Trox DRH Series User manual

&HQWULIXJDOURRIIDQV

'5+'59'59)'59)+%9'

%9')

,QVWDOODWLRQDQGRSHUDWLQJPDQXDO

5HDGWKHLQVWUXFWLRQVSULRUWRSHUIRUPLQJDQ\WDVN

)LUHJDVFRQVWUXFWLRQWHVWHGLQDFFRUGDQFHZLWK(1

*%HQ

1925112, 1, GB/en

© 2018

TROX X-FANS GmbH

Heinz Trox Str. 1

36251 Bad Hersfeld, Germany

Telephone: +49 6621/950-0

Fax: +49 6621/950-100

email: [email protected]

Internet: www.trox-xfans.de

08/2019

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600)

2

1 General............................................................... 4

1.1 About this manual........................................ 4

1.2 Explanation.................................................. 4

1.3 Limitation of liability..................................... 5

1.4 Copyright..................................................... 5

1.5 Replacement parts...................................... 5

1.6 Liability for defects....................................... 5

1.7 Customer service......................................... 5

2 Safety.................................................................. 7

2.1 System owner's responsibility..................... 7

2.2 Personnel requirements.............................. 7

2.2.1 Qualifications............................................ 7

2.2.2 Unauthorised persons.............................. 8

2.3 Correct use.................................................. 8

2.4 Explosion protection.................................... 8

2.5 Personal protective equipment.................. 10

2.6 Specific hazards........................................ 11

2.7 Safeguards................................................ 12

2.8 Behaviour in the event of hazardous situa-

tions or accidents...................................... 13

2.9 Labelling.................................................... 13

3 Technical data.................................................. 15

3.1 Design versions......................................... 15

3.1.1 Type codes for roof fans......................... 15

3.1.2 Additional labelling................................. 15

3.2 Series........................................................ 15

3.2.1 Type DRH-Minivent/DRH........................ 15

3.2.2 Type DRV-Minivent/DRV........................ 15

3.2.3 Type DRVF............................................. 15

3.2.4 Type DRVF-H......................................... 16

3.2.5 BVD........................................................ 16

3.3 Connection values..................................... 16

3.4 Noise emission values............................... 16

3.5 Operating conditions................................. 17

3.5.1 Information on setting up fans that are

installed outdoors................................... 18

3.6 Operating modes....................................... 18

3.6.1 S1 continuous operation......................... 18

3.6.2 S9 speed-controlled operation............... 18

3.6.3 Smoke extract........................................ 19

3.7 Rating plate............................................... 19

4 Parts and function........................................... 21

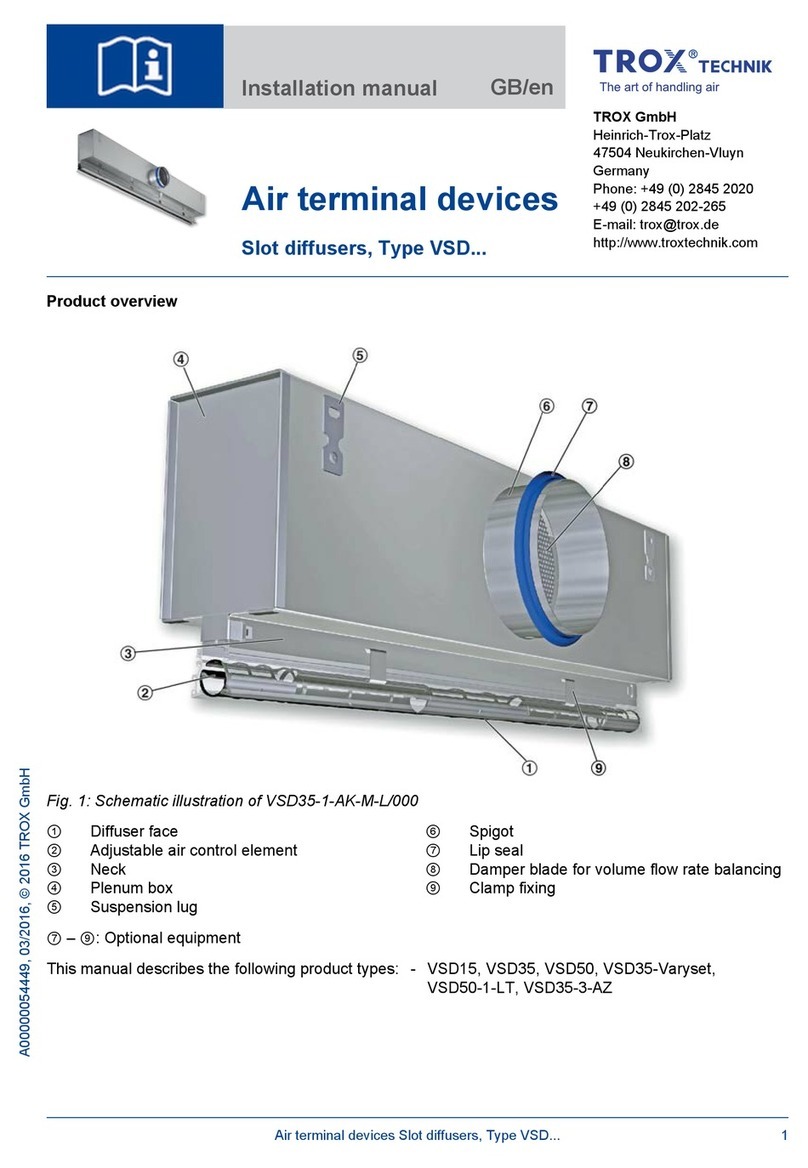

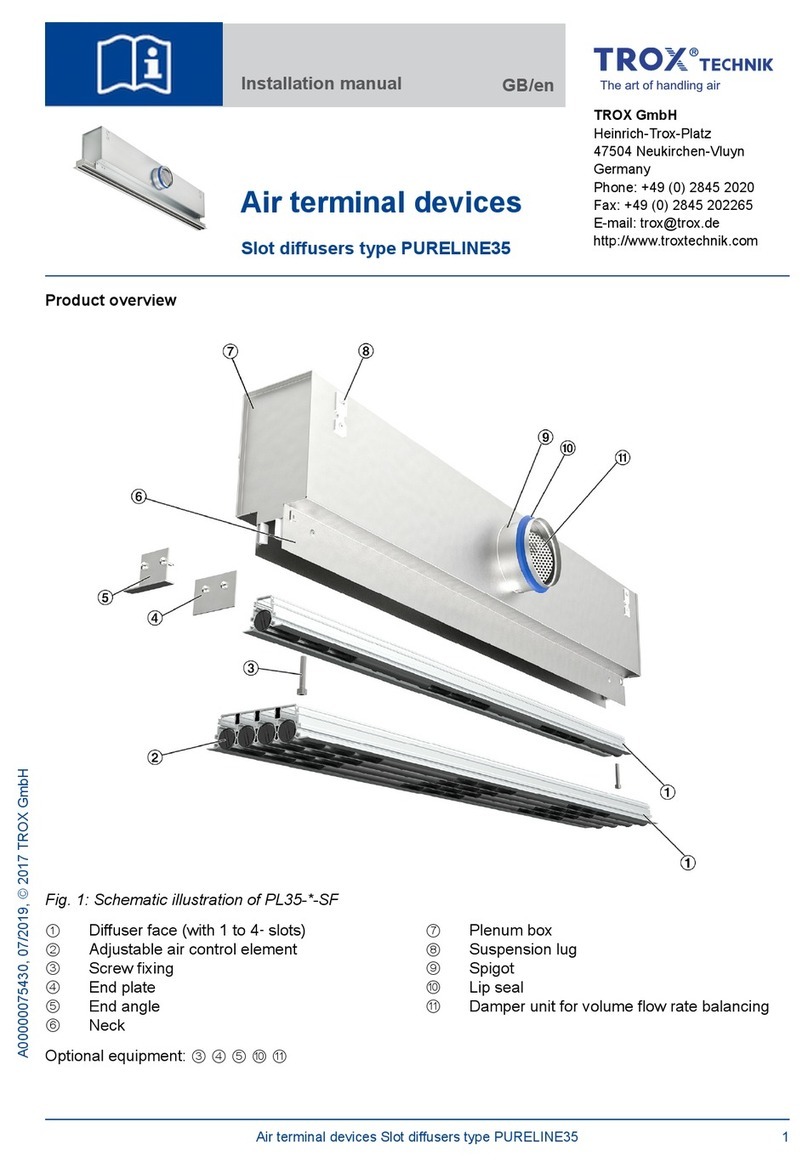

4.1 Overview.................................................... 21

4.2 Brief description......................................... 21

4.3 Description of the sub-assembly............... 21

4.3.1 Casing.................................................... 21

4.3.2 Impeller................................................... 21

4.3.3 Fixing...................................................... 22

4.3.4 Actuator.................................................. 22

4.3.5 Additional equipment for roof fans.......... 22

5 Transport, packaging and storage................. 25

5.1 Safety notes regarding transport............... 25

5.2 Checking delivered goods......................... 25

5.3 Packaging.................................................. 25

5.4 Symbols on the packaging........................ 25

