraw

、Auto CAD etc

professional drawing

、PLT、DXF、SVG、PDF、NC、

DST

formatted file

Simple drawing function

Automatic layout and path optimizatio

n

The motion controller of the lower plane of this system has the

following characteristics:

speed DSP master control chip, faster operation

speed, more advanced motion algorithm, better effect

7 inch TFT LCD touch screen, more intuitive interface,

asier operation

optical coupling isolates external electromagnetic

interference, making the system more stable and

TC-6832

Motion controller user manual

4

function more complex blade cutting production requirements and

end type vibration knife cutting motion controller.

he upper computer software with the motion

controller of the lower computer, which can greatly improve the

The upper computer software of this system, namely TroCutCAD

Intuitive and convenient

professional drawing

DST

、DSB、

The motion controller of the lower plane of this system has the

speed DSP master control chip, faster operation

speed, more advanced motion algorithm, better effect

7 inch TFT LCD touch screen, more intuitive interface,

optical coupling isolates external electromagnetic

interference, making the system more stable and

WWW.AWC608.COM

support network, USB, U disk and other fast file reading

and writing

Support multi

efficienc

y

1.2

Explanation of terms and abbreviations

1-2-1

Explanation of terms and abbreviations

Terms/abbreviations

uppercomputer

software

TFT touch screen

The LCD panel

The control panel

Panel (main board)

Base plate (terminal

board)

system hardware

1.3 Open box

After receiving the products, please c

Motion controller user manual

support network, USB, U disk and other fast file reading

and writing

Support multi

-

working together, can double the

y

Explanation of terms and abbreviations

Explanation of terms and abbreviations

Terms/abbreviations

explanation

TroCutCAD

software is a special

supporting software for TROCEN knife

cutting motion controller

Refers to the 7 inch TFT color LCD touch

control panel. The panel is used for specific

display and control operations, and is an

important part of the system.

Base plate (terminal

The

baseplate is a control panel that

integrates signal input and output control

and motor driver connection.

system of visible physical objects,

including: panel, terminal board, wire, etc.

After receiving the products, please c

onfirm whether the

TC-6832

Motion controller user manual

5

support network, USB, U disk and other fast file reading

working together, can double the

Explanation of terms and abbreviations

software is a special

supporting software for TROCEN knife

Refers to the 7 inch TFT color LCD touch

control panel. The panel is used for specific

display and control operations, and is an

baseplate is a control panel that

integrates signal input and output control

system of visible physical objects,

including: panel, terminal board, wire, etc.

onfirm whether the

WWW.AWC608.COM

products and accessories are complete. If they are missing, please

contact the after-

sales service of shenzhen TRCEN automation co.,

LTD.

name

panel

baseboard

USB

cable(3m)

Net cable(5m)

Motion controller user manual

products and accessories are complete. If they are missing, please

sales service of shenzhen TRCEN automation co.,

1-3-1 product list

appearance

describtion

TC-6832

mainboard

TC-

6832

(

wiring board

Connect the panel to

the computer via USB.

Network connection

between panel and

computer.

TC-6832

Motion controller user manual

6

products and accessories are complete. If they are missing, please

sales service of shenzhen TRCEN automation co.,

describtion

mainboard

6832

baseboard

wiring board

)

Connect the panel to

the computer via USB.

Network connection

between panel and

WWW.AWC608.COM

DB15 cable

(2.5m)

USBextension

cable

(0.5m)

Network

extension

cable(0.5m)

DB9 线

(2.5m)

