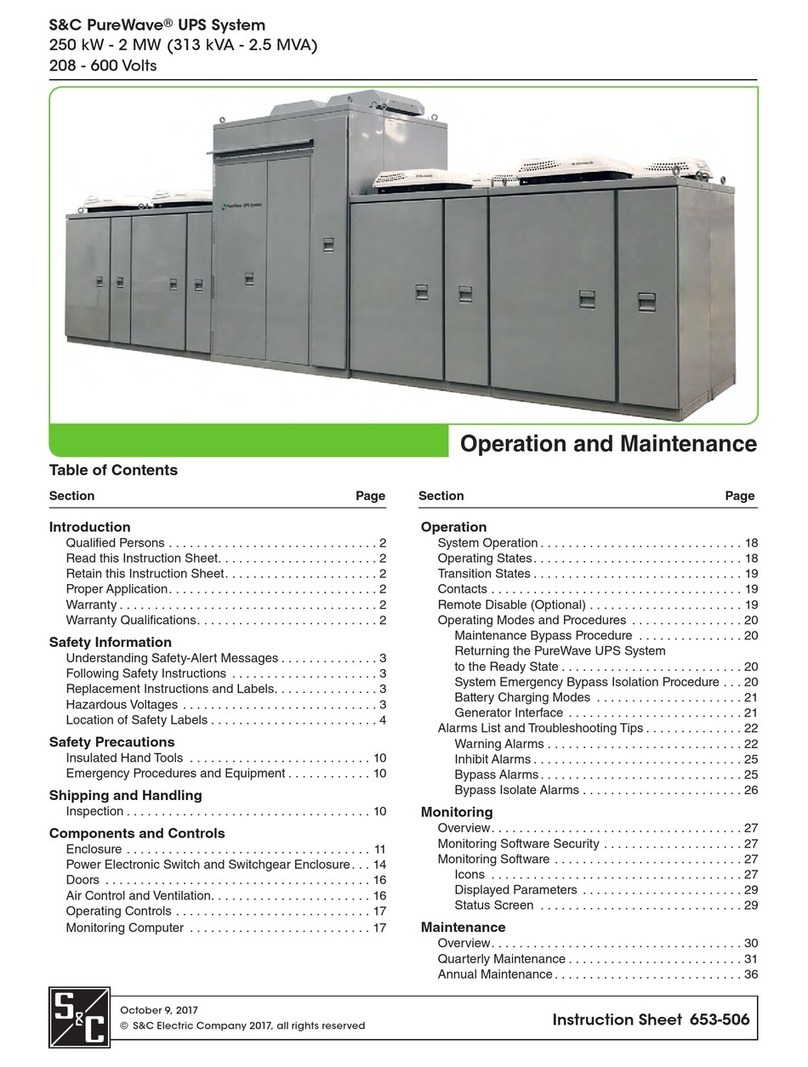

Trolex TX6649 User manual

TX6649

Uninterruptible Power Supply

(UPS) with Intrinsically Safe

Output and 25 Ah Battery

Backup

User Manual

rev A

1.1 Operating Features

1.2 Application

1.3 Product Options

1.4 Dimensions

1.5 Technical Information

3.1 Safety Precautions 11

3.1.1 Handling 11

3.2 Tools and Test Equipment

Required 1

3.3 Siting Recommendations 1

Positioning Re 1

1

1

1

1

1

1

1

4.2.2 Diagnostics

4.2.3 Connectivity

4.2.4 Support

3.4.Group Areas

4.1 Technical Maintenance

4.2

rev A

The TX664Power Supply converts an ac supply voltage into a stabilised and

regulated Intrinsically Safe source of power to approved sensors and electronic

control devices.

rev A

• Input voltage options: 110 V ac or 230 V ac

• Input supply is protected by two primary fuses

• Intrinsically Safe output voltage: 12 V dc

• Output circuit is resistively limited in accordance with certification standards for

