TRONZADORAS MG TL-600-A User manual

TL-600-A

MADE IN SPAIN

2011 EDITION

(VERSION 1.0)

2

TL

-

6

00

-

A

TABLE OF CONTENTS _ _ >>>

1. INTRODUCTION.

1.1. LEGISLATION APPLICABLE TO THE PLANNING AND CONSTRUCTION OF THE MACHINE.

2. GENERAL MACHINE DATA.

2.1. MACHINE IDENTIFICATION DATA.

2.2. TECHNICAL DATA.

2.3. ELECTRICAL DATA.

2.4. NOISE LEVEL.

3. INDICATIONS REGARDING TRANSPORT AND STORAGE.

4. INSTRUCTIONS FOR ANCJORING AND SERVICE START-UP.

4.1. ANCHORING INSTRUCTIONS.

4.2. POWER SUPPLY CONNECTION.

4.3. INSTRUCTION REGARDING BLADE INSTALLATION.

4.4. CUTTING COOLANT.

4.5. PNEUMATIC OIL.

5. INSTRUCTIONS FOR USE.

5.1. PROPER AND IMPROPER USE.

5.2. FUNCTION OF THE OPERATING MECHANISMS.

5.3. INSTRUCTIONS FOR THE ADJUSTMENT OF THE DIGITAL DEGREES.

5.4. GENERAL RULES AND SAFETY CHECKS.

6. RECOMENDATIONS AND MAINTENANCE.

6.1. TYPE AND FRECUENCY OF INSPECTIONS.

6.2. QUALIFIED PERSONNEL FOR MAINTENANCE AND REPAIR WORK.

6.3. MANUFECTURER RECOMENDATIONS.

7. DRAWIINGS AND SCHEMATICS.

7.1. GENERAL SCHEMATIC.

7.2. POWER CIRCUIT.

7.3. PNEUMATIC SCHEMATIC.

7.4. EXPLODED VIEW CAST IRON TABLE AND DISC ASSEMBLY.

7.5. EXPLODED VIEW ROCKER ASSEMBLY.

7.6. EXPLODED VIEW TURRET ASSEMBLY.

7.7. EXPLODED VIEW SHEET METAL BASE.

7.8. EXPLODED VIEW PROTECTIVE SHIELD.

3

TL

-

6

00

-

A

1. INTRODUCTION. >>>

This instruction manual has been made in compliance with the requirements of the Legislation

according to the Machine directive 2006/42/CEE and its subsequent amendments.

The instruction manual represents an integral part of the machine. It must be consulted

before, during and after the machine is put into service, as well as whenever it is considered

necessary, thereby respecting the content in each and every one of its parts.

This is the only way in which the fundamental objectives that have been established on the

basis of this manual will be achieved, such as accident prevention and making optimal use of the

machine features.

Within the framework of this manual, all aspects regarding safety and accident prevention on

the job while using the machine have been considered in every detail, herein highlighting the

information that is of greatest interest to the user.

ATTENTIÓN

Before installing the machine, read this manual carefully. The manual must be kept

throughout the life of the machine, so that it is easy to find if necessary. In the event that the

used machine is sold, the machine shall be sold together with this manual. In the event that

the machine is scrapped, the identification plate and any other document supplied with the

same must be destroyed.

1.1 Normativa aplicada en el proyecto y en la construcción.

EN-12100-1 Machine Safety. Basic concepts, general design principles.

EN-12100-2 Machine Safety. Basic concepts, general design principles.

EN-13857 Safety distances to prevent dangerous zones from being reached by the upper

extremities.

EN-60204/1 Electrical equipment of industrial machines.

EN-13850 Machine safety; emergency stop equipment.

and is in conformity with the Essential Requirements of the Directives:

2006/42/CEE on “Machine Safety.”

73/23/CEE on “Safety of Electrical Material.”

93/68/CEE on the CE Marking (amendment)

2004/108/CEE on “Electromagnetic Compatibility.”

4

TL

-

6

00

-

A

2. GENERAL INFORMATION. >>>

TRONZADORAS MG S.A.

Pol ind. FONT DE LA PARERA, s/n

08430 LA ROCA DEL VALLES

BARCELONA (ESPAÑA)

lfs: 34 93 842 41 60……Fax: 34 93 842 41 28

Web: www.tronzadorasmg.com

E-mail: [email protected]

2.1. Machine identification data.

Model:

..……………………………………………….

TL-600-A

Serial number:

……………………………………

Manufacturing year:

…………………………………

NOTE

In order to request spare parts, whether covered by the warranty or not, always indicate

the model and serial number of the machine, as well as the name of the part and the code that

appear in the last chapter of the parts exploded views.

2.2. Technical data.

Characteristic Dimension

Three phase motor 4 HP, 220/380V

Motor speed 3000 RPM

Interior Ø of blade 50 mm

Maximum Ø of saw blade Ø600 x Ø50 x 4,5 mm

Cutting speed 55 m/seg

Turn 90º RIGHT - 60º LEFT

Working pressure 7 atm

Pneumatic hold-down clamps 2 vertical +2 horizontal

Lubrication system Pneumatic, by sprayer

Dimensions 1300 x 1220x 1635

Weight 500 Kgs

5

TL

-

6

00

-

A

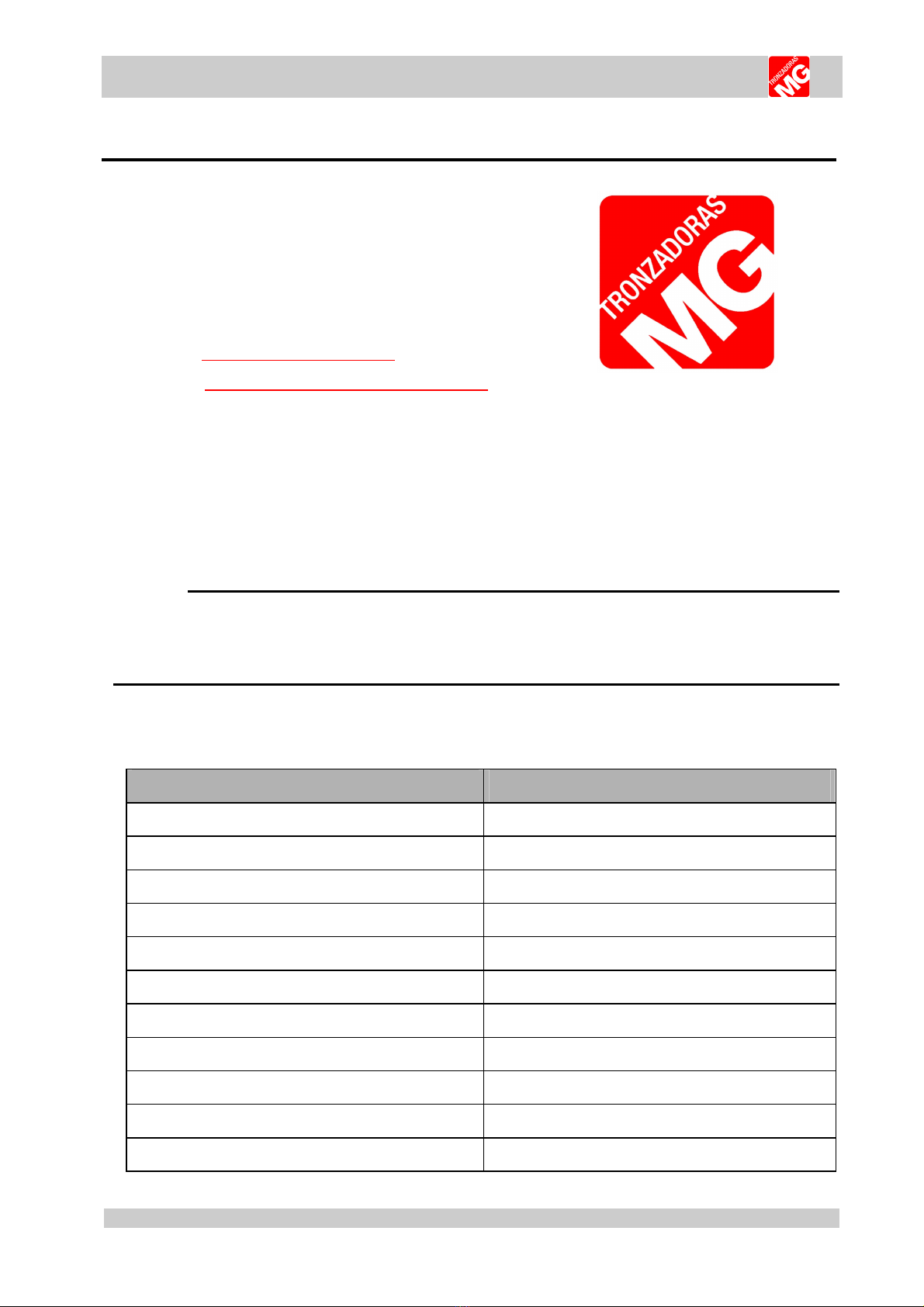

2.3. Dimensions of the machine.

770mm

934mm

ANCHO MAX: 1249mm

911mm

1636mm

850mm

905mm

1050mm

1301mm

1636mm

1052mm

2.4. Cutting capacity.

0

50

100

150

200

10

20

30

40

60

70

80

90

110

120

130

140

160

170

180

190

210

220

230

240

260

270

280

290

250

300

310

320

0

50

100

150

200

250

240

230

220

210

190

180

170

160

140

130

120

110

90

80

70

60

40

30

20

10

90º

45º

22.5º

10

20

30

40

60

70

50

TURRET

80

90

100

110

120

130

140

150

160

170

180

190

205

6

TL

-

6

00

-

A

2.5. Electrical data.

Power supply Motor power Total

220 V Three phase 3 kW / 4 HP 12 A

380 V Three phase 3 kW / 4 HP 7 A

2.6. Noise level.

At a distance of 60 cm RUNNING OFF-LOAD Leq 80 Db (A)

MACHINING A 70x50 PROFILE Leq 120 Db (A)

ATTENTION

When working with the machine, use individual hearing protection equipment.

