Trox EASYLAB TCU3 Series User manual

EASYLAB controller

Serie TCU3

Installation and operating manual GB/en

M375EV0, 2, GB/en

© TROX GmbH 2017

TROX GmbH

Heinrich-Trox-Platz

47504 Neukirchen-Vluyn

Germany

Telephone: +49 (0) 2845 202-0

Fax: +49 (0) 2845 202-265

E-mail: [email protected]

Internet: www.trox.de

06/2019

EASYLAB controller Serie TCU3

2

1 General information................................... 4

2Safety and correct use.............................. 6

General safety notes.................................... 6

Correct use.................................................. 7

Incorrect use................................................ 7

Residual risks............................................... 7

3 Technical data............................................ 8

4 Transport, storage and packaging......... 10

Delivery check............................................ 10

Transport on site........................................ 10

Storage...................................................... 10

Packaging.................................................. 10

5 Product description................................. 11

Volume flow control.................................... 11

Volume flow rate monitoring....................... 11

Pressure monitoring................................... 11

Shut-off monitoring..................................... 11

External signaling of setpoint deviation..... 12

Interfaces and signal lamps on the con-

troller casing............................................... 13

Interfaces and signal lamps in the con-

troller casing............................................... 15

6 Installation................................................ 17

Tube connection on the pressure trans-

ducer.......................................................... 20

7 Wiring........................................................ 20

Safety instructions...................................... 20

Notes on wiring.......................................... 21

Additional information on wiring................. 21

Limited voltage supply............................... 21

Polarity of the power supply....................... 21

Functional earth......................................... 21

Strain relief................................................. 21

Cabling....................................................... 21

8 Commissioning........................................ 22

9 Maintenance............................................. 25

Safety......................................................... 25

Operation and maintenance...................... 25

Zero point correction.................................. 25

Replacing the fuse..................................... 25

10 Decommissioning.................................... 26

Removing the electronic controller............. 26

11 Appendix................................................... 27

Table of contents

EASYLAB controller Serie TCU3 3

1 General information

About this manual

This manual enables operating and service per-

sonnel to correctly install the EASYLAB TCU3 con-

troller and to use it safely and efficiently.

The TCU3 electronic controller is used with a VAV

terminal unit; both products together form a func-

tional unit.

Depending on the scope of order, the electronic

controller can be equipped with optional expansion

modules (EM-xx) at the factory (retrofitting pos-

sible).

This operating and installation manual is intended

for use by fitting and installation companies, in-

house technicians, technical staff, instructed per-

sons, and qualified electricians or air conditioning

technicians.

It is essential that these individuals read and fully

understand this manual before starting any work.

The basic prerequisite for safe working is to comply

with the safety notes and all instructions in this

manual.

The local regulations for health and safety at work

and general safety regulations also apply.

This manual must be given to the system owner

when handing over the system. The system owner

must include the manual with the system documen-

tation. The manual must be kept in a place that is

accessible at all times.

Illustrations in this manual are mainly for informa-

tion and may differ from the actual design. Discrep-

ancies cannot be used to make any claims against

the manufacturer.

In addition to this manual, the following documents

apply

Operating manual

– EasyConnect configuration software

Installation manual for VAV terminal unit(s)

Installation manuals for EASYLAB components

– Expansion module EM-AUTOZERO

– Expansion module EM-LIGHT

– Expansion module EM-TRF/EM-TRF-USV

– Expansion module EM-LON

– Expansion module EM-BAC-MOD

– Expansion module EM-BAC-IP

– Control panel BE-LCD

– Control panel BE-SEG

– Face velocity transducer VS-TRD

– Sash distance sensor DS-TRD

General wiring documents

Project-specific wiring documents

All documents can be downloaded from

www.troxtechnik.com.

Project-specific information is provided together

with the order confirmation or delivered together

with the product.

TROX Technical Service

To ensure that your request is processed as quickly

as possible, please keep the following information

ready:

Product name

TROX order number

Delivery date

Brief description of the fault

Online www.troxtechnik.com

Phone +49 2845 202-400

General information

EASYLAB controller Serie TCU34

Limitation of liability

The information in this manual has been compiled

with reference to the applicable standards and

guidelines, the state of the art, and our expertise

and experience of many years.

The actual scope of delivery may differ from the

information in this manual for bespoke construc-

tions, additional order options or as a result of

recent technical changes.