Intrinsically Safe, ia, equipment

• Output circuit incorporates voltage regulation, current limiting and continuous

short circuit protection

• Robust stainless steel housing

• Integral Ah back-up battery with automatic uninterrupted power transfer and

charge to full capacity

• Output relay contact to signal power failure

• Analogue output signal to indicate battery charge condition

•

• Mining

• Tunnelling

rev A

rev A

Input voltage 110 V ac ± 10% or 230 V ac ± 10%-50/60 Hz

Output voltage 12 V dc

Output current 750 mA

Output ripple/noise 150 mV max

Line regulation <5% over the input voltage range

Load regulation <5% over 0 to 90% of load current

<10% between 90% and 100% of load current

Voltage limiting Over voltage detection with crowbar protection and

short circuit protection

Current limiting Automatic current limiting of the intrinsically safe

output also limits the current to less than the

rupturing capacity of the output protection fuse.

rev A

Max. operating

temperature

–20°C to +40°C

Storage

temperature

–20°C to +70°C

Humidity 0 to 95% RH, non-condensing

Vibration limits / low

frequency

0.25 mm peak, sinusoidal vibration in the range

10 Hz to 100 Hz in 3 perpendicular planes

Medium frequency 2g peak, sinusoidal vibration in the range 10 Hz to

600 Hz in 3 perpendicular planes

Mechanical shock 1000 shocks of 40g minimum in 3 perpendicular

planes

Housing material Stainless steel

Back-up battery Sealed lead-acid. Ah

Automatic charge control to full capacity

Automatic uninterrupted output power transfer

following input power failure

Power fail indication Relay contacts change state on power failure.

Contact rating: 0.25 A at 30 V dc max.

Charge condition Analogue output signal proportional to the charge

level of the battery

Choice of 0.4 V to 2.0 V or 4 to 20 mA signals

Battery life 6 years at 20°C

3 years at 30°C

1.5 years at 40°C

Net weight 35 kg

Important note Following initial commissioning or long periods of

storage the TX664requires a minimum of

24 hours charge time before the batteries will be at

full capacity.

ATEX (European Union) certification for use in underground mines (Group I).

Complies with ATEX Directive 2014/34/EU.

Standards:

EN IEC 60079-0:2018

EN 60079-5:2015

EN IEC 60079-7:2015+A1:2018

EN 60079-11:2012

IECEx (International) certification for use in underground mines (Group I).

Standards:

IEC 60079-0:2017

IEC 60079-5:2015

IEC 60079-7:2015+AMD1:2017

IEC 60079-11:2011

EAC certification for use in underground mines in Eurasian Customs Union

(including Russia).

.1. Underground mines

.2. The following Specific Conditions of Use apply to the ATEX and IECEx certificates

rev A

listed above:

Product Code: Ex Certificate Number: Ex Certification Code:

TX6649.35(.xx…).19

25 Ah UPS Power Supply

CML 21ATEX2404X

IECEx CML 21.0048X

I M2(M1) Ex eb q [ia Ma] I Mb (see Note 1)

I M1 Ex ia I Ma (see Note 2)

Ta = -20 ˚C to +55 ˚C

TX6649.35(.xx…).14

25 Ah UPS Power Supply RU C-GB.AA87.B.00155/19

PП Ex e q [ia Ma] I Mc X (see Note 1)

PO Ex ia I Ma X (see Note 2)

Ta = -20 ˚C to +40 ˚C

Note 1 –applies when mains powered

Note 2 –applies when powered from the backup battery

rev A

1. Make sure that all covers on Ex e housings and their fixing devices are properly

secured in compliance with statutory regulations before switching on the input

supply.

2. Never remove the cover of an Ex e housing whilst the input supply is

connected. Isolate elsewhere before removing the cover in accordance with

statutory regulations.

3. The housing of all power supplies must be securely earthed in compliance with

statutory regulations.

4. Carry out a current consumption audit to ensure that the maximum current

loading of the power supply is not exceeded.

5. Ensure that the installation of the power supply, particularly with regard to the

connecting cables, complies with the certification parameters (section 2.1).

6. The Ex e housing must be inspected and maintained regularly in accordance

with statutory regulations.