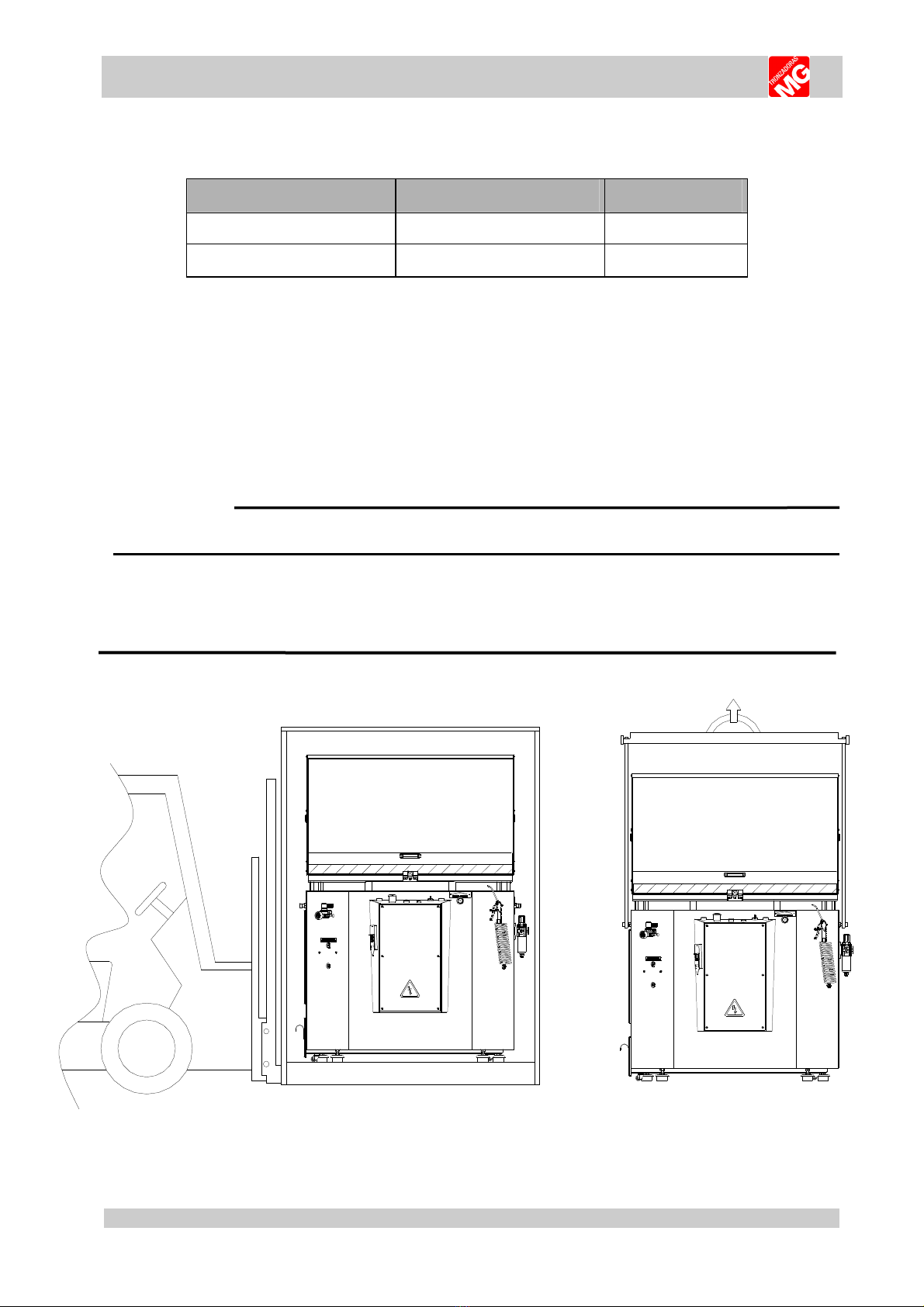

3. INDICATIONS REGARDING TRANSPORT AND STORAGE. >>>

Transp rt with a f rklift Transp rt with a crane bridge

7

TL

-

6

00

-

A

Recommendations:

•Store in the vertical position. Do not stack.

•If the machine remains stored for a long period of time, periodically lubricate.

•Do not expose to the elements.

•The packaging is made of properly designed and sized wood, and it is also supplied

wrapped in plastic.

CAUTION

Do not improperly dispose of the packaging. Send this material to be recycled or disposed

of in accordance with all legislation in force.

4. INSTRUCTIONS FOR ANCHORING AND SERVICE START-UP. >>>

4.1. Instructions for anchoring.

Ensure that the machine has not suffered any damage during transport by making an initial

visual inspection. If damage is observed, advise the manufacturer immediately.

The machine must be installed on a firm and level surface in order to thus reduce vibrations

during operation and so that the machine operates within the parameters established by the

manufacturer.

Verify that the power supply voltage corresponds to the voltage indicated on the specifications

plate of the machine. Connect the cable to the power supply using a plug that is appropriate for the

characteristics of the same, thereby respecting the colour codes. Once joined the machine, to verify

the sense of rotation; if the rotation is not the suitable one, to change two phases of the plug.

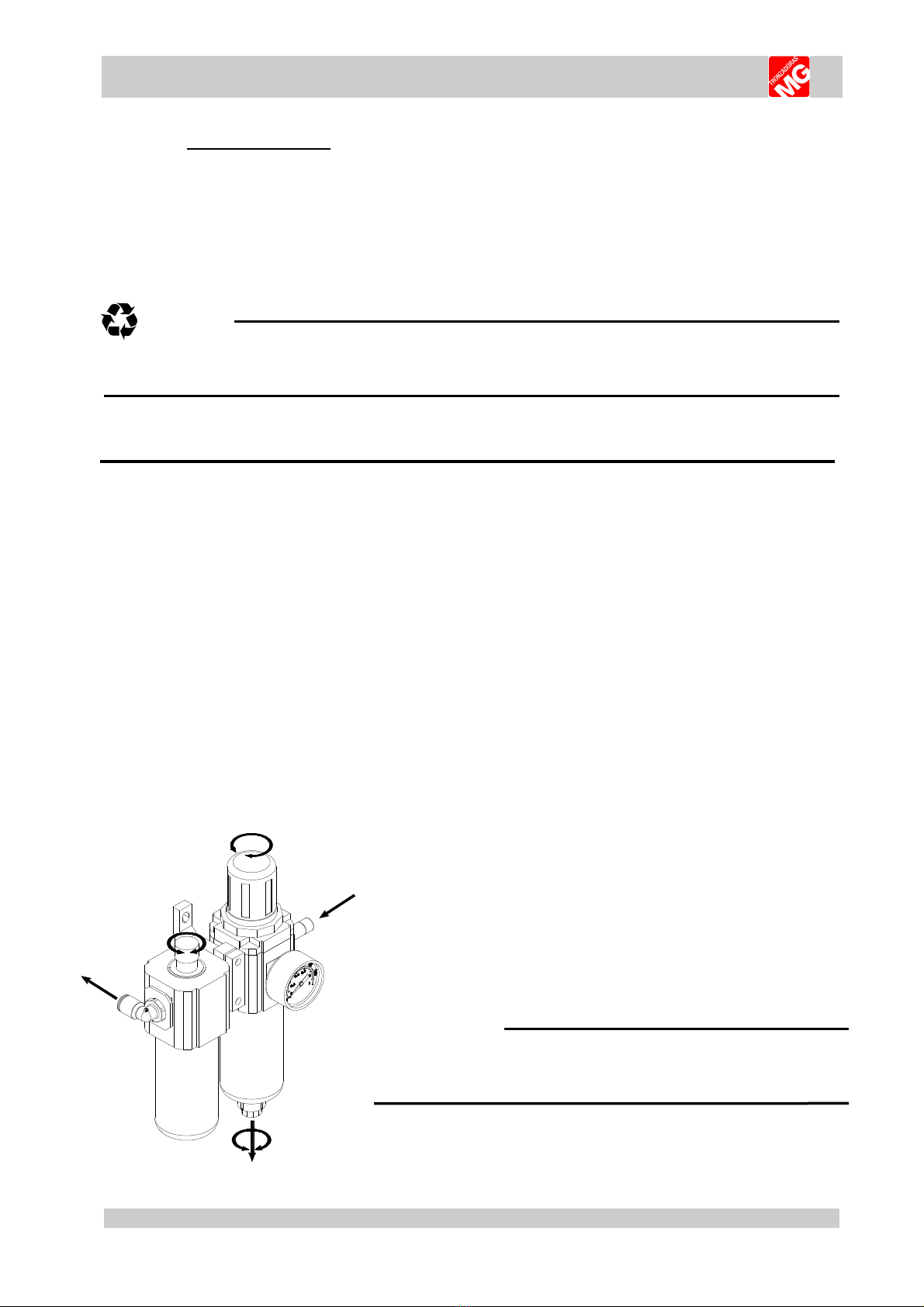

4.2. Reglaje de reguladores de presión.

The machine has in the entry of the pneumatic circuit of a

regulatory lubricating filter. The mission of this one is regular the

pressure of air inlet in the machine between 6-7bar and lubricant

the air that enters the machine not to damage the pistons and

mobile elements.

ATTENTION

The pneumatic working pressure for vertical

clamps must be between 6 and 7 atm

8

TL

-

6

00

-

A

ATTENTION

The pneumatic working

pressure for horizontal clamps

must be between 3 and 4 atm

4.3.

Instructions regarding blade installation.

To place the machine to 22,5 º

towards the left side and to fix with the

automatic anchorage, there slackens the

disc (4) with the bar and the fixed key sent

with the machine. To do it with the bar and

the fixed key sent with the machine. To place

the new disc (4) in the axis (3), fitting it into

the screw of dragging (2) mounted in the

axis. To place the socket-pan (5) and to fix it

by means of the bar, to press the nut (6) as

Indian the figure. In order to accede to the

disc using the lateral door of the machine, to

make sure that the sense of the teeth of the

mountain range agrees with the direction of

rotation of the motor. Asegúrese also that

the diameter of the disc is the adapted one

for this machine (600mm).