1.4

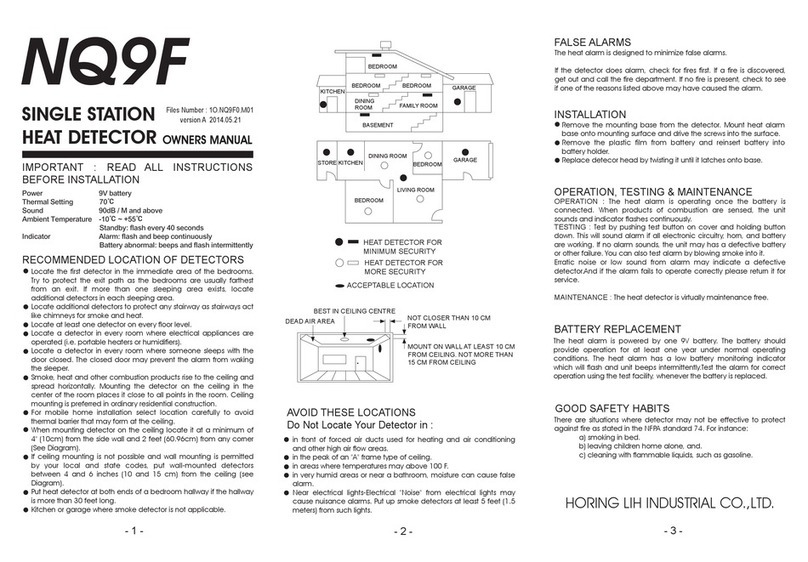

Panel appearance

system panel is designed with

Pic 1-4-1

Panel appearance and size drawing

Motion controller user manual

A DB15 line is attached

with the box to

the CN1 and port of the

panel and baseplate.

USB

extension cable

Network extension

cable

随箱附带

1

连接面板和底板的

端口。

Panel appearance

system panel is designed with

a display screen, soft buttons and a

usb jack.

Panel appearance and size drawing

TC-6832

Motion controller user manual

7

A DB15 line is attached

with the box to

connect

the CN1 and port of the

panel and baseplate.