7. All cables entering the mains input terminal chamber must be terminated with

suitable, certified cable entry devices.

8. Do not drill holes in the Ex e housing or modify it in any way.

9. The battery contains corrosive substances and must be disposed of in the

correct way.

10. Please return the complete unit to Trolex or an approved distributor for servicing

and replacement.

www.trolex.com

rev A

The TX664may be located in hazardous area

The equipment

Installation shall be carried out in accordance with the applicable code of

practice by suitably trained personnel.

Mount horizontally as shown in the illustrations on pages 4 and

See Technical section 1.5.

0.4 to 2 V dc Battery charge level monitor

4 to 20 mA Battery charge level monitor

Relay

No special tools are needed.

Rev A

Connecting cables must conform to the requirements of the appropriate

Approval and Certification standards for Mining applications. Trolex recommends

that they conform to BS5308.

rev A

Make periodic visual inspections to check for physical damage.

Check connections in both terminal chambers are secure.

Trolex recommends that the batteries are replaced every three years. This must be

carried out by a competent person. If the unit is returned to Trolex for this re-work,

a test of the internal safety integrity will also be carried out.

See Terms and Conditions for the Supply of Goods and/or Services at

www.trolex.com.

rev A

Check the correct function of the mains-fail relay by connecting a suitable test

meter across the contacts.

A 12 V dc output should be available at the intrinsically safe output terminals with

mains power input present, or absent.

Also check that the analogue battery monitoring signal is available at the output

terminals.

If you need technical support to operate this product, or would like details of our

after sales technical support packages, contact .

The internal safety crowbars have activated due to an external

condition on the input voltage or output side, the crowbars will

attempt to automatically reset. If this does not happen remove main

power for about 2 minutes.

It is probable that the input fuses have ruptured which has resulted

in the batteries completely discharging. To check this, remove

main power momentarily. If the relay does not change state then

it confirms the unit is continuously operating on the battery supply

only.

rev A

The information provided in this document contains general descriptions and

technical characteristics of the performance of the product. It is not intended as

a substitute for and is not to be used for determining suitability or reliability of this

product for specific user applications. It is the duty of any user or installer to

perform the appropriate and complete risk analysis, evaluation and testing of the

products with respect to the relevant specific application or use. Trolex shall not be

responsible or liable for misuse of the information contained herein. If you have

any suggestions for improvements or amendments, or find errors in this

publication, please notify us at .

No part of this document may be reproduced in any form or by any means,

electronic or mechanical, including photocopying, without express written

permission of Trolex.

All pertinent state, regional, and local safety regulations must be observed

when installing and using this product. For reasons of safety and to help ensure

compliance with documented system data, only Trolex or its affiliates should

perform repairs to components.

When devices are used for applications with technical safety requirements, the

relevant instructions must be followed.

© 2013 Trolex® Limited.

Trolex is a registered trademark of Trolex Limited. The use of all trademarks in this

document is acknowledged.

Issue 1 20 July 2005 Original publication of this document

Issue 2 6 September 2013 New format and minor revisions

Rev A

Trolex Ltd, Newby Road, Hazel Grove, Stockport, Cheshire, SK7 5DY,

At Trolex, we save lives.

We believe that no person should risk

their life to earn a living.

Our aim is to become the world’s leading name

in health and safety technology, through

pioneering products that provide real-world

benefits to our customers, whenever workers

operate in hazardous environments.