The obligations agreed in the order, the general

terms and conditions, the manufacturer's terms of

delivery, and the legal regulations in effect at the

time the contract is signed shall apply.

Defects liability

For details regarding defects liability please refer to

Section VI, Warranty Claims, of the Delivery and

Payment Terms of TROX GmbH.

The Delivery and Payment Terms of TROX GmbH

are available at www.troxtechnik.com.

Copyright

This document, including all illustrations, is pro-

tected by copyright and pertains only to the corre-

sponding product.

Any use without our consent may be an infringe-

ment of copyright, and the violator will be held liable

for any damage.

This applies in particular to:

Publishing content

Copying content

Translating content

Microcopying content

Saving content to electronic systems and

editing it

Safety notes

Symbols are used in this manual to alert readers to

areas of potential hazard. Signal words express the

degree of the hazard.

Comply with all safety instructions and proceed

carefully to avoid accidents, injuries and damage to

property.

DANGER!

Imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING!

Potentially hazardous situation which, if not

avoided, may result in death or serious injury.

CAUTION!

Potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE!

Potentially hazardous situation which, if not

avoided, may result in property damage.

ENVIRONMENT!

Environmental pollution hazard.

Safety signs on the controller

The following symbols and signs are usually found

in the work area. They apply to the very location

where they are found.

General information

EASYLAB controller Serie TCU3 5

Electric shock hazard!

Disconnect the power supply before you open the

device.

Only skilled qualified electricians are allowed to

work in areas marked as having electrical voltage.

Unauthorised persons must not enter areas, open

cabinets or work on components where an elec-

trical voltage is present and which are hence

marked with this symbol.

General warning

Read the operating and installation manual before

commissioning and before you open the casing.

Functional earth

WARNING!

Danger due to illegible signage!

Over time, stickers and signs may fade or

become otherwise illegible, meaning that hazards

cannot be identified and necessary operating

instructions cannot be followed. There is then a

risk of injury.

– Ensure that all of the safety, warning and

operating information is clearly legible.

– Replace illegible signs or stickers immedi-

ately.

2 Safety and correct use

General safety notes

DANGER!

Risk of injury from the damper blade of the

VAV terminal unit

The damper blades of VAV terminal units close or

open extremely quickly (∡ 90° within 3 seconds)

and may crush your hands and arms.

Connect ducts to both ends of a VAV terminal

unit; if one end cannot be ducted, at least fit a

perforated plate to prevent people from reaching

into the terminal unit.

CAUTION!

Risk of injury from the casing cover falling

shut

An open casing cover may suddenly fall shut and

crush your fingers.

–Secure an open casing cover with a bracket.

– Wear protective gloves.

NOTICE!

Risk of damage to property due to large tem-

perature differences

If any electronic components have been kept in

an unheated area, condensation may form and

damage the electronic components beyond

repair.

– Before you start commissioning, make sure

that all devices have warmed up to ambient

temperature. Only after about 2 hours will

the system have reached room temperature.

Safety and correct use

EASYLAB controller Serie TCU36

NOTICE!

Risk of damage to property due to electro-

static charge

Electrostatic charge can damage the electronics.

–Avoid skin contact with any components or

printed circuits.

– Touch an equipotentially bonded metal sur-

face before you touch any printed circuit

boards.

– Wear conductive footwear and antistatic

clothing.

NOTICE!

In an emergency

Immediately disconnect the power supply to the

controller. Emergencies include, for example, a

damaged mains cable, a damaged casing, the

ingress of a liquid or foreign matter, a smell or

smoke.

Have the device checked by the manufacturer

before you put it into operation again.

Correct use

Only use the device for its intended correct use and

in compliance with the safety precautions and infor-

mation in this manual in order to avoid danger to

persons and property.

The correct use of this device encompasses:

The electronic control of volume flow rates for

supply or extract air and for fume cupboards in

combination with a TROX air terminal unit.

Indoor use for ventilation and air conditioning

systems, especially for laboratories.

The controller is typically used in a group of

several controllers for complete room control,

but it may also be used as a single controller.

For error-free operation, the installation orien-

tation of the controller must be observed; pos-

sible installation orientations are indicated on

the installation orientation label on the device.

Incorrect use

Do not use the controller in an installation orienta-

tion or for areas of application that are not

described in this manual.

