Trolex TX7000 User manual

P5593.1600 Rev A 1

GasHawk TX7000 User Manual

www.trolex.com

TX7000

GasHawk – Personal Gas Monitor

2 P5593.1600 Rev A

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 3

GasHawk TX7000

Contents

1. Product Overview 5

1.1 Main features 5

1.2 Functions 6

1.3 Accessories 6

1.4 Credentials 6

2. Technical Information 7

3. Preparation 10

3.1 Contents 10

3.2 Charge the battery 11

3.3 Change the battery 11

4. Controls and Indicators 12

4.1 Layout 12

4.2 Main button functions 12

4.3 Short-cut button functions 12

5. Operation 13

5.1 Menu map 13

5.2 ON/OFF 14

5.3 Main display 15

5.3.1 Alarms and messages 16

5.3.2 System and diagnostic alerts 17

5.4 Pump operation 18

6. Facilities 19

6.1 Enter a password 19

6.2 Zero in clean air 21

6.3 Bump test 22

6.4 Extended bump test 23

6.5 Calibrate 24

6.6 Zero CO2in N2 26

7. View 27

7.1 About 27

7.2 Peak 27

7.3 TWA 27

7.4 STEL 27

7.5 Alarm settings 28

7.6 Test gas values 29

7.7 Bump and calibration diary 29

7.8 Quick guide 29

8. Setup 30

8.1 Preferences 30

8.1.1 Continuous ON mode 31

8.1.2 Main display 31

8.1.3 Confidence beep 31

8.1.4 Confidence flash 31

8.1.5 Disable vibrator 31

8.1.6 Alarm latch 31

8.1.7 Invert display 31

8.1.8 Require password 31

8.1.9 Change password 32

8.1.10 Time. Date 32

8.1.11 Language 32

8.1.12 STEL period 32

8.1.13 Auto zero on start-up 32

8.1.14 LEL units 33

8.1.15 CO2Units 33

8.1.16 Factory default 33

8.1.17 LCD power save 33

www.trolex.com

4 P5593.1600 Rev B

GasHawk TX7000

Contents

8.2 Calibration Mode 34

8.2.1 Mandate bump test 34

8.2.2 Mandate calibration if fail 34

8.2.3 Mandate calibration when due 34

8.2.4 Test gas values 34

8.2.5 Calibration intervals 35

8.2.6 Bump test intervals 35

8.3 CH4LEL Alarms 36

8.4 O2Alarms 36

8.5 CO Alarms 36

8.6 H2S Alarms 36

8.7 Reset LEL alarms 36

9. Data Log & Communications 37

10. Maintenance 37

10.1 Service and calibration 37

10.2 Annual safety check 37

11. Precautions 38

11.1 Operating safety 38

11.2 Hazardous areas 38

11.3 Evacuation 38

11.4 Battery charging 38

11.5 Flammable gas sensors 38

11.6 Toxic gas sensors 39

11.7 Service and repair 39

11.8 Disposal 40

11.9 Contamination 40

11.10 Aggressive chemicals 40

11.11 Atmospheric pressure variations 40

11.12 Condensation 40

12. Accessories 41

13. Certification 42

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 5

1. Product Overview

GasHawk is a hand-held personal gas monitor for safety protection of personnel working in

potentially hazardous areas.

1.1 Main Features

• Impact resistant construction with resilient shockproof housing sealed to IP67 ingress protection

• Fully sealed gas ports and sounder

• Rechargeable Prismatic Lithium Ion battery with automatic wireless charging

• Hot–swap intrinsically safe battery pack which can be changed in the hazardous area