extension cable

Network extension

1

条DB9 线,

连接面板和底板的

CN2

a display screen, soft buttons and a

Panel appearance and size drawing

WWW.AWC608.COM

Motion controller user manual

TC-6832

Motion controller user manual

8

WWW.AWC608.COM

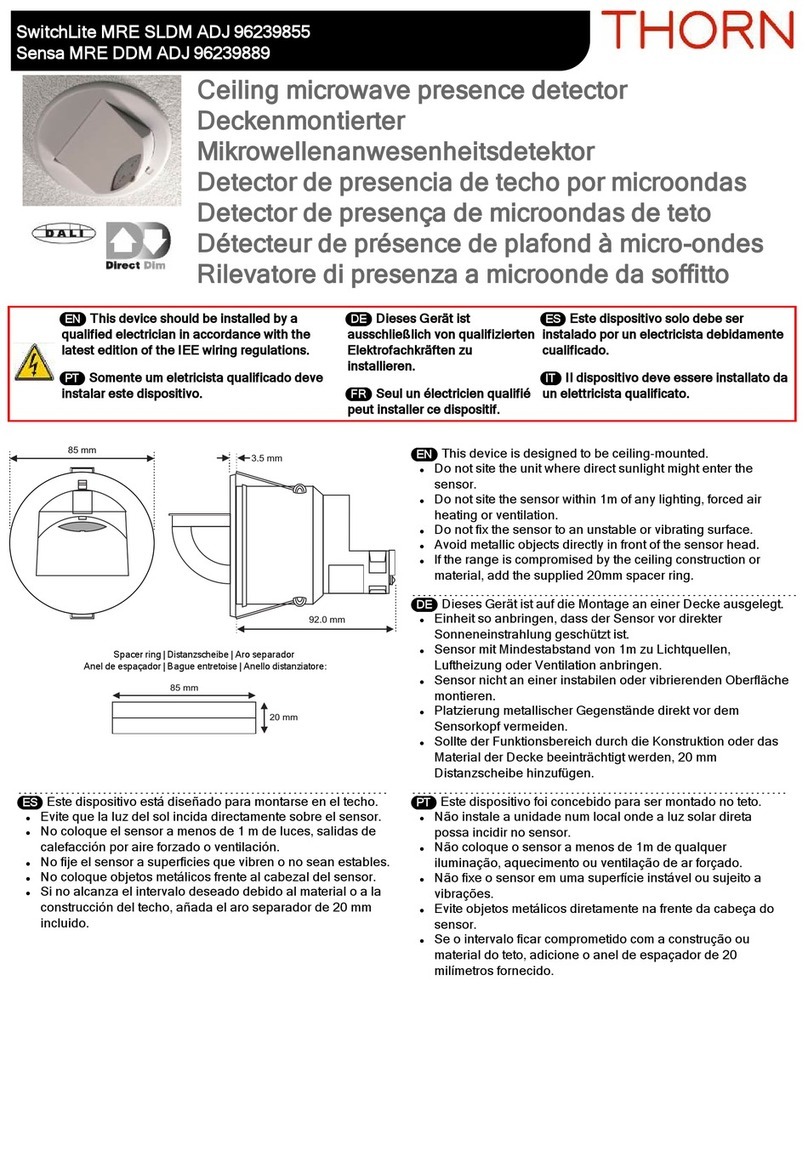

1.5

Panel appearance and size drawing

The base plate is used for the connection between the panel and

other parts of the machine. Include

Connected

Detection of motion axis limit signal

Input signal detection

IO

Control signal and output of corresponding power

supply

1.5.1

Baseplate appearance and port

Pic 1-5-1

Baseplate appearance display and dimension

Motion controller user manual

Panel appearance and size drawing

The base plate is used for the connection between the panel and

other parts of the machine. Include

Connected

motor driver

Detection of motion axis limit signal

Input signal detection

Control signal and output of corresponding power

Baseplate appearance and port

Baseplate appearance display and dimension

drawing

TC-6832

Motion controller user manual

9

The base plate is used for the connection between the panel and

Control signal and output of corresponding power

Baseplate appearance display and dimension

WWW.AWC608.COM

1.5.2 Port Instruction

1.5.2.1

Baseplate power port

The baseplate power port is used to supply power to the

baseplateand the panel. When connecting, please pay attention to

the positive and negative terminals.

1-5-1

Baseplate power port description

Pin Name

1 +24V

positive pole

2 GND

negative pole

Motion controller user manual

1.5.2 Port Instruction

Baseplate power port

The baseplate power port is used to supply power to the

baseplateand the panel. When connecting, please pay attention to

the positive and negative terminals.

Baseplate power port description

Description

positive pole

negative pole

TC-6832

Motion controller user manual

10

The baseplate power port is used to supply power to the

baseplateand the panel. When connecting, please pay attention to

WWW.AWC608.COM

1.5.2.2

The panel is connected to the baseplate

The panel is connected with the baseplate by 2 serial port lines,

and the corresponding port can be connected

1-5-2

Description of connection ports between panel and

Port

name

Description

CN1

Connect the baseplate to the CN1 port of the panel

with the DB15 line.

CN2

Connect the baseplate to the CN2 port of the panel

with DB9 line, connect two heads, optional

1.5.2.3

Signal input port

The baseplate provides

the acquisition of input signals.

Table1-5-

3 Wiring Board Signal Input Port Instruction

PIN

Name

Instruction

1 1 IN1

Open protection (input).

This feature must be enabled in the panel to be

effective.

2 IN2

Foot switch signal or pause signal(input). This

feature must be enabled in the panel to be

Motion controller user manual

The panel is connected to the baseplate

The panel is connected with the baseplate by 2 serial port lines,

and the corresponding port can be connected

Description of connection ports between panel and

Description

Connect the baseplate to the CN1 port of the panel

with the DB15 line.

Connect the baseplate to the CN2 port of the panel

with DB9 line, connect two heads, optional

Signal input port

The baseplate provides

multiple sets of input signal terminals for

the acquisition of input signals.

3 Wiring Board Signal Input Port Instruction

Instruction

Open protection (input).

This feature must be enabled in the panel to be

effective.

Foot switch signal or pause signal(input). This

feature must be enabled in the panel to be

TC-6832

Motion controller user manual

11

The panel is connected with the baseplate by 2 serial port lines,

Description of connection ports between panel and

baseplat

Connect the baseplate to the CN1 port of the panel

Connect the baseplate to the CN2 port of the panel

with DB9 line, connect two heads, optional

multiple sets of input signal terminals for

3 Wiring Board Signal Input Port Instruction

This feature must be enabled in the panel to be

Foot switch signal or pause signal(input). This

feature must be enabled in the panel to be

WWW.AWC608.COM

effective.