Do not use the controller outdoors, in wet areas, or

in areas with potentially explosive atmospheres.

Residual risks

Power failure

If the power fails, the damper blade of the VAV ter-

minal unit remains in the position at that time; the

controller will resume operation once power returns.

For safety related applications you may use expan-

sion module EM-TRF-USV, which ensures uninter-

ruptible power supply. If the emergency power unit

has been correctly connected and charged, it will

supply power for the set operating times (ÄTech-

nical Data for EM-TRF-USV).

Monitoring function

Alarm signal in the event of insufficient volume

flow rate,

Ä

on page 11

Alarm signal in the event of insufficient room

pressure,

Ä

on page 11

Alarm signal in the event of volume flow rate in

shut-off position,

Ä

on page 11

For safety related applications you should check

whether then safety measures are required, such

as alarms. You may use the alarm relay for

switching operations.

Safety and correct use

EASYLAB controller Serie TCU3 7

3 Technical data

Technical data

Supply voltage 24 V AC ±15% 50-60 Hz

24 V DC ±15%

Do not use 24 V AC and 24 V DC power supplies at the same time!

Optional: 230 V AC mains supply, only with the EM-TRF expansion module; optional: 230 V AC

mains supply with UPS, only with the EM-TRF USV expansion module

Power rating The maximum power required depends on the construction of the controller. Typical construc-

tions with different equipment result in the following values:

Fume cupboard controller with control panel

Room controller

Room controller with room control panel

Including all expansion modules

35 VA

29 VA

33 VA

40 VA max.

Connecting cable Double-stack terminal blocks for cables with a cross section up to 2.5 mm²

The 24 V supply voltage may be connected for a maximum of 5 controllers.

Micro fuse 2.5 A, slow blow, 250 V, as glass fuse 5 x 20 mm

Volume flow rate

measurement

Differential pressure transducer with room air induction to protect the measurement point

Optional: Automatic zero point correction only with expansion module EM-AUTOZERO

Actuator Fast-running high-precision actuator, ∡ 90°: 3 s

Flow rate setting time ≤ 2 s, depending on duct pressure

Controller recovery

time after supply

voltage failure

< 500 ms

Plug and play commu-

nication system

With automatic detection of the connected equipment and equipment functions:

Communication cable: 300 m max.

Number of controllers: max. 24 per segment

Temperature range Operation: 0 to +50 °C

Storage: -10 to +70 °C

Humidity <90% no condensation

Area of application Enclosed spaces

Protection level IP20

IEC protection class III (protective extra-low voltage)