• Two large push-buttons for intuitive control of all field functions

• Up to six gas sensors in a choice of combinations of toxic and flammable gases

• High intensity wide-angle LED alarm warning indicator and loud audible alarm both

modulated to signify alarm severity

• Infra red, non-contact data transfer communications

• Option with integrated remote sampling pump for confined space entry alert

• Large high definition illuminated LCD display providing a bright, clear readout and intuitive

message interface

• HawkEye PC application for data log download and setup spreadsheet

• Active atmospheric pressure compensation

• Up to 64 days automatic data logging

www.trolex.com

6 P5593.1600 Rev B

1.2 Functions

• Spot reading or continuous reading mode

• Auto Zero

• Two independent adjustable set point gas alarms for HIGH and LOW with function

selection for each channel

• Peak signal retention

• Automatic STEL and TWA calculations as defined by EH40 with alarm warnings

• Continuous data logging with time and date stamp and event record

• Time of day clock and calendar with display

• Language options to specification

• Automatic prompts for bump test and calibration due

• Password protected setup controls

• Active battery management for continuous charging, contents display and condition

warning alarms

• Pump function alarms

• Confidence beep and flash

1.3 Accessories

• Wireless battery charger powered from a universal voltage mains power supply

• Multi-way charging stations in vertical or horizontal formats

• Bump test station with gas application button for convenient and rapid gas response

testing – can be used in the hazardous area subject to local regulations

• Universal docking station – all support functions in one convenient package; bump test,

calibration wireless charging and infrared data link for PC implemented setup or data log

download

• Complete range of carrying accessories

1.4 Credentials

• International certifications for use in underground mining and industrial hazardous areas

with EMC protection

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 7

2. Technical Information

Operating temperature: -20°C to +50°C

Storage temperature: -20°C to +60°C

Humidity: 0 to 95% RH (non-condensing)

Pressure: 800 mbar to 1100 mbar ambient

Housing: Moulded polymer with integral resilient over-mould

Ingress protection: IP67

Nett weight: 350g, 375g with pump

Dimensions: L156 x W75 x H35

Battery: Sealed prismatic Lithium Ion with wireless charging. Hot-swap

intrinsically safe battery pack can be changed in the hazardous

area.

Battery run time: 168 hours with LED IR and electrochemical cells installed

20 hours with catalytic and electrochemical sensor installed

Battery charge time: 6 hours with automatic charge management for continuous

standby charging

Display: 52mm x 42mm high definition graphic LCD with automatic

power-down and LED rear illumination

Controls: Two sealed push-buttons for all field functions, profiled for

operation with gloved hands

Alarms: • Flashing wide-angle LED indicator and audible alarm,

modulated indication of gas risk present

• Audible alarm 95dB at 300mm

• Low battery warning

• Confidence tone and flash at user defined interval with green

flashing LED indicator

• Calibration and bump test due prompt

• STEL and TWA preset alarms

Data functions:

• Automatic data log of sensor signals, alarm events and

parameter changes; 30 to 64 days dependant on configuration

• Real-time clock and display showing HH:MM

• Language options to user specification

• Peak signal retention for each gas sensor

• STEL and TWA auto calculation with prescribed alarm level in

accordance with EH40 standards

Pressure compensation • Active atmospheric pressure compensation for the O2, CO2

and infrared CH4 sensors

T90 response time • 30 seconds nominal (dependent on the gas type)

www.trolex.com

8 P5593.1600 Rev B

2. Technical Information

Setup functions: • Calibrate ZERO and SPAN

• Alarm level 1 and alarm level 2

• Continuous ON mode selection

• Password security protection

• Display invert

• Auto ZERO enable

• Gas units of display

• Calibration alert interval

• Bump test alert interval

• Disable a gas sensor

• Main display format

• Confidence alert

• Date and time

• Language options

• STEL/TWA function

• LEL equivalence

PC Communications: HawkEye PC application for USB data exchange when the

GasHawk is loaded into a TX7005 Universal Docking Station.

• GasHawk cloning

• Data log download

• Historical data analysis

• Service records

• Printout requests

Diagnostics: • Individual gas sensor display

• Calibration due indicator

• Bump test due indicator with days remaining

• Service due indicator with days remaining

• Battery power remaining

• Alarm test

• Test gas report

• Sensor fault

• LED fault

• Audible fault

• Vibration fault

• Pump fail

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 9

TX7000 ......