ATTENTION

The blade nut is reverse threaded.

DANGER

After changing the blade, put the sheet metal front back on.

1234

56

9

TL

-

6

00

-

A

4.4. Cutting coolant.

In order to fill the machine with cutting coolant, open the reservoir and fill with PURE, NON-

EMULSIFIABLE CUTTING OIL (VISCOSITY ISO VG 16-32 cST 40ºC)

4.5. Pneumatic oil.

Both the oleo-pneumatic converters and the filter group lubricator must be filled with ISO VG

16 VISCOSITY PNEUMATIC OIL. If none is available, use hydraulic oil 16.

5. INSTRUCTIONS FOR USE. >>>

5.1. Proper and improper use.

This is a semiautomatic cut-off machine especially designed for cutting aluminium profiles.

The use of the machine for cutting other materials is hereby prohibited. Such use may cause

damage to the machine and put the health and safety of the worker at risk.

DANGER

We are not responsible for any possible accident caused by the failure to

comply with the aforementioned.

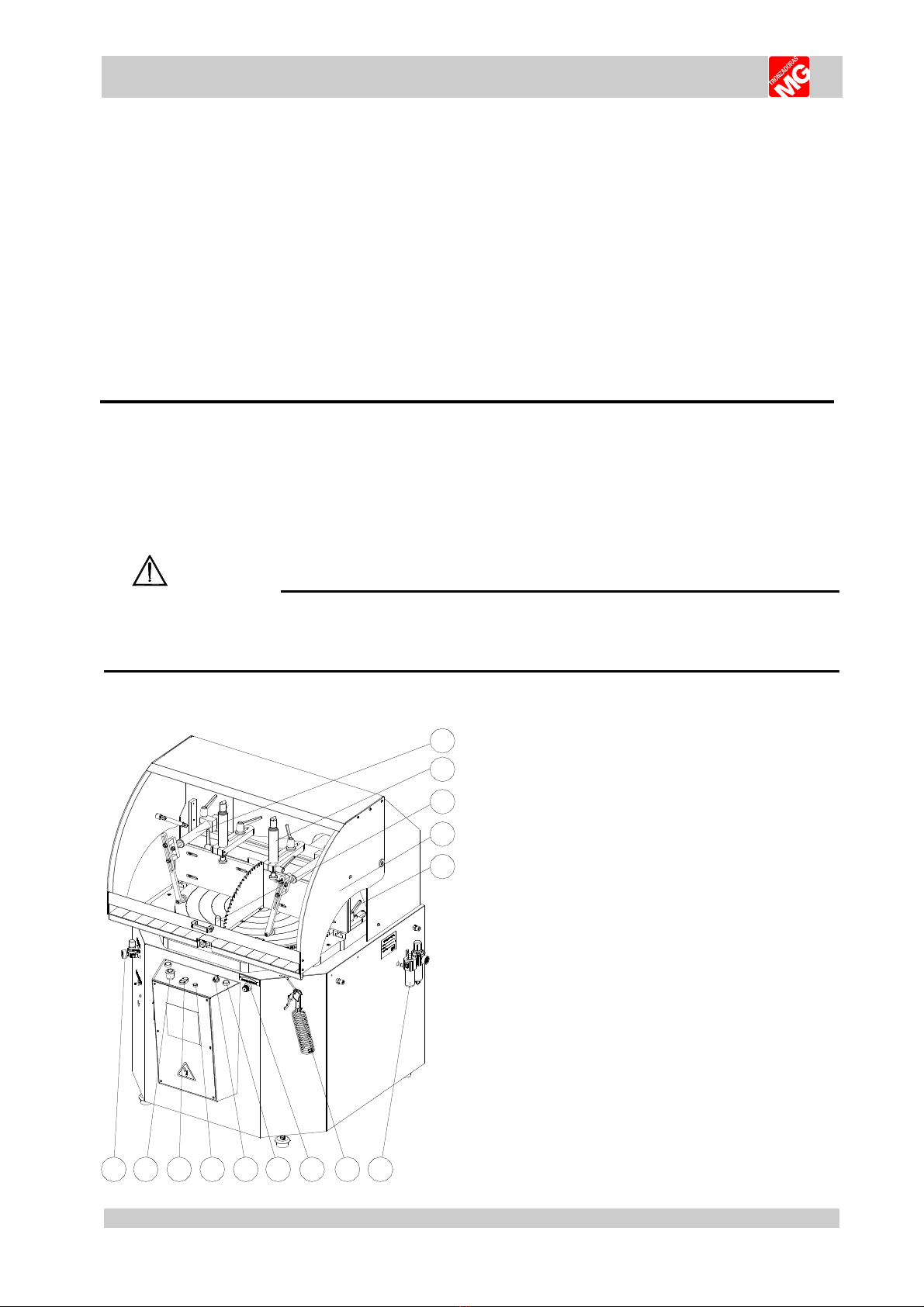

5.2. Function of the operating mechanisms.

1. Horizontal clamps.

2. Vertical clamps.

3. Lever I turn disc.

4. Protective shield.

5. M10x40 Lever.

6. Filter + Regulator + lubricator + manometer.

7. Clearing gun with hose.

8. Advanced regulator 3/8”.

9. Raise blade - green button.

10. 2-position selector.

11. Green indicator 380V.

12. Saw blade on-off.

13. Emergency.

14. Pressure regulator horizontal clamps.

1

2

3

4

5

6

7

89

10

11

1213

14

10

TL

-

6

00

-

A

DANGER

ALWAYS WORK WITH THE PROTECTIVE SHIELD LOWERED.

DO NOT DISCONNECT ANY SAFETY DEVICES.

5.3. Instructions for the adjustment of the digital degrees. (OPTIONAL)

For placed to the zero of the book-keeper of degrees, pulsate of simultaneous form (F+Set).

To change the way of reading of incremental to absolute, to touch (Inc/Abs).

Change of the book-keeper parameters, contact to the manufacturer of the machine.

ATTENTION

Clean the book-keeper with the pistol of cleanliness, not to try to clean it with other utensils

since the frame of plastic might be spoilt or grated, impeding the reading

5.3. General rules and safety checks.

•Before using the machine, check the efficiency and perfect operation of all safety devices, and

check that the moving parts of the machine are not blocked, that there are no damaged parts and

that all machine components are positioned and work correctly.

•It is entirely prohibited to manipulate the safety devices.

•It is entirely prohibited to work without the protective shield in position.

•It is mandatory to use gloves and protective eyewear.

•It is mandatory to use regulation work clothing (it must be worn fastened).

•Before starting work, the operator must ensure that all tools and wrenches used for maintenance or

adjustment have been removed.

•In the event of a fire, use powder extinguishers and disconnect the machine from the electric

system.

11

TL

-

6

00

-

A

6. RECOMMENDATIONS AND MAINTENANCE. >>>

6.1. Type and frequency of inspections.

The operator’s knowledge of the machine is one of the best ways of daily control of any

possible problem. If any failure is detected, work must be stopped and qualified personnel must be

informed immediately.

NOTE

Always clean the machine and the work area at the end of the workday.

LUBRICATION POINTS TYPE OF GREASE/OIL FREQUENCY

Turret travel rail SAE 30 LUBRICATING OIL WEEKLY

Rocker bearings (Fig. 7.4) ROLLER BEARINGS ANNUALLY

CHECK POINTS FREQUENCY

Machine cleaning WEEKLY

Condition of the transmission belt ANNUALLY

6.2. Qualified personnel for maintenance and repair work.

•All repairs shall be made exclusively by qualified personnel, thereby always using original

replacement parts. If not, the machine may be damaged or the user may be injured.

6.3. Manufacturer recommendations.

⇒In the event that the machine is broken down or the saw blades must be replaced, place a padlock

on the protection switch and place the keys under the care of qualified personnel.

⇒Before working on any electrical devices, disconnect the plug from the power supply.

⇒If extension cords are used, ensure that the cable has the appropriate cross-section for the power

of the machine.

⇒Whenever any part has to be replaced, use an original replacement part and endeavour to use the

oil recommended by the manufacturer.

NOTE

In case of any doubt or problem, do not hesitate to consult the manufacturer.

ATTENTION

The manufacturer hereby guaranties the supply of each one of the parts or components for at

least 3 years as from the manufacturing date of the machine.