Enquiries

sales@trolex.com

Telephone

+44 (0) 161 483 1435

Fax

+44 (0) 161 483 5556

Trolex Ltd

Newby Road, Hazel Grove

Stockport, Cheshire

SK7 5DY, United Kingdom

Website

www.trolex.com

For more information about Trolex, please contact us at:

Other manuals for TX6649

1

Popular UPS manuals by other brands

LEGRAND

LEGRAND Trimod HE user manual

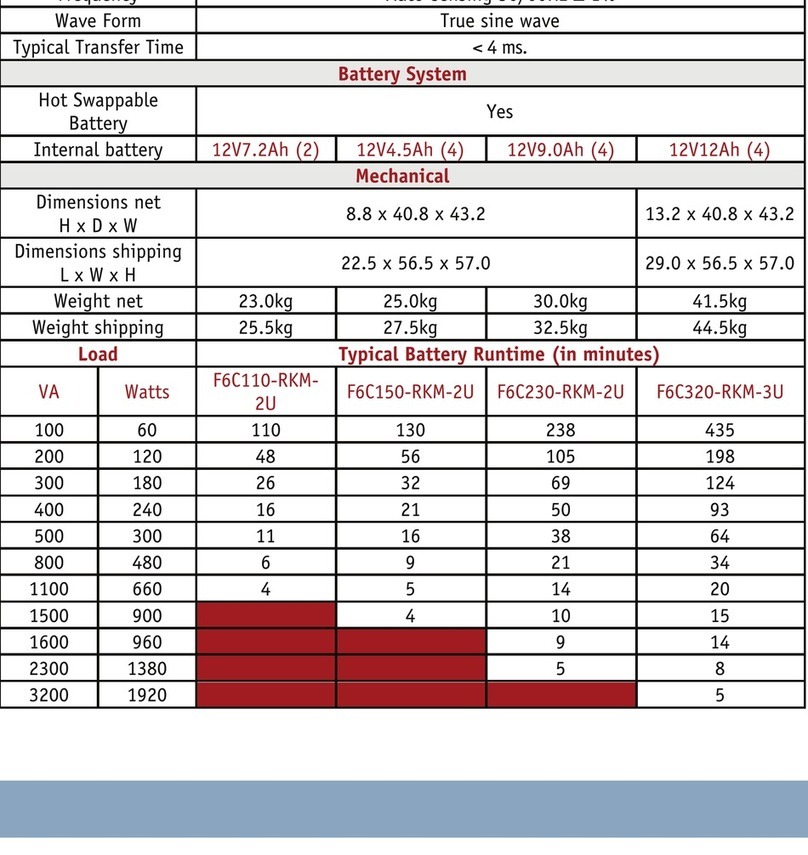

CyberPower

CyberPower 649532006854 Specification sheet

Eaton

Eaton Power Xpert 9395 550 Installation and operation manual

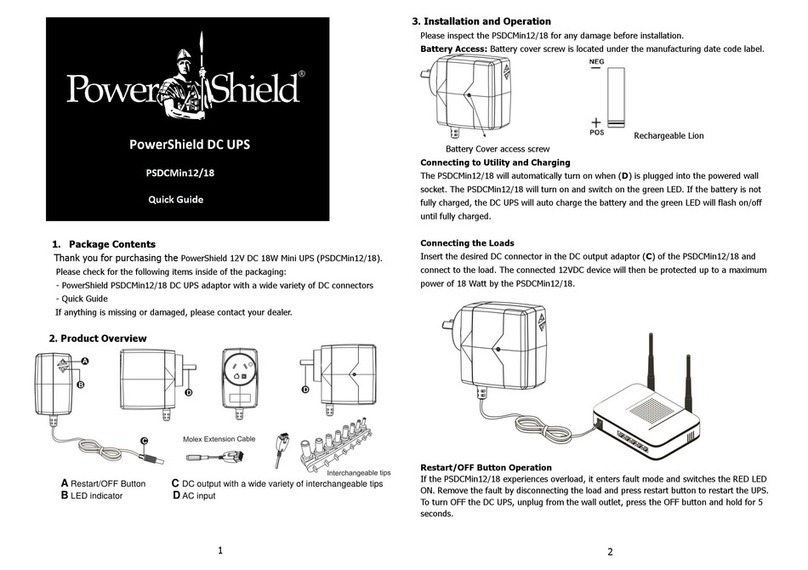

PowerShield

PowerShield PSDCMin12 quick guide

HP

HP J4367A - UPS R3000 XR user guide

Mitsubishi Electric

Mitsubishi Electric 2033D SERIES Owner technical manual