ATEX/IECEx Group I 19

ATEX/IECEx Group II 20

CH45% v/v IR 04

CH4100% LEL (4,4%) IR 05

CH4100% LEL (5%) IR 06

CH4

+

CO2

5% v/v

5% v/v

07

CH4

+

CO2

100% LEL (4,4%)

5% v/v

08

CH4

+

CO2

100% LEL (5%)

5% v/v

09

CH45% v/v 10

CH4100% LEL (4.4%) 11

CH4100% LEL (5%) 12

No pump 00

With pump 01

O225% v/v 01 CO 500 ppm 01

CO 2000 ppm 20

CL210 ppm 02

H2 1000 ppm 03

H2S 50 ppm 04

NO 250 ppm 05

NO220 ppm 06

SO220 ppm 07

CO

+

H2S

500 ppm

200 ppm

08

H2S

+

SO2

100 ppm

20 ppm

09

SENSOR A SENSOR CSENSOR B SENSOR D

CO 500 ppm 01

CO 2000 ppm 20

CL210 ppm 02

H2 1000 ppm 03

H2S 50 ppm 04

NO 250 ppm 05

NO220 ppm 06

SO220 ppm 07

Product options:

www.trolex.com

10 P5593.1600 Rev B

3. Preparation

3.1 Contents

No Pump TX7000.xx.xx.xx.xx.xx.00

1 x GasHawk instrument

Complete with battery pack

1x Test gas hood with flexible tube – 1m long

1x Workwear clip

1x User manual

No Pump TX7000.xx.xx.xx.xx.xx.01

Additional items included

1x Pump hood complete

1x 3m long flexible FKM suction tube with fittings

1x Hydrophobic line filter

Checkpoint

• Check that the gas sensor make-up of the instrument is

correct for the gas risks anticipated.

• View the gas sensor make-up in the MAIN DISPLAY

when the instrument is switched on. Section 5.3 >>

Section 2 >>

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 11

3.2 Charge the battery

Charger type: • TX7001 Charger

• TX7005 Universal Docking Station

Power supply: Universal mains power supply

90 – 265V AC 50/60Hz 250mA

Initial charge: 10 hours

Routine charge: 6 hours

Charge cycles: 500 approx

3.3 Change the battery

Checkpoint

• Charge periodically to maintain battery condition

• GasHawk may be docked on permanent charge standby

• Only Trolex GasHawk chargers may be used

• Do not charge in the hazardous area

• Transport regulations demand that the TX7010 spare battery pack

must be shipped in a fully discharged state. Charge before use.

• Spare batteries are best stored in a low state of charge

Fault On

3.4 Clock update

The clock and calendar may need to be updated. Section 8.1.10 >>

>>

=

www.trolex.com

12 P5593.1600 Rev B

Invert display Click and hold

Adjust display contrast Click and hold both to access...