5.5 Factory settings......................................... 26

5.6 Transport................................................... 26

5.7 Storing packages....................................... 27

6 Installation and commissioning..................... 28

6.1 Safety........................................................ 28

6.2 Installation................................................. 29

6.2.1 Assembly of the fan................................ 29

6.2.2 Assembly of the flexible connector......... 31

6.3 Commissioning.......................................... 31

6.3.1 System with inductor/return smoke con-

trol dampers........................................... 31

6.3.2 Multiple fan operation............................. 31

6.3.3 Explosion-proof fans............................... 32

7 Operation.......................................................... 33

7.1 Safety........................................................ 33

7.2 Stopping in an emergency......................... 33

8 Faults................................................................ 34

8.1 Safety........................................................ 34

8.2 List of faults............................................... 36

8.3 Commissioning once a fault has been rec-

tified........................................................... 38

9 Maintenance..................................................... 39

9.1 Personnel requirements............................ 39

9.2 Safety........................................................ 39

9.3 Maintenance.............................................. 40

9.3.1 Use of monitoring systems..................... 41

9.4 Maintenance.............................................. 41

9.4.1 Lubrication.............................................. 41

9.4.2 Replacing the motor bearings................ 41

9.5 Repair........................................................ 42

9.5.1 Replacing the impeller and electric

motor...................................................... 42

9.6 Measures following maintenance work..... 42

10 Decommissioning............................................ 43

10.1 Safety...................................................... 43

10.2 Disassembly............................................ 43

10.3 Disposal................................................... 43

11 Lists of replacement parts.............................. 44

12 Index................................................................. 45

Appendix.......................................................... 47

A Commissioning report.................................. 48

B Maintenance report...................................... 50

C Tables........................................................... 53

D Installation manuals..................................... 55

Table of contents

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600) 3

*HQHUDO

$ERXWWKLVPDQXDO

7KLVPDQXDOHQDEOHVVDIHDQGHIILFLHQWZRUNLQJZLWKWKH

XQLW7KHPDQXDOPXVWEHNHSWQHDUWKHXQLWWREHDYDLO

DEOHIRUXVHDWDOOWLPHV,WLVHVVHQWLDOWKDWWKHVHLQGLYLG

XDOVUHDGDQGIXOO\XQGHUVWDQGWKLVPDQXDOEHIRUH

VWDUWLQJDQ\ZRUN7KHEDVLFSUHUHTXLVLWHIRUVDIH

ZRUNLQJLVWRFRPSO\ZLWKWKHVDIHW\QRWHVDQGDOO

LQVWUXFWLRQVLQWKLVPDQXDO7KHORFDOUHJXODWLRQVIRU

KHDOWKDQGVDIHW\DWZRUNDQGJHQHUDOVDIHW\UHJXODWLRQV

DOVRDSSO\,OOXVWUDWLRQVLQWKLVPDQXDODUHPDLQO\IRU

LQIRUPDWLRQDQGPD\GLIIHUIURPWKHDFWXDOXQLWGHVLJQ

,QDGGLWLRQWRWKLVPDQXDOWKHRSHUDWLQJPDQXDOVRIWKH

LQWHJUDWHGFRPSRQHQWVLQWKHDSSHQGL[DOVRDSSO\7KH

LQVWUXFWLRQVLQWKHPDQXDOV±SDUWLFXODUO\VDIHW\QRWHV±

PXVWEHREVHUYHG

([SODQDWLRQ

6DIHW\QRWHV

6\PEROVDUHXVHGLQWKLVPDQXDOWRDOHUWUHDGHUVWR

DUHDVRISRWHQWLDOKD]DUG6LJQDOZRUGVH[SUHVVWKH

GHJUHHRIWKHKD]DUG

&RPSO\ZLWKDOOVDIHW\LQVWUXFWLRQVDQGSURFHHGFDUHIXOO\

WRDYRLGDFFLGHQWVLQMXULHVDQGGDPDJHWRSURSHUW\

'$1*(5

,PPLQHQWO\KD]DUGRXVVLWXDWLRQZKLFKLIQRWDYRLGHG

ZLOOUHVXOWLQGHDWKRUVHULRXVLQMXU\

:$51,1*

3RWHQWLDOO\KD]DUGRXVVLWXDWLRQZKLFKLIQRWDYRLGHG

PD\UHVXOWLQGHDWKRUVHULRXVLQMXU\

&$87,21

3RWHQWLDOO\KD]DUGRXVVLWXDWLRQZKLFKLIQRWDYRLGHG

PD\UHVXOWLQPLQRURUPRGHUDWHLQMXU\

(;3/26,21+$=$5'