Technical data

EASYLAB controller Serie TCU38

Dimensions

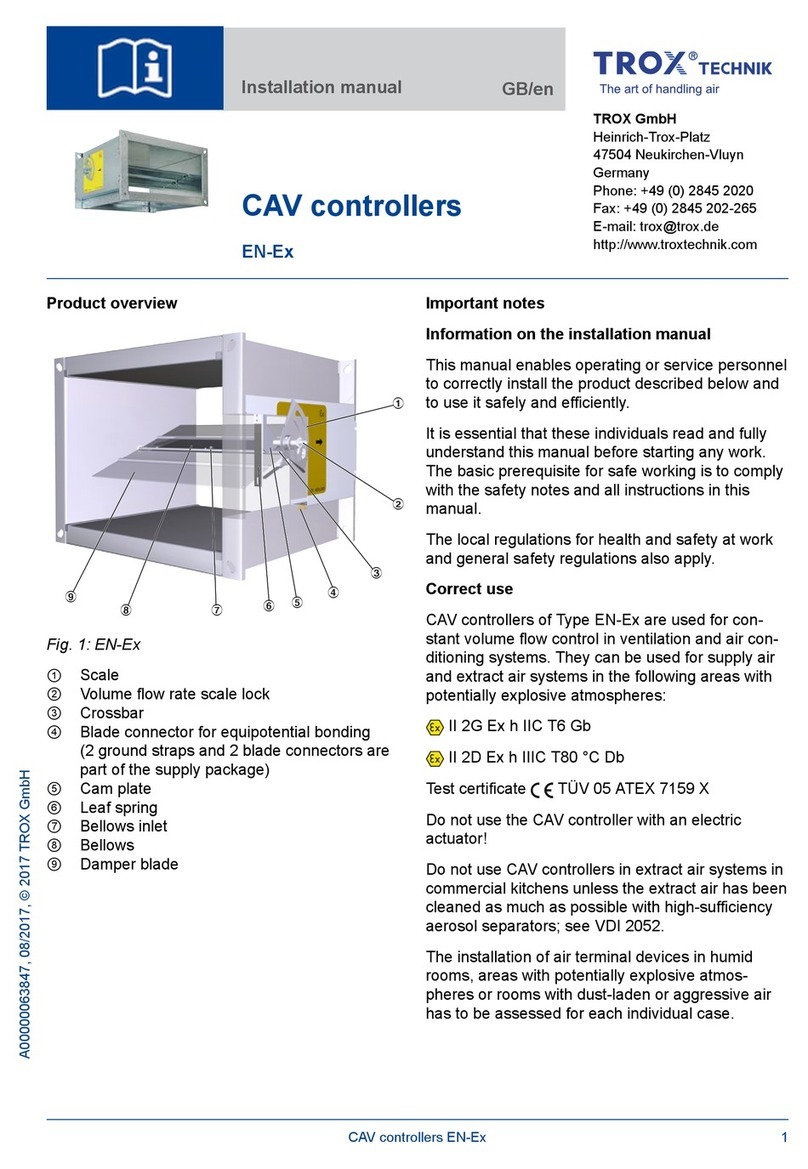

Fig. 1: Dimensions

①Keep clear to provide access

1When combined with TAM, TVRK, TVR, TVA, TVZ, TVJ or TVT

Technical data

EASYLAB controller Serie TCU3 9

4 Transport, storage and packaging

Delivery check

Check delivered items immediately after arrival for

transport damage and completeness. In case of any

damage or an incomplete shipment, contact the

shipping company and your supplier immediately.

A complete shipment includes:

Electronic controller in a closed two-part

casing, including:

– Bracket for the cover

– 2 cable glands, plastic (black)

– 2 cable clips for strain relief (reusable)

– Flow rate transducer (with tubes con-

nected)

– 2-pin plug connector for connection X1

– 3-pin plug connector for connection X5

(sensor AI)

– Network patch cable, 5 m, S-FTP green

(only for fume cupboard controllers,

equipment function FH-xxx)

Expansion modules as ordered (see delivery

note)

Operating and installation manual

TCU3 is usually factory mounted to a TROX VAV

terminal unit.

If any expansion modules have been ordered, the

controller is factory fitted with these modules and

shipped as a complete unit.

Transport on site

If possible, take the controller in its transport

packaging up to the installation location.

Do not remove the protective wrapping until

just before installation.

Storage

For temporary storage please note:

Leave the device in its packaging and do not

expose it to the effects of weather.

Store the product in a dry place and away from

direct sunlight

Temperature -10 to +70 °C, humidity 90% max.

(no condensation)

Packaging

Properly dispose of packaging material.

Transport, storage and packaging

EASYLAB controller Serie TCU310

5 Product description

Volume flow control

Fig. 2: Example

1 VAV terminal unit, e.g. TVR

2 Differential pressure sensor

3 Electronic controller TCU3

4 Actuator

5 Sticker showing installation orientations

The electronic controller is used in combination with

an air terminal unit to control variable supply or

extract air volume flow rates or for room pressure

control.

The controller includes a diaphragm pressure trans-

ducer that transforms the differential pressure

(effective pressure) into an electric signal. The con-

troller compares the actual value with the setpoint

value and alters the control signal of the actuator if

there is a difference between the two values.

Volume flow rate monitoring

The controller monitors the volume flow rate. If the

actual value deviates by more than 4% (can be con-

figured) from the setpoint value, a signal is emitted:

The red LEDs (on opposite sides of the con-

troller casing) blink continuously.

The alarm relay of the controller drops out

(wire break-proof).

If necessary, external alarm signal

Ä

External

signaling of setpoint deviation

Pressure monitoring

The target pressure is monitored by the controller, if

the actual value deviates from the configured pres-

sure deviation, the following signal is emitted:

The red LEDs (on opposite sides of the con-

troller casing) blink continuously.

The alarm relay of the controller drops out

(wire break-proof).

If necessary, external alarm signal

Ä

External

signaling of setpoint deviation

Shut-off monitoring

The controller monitors the damper blade position;

if a volume flow is detected although the damper

blade is in shut-off mode (override control), an

alarm is emitted:

The red LEDs (on opposite sides of the con-

troller casing) blink continuously.