12

TL

-

6

00

-

A

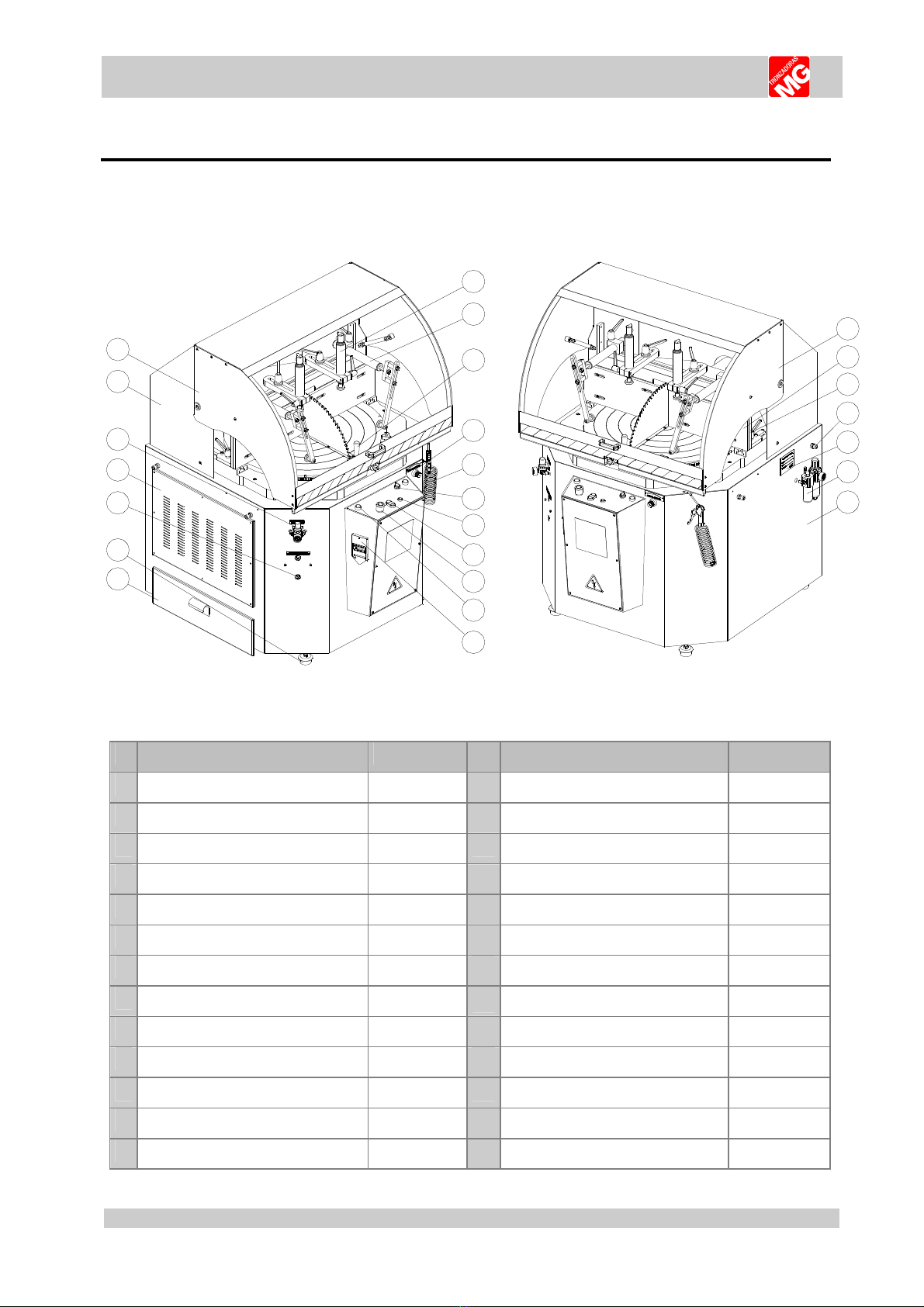

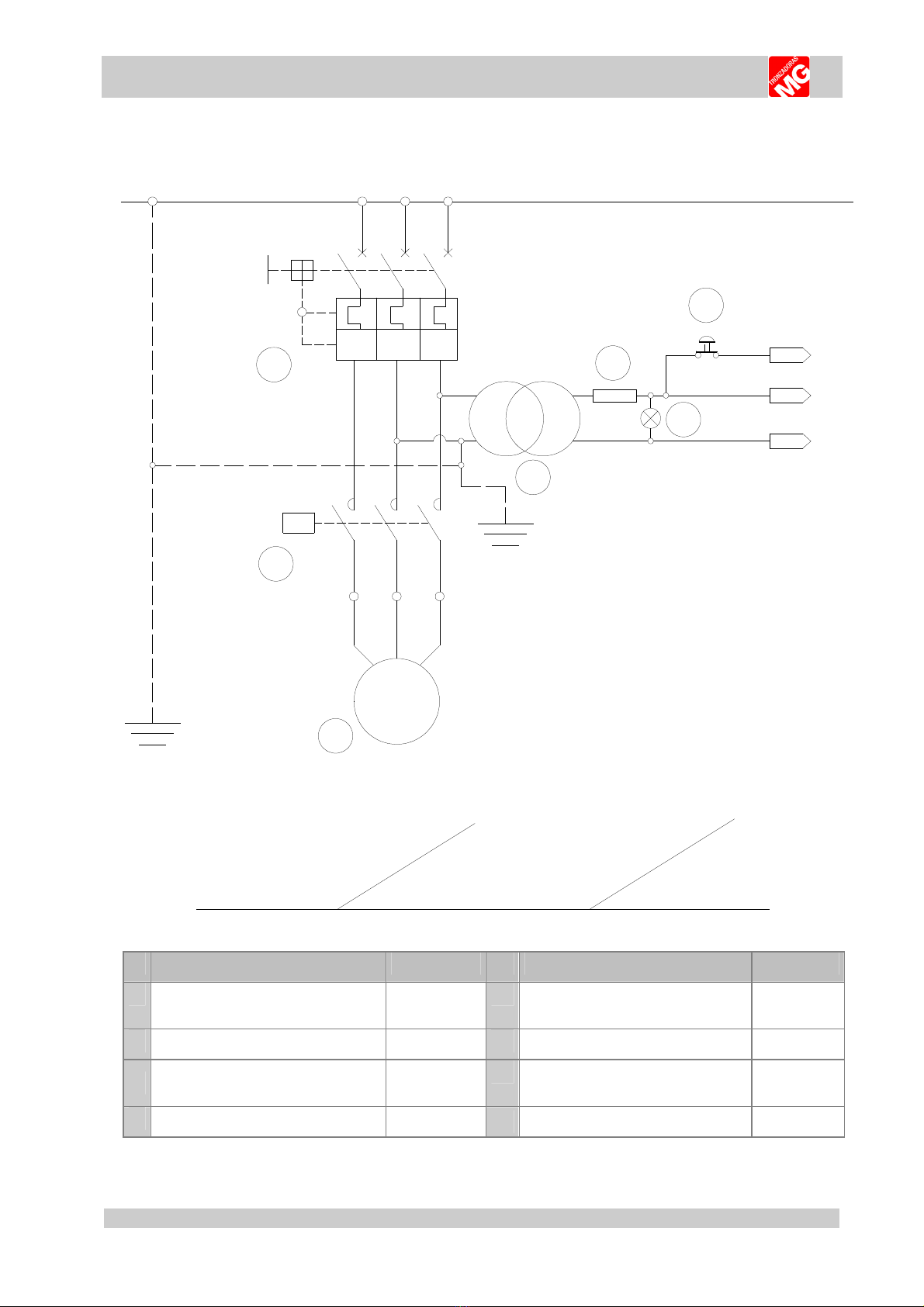

7. DRAWINGS AND SCHEMATICS. >>>

7.1. General schematic.

1

2

3

4

5

6

7

8

9

10

11

18

17

16

15

14

13

12

19

20

21

22

23

24

25

Nº DESCRIPTION CODE Nº DESCRIPTION CODE

1 Ø45 PNEUMATIC HOLD-DOWN CLAMP 2050000202 14 OLEONEUMATIC CONVERTER 2040000092

2 HORIZONTAL CLAMPS ØEXT 40 N00PTI4050 15 LEFT DOOR

3 ANGLE LOC 2040000482 16 PRESSURE REGULATOR N000000030

4 ADVANCE REGULATOR 3/8” N000000018 11 PROTECTIVE SHIELD SUPPORT

5 BLOW AIR DUSTER 18 PROTECTIVE SHIELD

6 2- POSITION SELECTOR 19

SHIELD END-OF-TRAVEL STOP

E00000BD25

7 GREEN INDICATOR E0000000030 20 TURRET

8 SAW BLADE ON-OFF 21 M10x40 LEVER B000091040

9 EMERGENCY 22 M14x40 SCREW + M14 NUT x (2)

10 GEEN VERTICAL ALINGMENT BUTTON 23 CE IDENTIFICATION

11 GENERAL SWITCH 24 FILTER+REG.+LUBRIC.+MANOM. N000000A17

12 SIDE DRAWER. CUTTINGS 25 SHEET METAL BASE

13 FEET LEVELERS

13

TL

-

6

00

-

A

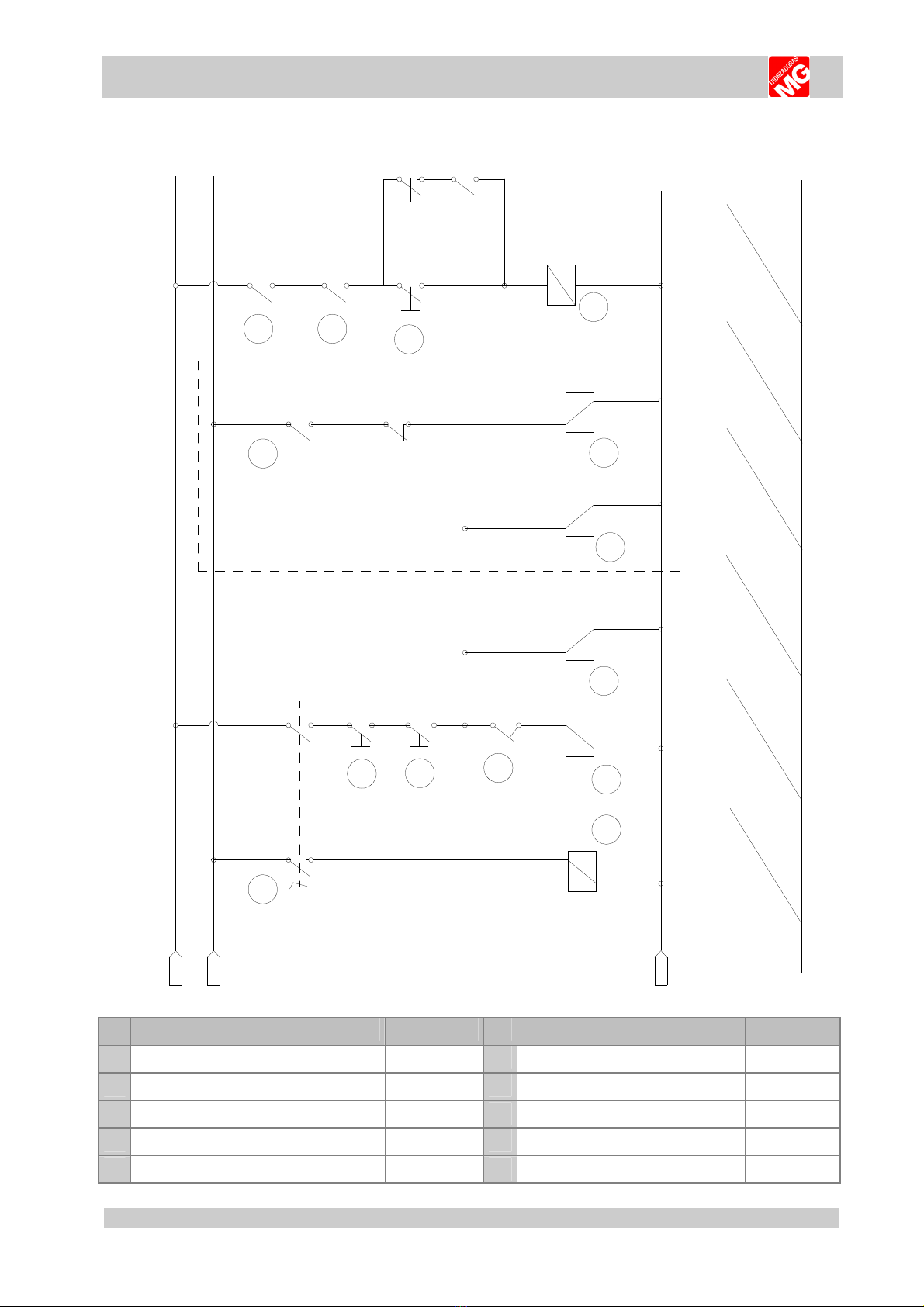

7.2. Power circuit.

L1 L2 L3

1L1 1L2 1L3

I> I> I>

M1

U1 V1 W1

QM1

KM1

~3Kw III 400V

3Kw III 220V

50/60 Hz

4,7A / 8,14A

380V --> 8A

220V --> 13A

50VA

2A

RS T

P

(380-220)V --> 24V

24

0

124

1

2

3

4

5

6

7

BRAKEMOTOR3Kw