...then click to adjust

Return to MAIN DISPLAY Click both from any point in a MENU

Start/Stop pump Double click

4. Controls and Indicators

4.1 Layout

4.2 Main Function Buttons

4.3 Short-cut button functions

ON/OFF or select a function

Scroll menus

Double click

Click and hold

Click both together

Section 5.4 >>

Green On LED

Pump inlet cover

Red Alarm LEDs

Gas entry port

Push buttons

LCD readout

Mounting for

carrying clips

Hot swap

intrinsically safe

battery pack

Wireless

charging zone

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 13

5. Operation

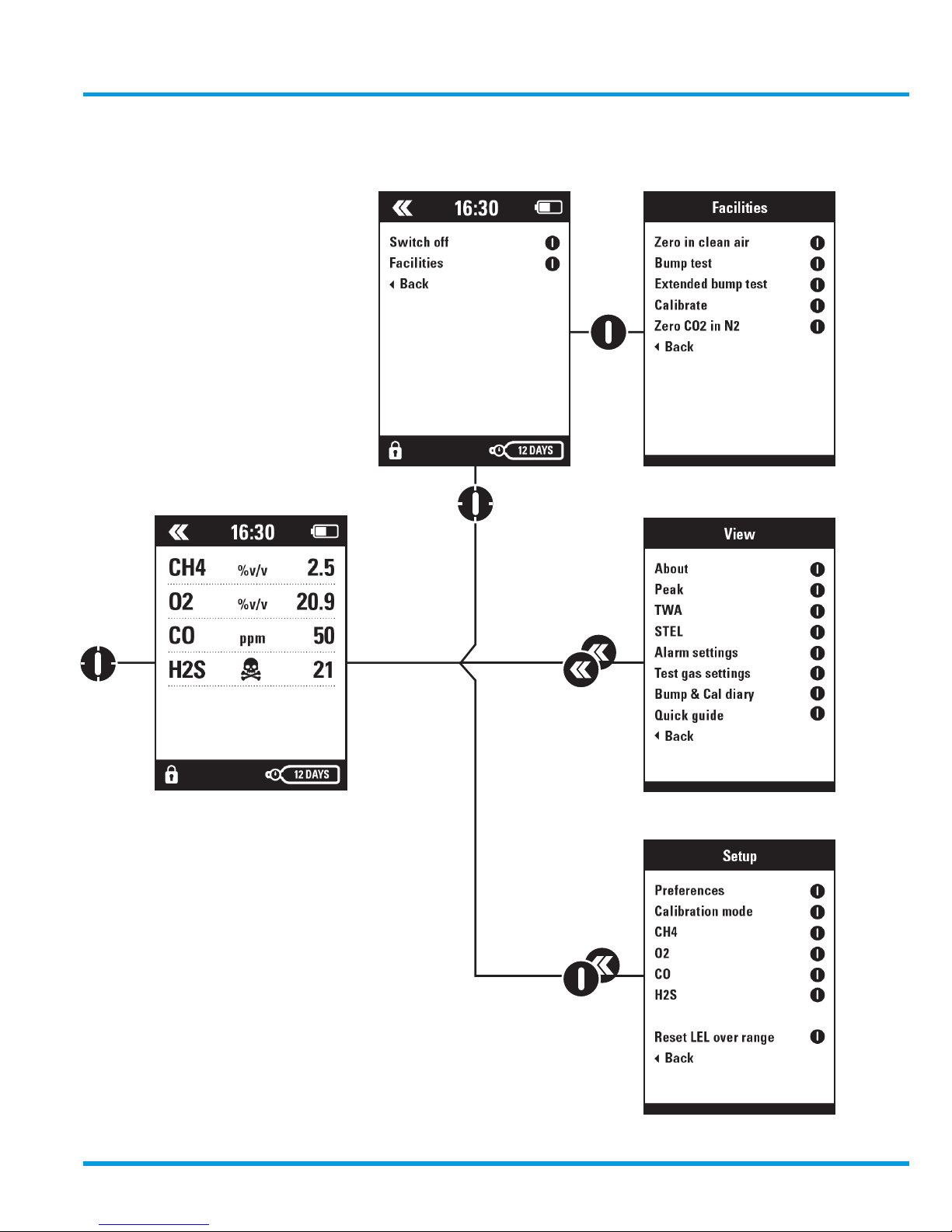

5.1 Menu map

MAIN DISPLAY

Section 5.3

Section 6

Section 7

Section 8

www.trolex.com

14 P5593.1600 Rev B

5.2 Switch On/Off

Switch ON

• Hardware condition check list

• Alarm settings for each sensor

• Sensor warming up

• Main display

Switch OFF

Checkpoint

• The switch ON sequence may be interrupted by FAULT messages.

• If BUMP TEST or CALIBRATE have been MANDATED any

further operation of the instrument will be suspended and the

FACILITIES screen displayed for resolution.

• Auto zero in clean air may occur in the sequence, where it has been

previously set up

• The CONDITION CHECK sequence will not

function if the battery pack is less than 25%

Section 5.3.2 >>

Section 8.2.1 >>

Section 8.1.12 >>

Section 9.1.13 >>

Section 8.2.2 & 6 >>

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 15

Checkpoint

System alerts

System alerts may occur at this point if a fault is present and will prevent any further operation.