Foot switch function includes the function of start

work and pause or continue when machine is

working.

The panel pause key only has the function of

p

ause work or continue to work.

Setting method: turn on the foot switch, no matter

whether the pause function is on or off, there is no

effect;Stop function,must first turn off the foot

switch function, panel pause key can be used.

3 IN3

Servo error check

This feature must be enabled in the panel to be

effective.

4 IN4

Servo error check 2 (input).

This feature must be enabled in the panel to be

effective.

5 GND

Power ground.

2 1 IN5

Servo error check 3 (input).

This feature must be

effective.

2 IN6

Servo error check 4 (input).

This feature must be enabled in the panel to be

effective.

3 IN7

Reserved (input).

4 IN8

Reserved (input).

5 GND

Power ground.

Motion controller user manual

effective.

Foot switch function includes the function of start

work and pause or continue when machine is

working.

The panel pause key only has the function of

ause work or continue to work.

Setting method: turn on the foot switch, no matter

whether the pause function is on or off, there is no

effect;Stop function,must first turn off the foot

switch function, panel pause key can be used.

Servo error check

1 (input).

This feature must be enabled in the panel to be

effective.

Servo error check 2 (input).

This feature must be enabled in the panel to be

effective.

Power ground.

Servo error check 3 (input).

This feature must be

enabled in the panel to be

effective.

Servo error check 4 (input).

This feature must be enabled in the panel to be

effective.

Reserved (input).

Reserved (input).

Power ground.

TC-6832

Motion controller user manual

12

Foot switch function includes the function of start

work and pause or continue when machine is

The panel pause key only has the function of

Setting method: turn on the foot switch, no matter

whether the pause function is on or off, there is no

effect;Stop function,must first turn off the foot

switch function, panel pause key can be used.

This feature must be enabled in the panel to be

This feature must be enabled in the panel to be

enabled in the panel to be

This feature must be enabled in the panel to be

WWW.AWC608.COM

3 1 X-

The origin limit of the X axis. When

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

2 Y-

The origin limit of the Y axis. When the Y axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

3 X+

The hard limit of X axis. When the X axis moves to

the maximum coordinate position, the limit sensor

inputs signal.

4 Y+

The hard limit of Y axis. When the Y axis moves to

the maximum coordinate position, the limit sensor

inputs signal.

5 GND

Power gr

4 1 Z-

The origin limit of the Z axis. When the Z axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

2 U-

The origin limit of the U axis. When the U axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

3 UD1

The origin limit of the UD1 axis. When the UD1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

4 UD2

The origin limit of the UD2 axis. When the UD2 axis

moves to the minimum coordinate position (zero

positi

5 GND

Power ground.

Motion controller user manual

The origin limit of the X axis. When

the X axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the Y axis. When the Y axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The hard limit of X axis. When the X axis moves to

the maximum coordinate position, the limit sensor

inputs signal.

The hard limit of Y axis. When the Y axis moves to

the maximum coordinate position, the limit sensor

inputs signal.

Power gr

ound.

The origin limit of the Z axis. When the Z axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the U axis. When the U axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the UD1 axis. When the UD1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the UD2 axis. When the UD2 axis

moves to the minimum coordinate position (zero

positi

on), the limit sensor inputs signal.

Power ground.

TC-6832

Motion controller user manual

13

the X axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the Y axis. When the Y axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The hard limit of X axis. When the X axis moves to

the maximum coordinate position, the limit sensor

The hard limit of Y axis. When the Y axis moves to

the maximum coordinate position, the limit sensor

The origin limit of the Z axis. When the Z axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the U axis. When the U axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the UD1 axis. When the UD1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the UD2 axis. When the UD2 axis

moves to the minimum coordinate position (zero

on), the limit sensor inputs signal.

WWW.AWC608.COM

5 1 R1-

The origin limit of the R1 axis. When the R1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

2 R2-

The origin limit of the R2 axis. When

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

3 N1

The origin limit of the N1 axis. When the N1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

4 N2

The origin limit of the N2 axis. When the N2 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

5 GND

Power ground.