The alarm relay of the controller drops out

(wire break-proof).

If necessary, external alarm signal

Ä

External

signaling of setpoint deviation

Product description

EASYLAB controller Serie TCU3 11

External signaling of setpoint deviation

The monitoring signals can be forwarded externally

(only with optional equipment)

Monitoring of volume flow rate or room pres-

sure

Display on the control panel (BE-SEG and/or

BE-LCD):

–Red light and sound (flow rate below set-

point)

– Yellow light (flow rate above setpoint)

Signaling to the higher-level system (only with

expansion module EM-LON, EM-IP or EM-

BAC-MOD)

Monitoring shut-off:

Display on the control panel (BE-SEG and/or

BE-LCD):

– Yellow light (flow rate above setpoint)

Signaling to the higher-level system (only with

expansion module EM-LON, EM-IP or EM-

BAC-MOD)

When installed, the controller is usually not acces-

sible and the LEDs are not visible; for safety related

applications, however, signals should be made

visible (with an alarm relay, by others).

Product description

EASYLAB controller Serie TCU312

Interfaces and signal lamps on the controller casing

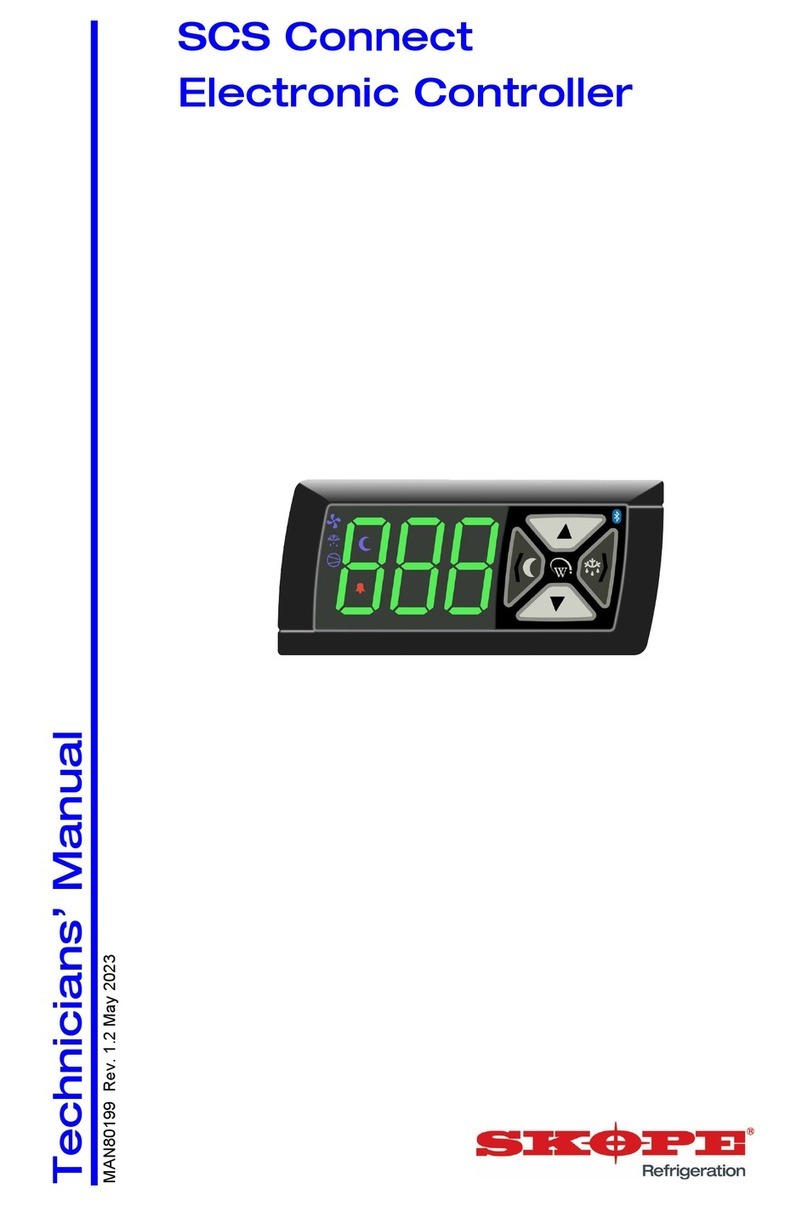

Fig. 3: Controller casing

Status LEDs

No. Colour Name LED Description

1 Red Error LED on Up to 3 s: Switch-on procedure. Permanently: Switch-on

procedure error

LED blinking Error; for detailed diagnosis use EasyConnect software

LED blinking slowly Undefined equipment function; for detailed diagnosis

use EasyConnect software

LED off Normal operation; if no. 5 is also off ⇒ Equipment not

ready for operation

2 Yellow Cable termina-

tion

LED on Cable termination is active

LED off Cable termination is inactive