Contactor

MAINSWITCH

FUSE

TRANSFORMER

50VA

M RG NCIA

L D T NSIÓN

Nº DESCRIPTION CODE Nº DESCRIPTION CODE

1 MAIN SWITCH 10A

MAIN SWITCH 16A

E000000004

E000000005

5 FUSE 2A E000000024

2 CONTACTOR T C9 24V 50/60HZ E000000034 6 EMERGENCY (NC) E000000G44

3 3 W MOTOR III 400V C/FRENO

3 W MOTOR III 220V C/FRENO

21600000M3

21600220M3

7 GREEN INDICATOR Ø17 VERDE 24V E000000030

4 TRANSFORMER 50VA - 24V E000000014

14

TL

-

6

00

-

A

124

24

124

124

24

1

Q1

Q3

Q2

11

124

3

4

5

12 13

KM1

14

6

7

126

125

8

13

12

12

9

10

10

11

14 15

OPENCLAMPS

BLADEROTATION

BLADEUP

CLAMPS

BLAD UP

BLAD UP

SHI LD

LAT RAL

DOOR

R AR

DOOR

START - STOP

BLAD

KM1

MAX-MINPRESURE

5B

0

124

24

0

R1

15

17

5

16

LOW R BLAD

R1

Q4

16

13

9

8

OPENSHIELD

RELAYOFRAISE

13

AUTOMATIC

SWITCHING POWER CIRCUIT

SHIELD

Nº DESCRIPTION CODE Nº DESCRIPTION CODE

8 2-POSITION SELECTOR E000000G71 13 5/2 WAYS MONO. ELECTROVALVE N000000A34

9 SHIELD END-OF-TRAVEL STOP E00000BD25 14 HIGH + LOW PRESSURE NEUMATIC N000000069

10 END-OF- TRAVEL M-12 E000000015 15 T C9 CONTACTOR 24V 50/60 Hz E000000034

11 SAW BLADE , ON-OFF E000000G75 16 MAGNETIC SENSOR MAGI 6,2 ECN T50RQD

12 GREEN PUSH-BUTTON NO E000000G50 17 RELAY BORNA 6MM + BASE 24VAC/DC E000000095