)DLOXUHWRFRPSO\ZLWKWKHVHQRWHVOHDGVWRORVVRI

H[SORVLRQSURWHFWLRQDQGPD\UHVXOWLQVHULRXVLQMXU\

DQGGHDWK

127,&(

3RWHQWLDOO\KD]DUGRXVVLWXDWLRQZKLFKLIQRWDYRLGHG

PD\UHVXOWLQSURSHUW\GDPDJH

(19,5210(17

(QYLURQPHQWDOSROOXWLRQKD]DUG

7LSVDQGUHFRPPHQGDWLRQV

8VHIXOWLSVDQGUHFRPPHQGDWLRQVDVZHOODVLQIRUPD

WLRQIRUHIILFLHQWDQGIDXOWIUHHRSHUDWLRQ

*HQHUDO

([SODQDWLRQ

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

6SHFLILFVDIHW\QRWHV

7KHIROORZLQJV\PEROVDUHXVHGLQVDIHW\QRWHVWRDOHUW

\RXWRVSHFLILFKD]DUGV

:DUQLQJVLJQV 7\SHRIGDQJHU

:DUQLQJGDQJHURI

FUXVKLQJ

:DUQLQJ±KLJKYROWDJH

:DUQLQJ±VXVSHQGHG

ORDG

:DUQLQJ±GDQJHU]RQH

2WKHUPDUNHUV

7KHIROORZLQJPDUNHUVDUHXVHGWRKLJKOLJKWLQVWUXFWLRQV

UHVXOWVOLVWVUHIHUHQFHVDQGRWKHUHOHPHQWVLQWKLV

PDQXDO

0DUNHU ([SODQDWLRQ

6WHSE\VWHSLQVWUXFWLRQV

Ö5HVXOWVRIDFWLRQV

5HIHUHQFHVWRVHFWLRQVLQWKLV

PDQXDODQGWRRWKHUDSSOLFDEOH

GRFXPHQWV

/LVWVZLWKRXWDGHILQHGVHTXHQFH

>3XVKEXWWRQ@ &RQWUROHOHPHQWVHJSXVKEXWWRQV

VZLWFKHVRUGLVSOD\HOHPHQWVHJ

/('V

µ'LVSOD\¶ 6FUHHQHOHPHQWVHJEXWWRQVRU

PHQXV

/LPLWDWLRQRIOLDELOLW\

7KHLQIRUPDWLRQLQWKLVPDQXDOKDVEHHQFRPSLOHGZLWK

UHIHUHQFHWRWKHDSSOLFDEOHVWDQGDUGVDQGJXLGHOLQHV

WKHVWDWHRIWKHDUWDQGRXUH[SHUWLVHDQGH[SHULHQFHRI

PDQ\\HDUV

7KHPDQXIDFWXUHUGRHVQRWDFFHSWDQ\OLDELOLW\IRUGDP

DJHVUHVXOWLQJIURP

1RQFRPSOLDQFHZLWKWKLVPDQXDO

,QFRUUHFWXVH

2SHUDWLRQRUKDQGOLQJE\XQWUDLQHGLQGLYLGXDOV

8QDXWKRULVHGPRGLILFDWLRQV

7HFKQLFDOFKDQJHV

8VHRIQRQDSSURYHGUHSODFHPHQWSDUWV

3OHDVHREVHUYHRXUFRPPLVVLRQLQJDQGPDLQWHQDQFH

LQVWUXFWLRQVLQ&KDSWHUV

ª

µ,QVWDOODWLRQDQGFRP

PLVVLRQLQJ¶RQSDJHDQG

ª

µ0DLQWHQDQFH¶

RQSDJH

7KHDFWXDOVFRSHRIGHOLYHU\PD\GLIIHUIURPWKHH[SODQ

DWLRQVDQGLOOXVWUDWLRQVSURYLGHGLQWKLVPDQXDOIRUVSH

FLDOYHUVLRQVWKHXVHRIDGGLWLRQDORUGHURSWLRQVRUDVD

UHVXOWRIUHFHQWWHFKQLFDOFKDQJHV7KHREOLJDWLRQV

DJUHHGLQWKHRUGHUWKHJHQHUDOWHUPVDQGFRQGLWLRQV

WKHPDQXIDFWXUHUVWHUPVRIGHOLYHU\DQGWKHOHJDOUHJX

ODWLRQVLQHIIHFWDWWKHWLPHWKHFRQWUDFWLVVLJQHGVKDOO

DSSO\:HUHVHUYHWKHULJKWWRPDNHWHFKQLFDOFKDQJHV

&RS\ULJKW

7KLVPDQXDOLVSURWHFWHGE\FRS\ULJKWDQGLVH[FOXVLYHO\

IRUXVHLQ\RXUFRPSDQ\E\DXWKRULVHGSHUVRQQHO9LROD

WRUVZLOOEHKHOGOLDEOHIRUDQ\GDPDJH7KHULJKWWRIXU

WKHUFODLPVUHPDLQVUHVHUYHG

5HSODFHPHQWSDUWV

:$51,1*

6DIHW\ULVNFDXVHGE\LQFRUUHFWUHSODFHPHQW

SDUWV

&RXQWHUIHLWRUIDXOW\UHSODFHPHQWSDUWVPD\DIIHFW

VDIHW\DQGFDXVHGDPDJHPDOIXQFWLRQVRUWRWDO

IDLOXUH

7KHUHIRUH

± 2QO\XVHRULJLQDOUHSODFHPHQWSDUWVSURYLGHGE\

WKHPDQXIDFWXUHU

%X\UHSODFHPHQWSDUWVIURPDQDXWKRULVHGVXSSOLHURU

IURPWKHPDQXIDFWXUHU6HHDGGUHVVRQSDJH

7KHOLVWVRIUHSODFHPHQWSDUWVFDQEHIRXQGLQ&KDSWHU

ª

µ/LVWVRIUHSODFHPHQWSDUWV¶RQSDJH

/LDELOLW\IRUGHIHFWV

7KHSURYLVLRQVRQOLDELOLW\IRUGHIHFWVDUHGHVFULEHGLQ

3RLQW9,RIWKH*HQHUDO7HUPVRI'HOLYHU\DQG3D\PHQW

7KHSURYLVLRQVFDQEHYLHZHGRQRXUZHEVLWHDW

ZZZWUR[[IDQVGHXQGHU³'HOLYHU\DQGSD\PHQWWHUPV´

&XVWRPHUVHUYLFH

2XUFXVWRPHUVHUYLFHWHDPLVDYDLODEOHWRSURYLGHDQ\

WHFKQLFDOLQIRUPDWLRQ,QIRUPDWLRQDERXWWKHUHVSRQVLEOH

FRQWDFWSHUVRQLVDOZD\VDFFHVVLEOHRYHUWKHSKRQHE\

ID[E\HPDLORURYHUWKH,QWHUQHWVHHWKHPDQXIDFWXU

HU¶VDGGUHVVRQSDJH:HRIIHUWKHIROORZLQJVHUYLFHV

*HQHUDO

&XVWRPHUVHUYLFH

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

Assembly, commissioning and maintenance of the

fans

Measurement, analysis and evaluation of all the

data required for operation (e.g.: pressure, volume,

sound, vibrations)

Operational balancing

Replacement parts service

Individual advice and help placing orders

General

Customer service

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600)6

2 Safety

This section provides an overview of all the important

safety issues for the best possible protection of per-

sonnel as well as for safe and fault-free operation.

Failure to comply with the instructions and safety notes

listed in this manual can lead to serious hazards.

2.1 System owner's responsibility

The unit is intended for commercial use. The system

owner is therefore subject to the legal obligations of

occupational health and safety regulations. In addition

to the safety notes in this manual, the applicable regula-

tions for safety, accident prevention and environmental

protection must also be complied with. In particular:

The system owner must be aware of the applicable

occupational health and safety regulations and carry

out a risk assessment to determine any additional

hazards that may exist or result from the specific

working conditions at the installation location of the

unit. The system owner has to create operating

instructions for the unit that reflect the results of this

risk assessment.

The system owner must ensure, throughout the

unit’s entire operating period, that the operating

instructions they create comply with the applicable

standards and guidelines and must adapt them as

required.

The system owner must clearly regulate and define

the responsibilities for assembly / installation, opera-

tion, maintenance and cleaning.

The system owner has to ensure that all individuals

who handle or use the unit have read and under-

stood this manual.

The system owner must regularly provide training

for the personnel and inform them of any dangers.

The system owner must provide the employees with

the required personal protective equipment.