3 Green Not used

4 Yellow Data reception

in progress

LED on Data is being received from several controllers

LED on with brief inter-

ruptions

Data is being received from few controllers

LED off No data reception from other devices

5 Green Controller opera-

tion (heartbeat)

LED blinking slowly Normal controller operation

LED flickering Controller operation; PC communication with EasyCon-

nect configuration/diagnosis software

LED off Device not ready

Product description

EASYLAB controller Serie TCU3 13

External interfaces

No. Name Connection

point for

Description

6 Contact 500 mm

(X1)

Sash Connection for a volt-free switch contact used to monitor the maximum

operational sash opening (to EN 14175, only for fume cupboard controllers)

7 Terminal-1 (X2) Control panel 1 Connection point for:

EasyLAB control panel, e.g. type BE-SEG-xx, BE-LCD-01

PC with EasyCONNECT software with

–BlueCon adapter

– Special configuration cable

Terminal-2 (X3) Control panel 2

8 Actuator (X4) Actuator The damper actuator is factory fitted if the actuator is part of the supply

package (not for TAM).

9 Sensor (X5) Analogue input

AI5

On a fume cupboard controller: Equipment function FH-VS ⇒ face velocity

transducer; can otherwise be used for the connection of variable extract air

or supply air volume flows with a 0-10 V DC signal. (Characteristic can be

configured)

10 Comm-1 (X6) Communication 1 RJ45 socket for SF-UTP network patch cables

Comm-2 (X7) Communication 2

11 Fume cupboard

lighting

230 V AC socket, switching with control panel Only for use with expansion

module EM-LIGHT.

Max. switch rating of TCU3 relays: 250 V AC 8 A; switch-on current 12 A.