15

TL

-

6

00

-

A

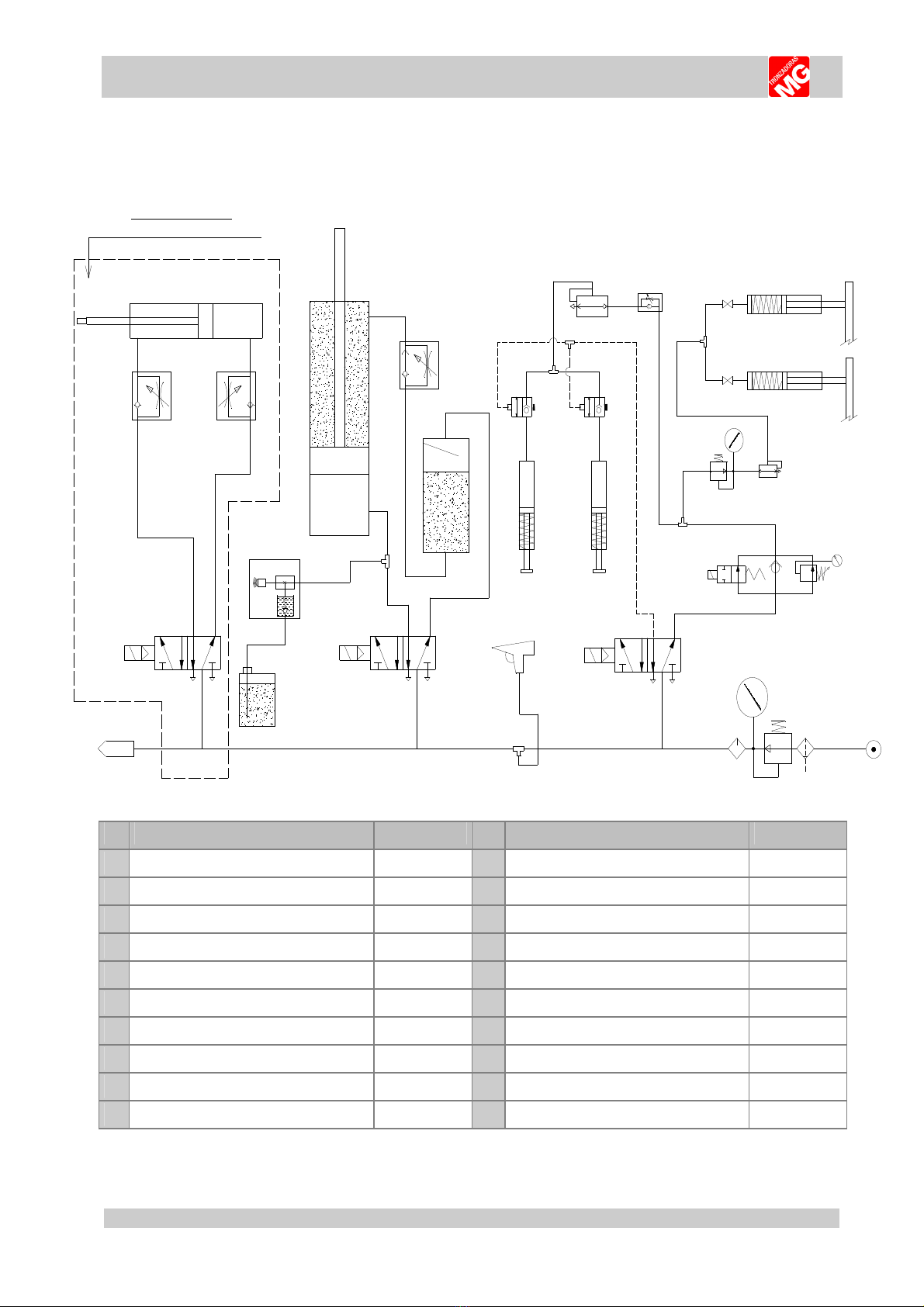

7.3. Pneumatic schematic.

51

42

51

42

EQ1

EQ2

LIN A

EQ3

00

01

02

03

05 04

06

06

08

09

1010

11 11

12

13

14

15

16

18

17

07

07

51

42

EQ4

13

TL-600-PLUS

AUTOMATIC SHI LD

Nº DESCRIPTION CODE Nº DESCRIPTION CODE

00 LINE -------------------- 10 UNI DIRECTIONAL VALVE 2/2 1/8” N000000015

01 F+R+L 1/4 “ N000000A17 11 VERTICAL CLAMPS Ø45 2040000212

02 5/2 WAYS MONO. ELECTROVALVE N000000A34 12 BLOW AIR DUSTER N000000010

03 HIGH+LOW PRESSURE NEUMATIC N000000069 13 5/2 WAYS MONO. ELECTROVALVE N000000A34

04 QUIC EXHAUST VALVE 1/8” N000000038 14

OLEONEUMATIC CONVERTER

2040000092

05 PRESSURE REGULATOR ¼” N000000030 15 OIL REGULATOR 3/8” N000000018

06 CLAMPING CYLINDER Ø40x320 N02PTI4050 16 CYLINDER ISO 50x200 N000000025

07 MINI BALL VALVE 1/8” M-H 2 20000281 17

VENTURI

N000000036

08 FLOW REGULATION 1/8" Ø6 CIL. N0CCRC1806 18

CUTTING OIL RESERVOIR

2060000383

09 QUIC EXHAUST VALVE 1/8” N000000038 19

16

TL

-

6

00

-

A

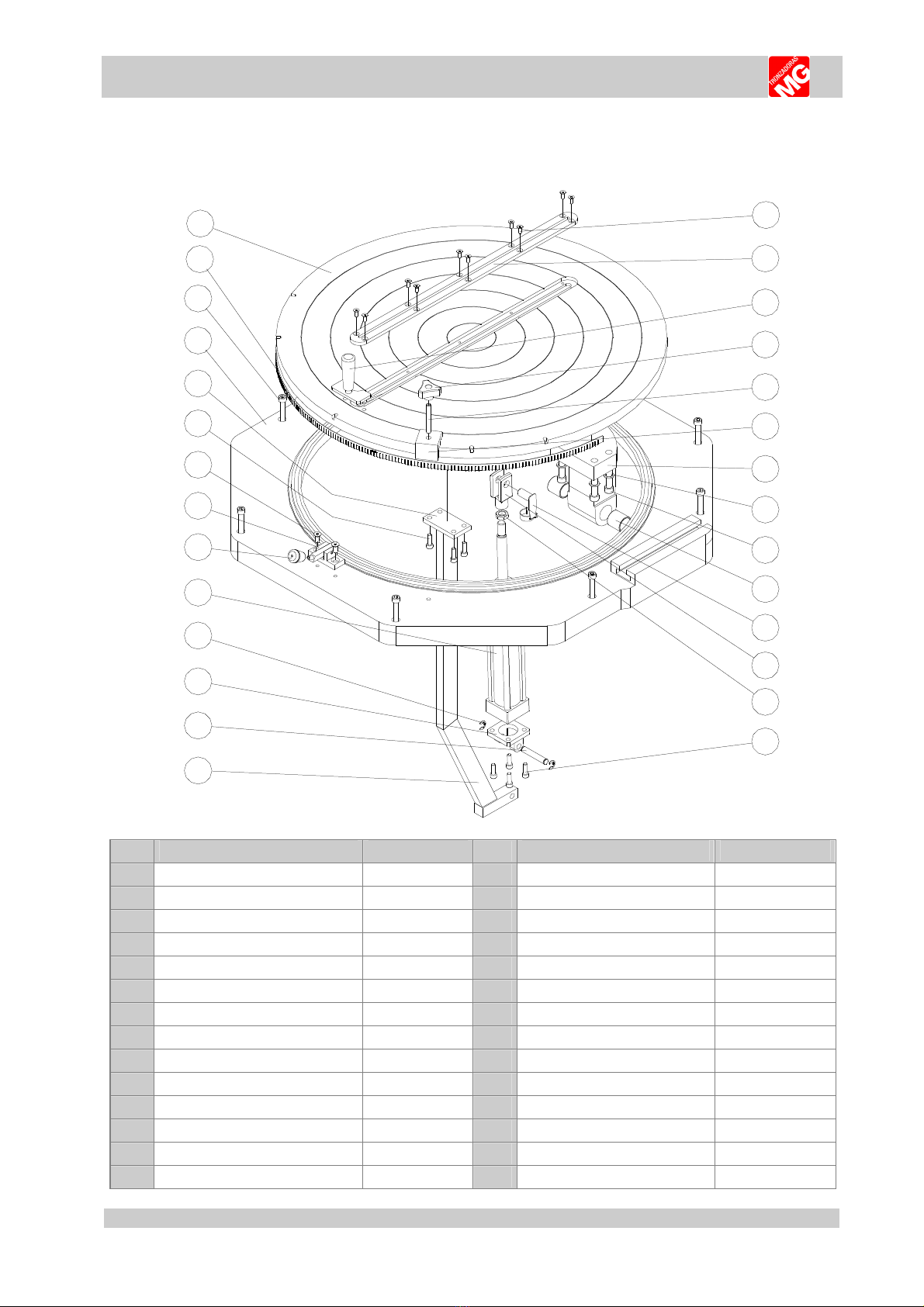

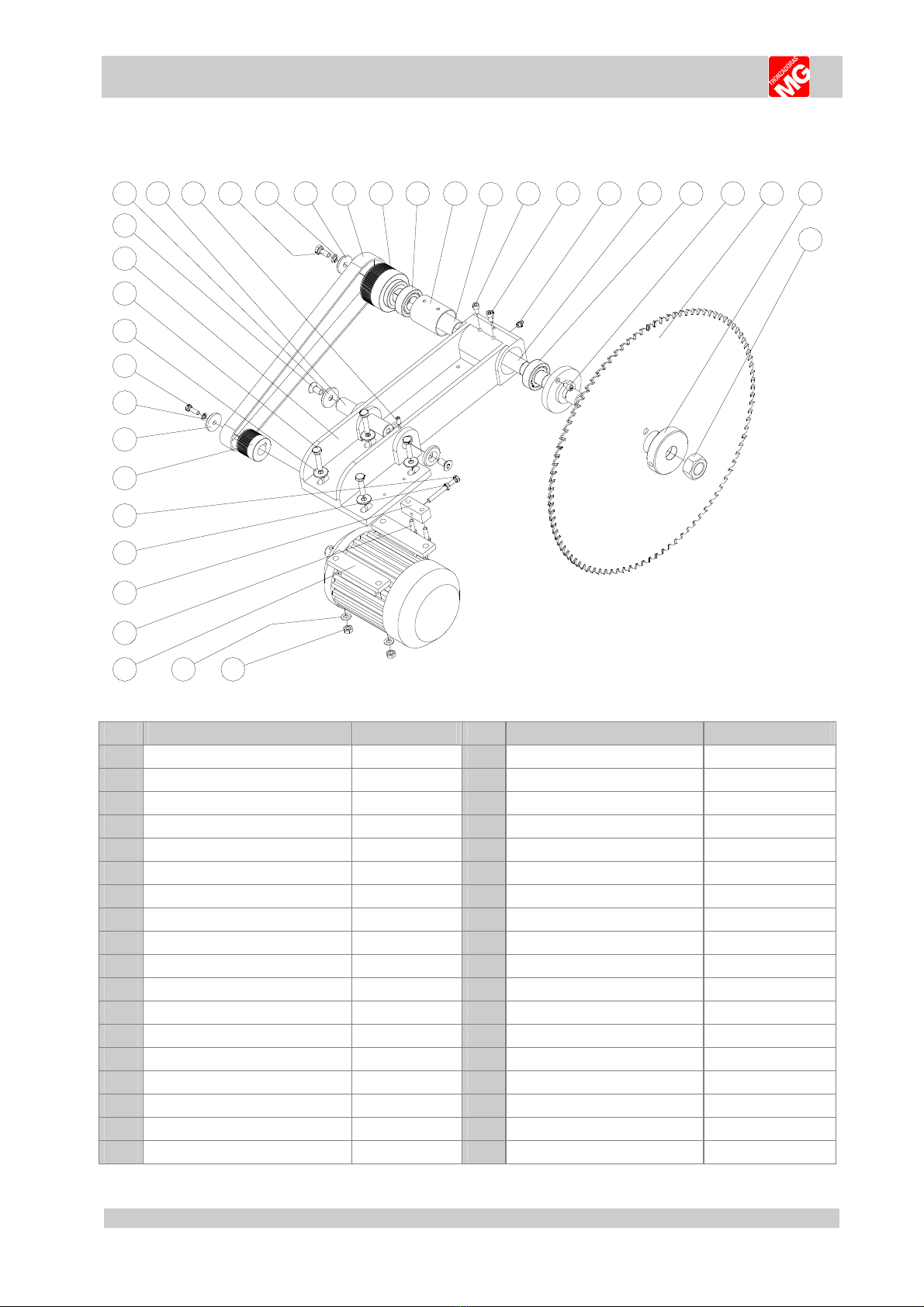

7.4. Exploded view cast iron table and disc assembly.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Nº DESCRIPTION CODE Nº DESCRIPTION CODE