Display illumination

The display illumination will automatically switch down to low level standby after a short period. It can

also be setup to switch completely OFF dependant upon which power saving mode is selected.

5.3 Main display

Function heartbeat

Type of gas

Units of gas

Continuous mode

Clock

Battery power

Gas concentration

Low alarm

High alarm

Days remaining

to calibration

Four Gas Format

LED fault

Alternative overview format

Five Gas Format

Section 8.1.16 >>

Section 8.1.2 >>

Click to restore display

SAFE

www.trolex.com

16 P5593.1600 Rev B

5.3.1 Alarms and messages

Gas alarms

Each gas sensor fitted has two independently adjustable alarm warning levels.

Some toxic gas sensors also have an independently adjustable TWA alarm warning level, plus

an independently adjustable STEL alarm warning alarm warning level.

Oxygen sensors have two independently adjustable CRITICAL alarms:

one for HIGH (Excess)

one for LOW (Depletion)

LED Audible Vibrator Display

(Typical)

Low

High

Low

High

High

High

GAS

OXYGEN

TWA

STEL

MUTE

CO 10

CO 20

CO 20

O2 19

O2 23

CO

30

CO

200

Checkpoint

• LOW alarms can be set up to AUTO RESET or to LATCH

• HIGH alarms will always LATCH

• Audible alarms can be MUTED

• LATCHED alarms can be RESET when the gas concentration has receded Section 8.1.6 >>

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 17

5.3.2 System and diagnostic alerts

LED Audible Vibrator Display

Condence alert

Sensor fault

Sensor fault

LED fault

LED fault

Audible fault

Audible fault

Vibrator fault

Vibrator fault

Battery low

Battery min

Shut down

Days to calibration

1 day to calibration

Overdue

Continuous ON

mode

Pump blocked

Pump blocked

Calibration is

overdue and is

mandated Calibration required

Bump test is

overdue and is

mandated Bump test required

12 days

1 day

0 days

www.trolex.com

18 P5593.1600 Rev B

5.4 Pump operation

Some versions of the GasHawk are fitted with an

integral pump for assisted gas infusion in confined

space entry applications.

TX7000.xx.xx.xx.xx.xx.01

1. Lift the pump inlet cover

2. Clip the pump hood over the gas entry grill

ensuring that the gas entry inlet is fully engaged

3. Connect the suction tube

4. Double click to Start/Stop the pump

Checkpoint

• A pump alarm will be generated if the suction tube is blocked, or the filter in the pump hood is

blocked.

• The increased power requirement of the pump will reduce the normal battery run-time dependant on

frequency of use.

• Gas concentration reading can be diluted in conditions where air may be drawn into the

intake pipe along with the subject gas.

Section 10.3 >>

www.trolex.com

GasHawk TX7000 User Manual

P5593.1600 Rev B 19

Telescopic Probe

Trolex accessory TX7012 Telescopic Probe can

be used to support the flexible suction tube to

aid access into restricted locations and confined

space applications:

• Extend the Telescopic Probe to the required length

• Push the suction tube through the clamping ring into the

Telescopic Probe and feed-in up to a positive stop.

• Hand tighten the clamping ring to hold the tube in position

Line Filter

A disposable Hydrophobic line filter should be fitted to the end of the flexible

suction tube or the Telescopic Probe to prevent water or particle ingress.

Checkpoint

• When extending or collapsing the Telescopic Probe, move each section one-at-a-time, to the desired

length. Rapid end-to-end pulling and pushing may stress and damage the sliding couplings.

• Apply light lubricating oil to the Probe when required to ensure smooth operation.

www.trolex.com

20 P5593.1600 Rev B

6. Facilities

Selection and control of the ancillary functions

when required

6.1 Enter a password

A password may be requested for Facilities menu if security is active. Factory default 1959.

Enter a digit

Confirm and step

www.trolex.com

Table of contents

Other Trolex Monitor manuals