For details on the electrical data for each connection see

Ä

Appendix ‘List of terminal connections’ on page 29

Product description

EASYLAB controller Serie TCU314

Interfaces and signal lamps in the controller casing

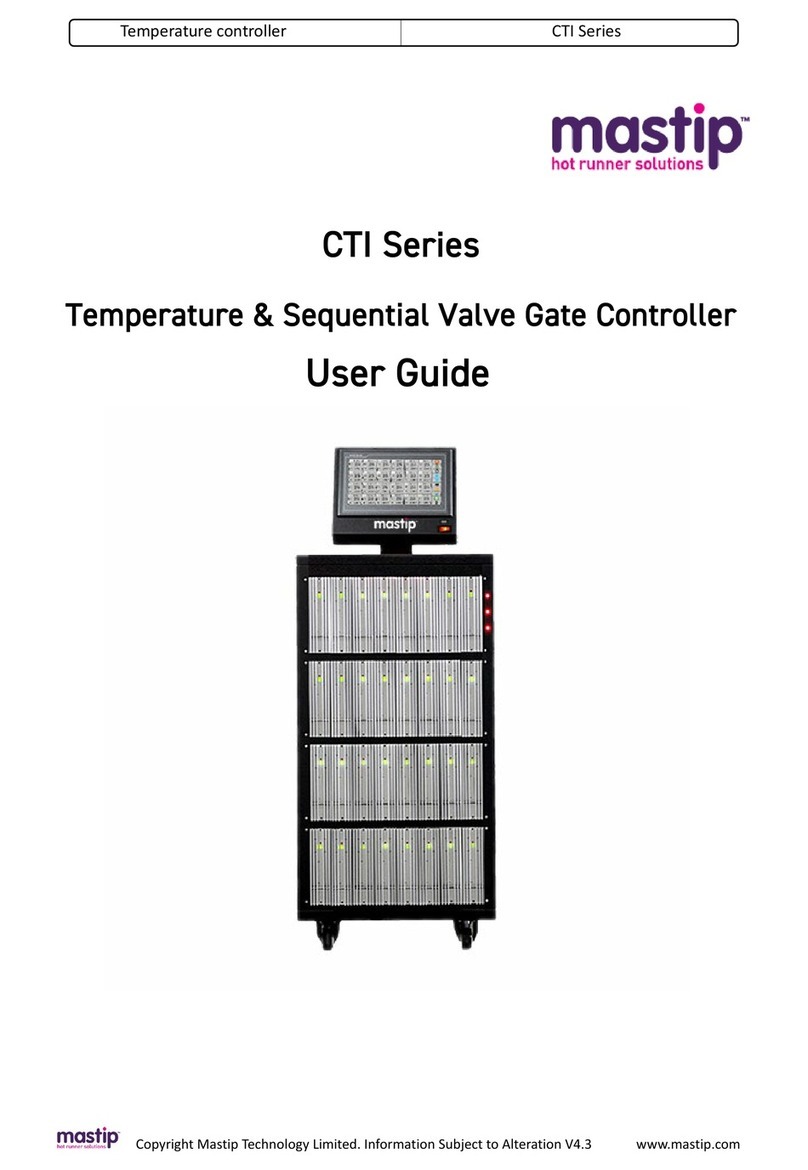

Fig. 4: Interfaces and signal lamps on the PCB

No. Name Description

1 Valve connection Connection point for expansion module EM-AUTOZERO

2 Analogue input 1 (AI1) Connection point for the integral diaphragm pressure transducer, analogue voltage

0-10 VDC, 10 mA max.

3 Expansion slot 1 (ESP-

KOM)

Connection for expansion modules to connect the controller to higher-

level systems:

EM- LON: BUS communication LonWorks FT10

EM-BAC-MOD: BUS communication BACNet MS/TP or MODBUS

RTU

EM-IP: BUS communication BACnet IP or MODBUS IP as well as

web server

4 Power 24 V LED on 24 V supply voltage OK

Product description

EASYLAB controller Serie TCU3 15

No. Name Description

LED off 24 V supply voltage failed / sagging

5 Connection of mains

supply

Connection for EM-TRF and EM-TRF-USV expansion modules

6 Status display for digital

inputs DI1…DI6

LED on Digital input DI is active

LED off Digital input DI is not active

7 Status display for digital

outputs DO1…DO6

LED on Digital output DO is active

LED off Digital output DO not active

8 Terminal block DO1…DO6 Digital outputs 1...6 Changeover relays

max. 250 V AC 8 A, switch-on current 12 A max.

9 Terminal block, 24 V Supply voltage 24 V AC or 24 V DC

Do not use 24 V AC and 24 V DC power supplies at the same time!

10 Terminal block AO1... AO3 Analogue outputs 1...3 Can be configured for 0-10 V DC, 10 mA max.

11 Terminal block DI2…DI6 Digital inputs 2...6 For volt-free switch contacts 5 V DC xx mA

12 Terminal block TI1 Input for temperature sensor PT1000 (only for fume cupboards from software version

V8)

Input for temperature sensor PT1000 (not supported)

13 Terminal block AI1…AI4 Analogue inputs 1...4 Can be configured for 0-10 V DC, 10 mA max.

14 Clip / connection Strain relief / connection for communication cable shield

15 Functional earth Connection point for the functional earth to improve electromagnetic compatibility

(EMV)

16 COMM-1 connection

COMM-2 connection

Alternative terminals for the communication cable; in general, however, connection

points Comm-1 (X6) and Comm-2 (X7) should be used (

Ä

on page 13/10).

SF-UTP network cable

17 COMM terminal resistor Switch ON Communication cable termination is active

Switch OFF Communication cable termination is inactive

18 Terminal 3 Connection for TROX HPD actuator

Do not connect PD here

For details on the electrical data for each connection see

Ä

‘List of terminal connections’ on page 29

Product description

EASYLAB controller Serie TCU316

6 Installation

Installation orientation

The installation orientation of the controller is critical

because of the diaphragm pressure transducer;

approved installation orientations are shown on a

sticker (Fig. 5) on the controller casing.

Fig. 5: Sticker showing the installation orientation

Installation orientation OK

Installation orientation not OK

Install the controller only as follows:

On horizontal ducts (left side of the sticker)

–Only on the side of a duct

Do not install the controller above or

below a duct and neither anywhere in

between.

