Tropicair KOWHAI Mk3 User manual

Revised February 2017

HEATING Ltd

Over

40

years experience in heating manufacture

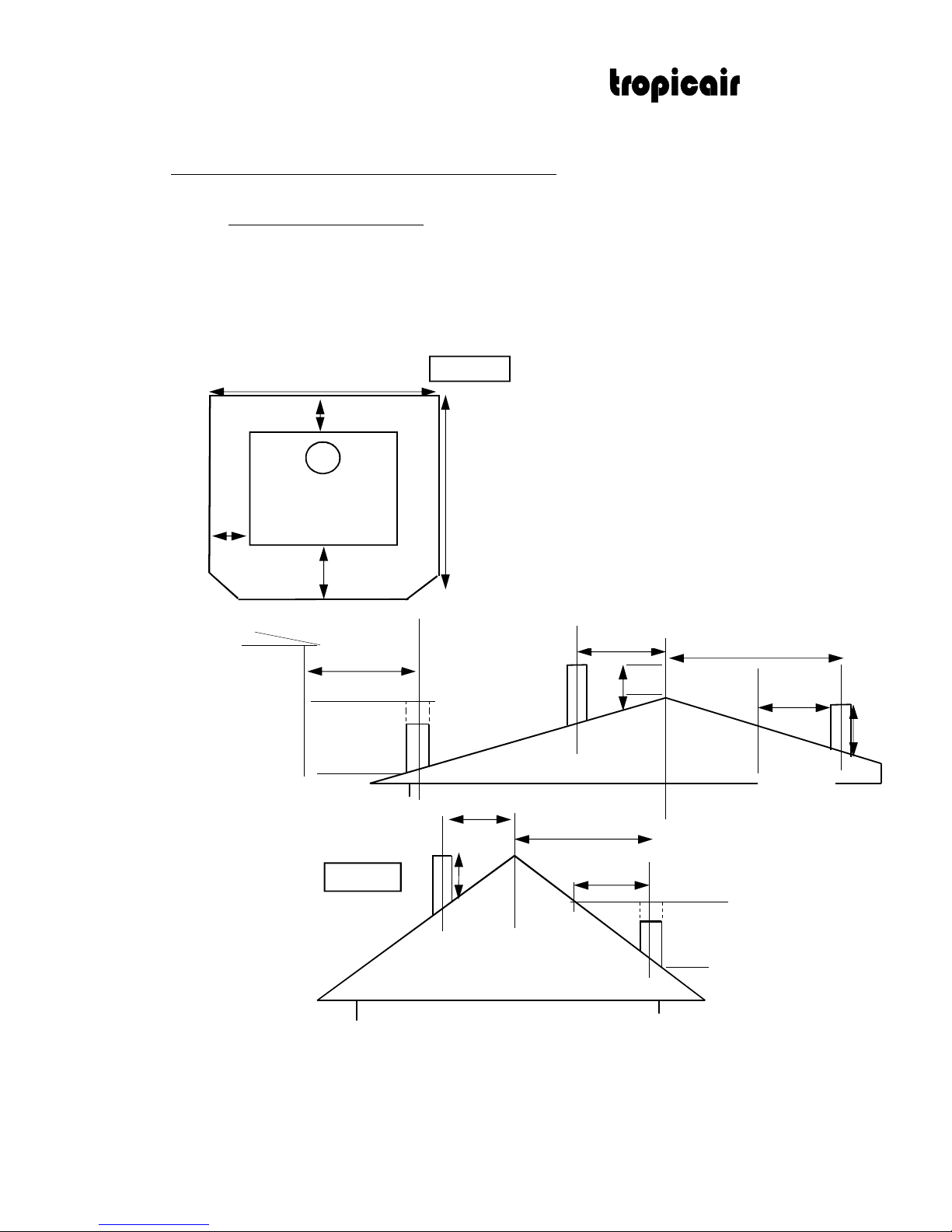

a. A minimum of 4m of the flue height is recommended for the correct flue draft. [i.e.4600mm minimum overall height from the (floor

protector) hearth]

b. In case of a pitched roof the chimney shall extend not less than 600mm above the highest point of the roof.

c. All parts of the chimney exposed to the outside air shall be suitably insulated in accordance with Tropicair Heating Ltd’s

recommendation.

d. Where possible install our Tropicair flue kit with the unit. (or a flue kit which complies with NZS7421:1990)

e. When deciding the position of the unit try to avoid unnecessary complications in the ceiling. i.e. rafters, beams, valleys and ridges.