Note:

All input ports: Voltage 24v or 0v, need to open the function in the

panel, high and

low level can be optional.

Manufacturers recommend:axis origin, hardware limit switch: it is

recommended to choose NPN type, often open.Common sensors:

black line connect signal feet, blue line connect GND, brown line

connect 24v.

All input ports can be c

1.5.2.4 signal output end

Output voltage: 24v, effective at high voltage.Each outlet must be

connected to rated dc voltage 24V or more relay to use, not directly

connected to the load!

All outlets can output test inter

Motion controller user manual

The origin limit of the R1 axis. When the R1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the R2 axis. When

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the N1 axis. When the N1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the N2 axis. When the N2 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

Power ground.

All input ports: Voltage 24v or 0v, need to open the function in the

low level can be optional.

Manufacturers recommend:axis origin, hardware limit switch: it is

recommended to choose NPN type, often open.Common sensors:

black line connect signal feet, blue line connect GND, brown line

All input ports can be c

hecked in the panel's test interface.

1.5.2.4 signal output end

Output voltage: 24v, effective at high voltage.Each outlet must be

connected to rated dc voltage 24V or more relay to use, not directly

connected to the load!

All outlets can output test inter

face to test, respectively: one key to

TC-6832

Motion controller user manual

14

The origin limit of the R1 axis. When the R1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the R2 axis. When

the R2 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the N1 axis. When the N1 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

The origin limit of the N2 axis. When the N2 axis

moves to the minimum coordinate position (zero

position), the limit sensor inputs signal.

All input ports: Voltage 24v or 0v, need to open the function in the

Manufacturers recommend:axis origin, hardware limit switch: it is

recommended to choose NPN type, often open.Common sensors:

black line connect signal feet, blue line connect GND, brown line

hecked in the panel's test interface.

Output voltage: 24v, effective at high voltage.Each outlet must be

connected to rated dc voltage 24V or more relay to use, not directly

face to test, respectively: one key to

WWW.AWC608.COM

open or close all OUT ports;Open or close all odd OUT ports with

one click;Open or close all even number OUT ports with one

click;Open or close each OUT port individually.

Table1-5-

4 Wiring Board Signal Output Port

Name

Instruction

OUT1

Head

OUT2

Head

OUT3

Head

OUT4

Clip Material

OUT5

Feeding

OUT6

Punch motor

OUT7

OUT8

Micro Punching

OUT9

Small Punching

OUT10

Big Punching

OUT11

V-

Punching

OUT12

Reserved

OUT13

Reserved

OUT14

Reserved

OUT15

Red indicating

Motion controller user manual

open or close all OUT ports;Open or close all odd OUT ports with

one click;Open or close all even number OUT ports with one

click;Open or close each OUT port individually.

4 Wiring Board Signal Output Port

Instruction

Instruction

Name

Instruction

Head

-1 Working

OUT18

Global adsorption

Head

-2 Working

OUT19

Adsorb 1

Head

-3 Working

OUT20

Adsorb 2

Clip Material

OUT21

Adsorb 3

Feeding

OUT22

Adsorb 4

Punch motor

works OUT23

Adsorb 5

pen OUT24

Adsorb 6

Micro Punching

OUT25

Adsorb 7

Small Punching

OUT26

Adsorb 8

Big Punching

OUT27

Adsorb 9

Punching

OUT28

Adsorb 10

Reserved

OUT29

Adsorb 11

Reserved

OUT30

Adsorb 12

Reserved

OUT31

dispensing

Red indicating

OUT32

Reserved

TC-6832

Motion controller user manual

15

open or close all OUT ports;Open or close all odd OUT ports with

one click;Open or close all even number OUT ports with one

Instruction

Instruction

Global adsorption

Adsorb 1

Adsorb 2

Adsorb 3

Adsorb 4

Adsorb 5

Adsorb 6

Adsorb 7

Adsorb 8

Adsorb 9

Adsorb 10

Adsorb 11

Adsorb 12

dispensing

Reserved

WWW.AWC608.COM

1.5.2.5 Wiring Board motor driver control port

The wiring board can provide the connection of up to 10 motor

drivers, the user can choose the step driver or the servo driver

according to the need.