On vertical ducts (right side of the sticker)

– Any installation orientation

Alternative installation orientation

The installation orientations shown on the sticker

apply to the controller at the time of shipping.

They depend on the position of the diaphragm

pressure transducer in the controller casing. If

you install the controller above or below a duct,

you have to adapt the position of the diaphragm

pressure transducer

Ä

17.

Alternative installation position of the dia-

phragm pressure transducer

Fig. 6: Original position of the diaphragm pressure

transducer at the time of shipping

The diaphragm pressure transducer (Fig. 6/1) and

its holder (Fig. 6/2) are factory fitted in such a way

that the installation orientations of the controller cor-

respond to the sticker.

If necessary, you can adapt the controller for instal-

lation above or below a duct. To do so, you have to

turn the diaphragm pressure transducer by 90°.

1. Grasp the diaphragm pressure transducer

together with the holder and carefully lift it

out of the casing. Be careful so as not to

kink the pneumatic measuring tubes or to

inadvertently disconnect any wires or

cables.

Installation

EASYLAB controller Serie TCU3 17

2. Turn the diaphragm pressure transducer by

90°.

3. Insert the holder with the diaphragm pres-

sure transducer again.

If the position of the diaphragm pressure

transducer has been adapted, the con-

troller must not be installed on the side of

horizontal or vertical ducts.

Fig. 7: Tubing

4. Check all connections and make sure that

the tubes and wires of the transducer are

properly connected and have not been

kinked.

Connect any disconnected wires on the

PCB:

Valve (1) - Connection to ‘Valve’

(Fig. 4/1)

Diaphragm

pressure

transducer (2)

- Connection to

‘Transducer’ (Fig. 4/2)

Replace loosened tubing:

Blue tube - Connection to – (Minus)

transparent tube - Connection to + (Plus)

Installation

EASYLAB controller Serie TCU318

Wall installation

For restricted spaces you can detach the controller

from the VAV terminal unit and install it on the wall

next to the terminal unit or anywhere else nearby; to

fix the controller on a wall, you can use a mounting

bracket (Part no. E346GL3).

Do not extend the actuator cable or any measuring

tubes.

Be sure to install the controller according to the

sticker showing the correct installation orientations

Ä

17.

Fig. 8: Detaching the controller

1. Use a screwdriver to flip up the lug (1) and

lift the controller.

In some cases, e.g. with TVLK, the controller

is factory fitted to the terminal unit without a

bracket.

2. Use suitable screws ∅ 4 mm to fix the

mounting bracket to the wall.

3. Press the controller casing as shown onto

the mounting bracket until it clicks into place.

Installation

EASYLAB controller Serie TCU3 19

Tube connection on the pressure transducer

Room pressure control – supply air

Measuring

point

Tube connection PT699

Positive

Room pressure

Negative

Room pressure

1 + –

2 – +

Room pressure control – extract air

Measuring

point

Tube connection PT699

Positive

Room pressure

Negative

Room pressure

1 + –

2 – +

7 Wiring

Safety instructions

Personnel:

Skilled qualified electrician

DANGER!

Danger of death due to electric current!

Danger of electric shock! Do not touch any live

components!

–Switch off the supply voltage and secure it

against being switched on accidentally

before working on the unit.

– Ensure that no voltage is present.

– Work on the electrical system must only be

carried out by skilled qualified electricians.

CAUTION!

Risk of damage to the controller

For wiring please note:

–Do not connect the 24 V supply if the EM-

TRF or EM-TRF-USV expansion module has

been installed.

– Do not connect 230 V and 24 V supply vol-

tages at the same time.

– Do not connect Terminals 1 + 2 with

Comm 1 + 2.

– Never connect 24 V AC and 24 V DC supply

voltage at the same time.

– Never connect the PC or Comm 1 + 2 to the

connection (Fig. 4/18 - Terminal 3).

Wiring

EASYLAB controller Serie TCU320

Table of contents

Other Trox Controllers manuals

Popular Controllers manuals by other brands

Texas Instruments

Texas Instruments bq34z100 user guide

Siemens

Siemens SIRIUS 3RW40 5 Original operating instructions

Avlite

Avlite AV-OL-CTRL-T3 Installation & service manual

Panasonic

Panasonic EYFRZ01 operating instructions

Garnet

Garnet SPILLSTOP ULTRA 815-UHP/H user manual

Pakton

Pakton JVA Z Series user manual