600m

in.

3000 or less

600m

in.

100mm

I. GENERAL INFORMATION.

a. The installation must comply with local council regulations.

b. It is recommended that the woodburner be installed by a registered plumber or a NZ Home Heating Association qualified

heating installer, who should work in accordance with good trade practice.

c. The unit should be installed in such a manner that parts are accessible for inspection and maintenance

d. A suitable fire extinguisher should be installed on the premises.

1000mm

900mm

II. ASH HEARTH

III. FLUE HEIGHT.

1000 min. if clear

within

3000 of flue top

fig. 2

1

.

300mm

50mm

fig. 1

3000 or less

more than 3000

more than 3000

increase from 1000

min. until clear

within

3000 of flue top

3000

3000

3000

nearby

structure

increase as nec.

until nothing

within 3000 of

flue top

Installation Instructions for KOWHAI Mk3 (in accordance with AS/NZS2918:2001)

AUTHORISATION NUMBER: 090722

1. An ash hearth shall must be 300mm in front of the firebox and

100mm at each side. Measured as per AS/NZS2918:2001

2. A woodburner must have a minimum of 1 metre clearance in

front of any building structure or any other substantial

immovable object.

3. Minimum Corner hearth size 1120mm x 1120mm

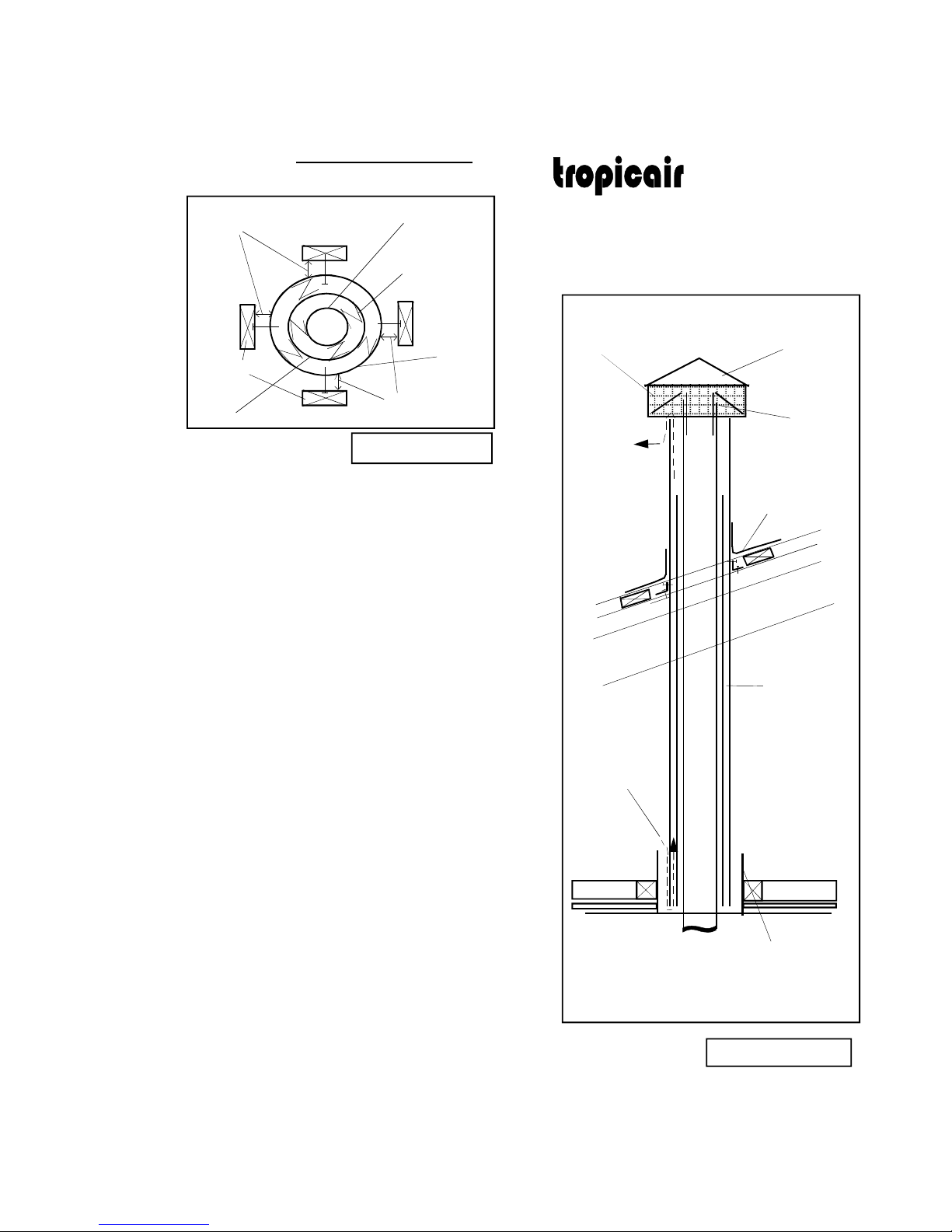

Installing the

TROPICAIR

FLUE

kit

150mm flue

200mm

liner

Timber

250mm

liner

centralising z

brackets

fig. 3 Plan View

fig. 4 cross-section

cooling

air

OPTIONAL

secondary

300mm

Shield

AQUASEAL

or LEAD roof

flashing

cowl

150mm

flue

To

outside

250mm

liner

optional

bird-proof

netting

2.

25mm

air gap

25mm

air gap

HEATING Ltd

Over 35 years experience in heating manufacture

1. Position the heater on floor, drop a plumb line

from the ceiling to the centre of the unit collar

to mark the position where the flue will pass

through the ceiling.

2. Cut a 300mm diameter hole in the ceiling and

roof above, and frame timber around both

300mm holes, to support heat shield liners.

3. Fix 300 mm diameter x 240mm long shield

(provided in flue kit) to timber framing. Allow