The system owner is also responsible for ensuring that

the unit is always in a technically perfect condition. The

following therefore applies:

The system owner must ensure that the mainte-

nance intervals specified in this manual are

observed.

The system owner must have all safeguards tested

regularly to ensure that they are functional and com-

plete.

2.2 Personnel requirements

2.2.1 Qualifications

WARNING!

Danger of injury due to insufficiently qualified

individuals!

Incorrect use may cause considerable injury or

damage to property.

Therefore:

– Only specialist personnel must carry out work.

The following degrees of qualification are required for

the work described in the operating manual:

Instructed person

The instructed person has been instructed by the

system owner with regard to the tasks delegated to

them and potential hazards in the event of inappropriate

behaviour.

Skilled qualified electrician

Skilled qualified electricians are individuals who have

sufficient professional or technical training, knowledge

and actual experience to enable them to work on elec-

trical systems, understand any potential hazards related

to the work under consideration, and recognise and

avoid any risks involved.

The qualified electrician is trained especially for the field

in which they work and is familiar with the relevant

standards and regulations.

Specialist personnel

Specialist personnel are individuals who have sufficient

professional or technical training, knowledge and actual

experience to enable them to carry out their assigned

duties, understand any potential hazards related to the

work under consideration, and recognise and avoid any

risks involved.

Only persons who can be expected to perform their

work reliably are acceptable as personnel. Individuals

whose reaction time is delayed due to alcohol, drugs or

other medication must not carry out any work.

The age-specific and occupational regulations appli-

cable at the operation site must be observed when

appointing personnel.

Safety

Personnel requirements > Qualifications

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600) 7

2.2.2 Unauthorised persons

WARNING!

Danger for unauthorised persons!

Unauthorised persons who do not fulfil the require-

ments specified here are usually not aware of the

dangers in the work area.

Therefore:

– Keep unauthorised persons away from the work

area.

– Instruct these persons to leave the hazardous

area or work area.

– Stop work while unauthorised persons are

present in the work area.

2.3 Correct use

The unit is only designed and constructed for the

intended use described here.

The ventilation fan is only designed to convey

normal, dust-free and conditioned air, and other

non-aggressive, non-explosive gases.

The smoke exhaust fan is also designed to

convey fire gases in accordance with its tempera-

ture and time specifications.

Replace fan after use in the event of a fire!

The explosion-proof fan is designed to convey

explosive media and/or for installation in poten-

tially explosive atmospheres according to its

labelling.

Other intended uses approved by the manufacturer and

derived from the optional fan equipment are detailed in

the customer specifications.

WARNING!

Danger due to incorrect use!

Any use that extends beyond the correct use and/or

different use of the unit can lead to hazardous situa-

tions.

Therefore:

– Only use the unit for its correct use.

– Strictly comply with all of the information in this

operating manual.

Claims of any type for damages resulting from incorrect

use will not be accepted.

The system owner is solely responsible for all damages

resulting from incorrect use.

2.4 Explosion protection

ATEX Product Directive 2014/34/EU (ATEX 95)

The aim of the Directive is to protect individuals who

work in potentially explosive atmospheres. The Directive

contains the essential health and safety requirements

that the manufacturer must observe and that must be

verified by means of appropriate conformity assess-

ments. Since 30 June 2003, only units, components and

protective systems which comply with the ATEX Product

Directive 2014/34/EU can be used.

The deliverable version options are highlighted below:

Equipment groups

Equipment

group

For use in....

I Units for use in mining

II Units for use in the other areas

Classification

Zone Category EPL Safety

0 1 Ga Very high level of

safety

1 2 Gb High level of safety

2 3 Gc Normal operation

Atmosphere

G = Gases

D = Dusts

Explosion group (gas group)

Gases and vapours are split into three explosion groups

(IIA, IIB and IIC) based on their particular flammability.

The danger increases from explosion group IIA to IIC.

(The higher explosion group includes the lower ones.)

Safety

Explosion protection

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600)8

7HPSHUDWXUHFODVV

6L[WHPSHUDWXUHFODVVHV7WR7KDYHEHHQGHILQHGIRUWKHSHUPLVVLEOHVXUIDFHWHPSHUDWXUHV&HUWDLQFRPEXVWLEOH

JDVHVDQGYDSRXUVFDQEHDVVLJQHGWRWKHVHWHPSHUDWXUHFODVVHVEDVHGRQWKHUHOHYDQWLJQLWLRQWHPSHUDWXUHV

7KHIROORZLQJWDEOHSURYLGHVDQRYHUYLHZRIWKHPD[LPXPSHUPLVVLEOHVXUIDFHWHPSHUDWXUHVRQWKHXQLWVDQGVRPH

DVVRFLDWHGJDVHVWKDWDSSO\WRWKHWHPSHUDWXUHFODVVHV

*URXS

7HPSHUDWXUHFODVVVXUIDFHWHPSHUDWXUH

7

&

7

&

7

&

7

&

7

&

7

&

, 0HWKDQH

,,$ $PPRQLD

PHWKDQRO

QEXW\ODOFRKRO

QEXWDQH

%HQ]LQH

GLHVHO

KHDWLQJRLO

$FHWDOGHK\GH

,,% 7RZQJDV (WK\OHQH

DOFRKROHOWK\

OHQH

(WK\OHWKHU

,,& +\GURJHQ $FHW\OHQH &DUERQGLVXO

SKLGH

&RUUHFWXVH

)DQVGHVLJQDWHGDV³H[SORVLRQSURRI´DUHVXEMHFWWRWKH

OHJDOUHTXLUHPHQWVLQIRUFHZLWKUHJDUGWRWKH([SORVLRQ

3URWHFWLRQ5HJXODWLRQDQG'LUHFWLYH(87KH\

DUHSDUWRIHTXLSPHQWJURXS,,DQGDUHVXLWDEOHIRUFRQ

YH\LQJFODVV,,$DQG,,%JDVHVIURP]RQHVDQG7KH

IDQVDUHDOVRVXLWDEOHIRULQVWDOODWLRQLQDQH[SORVLYH

DWPRVSKHUHLQWKHDERYHPHQWLRQHG]RQHV

0DUNHU

,QDFFRUGDQFHZLWK'LUHFWLYH(8±NQRZQDV

$7(;±RQO\XQLWVWKDWFRQIRUPWRWKLV'LUHFWLYHFDQ

EHXVHGLQSRWHQWLDOO\H[SORVLYHDWPRVSKHUHVVLQFH

-XO\

7KHIDQVDUHVXLWDEOHIRUFRQYH\LQJSRWHQWLDOO\H[SORVLYH

PHGLDDQGRUIRULQVWDOODWLRQLQURRPVZLWKSRWHQWLDOO\

H[SORVLYHPHGLD

6SHFLDOSURYLVLRQVDFFRUGLQJWR

ª

µ&RPPLVVLRQLQJ

UHSRUW¶RQSDJHDQG

ª

µ0DLQWHQDQFHUHSRUW¶

RQSDJHPXVWEHREVHUYHGGXULQJFRPPLVVLRQLQJ

DQGPDLQWHQDQFH

(;3/26,21+$=$5'

8QLWFRPSRQHQWVWKDWFRPSO\ZLWK'LUHFWLYH

(8LQFOXGHDGGLWLRQDOLQIRUPDWLRQRQWKH

UDWLQJSODWH

)LJ0DUNLQJDFFRUGLQJWR$7(;