The servo driver is more accurate than the step driver, the user can

choose the appropriate driver according to the use of the scene,

cutting precision requirements and

Table1-5-

5 Motor Driver connection Instruction

OUT16

Green indicating

OUT17

Yellow indicating

PI

N

Nam

e

Instruction

X_AXI

S

1 PUL-

Pulse Negative

2 PUL

+

Pulse Positive

3 DIR-

Negative Signal

Motion controller user manual

1.5.2.5 Wiring Board motor driver control port

The wiring board can provide the connection of up to 10 motor

drivers, the user can choose the step driver or the servo driver

according to the need.

The servo driver is more accurate than the step driver, the user can

choose the appropriate driver according to the use of the scene,

cutting precision requirements and

cost factors.

5 Motor Driver connection Instruction

light

Green indicating

light

Yellow indicating

light GND

Power ground.

Instruction

PI

N

Nam

e

Pulse Negative

Signal R1_AXI

S

(Rotat

e)

1 PUL-

Pulse Positive

Signal 2 PUL

+

Direction

Negative Signal

3 DIR-

TC-6832

Motion controller user manual

16

The wiring board can provide the connection of up to 10 motor

drivers, the user can choose the step driver or the servo driver

The servo driver is more accurate than the step driver, the user can

choose the appropriate driver according to the use of the scene,

5 Motor Driver connection Instruction

Power ground.

Instruction

Pulse

Negative

Signal

Pulse Positive

Signal

Direction

Negative

Signal

WWW.AWC608.COM

4 DIR+

Positive Signal

Y_AXI

S

1 PUL-

Pulse Negative

2 PUL

+

Pulse Positive

3 DIR-

Negative Signal

4 DIR+

Positive Signal

U_AXI

S

(Feed

ing)

1 PUL-

Pulse Negative

2 PUL

+

Pulse Positive

3 DIR-

Negative Signal

4 DIR+

Positive Signal

Z_AXI

S

1 PUL-

Pulse Negative

2 PUL

Pulse Positive

Motion controller user manual

Direction

Positive Signal

4 DIR

+

Pulse Negative

Signal

UD1_A

XIS

(Up-Do

wn)

1 PUL-

Pulse Positive

Signal

2 PUL

+

Direction

Negative Signal

3 DIR-

Direction

Positive Signal

4 DIR

+

Pulse Negative

Signal

R2_AXI

S

(Rotat

e)

1 PUL-

Pulse Positive

Signal

2 PUL

+

Direction

Negative Signal

3 DIR-

Direction

Positive Signal

4 DIR

+

Pulse Negative

Signal

UD2_A

XIS

(Up-Do

1 PUL-

Pulse Positive

2 PUL

TC-6832

Motion controller user manual

17

Direction

Positive Signal

Pulse

Negative

Signal

Pulse Positive

Signal

Direction

Negative

Signal

Direction

Positive Signal

Pulse

Negative

Signal

Pulse Positive

Signal

Direction

Negative

Signal

Direction

Positive Signal

Pulse

Negative

Signal

Pulse Positive

WWW.AWC608.COM

2. TroCutCAD Installation

You can go through

about installation and how

3.

Coordination System

In order to help the users to understand the relevant operation

instructions better, the coordinate system involved is described in

detail here. The translation axis is applicable to the cartesian

coordinate system (the two

The rotation axis is suitable for the rotation coordinate system.

3.1 Plane Coordinate

(Hea

d-3)

+

3 DIR-

Negative Signal

4 DIR+

Positive Signal

N1_AX

IS

(Rese

rved)

1 PUL-

Pulse Negative

2 PUL

+

Pulse Positive

3 DIR-

Negative Signal

4 DIR+

Positive Signal

Motion controller user manual

2. TroCutCAD Installation

You can go through

《TroCutCAD User Manual》

for more details

about installation and how

-to-use TroCutCAD.