shield to penetrate inside the room for 5mm.

4. Position the 250mm liner inside the fixed shield

and fasten to timber top and bottom. (with

bracket supplied and 25mm clear of timber)

5. Fasten the flue together with stainless steel

pop-rivets (swagged end of the flue at bottom)

and drop through liner into the heater spigot.

At this stage the ceiling plate should be fitted

through flue and can be lifted up and screwed on.

6. Flash the roof to the galvanised liner with appropriate

Flashing (Varies from council to council)

7. Where the chimney extends more than 1.2m-2m above

roof penetration (council depending), it will require restraining

aluminium stays.

8. After installation of the flue, the installer is to

ensure the unit is level and fixed securely to the floor

using seismic restraints (8mm dynabolts or flush head

sleeve anchors) fitted at the rear.

F

100mm

C

425mm

I

425

I

100

C

D

175mm

B

50mm

fig. 7

corner clearances

fig. 5

side clearances

A

455mm

V. CLEARANCES for Kowhai Mk III

fig. 6

back clearances

D

E

G

J

3

.

H

HEATING Ltd

Over 35 years experience in heating manufacture

SPECIFICATIONS for KOWHAI Mk III

FIREBOX DIMENTIONS / MATERIAL

450mm x 350mm / 6mm plate steel

SECONDARY COMBUSTION AIR standard equipment

MAXIMUM LOG LENGTH 460mm

HEAT OUTPUT MAXIMUM 18kw

HEAT OUTPUT LOW AVERAGE 9.5kw

EFFICIENCY MAXIMUM 76%

EFICIENCY OVERALL AVERAGE 71.8%

DOOR OPENING SIZE 390mm x 270mm

GLASS SIZE / MATERIAL 325mm x 195mm/5mm Robax

ceramic

CONTROLS single slide top front right

FLUE DIAMETER / MATERIALS 150mm / 24g T304 stainless steel

HEIGHT OF STANDARD FLUE KIT 3 x 1200mm flues

CLEAN AIR TESTING AS/NZS 4012:1999 passed 71.8%

AS/NZS 4013:1999 passed 0.89g/kg

APPLIANCE WEIGHT 88kg

COOKING FACILITY standard

COLOUR CHOICE black,brown,grey,green,navy

WARRANTY 5 years

MINIMUM ASH HEARTH SIZE 900mm wide x 1000mm deep

MINIMUM CORNER ASH HEARTH

1100mm X 1100mm

HEATING Ltd

Over 35 years experience in heating manufacture

A SIDE OF

WOODBURNER TO WALL

4

45

mm (shielded flue)