&(PDUN

8QLWLVFHUWLILHGIRU([DUHD

,, (TXLSPHQWJURXSQRWIRUXVHLQPLQLQJ

* 8QLWFDWHJRU\DQGDWPRVSKHUH

K 7\SHRISURWHFWLRQQRQHOHFWULFDO

,,% *DVJURXS

7 7HPSHUDWXUHFODVV

*E (3/HTXLSPHQWSURWHFWLRQOHYHO

2SHUDWLQJFRQGLWLRQV

:$51,1*

7KHLQOHWWHPSHUDWXUHRIWKHIORZPHGLXPPXVWEH

EHWZHHQ&DQG&7KHPDQXIDFWXUHUPXVW

EHFRQVXOWHGLIKLJKHUWHPSHUDWXUHVDUHUHTXLUHG

:$51,1*

7KHPD[LPXPRSHUDWLQJVSHHGVSHFLILHGRQWKHIDQ

UDWLQJSODWHPXVWEHREVHUYHG

6DIHW\

([SORVLRQSURWHFWLRQ

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

9LEUDWLRQPRQLWRULQJ

,WLVUHFRPPHQGHGWKDWWKHV\VWHPRZQHULQVWDOOD

SHUPDQHQWYLEUDWLRQPRQLWRULQJV\VWHPWRSUHYHQW

VSDUNVIURPEHLQJJHQHUDWHGDVDUHVXOWRIWKH

LPSHOOHUVWULNLQJDJDLQVWSDUWVRIWKHFDVLQJIROORZLQJ

LPEDODQFHGXULQJRSHUDWLRQ$SHUPDQHQWYLEUDWLRQ

PRQLWRULQJV\VWHPLVREOLJDWRU\LIPLVWRUGXVWLV

EHLQJFRQYH\HG

(;3/26,21+$=$5'

,JQLWLRQVRXUFHVVXFKDVVSDUNVQDNHGIODPHVDQG

KRWVXUIDFHVFDQOHDGWRH[SORVLRQVLQSRWHQWLDOO\

H[SORVLYHDWPRVSKHUHV7KHIROORZLQJWKHUHIRUH

DSSOLHVWRDOOZRUNRQXQLWVLQWKH([DUHD

±*HWZULWWHQSHUPLVVLRQEHIRUH\RXVWDUWWKHZRUN

±2QO\SHUIRUPZRUNLIWKHUHDUHQRGXVWGHSRVLWV

RUDSRWHQWLDOO\H[SORVLYHDWPRVSKHUH

±8VHRQO\WRROVWKDWKDYHEHHQDSSURYHGIRUXVH

LQDUHDVZLWKSRWHQWLDOO\H[SORVLYHDWPRVSKHUHV

$GGLWLRQDOO\

±,WPXVWEHHQVXUHGWKDWVXIILFLHQWFRROLQJDLULV

VXSSOLHGWRWKHIDQGULYHPRWRUDWDOOWLPHV

±0RWRUVZLWKDFRYHUPXVWEHXVHGLIIDQVZLWKD

YHUWLFDOPRWRUVKDIWDUHLQVWDOOHG

±6HUYLFLQJDQGPDLQWHQDQFHZRUNRQH[SORVLRQ

SURRIIDQVPXVWRQO\EHFDUULHGRXWE\TXDOLILHG

SHUVRQQHOZLWKWKHUHOHYDQWH[SORVLRQSURWHFWLRQ

TXDOLILFDWLRQVXVLQJRULJLQDOUHSODFHPHQWSDUWV

)DLOXUHWRFRPSO\ZLWKWKHVHQRWHVOHDGVWRORVVRI

H[SORVLRQSURWHFWLRQDQGPD\UHVXOWLQVHULRXVLQMXU\

DQGGHDWK

(;3/26,21+$=$5'

,IDFRPSRQHQWRUGHYLFHLVWREHLQVWDOOHGLQD

V\VWHPLQWHQGHGIRUXVHLQSRWHQWLDOO\H[SORVLYH

DWPRVSKHUHVDFFRUGLQJWR(8WKHV\VWHP

RZQHUKDVWRHQVXUHFRPSOLDQFHRIWKHHQWLUHV\VWHP

ZLWKWKDWGLUHFWLYH1RQFRPSOLDQFHPD\OHDGWRDQ

H[SORVLRQ

3HUVRQDOSURWHFWLYHHTXLSPHQW

3HUVRQDOSURWHFWLYHHTXLSPHQWPXVWEHZRUQIRUDQ\

ZRUNLQRUGHUWRUHGXFHKHDOWKRUVDIHW\KD]DUGVWRWKH

PLQLPXP

:HDUWKHSURWHFWLYHHTXLSPHQWQHFHVVDU\IRUWKH

UHVSHFWLYHZRUNIRUDVORQJDVWKHZRUNWDNHV

2EVHUYHLQVWUXFWLRQVUHODWLQJWRSHUVRQDOSURWHFWLYH

HTXLSPHQWWKDWDUHGLVSOD\HGLQWKHZRUNDUHD

6SHFLDOSURWHFWLYHHTXLSPHQWLVUHTXLUHGZKHQFDUU\LQJ

RXWVSHFLILFZRUN7KLVLVUHIHUUHGWRVHSDUDWHO\LQWKH

LQGLYLGXDOFKDSWHUVRIWKLVPDQXDO

+HDULQJSURWHFWLRQ

7RSUHYHQWKHDULQJGDPDJH

3URWHFWLYHFORWKLQJ

LVFORVHILWWLQJZLWKORZWHDUUHVLVWDQFHFORVHILWWLQJ

VOHHYHVDQGQRSURMHFWLQJSDUWV,WSUHYHQWVHQWDQJOH

PHQWLQPRYLQJPDFKLQHU\'RQRWZHDUULQJVFKDLQVRU

DQ\RWKHUMHZHOOHU\

3URWHFWLYHJORYHV

3URWHFWLYHJORYHVDUHXVHGWRSURWHFWKDQGVIURPIULF

WLRQDEUDVLRQVSXQFWXUHVGHHSFXWVDQGGLUHFWFRQWDFW

ZLWKKRWVXUIDFHV

6DIHW\KHOPHW

IRUSURWHFWLRQIURPIDOOLQJDQGIO\LQJSDUWVDQGPDWHULDOV

6DIHW\VKRHV

IRUSURWHFWLRQIURPKHDY\IDOOLQJSDUWVDQGIURPVOLSSLQJ

RQVOLSSHU\VXUIDFHV

6DIHW\

3HUVRQDOSURWHFWLYHHTXLSPHQW

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

2.6 Specific hazards

Electric current

DANGER!

Danger of death due to electric current!

Danger of electric shock! Do not touch any live com-

ponents! Damaged insulation or damaged parts are

a life threatening hazard.

– Have work on the electrical system carried out

only by skilled qualified electricians.

– If the insulation is damaged, disconnect the

power supply immediately and have the insula-

tion repaired.

– Before you start working on electric systems and

equipment, switch off the supply voltage and

secure it against being switched on accidentally.

Comply with the 5 safety rules:

– Disconnect.

– Secure it against being switched on acciden-

tally.

– Ensure that no voltage is present.

– Connect to the earth; short circuit connection.

– Either cover nearby parts that carry a voltage

or install barriers.

– Do not bypass or disable any circuit breakers. Be

sure to maintain the correct current rating when

you replace a circuit breaker.

– Ensure that live parts do not come into contact

with moisture. Moisture can cause a short circuit.

Noise

WARNING!

Hearing damage due to noise!

The noise level in the work area can cause severe

hearing damage.