1 DIN 7991 M6x16 SCREW TD79910616 15 POST

2 BLADE GROOVE 16 ISO 50 CYL. YO E N000000059

3 DEGREES TURN LEVER

2352000171

17 ISO 50 CYL. YO E N000000059

4 HANDLE TRISTAR M10

B0000000H2

18 STOP COLLAR CIL. ISO 50 N000000059

5 DIN 913 M10x70 SCREW TD91310070 19 ISO 50x200 CYLINDER N000000026

6 BRA E OF DEGREES 20 M8 NOB B000000011

7 ROC ER SUPPORT 21 ANGLE LOC 2040000482

8 DIN 128 Ø12 WASHER TD12800012 22 DIN 7991 M8x20 SCREW TD79910820

9 DIN 912 M12x50 SCREWS TD91212050 23 DIN 912 M8x25 SCREW TD91208025

10 AUTOLUBRICATED TIP 30-35-35 24 LEVER SUPPORT

11 ISO 50 CYL. FEMALE PIN JOINT N000000057 25 CAST IRON TABLE

216000F012

12 ISO 50 CYL. FEMALE PIN JOINT N000000057 26 DIN 912 M10x70 SCREW

TD91210070

13 DIN 934 M16 NUT TD93400016 27 INDICATOR OF DEGREES

2160000CG2

14 DIN 912 M8x25 SCREW TD91208025 28 CAST IRON DISC

2160000022

17

TL

-

6

00

-

A

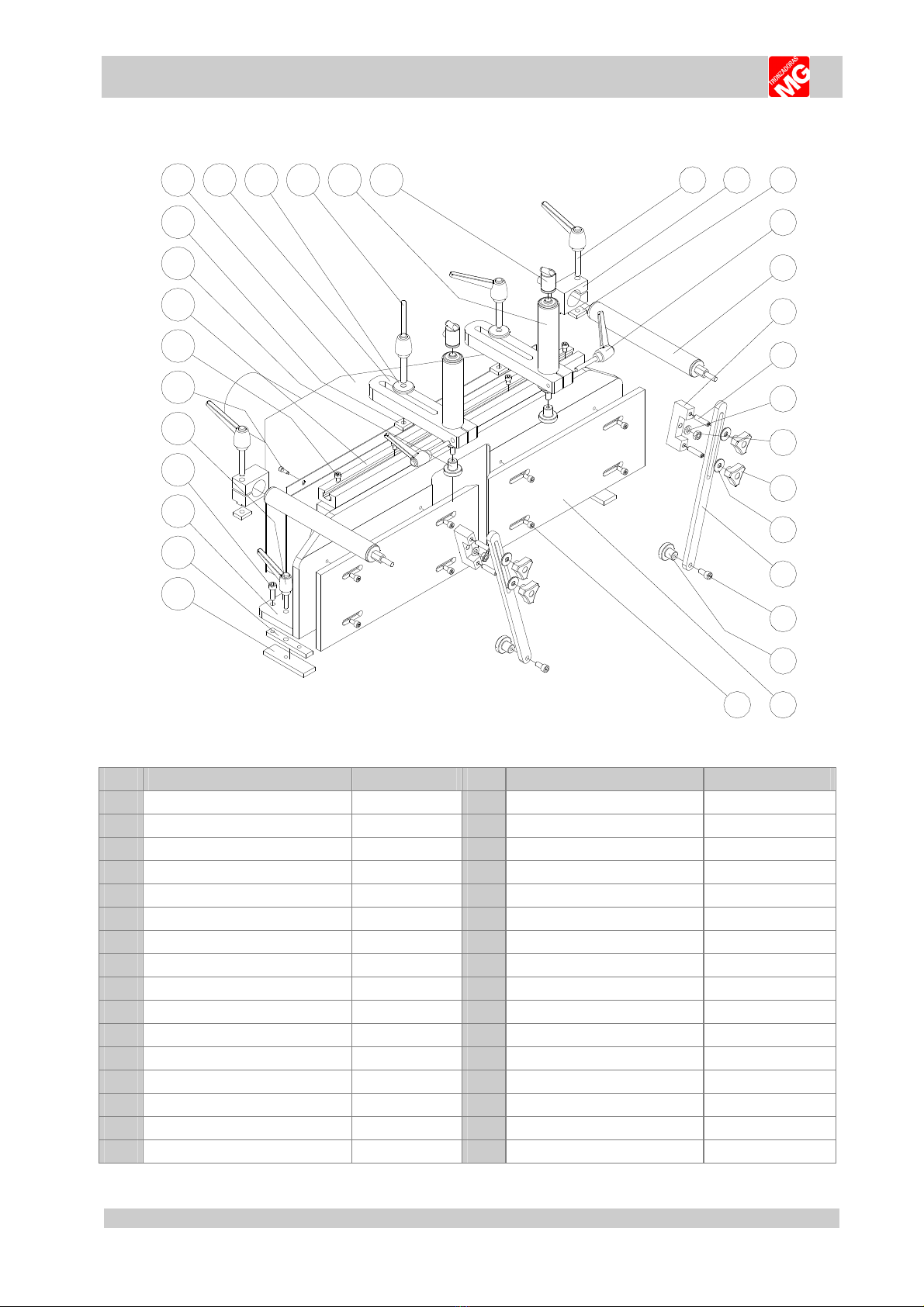

7.5. Exploded view rocker assembly.

1

23

45

6

7

89

10

11

1213

1415

16

17

181920

21

22

23

24

25

26

27

28

29

30

31

32

33 34 35

Nº

DESCRIPTION CODE Nº

DESCRIPTION CODE

1

DIN 934 M30

NUT

TD93400030

19

CONNECTING ROD PIN

2

BLADE WASHER

2040000042

20

Ø45x7 AVELL. M12

WASHER

216000A452

3

WIDIA BLADE

Ø600xØ50x5

205DW60032

21

DIN 7991 M12x25

SCREW

TD79911225

4

DIN 912 M8x12

SCREW

TD91208012

22

CAST IRON ROC ER

TL

-

600

2160000032

5

4206

BEARING

2040000172

23

DIN 933 M10x50

SCREW

TD93310050

6

Ø30 SHAFT

2040000102

24

Ø10 INT. PISAD.

WASHER

204000A401

7

LUBRICATOR

1/8”

2070

000012

25

DIN 933 M8x25

SCREW

TD93308025

8

DIN 912 M6x10

SCREW

TD91206010

26

DIN 128 Ø8

WASHER

TD12800008

9

DIN912 M8x16

SCREW

TD91208016

27

Ø40x

Ø8x

6mm

WASHER

204000A402

10

Ø36

SEPARATOR

2040025582

28

MOTOR PULLEY

11

Ø60

SEPARATOR

2040060582

29

D

IN933 M8x80

SCREW

TD93308080

12

4206

BEARING

2040000172

30

DIN934 M8

NUT

TD93400008

13

ROC ER SHAFT PULLEY TL

-

600

31

BELT TENSION ADJUSTER

14

960

J12

POLY

-

V BELT

32

DIN 912 M8x30

SCREW

TD91208030

15

Ø40xØ10x6mm

WASHER

204000A401

33

4HP III P

HASE MO

TOR

21600000M3

16

DIN 128 Ø10

WASHER

TD128000010

34

DIN 125 Ø10

WASHER

TD125000010

17

DIN 933 M10x25

SCREW

TD93310025

35

DIN 934 M10

NUT

TD93400010

18

DIN 913 M8x16

SCREW

TD91308016

18

TL

-

6

00

-

A

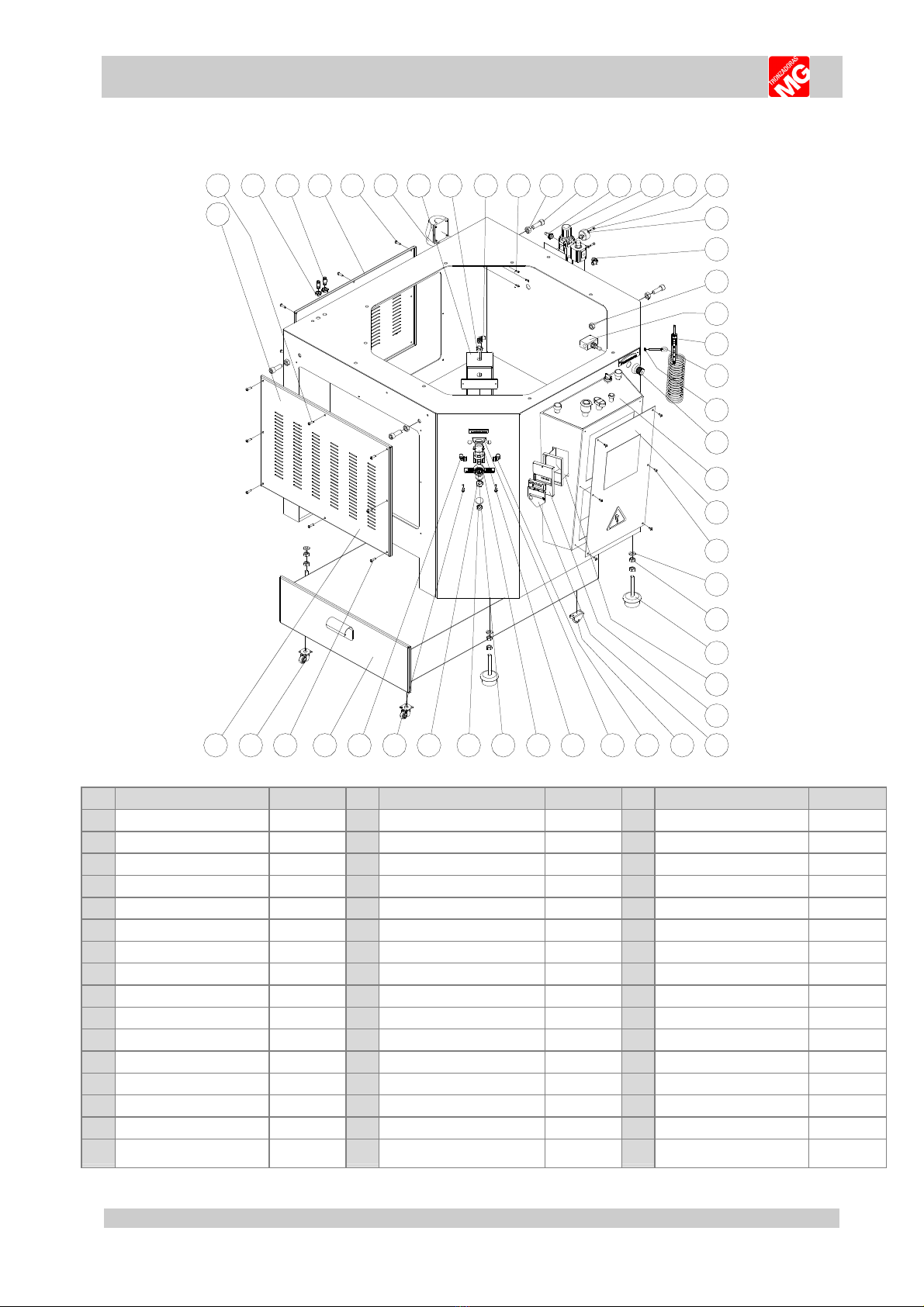

7.6. Exploded view turret assembly.

1

2

3

4

5

6

7

8

9

12 13 14 15 16 17 18 19

20

21

22

23

24

25

26

27

28

29

30

10

11

3132

Nº

DESCRIPTION

CODE

Nº

DESCRIPTION

CODE

1

LOC GUIDE PLATE

17

M12x70

LEVER

B0000P1270

2

TURRET COTTER

18

ALUMINIUM ROD. HOR. CLAMP

204000A502

3

IRON TURRET

19

FLAT NUT M12

4

DIN 912 M10x30

SCREW

TD91210030

20

M10x60

LEVER

B0000P1060

5

M

10x40

LEVER

B000091040

21

HORIZONTAL CLAMP

Ø40x160

N00PTI4050

6

DIN 912 M6x16

SCREW

TD91206016

22

SUPPORT OF DRAWER

.