Coordination System

In order to help the users to understand the relevant operation

instructions better, the coordinate system involved is described in

detail here. The translation axis is applicable to the cartesian

coordinate system (the two

-

dimensional plane coordinate sys

The rotation axis is suitable for the rotation coordinate system.

3.1 Plane Coordinate

Signal wn) +

Direction

Negative Signal

3 DIR-

Direction

Positive Signal

4 DIR

+

Pulse Negative

Signal

N2_AXI

S

(Rese

rved)

1 PUL-

Pulse Positive

Signal

2 PUL

+

Direction

Negative Signal

3 DIR-

Direction

Positive Signal

4 DIR

+

TC-6832

Motion controller user manual

18

for more details

In order to help the users to understand the relevant operation

instructions better, the coordinate system involved is described in

detail here. The translation axis is applicable to the cartesian

dimensional plane coordinate sys

tem).

The rotation axis is suitable for the rotation coordinate system.

Signal

Direction

Negative

Signal

Direction

Positive Signal

Pulse

Negative

Signal

Pulse Positive

Signal

Direction

Negative

Signal

Direction

Positive Signal

WWW.AWC608.COM

Origin

The same position as where limit switch is located in.

X+ Axis

The positive rotation that is the opposite direction away from limit

switch on X axis.

X- Axis

The negative rotation that is the opposite direction to X+.

Y+ Axis

The positive rotation that is the opposite direction away from limit

switch on Y axis.

Y- Axis

The negative rotation that is the opposite direction t

3.2 Rotation Coordinate

Origin

The point of cutting table mapping from center point for rotary axis.

Clockwise

Rotation from X+ direction to Y+. Coordinate value increases if axis

is rotating clockwise.

Counter-

Clockwise

Coordinate value decreases if axis is rotating counter

The origin will be changing depending on axis’s moving.TC

PLUS Motion Controller User Manual

Coordinate Value

The rotation coordinate value is the number of cycles, like 360

degree

for one cycle. If the axis rotates positively and the

coordinate value increases from 0 to 360, then the rotation

coordinate value will be reset to 0. If the axis rotates negatively and

Motion controller user manual

The same position as where limit switch is located in.

The positive rotation that is the opposite direction away from limit

The negative rotation that is the opposite direction to X+.

The positive rotation that is the opposite direction away from limit

The negative rotation that is the opposite direction t

o Y

-

3.2 Rotation Coordinate

The point of cutting table mapping from center point for rotary axis.

Rotation from X+ direction to Y+. Coordinate value increases if axis

is rotating clockwise.

Clockwise

Coordinate value decreases if axis is rotating counter

-

clockwise.

The origin will be changing depending on axis’s moving.TC

PLUS Motion Controller User Manual

Coordinate Value

The rotation coordinate value is the number of cycles, like 360

for one cycle. If the axis rotates positively and the

coordinate value increases from 0 to 360, then the rotation

coordinate value will be reset to 0. If the axis rotates negatively and

TC-6832

Motion controller user manual

19

The positive rotation that is the opposite direction away from limit

The negative rotation that is the opposite direction to X+.

The positive rotation that is the opposite direction away from limit

-

.

The point of cutting table mapping from center point for rotary axis.

Rotation from X+ direction to Y+. Coordinate value increases if axis

clockwise.

The origin will be changing depending on axis’s moving.TC

-6828

The rotation coordinate value is the number of cycles, like 360

for one cycle. If the axis rotates positively and the

coordinate value increases from 0 to 360, then the rotation

coordinate value will be reset to 0. If the axis rotates negatively and

Table of contents

Other Trocen Security Sensor manuals

Popular Security Sensor manuals by other brands

Inficon

Inficon HLD6000 installation manual

Crewsaver

Crewsaver CREWFIT 165 SPORT owner's manual

Honeywell

Honeywell 14506873-001 installation instructions

STEINEL

STEINEL Multisensor True Presence DALI-2 IPD manual

Allen-Bradley

Allen-Bradley GuardShield Micro 400 installation instructions

Clare Controls

Clare Controls ClareOne CLR-C1-PIR Installation sheet