– Always wear hearing protection while working.

– Only remain in the hazardous area if absolutely

necessary.

Moving components

WARNING!

Risk of injury due to moving components!

Moving components can cause serious injuries.

– Do not reach into or handle moving components

during operation.

– Never open covers during operation.

– The fan does not stop immediately! Check that

no components are moving before you open the

covers.

–Wear tight-fitting clothing with low tear resistance

in the hazardous area.

Rotating parts

WARNING!

Risk of injury from rotating parts!

Rotating parts in the fan can cause serious injuries.

– Do not reach into or handle the moving impeller

wheel during operation.

– Do not open covers and maintenance covers

during operation.

– Ensure that the impeller wheel is not accessible

during operation.

–The fan does not stop immediately! Ensure that

none of the components are still moving before

opening the covers for maintenance purposes.

– Switch off the unit and secure it against being

switched back on again before starting any work

on moving fan components. Wait until all parts

have come to a standstill.

Vibrations

WARNING!

Risk of injury due to strong vibrations!

Strong vibrations can result in serious injury and

chronic health impairments in the long term. The

source of the vibration can be decoupled from the

surrounding area using a vibration damper.

–Do not deactivate the vibration damper.

– Do not remain in the vibrating area during opera-

tion.

Safety

Specific hazards

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600) 11

6XVSHQGHGORDGV

'$1*(5

'DQJHURIGHDWKGXHWRVXVSHQGHGORDGV

)DOOLQJORDGVPD\FDXVHVHULRXVLQMXU\RUGHDWK

7KHUHIRUH

± 1HYHUZDONXQGHUVXVSHQGHGORDGV

± 2QO\PRYHORDGVXQGHUVXSHUYLVLRQ

± 2EVHUYHWKHVSHFLILFDWLRQVIRUWKHLQWHQGHG

ODVKLQJSRLQWV

± 'RQRWDWWDFKWKHOLIWLQJJHDUWRSURWUXGLQJ

PDFKLQHSDUWVRUOXJVRQDWWDFKHGFRPSRQHQWV

± (QVXUHWKDWWKHOLIWLQJJHDULVVHFXUH

± 2QO\XVHDSSURYHGKRLVWLQJGHYLFHVDQGOLIWLQJ

JHDUZLWKZLWKVXIILFLHQWORDGEHDULQJFDSDFLW\

± 'RQRWXVHDQ\IUD\HGRUZRUQURSHVDQGEHOWV

± 'RQRWSODFHURSHVRUEHOWVQHDUVKDUSHGJHVRU

FRUQHUVGRQRWNQRWRUWZLVW

± 3ODFHWKHORDGRQWKHJURXQGEHIRUHOHDYLQJWKH

ZRUNSODFH

)DOOLQJPDWHULDOV

:$51,1*

5LVNRILQMXU\GXHWRIDOOLQJPDWHULDOV

'XULQJRSHUDWLRQPDWHULDOFDQIDOOLQDQXQFRQWUROOHG

PDQQHURUEHHMHFWHGDQGFDXVHVHULRXVLQMXULHV

± 'RQRWHQWHUWKHKD]DUGRXVDUHDVGXULQJQRUPDO

RSHUDWLRQ

± :HDUDQLQGXVWULDOVDIHW\KHOPHWVDIHW\VKRHV

DQGSURWHFWLYHFORWKLQJZKHQHQWHULQJWKHKD]

DUGRXVDUHDHJGXULQJVHWWLQJPRGH

6DIHJXDUGV

:$51,1*

5LVNWROLIHIURPGHIHFWLYHVDIHJXDUGV

6DIHW\LVRQO\DVVXUHGLIWKHVDIHJXDUGVDUHLQWDFW

7KHUHIRUH

± %HIRUHVWDUWLQJZRUNFKHFNZKHWKHUWKHVDIH

JXDUGVDUHIXOO\IXQFWLRQDODQGLQVWDOOHGFRUUHFWO\

± 1HYHUGHDFWLYDWHVDIHJXDUGV

± (QVXUHWKDWVDIHJXDUGVVXFKDVWKHHPHUJHQF\

VWRSSXVKEXWWRQWULSFRUGVHWFDUHDFFHVVLEOH

DWDOOWLPHV

,03257$17

)RUIXUWKHULQIRUPDWLRQRQWKHSRVLWLRQRIWKHVDIH

JXDUGVVHH&KDSWHU

ª

µ3DUWVDQGIXQFWLRQ¶

RQSDJH

,VRODWRURSWLRQDO

)LJ,VRODWRU

6RPHIDQVDUHHTXLSSHGZLWKDQLVRODWRU

:$51,1*

'DQJHURIGHDWKGXHWRXQFRQWUROOHGUHDFWLYDWLRQ

8QFRQWUROOHGUHDFWLYDWLRQFDQOHDGWRVHULRXVSHU

VRQDOLQMXU\RUGHDWK

7KHUHIRUH

± %HIRUHUHDFWLYDWLRQHQVXUHWKDWDOORIWKHVDIH

JXDUGVDUHDVVHPEOHGDQGIXOO\IXQFWLRQDO

± (QVXUHWKDWQRERG\LVLQWKHKD]DUGRXVDUHD

6HFXUHGLVRODWRU

6DIHW\

6DIHJXDUGV

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

Fig. 3: Secured isolator

The isolator can be locked in the “0” position with a pad-

lock to prevent reactivation.

Additional smoke exhaust fan option

The isolator can also be locked in the “1” position with a

padlock to prevent deactivation in order to guarantee

the smoke extract function.

DANGER!

Danger of death due to impermissible activation

and deactivation!

Individuals can enter the hazardous area if the iso-

lator has been locked with a padlock to prevent acti-

vation. Activation could cause life-threatening injuries

to these individuals.

If the fan has been secured with a padlock to prevent

it from being deactivated, it can be equipped with an

automatic start-up feature in the event of a fire.

Deactivation ensures that the fan is not ready for

operation in the event of a fire and cannot transport

fire gases.

Therefore:

– Never remove the padlock without authorisation.

– Before removing the padlock, ensure that there

are no more individuals in the hazardous area.

Integration in an emergency stop concept required

The unit is designed for use within a system. It does not

have its own control and there is no autonomous emer-

gency stop function.

Before the unit is unit started up, install emergency stop

equipment for the unit and connect it to the system con-

trol’s safety chain.

This does not apply to smoke exhaust fans.

Connect the emergency stop equipment in such a way

that any hazardous situations for individuals and prop-

erty are excluded in the event of the power supply being

interrupted or the power supply being activated fol-

lowing an interruption.

The emergency stop equipment must be freely acces-

sible at all times.

2.8 Behaviour in the event of haz-

ardous situations or accidents

Preventative measures

Always be prepared for accidents or fire!

Keep first aid equipment (first aid kit, blankets, etc.)

and fire extinguishers close at hand.

Familiarise personnel with accident reporting, first

aid and rescue equipment.

Keep access paths for rescue vehicles clear.

Measures in the event of accidents

Trigger an emergency stop immediately, and put the

isolator into the “0” position if necessary.

Implement first aid measures.

Rescue individuals from the hazardous area.

Inform the responsible person at the operation site.

Notify the emergency services.

Clear access paths for rescue vehicles.

2.9 Labelling

The following symbols and signs are usually found in

the work area. They apply to the very location where

they are found.

WARNING!

Risk of injury due to illegible symbols!

Over time, stickers and signs can become dirty or

otherwise illegible.