7

DIN 912 M8x12

SCREW

TD91208012

23

D913 M10x40

TD93310040

8

CLAMPS ALUMINIUM GUIDE

24

D125 Ø10

WASHER

TD12500010

9

NYLON CLEAT BLA

C

M10

2350000131

25

D934 M10

NUT

TD93400010

10

FLAT NUT M12

26

HANDLE

TRISTAR HEMBRA M10

B0000000H2

11

TURRET PROTECTOR

27

Ø20

-

Ø10 WASHER

2130000011

12

Ø45 ALUMINIUM ROD

28

HORIZONTAL CLAMPS ARM

13

Ø45

-

Ø12 WASHER

204000A401

29

DIN 912 M10x20

SCR

EW

TD91210020

14

M12x70

LEVER

B0000P1270

30

NYLON CLEAT BLAC

M10

2350000131

15

PNEUMATIC CLAMPS

Ø45x115

2040000212

31

ALUMINIUM PLATES

TL

-

600

16

SECURITY VALVE

N000000015

32

DIN 912 M8x16

SCREW

TD91208016

19

TL

-

6

00

-

A

7.7. Exploded view sheet metal base.

1

234 5 678910 11 12 13 14 15 16 17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34353637

38

3940

41

4243

4445

46

47

48

Nº

DESIGNATION

CODE

Nº

DESIGNATION

CODE

Nº

DESIGNATION

CODE

1

LEFT DOOR

17

D912 M5x16

SCREW

TD91205016

33

COVER BOX SWITCH

2

ISO7380 M6x20

SCREW

TI73800620

18

D128 Ø5

WASHER

TD12800005

34

CLOSING PADLOC S

3

D934 M14 NUT

TD93400014

19

MALE STUD ELBOW 1/4 - Ø8

N000CC1408

35

WHEEL FIXES

PP Ø30

216000030F

4

CONNECT

Ø6

-

Ø6

2050000262

20

D934 M14 NUT

TD93400014

36

MALE STUD ELBOW 1/4 - Ø6

N000CC1406

5

BAC DOOR

21

OIL

REGUL

ATOR

.

3/8”

N000000018

37

SQUARE REGULATOR

N00000

0E30

6

ISO7380 M6x20

SCREW

TI73800620

22

CLEANING GUN WITH HOSE

N000000021

38

D912 M5x10

SCREW

TD91205010

7

THREE

-

PHASE BASE

E000000022

23

SUPPORT

M6

T0000000H6

39

PRESURE REGULATOR

1/4”

N000000030

8

OLEONEUMATIC CONV.

24

D934 M6

SCREW

TD93400006

40

Ø40

MANOMETER

N000000020

9

REDUCTION

1/2M

–

1/4H

N00RHM1412

25

OIL REGULATOR

NOB

B000003823

41

METAL STOPPER

GAS 3/8”

N0000TA012

10

MALE STUD ELBOW 1/4 - Ø8

N000CC1408

26

CONTROL PANEL

42

METAL STOPPER GAS 3/8

”

N0000TA012

11

D912 M4x10

SCREW

TD91

204010

27

COVER CONTROL PANEL

43

D912 M6x16

SCREW

TD91206016

12

D934 M14 NUT

TD93400014

28

ISO 7380 M5x10 SCREW

TI73800510

44

MALE STUD ELBOW 1/4 - Ø6

N000CC1406

13

D912 M14x40

SCREW

TD91214040

29

D125 Ø12

WASHER

TD12500012

45

BOOTH OF SHAVING

14

ADA

PTOR

¼

”

Ø8

N0000E0914

30

D934 M12

NUT

TD93400012

46

ISO7380 M6x20

SCREW

TI73800620

15

F+R+L 1/4”

N000000017

31

FOOT LEVELER M12

2FR450B003

47

WHEEL

Ø30

216000030P

16 Ø40 MANOMETER N000000020 32 BOX SWITCH E0000000M6 48 LEFT DOOR

20

TL

-

6

00

-

A

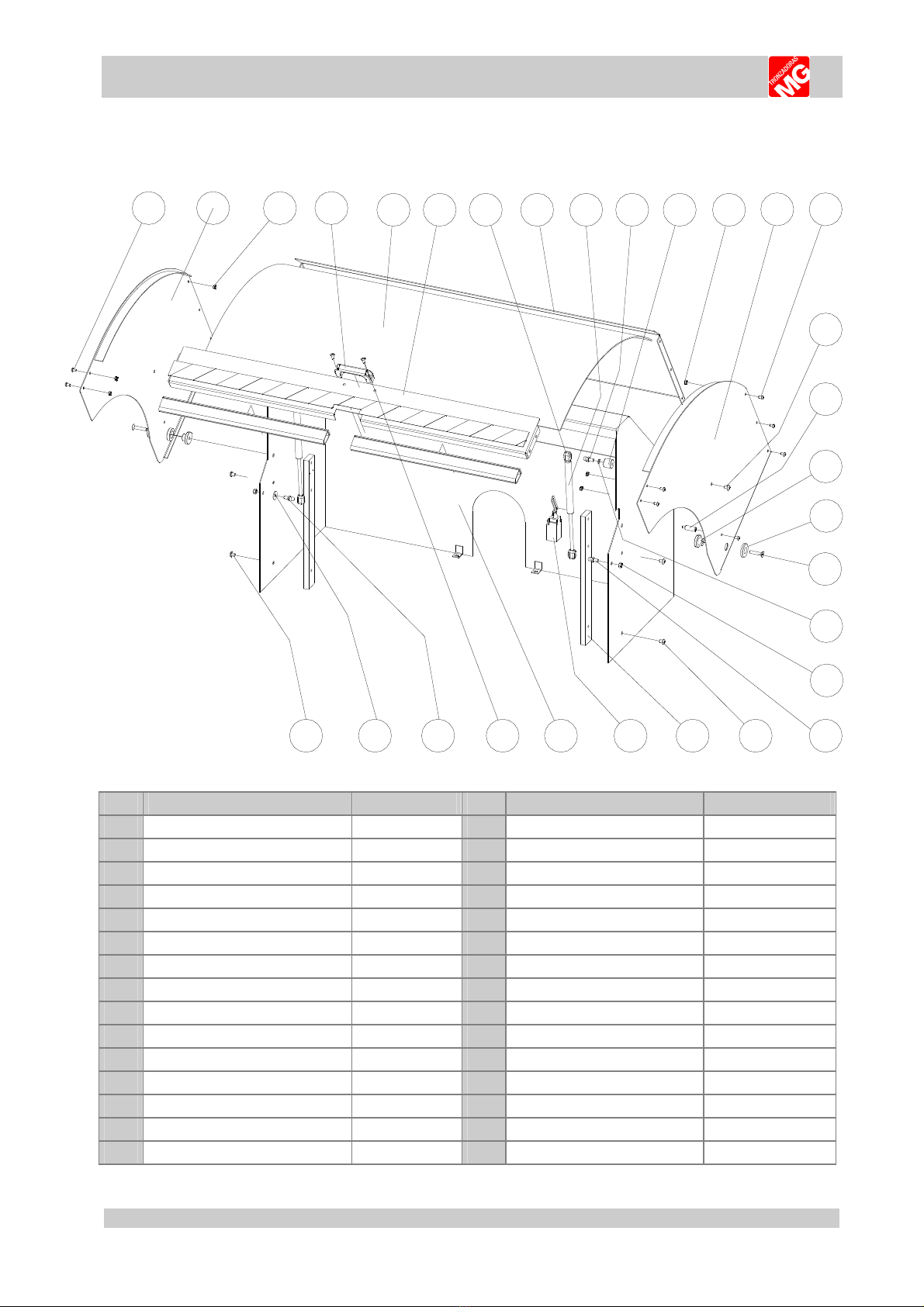

7.8. Exploded view protective shield.

12 3 456789

10 11 12 13 14

15

16

17

18

19

21

2223242528 262930

20

27

Nº

DESCRIPTION

CODE

Nº

DESCRIPTION

CODE

1

ISO

-

7380 M6x10

SCREW

TI73800610

16

FINAL GUIDE OF

END

-

OF

-

TRAVEL

-----------------

2

LEFT PROTECTIVE SHIELD

-----------------

17

CONNECTING ROD PIN P. SHIELD

-----------------

3

DIN

-

934 M6

NUT

TD93400006

18

Ø40x6 AVELL. M8

WASHER

204000A401

4

M8

HANDLE

B000000015

19

DIN 7991 M8x40

SCREW

TD79910840

5

1090x670x3

METHECRYLITE

2160000142

20

DIN 125 Ø8

WASHER

TD12500008

6

FRONT CLOSING

-----------------

2

1

DIN

-

985 M8

NUT

TD98500008

7

SWIBEL JOINT

204000R452

22

BALL SCREW

Ø10 M8

20400TB452

8

ABOVE CLOSING

----------------

23

ISO

-

7380 M6x10

SCREW

TI73800610

9

SHOC ABSO.

R300

-

L125

-

250N

2160000300

24

SHIELD POST

-------------------

10

BALL SCREW

Ø10 M8

20400TB452

25

END OF

TRAVEL

E00000BD25

11

SEPARATOR M8x20 Ø25mm

---------------

26

PROTECTIVE SHIELD SUPPORT

-------------------

12

DIN

-

934 M6

NUT

TD93400006

27

DIN 912 M6x16 + DIN 934 M6

TD91206016

13

RIGTH PROTECTIVE SHIELD

-------

---------

28

BALL SCREW

Ø10 M8

20400TB452

14

ISO

-

7380 M6x10

SCREW

TI73800610

29

DIN125 Ø8

WASHER

TD12500008

15

ISO

-

7380 M8x10

SCREW

TI73800810

30

ISO

-

7380 M6x10

SCREW

TI73800610

Table of contents

Popular Saw manuals by other brands

Central Machinery

Central Machinery 97099 Set up and operating instructions

Toolex

Toolex 532215 instruction manual

Scheppach

Scheppach Special Edition HS 720 Translation from original manual

Metabo

Metabo KGS 303 PLUS Original operating instructions

Sears

Sears 113.244200 owner's manual

Stanley

Stanley STEL701 instructions

CUTS DIAMANT

CUTS DIAMANT MC 301 User and maintenance manual

Craftsman

Craftsman 172.10865 12 Amp Operator's manual

Charnwood

Charnwood SS16F owner's manual

Stanley

Stanley Fatmax SFMCS701 Original instructions

Craftsman

Craftsman 113.196421 owner's manual

King Industrial

King Industrial KC-1433FXR instruction manual