B BACK OF WOODBURNER TO WALL 50mm (shielded flue)

C REAR CORNER OF WOODBURNER TO WALL 100mm (shielded flue)

D CENTRE FLUE TO BACK OF WOODBURNER 175mm

E FIRE OVERALL HEIGHT 710mm

F FIRE OVERALL DEPTH 590mm

G OVERALL WIDTH 560mm

H CENTRE FLUE TO WALL 225mm See Appendix A (1)

I CENTRE FLUE TO WALL - CORNER SITUATION 425mm See Appendix A (1)

J DIAMETER OF FLUE SPIGOT 150mm

CLEARANCE FROM COMBUSTIBLES & DIMENSIONS (figs. 5,6 &7)

~ Special Conditions

(1) Flue Center Measurements

Flue center measurements as tested for this appliance under AS/NZS2918:2001 Appendix F in the standard orientation

(back of appliance parallel to wall) has a tested center measurement of 225mm. In a corner environment the flue center at

the heater flue outlet is 425mm. This measurement should be treated as indicative to centering the logfire as actual safe

tested clearance is permitted down to 225mm at the heater flue outlet regardless of orientation Eg: a corner install could

be offset at or above the appliance to arrive at a 225mm flue center with standard 1200mm flue shield altered to give

cover down to the appliance.

(2) Offsets

Offsetting as long as it is after the first 1200mm flue length, which has been fitted with specified minimum 1200mm single

skin shield (Multi skinned shields acceptable) As per AS/NZS2918:2001 4.5.2 is found to have “Cooled Considerably”, and as

such we are happy for offsets up to 150mm to center from combustibles to be used without shielding. Should the required

offset shift the flue center closer than 150mm toward combustibles, then shielding to the wall must be used. This has been

determined through both historic experience and parameters within the standard.

It is important to note that while combustible temperatures may not be significant enough to cause rise above ambient of

65 Degrees C as set out in the standard’s Appendix F, Prolonged exposure to heat may cause wall linings and furnishings to

tarnish, deform or discolour over time and this should be considered when offsetting.

(3) Alcoves

Though this unit has not been tested in a combustible lined alcove specifically, The unit has been tested to Appendix B of

AS/NZS2918:2001 for side clearance to a left or right adjacent wall. The alcove being simply an adjacent wall to the left

and right should be factored as follows.

An alcove of 1460mm is the smallest permitted alcove at standard clearances for this model fire (445mm Left clearance +

560mm fire width + 445mm right clearance + 10mm Variable).

Wall shields shielding side or rear walls can reduce these clearances as appropriate under the standard’s Section 3.2.3 table

3.1 and 3.2

Horizontal surface at the top of an alcove must be a minimum of 2210mm above floor protector (1500mm + Heater top face

710mm). Clearances can be reduced through shielding as per Section 3.2.3 Table 3.1 and 3.2

If building the alcove we would recommend the top of the alcove be built with a slope between 5-15 degrees to assist

convection. Alcoves with shielded walls may funnel more heat up to the ceiling and a sloped ceiling or a Larger 600mm x

600mm should be used where practical. Using Eterpan or a similar non combustible lining would reduce the need for an

oversized ceiling plate.

(4) Front clearance

Tropicair fires can have the 300mm front clearance measured from the bottom lip of the firebox opening with the door in

an open position as per AS/NZS2918:2001 Section 3, 3.3.2

(5) Triple skinned Offsets

TS Offsets are an acceptable alteration as long as all clearance factors (25mm to combustibles) are adhered to at all times,

the flue remains concentric inside the offset and all skins (150 – 200 – 250) are used in there entirety.

(6) Installations

While it is not required by law that this appliance is installed by an NZHHA accredited SFAIT installer failure to

install this appliance and flue system to the specified standard or applicable acceptable standard AS/NZS2918:2001

may affect performance and warranty of this product in the future.

This instruction can be used for the Kowhai 2000 including Wetback model

Table of contents