Therefore:

– Ensure that all of the safety, warning and oper-

ating information is clearly legible.

– Replace illegible signs or stickers immediately.

Safety

Labelling

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600) 13

7HFKQLFDOGDWD

'HVLJQYHUVLRQV

,03257$17

7KURXJKWKHVHOHFWLRQRIWKHFRQVWUXFWLRQVW\OHHDFK

URRIIDQRIWKHW\SHV'5DQG%9LVDGMXVWHGWRWKH

UHTXLUHPHQWVDWWKHRSHUDWLRQVLWH$GGLWLRQDORSWLRQV

DYDLODEOHXSRQUHTXHVW

7\SHFRGHVIRUURRIIDQV

7KHW\SHFRGHLVDGLVWLQFWLYHDQGXQLTXHSURGXFWGHVLJ

QDWLRQ$OORIWKHWHFKQLFDOGDWDRIWKHSURGXFWLQWKH

752;;ϣ)$16FDWDORJXHRUSURGXFWFRQILJXUDWRUFDQEH

DFFHVVHGZLWKWKLVFRGH

)LJ7\SHFRGHBURRIIDQ

%9 %9 VPRNHH[KDXVWIDQILUHJDV

+9 9 YHUWLFDOGLVFKDUJH+ KRUL]RQWDOGLVFKDUJH

'5 FHQWULIXJDOURRIIDQQRWUHTXLUHGIRUILUHJDV

) 6WDQGDUGPRWRURXWVLGHWKHDLUIORZUHTXLUHGIRU

ILUHJDV

+. . SODVWLFIDQ+ DGGLWLRQDOPRWRUYHQWLODWLRQ

V\VWHPIRUKLJKHUFRQYH\LQJWHPSHUDWXUHVQRW

UHTXLUHGIRUILUHJDV

)DQVL]H

%ODGHH[LWDQJOH

6'9 $GGLWLRQDOHTXLSPHQW6', LQWHJUDWHGRXWOHW

VRXQGDWWHQXDWRU6'9 YHUWLFDORXWOHWVRXQG

DWWHQXDWRU6'+ KRUL]RQWDORXWOHWVRXQGDWWHQX

DWRU

$GGLWLRQDOODEHOOLQJ

7KHWHPSHUDWXUHFODVVLILFDWLRQRIVPRNHH[KDXVWIDQV

%9LVEDVHGRQ(1

) WHPSHUDWXUHRI&PLQLPXPRSHUDWLQJ

WLPHRIPLQXWHV

) WHPSHUDWXUHRI&PLQLPXPRSHUDWLQJ

WLPHRIPLQXWHV

) WHPSHUDWXUHRI&PLQLPXPRSHUDWLQJ

WLPHRIPLQXWHV

) WHPSHUDWXUHRI&PLQLPXPRSHUDWLQJ

WLPHRIPLQXWHV

) WHPSHUDWXUHRI&

6HULHV

7\SH'5+0LQLYHQW'5+

)LJ7\SH'5+0LQLYHQW'5+

7\SH'590LQLYHQW'59

)LJ7\SH'590LQLYHQW'59

7\SH'59)

)LJ7\SH'59)

7HFKQLFDOGDWD

6HULHV!7\SH'59)

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

3.2.4 Type DRVF-H

Fig. 9: Type DRVF-H

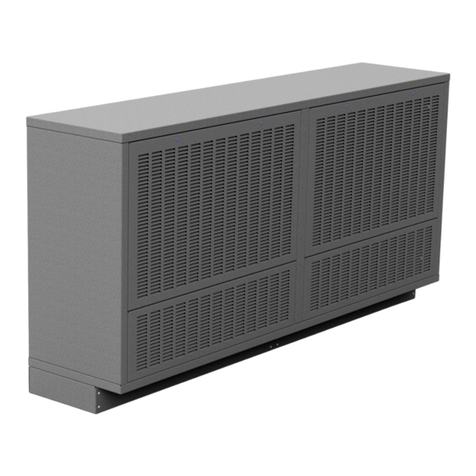

3.2.5 BVD

3.2.5.1 BVD F400

Fig. 10: Type BVD F400

3.2.5.2 BVD F600

Fig. 11: Type BVD F600

3.3 Connection values

The connection values are dependent on the type of

electric motor that is installed (rating plate of electric

motor, see

Ä

3.7 ‘Rating plate’ on page 19).

3.4 Noise emission values

The characteristic noise values of the fans are specified

in the characteristic curve sheets in the catalogue/

product configurator. The characteristic values are

dependent on the operating point.

Technical data

Noise emission values

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600)16

3.5 Operating conditions

Type DRV/DRH/DRVF

Data Value Unit

Min./max. flow medium temperature -20/+60 °C

Min./max. ambient temperature -20/+60 °C

Max. operating time according to EN 60034-1 24 hrs/day

Smoke extract None -

Installation vertical -

Axial inclination of the drive Inclined by max. ±20°1) -

1) Rain protection is limited on inclined devices

Type DRVF-H

Data Value Unit

Min./max. flow medium temperature -20/+120 °C

Min./max. ambient temperature -20/+60 °C

Max. operating time according to EN 60034-1 hrs/day hours

Smoke extract None -

Installation vertical -

Type BVD

Data Value Unit

Min./max. flow medium temperature -20/+120 °C

Min./max. ambient temperature -20/+60 °C

Max. operating time according to EN 60034-1 24 hrs/day

Smoke extract 2) -

Installation vertical -

2) Temperature/time category according to EN 12101-3 (see

Ä

3.1 ‘Design versions’ on page 15)

ATEX

Data Value Unit

Min./max. flow medium temperature -20/+40 3) °C

Min./max. ambient temperature -20/+40 °C

Max. operating time 24 hrs/day

Smoke extract None -

Installation vertical -

3) Other values upon request

Technical data

Operating conditions

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600) 17

3.5.1 Information on setting up fans that

are installed outdoors

3.5.1.1 Penetration of precipitation

Centrifugal roof fans

Fans from the ViVent, Minivent, DRH, DRV, DRVF, BVD

and BVW-D series are suitable for use in standard

weather conditions that normally occur. In rare cases,

rain can enter the building in extreme, stormy condi-

tions. Particular installation conditions and locations,

such as near the coast or tall freestanding buildings,

can be beneficial in these circumstances.

In the case of roof fans with vertical blow-out, the pene-

tration of precipitation into the fan casing is permitted for

function-related reasons. Existing drain holes in the

lower part of the casing are used to drain off the pene-

trating precipitation.

3.5.1.2 Formation of condensation

Uninsulated building penetrations are generally avoided

and should be insulated by others. Uninsulated fan

parts or accessory parts which can have different out-

side and inside temperatures and which cannot exclude

the formation of condensation must be insulated by

others following assembly (min. 20 mm-thick insulation

e.g. made of mineral wool or comparable insulation

materials). The fire safety engineering requirements

must be observed.

3.5.1.3 Stability

Particular installation conditions and locations, such as

near the coast or freestanding buildings, may require

certain safety measures. (stability, prevention of proper

motion). The safety measures can be implemented by

means of suitable restraints.

3.5.1.4 Penetration of foreign matter

The blow-out casings of the roof fan types have a con-

structive protection against ingress of foreign matter and

animals. Optionally, an additional cover grille can be

attached to the types DRV/DRVF/DRVF-H/BVD. Gener-

ally speaking, corresponding protective equipment (e.g.

cover grille) must be attached to free-outlet and free-

inlet fans.

3.6 Operating modes

3.6.1 S1 continuous operation

The fans are designed for continuous operation (S1

operating mode according to DIN EN 60034-1).

3.6.2 S9 speed-controlled operation

General

Fans are speed-controlled to adjust the operating point

to the system and utilisation requirements.

Speed control, maximum speed

The maximum speed specified on the rating plate must

not be exceeded.

Measures in the case of natural frequencies

Mechanical components have natural frequencies that

can cause the components to fail if accelerated to

impermissibly high vibrations. There is a possibility that

casing parts, bearings, crankshafts, attachments and

impellers can be damaged.

Excitation frequencies are, for example, caused by the

impeller’s rotary frequency, the blades’ frequency, the

blades’ rotational frequency, the motor’s rotary fre-

quency or aerodynamically.

If the excitation frequency is exactly or practically the

same as a component’s natural frequency, resonance

frequencies that can cause the component to fail will

occur. The excitation forces are dependent on the com-

ponents’ balancing condition, true running characteris-

tics, aerodynamic forces and damping features.

DANGER!

Danger due to resonance frequencies!

The fan must not be operated in the higher speed

range in which increased vibration values occur.

These areas must be skipped or removed for the

operation. The areas must be passed through so

quickly that the permissible vibration values in the

resonance frequency are not engaged or exceeded.

A permanent vibration monitoring system is recom-

mended for speed-controlled fans to ensure the long-

term, safe operation of the fan.

After commissioning speed-controlled fans, it is

common practice to initially start them with short mainte-

nance intervals, and if no damage occurs, to gradually

adjust the maintenance intervals to the intervals speci-

fied in the operating manual.

Commissioning of speed-controlled fans

During commissioning, the fan vibrations must be

checked over the entire speed control range of the fan.

During this process, the vibrations on the casing and

bearing must be determined and evaluated in accord-

ance with DIN ISO 14694 depending on the installation

and motor rating. Refer to the “Vibration velocities” table

in the appendix of the operating manual for the permis-

sible vibration velocities.

Ä

Appendix ‘Tables’

on page 53

The amplitude of the vibration velocities is dependent

on different factors.

Technical data

Operating modes > S9 speed-controlled operation

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600)18

7KHW\SHRILQVWDOODWLRQWKHXSVWUHDPDQGGRZQVWUHDP

FRQGLWLRQVWKHFKDUDFWHULVWLFVRIWKHVXSSRUWLQJVWUXF

WXUHIRXQGDWLRQIDQRSHUDWLQJSRLQWDWWDFKPHQWVDQG

DFFHVVRULHVLQIOXHQFHWKHTXLHWUXQQLQJRIWKHPDFKLQH

DQGFDQWKHUHIRUHRQO\EHHYDOXDWHGIRUFRUUHFWRSHUD

WLRQZKHQLQVWDOOHG

7HVWLQJPXVWEHFRPSOHWHGE\VSHFLDOLVWSHUVRQQHORU

FDQEHFRQWUDFWHGRXWWR752;;

ϣ

)$16

6SHHGFRQWUROVSHFLDOSURYLVLRQV

%\FKDQJLQJWKHVSHHGDGGLWLRQDODFFHOHUDWLRQIRUFHV

DUHDSSOLHGWRWKHIDQFRPSRQHQWV

&KDQJHVWRWKHVSHHGGXULQJFRQWUROOHGRSHUDWLRQ

PXVWQRWFDXVHWKHSHUPLVVLEOHPRWRUWHPSHUDWXUHV

DQGEHDULQJORDGVWREHH[FHHGHG

7KHUXQXSWLPHVKRXOGWKHUHIRUHEHDSSUR[VHF

RQGV

&KDQJHVWRWKHVSHHGWRDGMXVWSURFHVVYDULDEOHV

FRQWUROOHGRSHUDWLRQVKRXOGEHPD[UHYVHF

UDGVHFH[FHSWZKHQUXQQLQJWKURXJKUHVR

QDQFHIUHTXHQFLHV

7KHIDQV¶VHUYLFHOLIHFDQEHLQFUHDVHGE\TXLFNO\

UXQQLQJWKURXJKUHVRQDQFHIUHTXHQFLHV

7KHRSHUDWLQJPDQXDOVIURPWKHFRQWUROXQLWPDQX

IDFWXUHUPXVWEHREVHUYHG

7KH(0&'LUHFWLYH(8PXVWEHFRPSOLHG

ZLWK

*HQHUDOQRWHV

7KHPRWRUDQGWUDQVIRUPHUPXVWEHSRVLWLRQHGDV

FORVHWRRQHDQRWKHUDVSRVVLEOH

&DEOHVPXVWEHVKHDWKHGDQGVKLHOGHG

&DEOHVFDEOHHQGVWKHIUHTXHQF\LQYHUWHUDQGWKH

PRWRUPXVWEHHDUWKHG

,WLVDGYLVDEOHWRXVHDOOSROHVLQHILOWHUV

6PRNHH[WUDFW

'XULQJVPRNHH[WUDFWRSHUDWLRQWKHIDQVRQO\H[WUDFW

VPRNHJDVHVLQWKHHYHQWRIDILUHWRUHPRYHWKHVPRNH

IURPWKHILUHFRPSDUWPHQWV

&(PDUNLQJRIVPRNHH[KDXVWIDQV%9

)LJ&(PDUNLQJ

7KHUDWLQJSODWHRIWKHVPRNHH[KDXVWIDQV%9DOVR

FRQWDLQVLQIRUPDWLRQDERXWWKHDSSOLFDWLRQDQGSHUPLV

VLEOHWHPSHUDWXUHWLPHFDWHJRU\

,QDGGLWLRQD&(PDUNDVSHU(13DUWLV

DWWDFKHGWRGHPRQVWUDWHSURGXFWFRQIRUPLW\

5DWLQJSODWH

)LJ)DQ¶VUDWLQJSODWH

7KHIDQ¶VUDWLQJSODWH)LJ)LJLVORFDWHGRQ

WKHRXWVLGHDQGFRQWDLQVWKHIROORZLQJLQIRUPDWLRQ

DPRQJRWKHUWKLQJV

7HFKQLFDOGDWD

5DWLQJSODWH

&HQWULIXJDOURRIIDQV'5+'59'59)'59)+%9'%9')

Manufacturer

Year of manufacture

Manufacturing no.

Part no.

Type

Volume flow rate

Speed

Motor rating

Total pressure increase

Voltage (V) / frequency (Hz)

Fig. 14: Arrangement of the rating plates on roof fans

The rating plate of the explosion-proof fan also includes

the following information:

Explosion protection mark

Category

Fig. 15: Electric motor’s rating plate

The electric motor’s rating plate (Fig. 15, Fig. 14/2) is

located on the outside. For information on this rating

plate, refer to the electric motor operating manual.

Technical data

Rating plate

Centrifugal roof fans DRH; DRV; DRVF; DRVF-H; BVD; BVD(F600)20

This manual suits for next models

5

Table of contents

Other Trox Fan manuals

Popular Fan manuals by other brands

MILUX

MILUX MCF- E120 Operating and installation instructions

Flexit

Flexit Motion 114258 user guide

Fanimation

Fanimation Edgewood TF600 Series owner's manual

Emerson

Emerson CF370BS00 owner's manual

Helios

Helios SB Series Installation and operating instructions

Dustcontrol

Dustcontrol RAF 2501 Original instructions

Bionaire

Bionaire BPF650 instruction manual

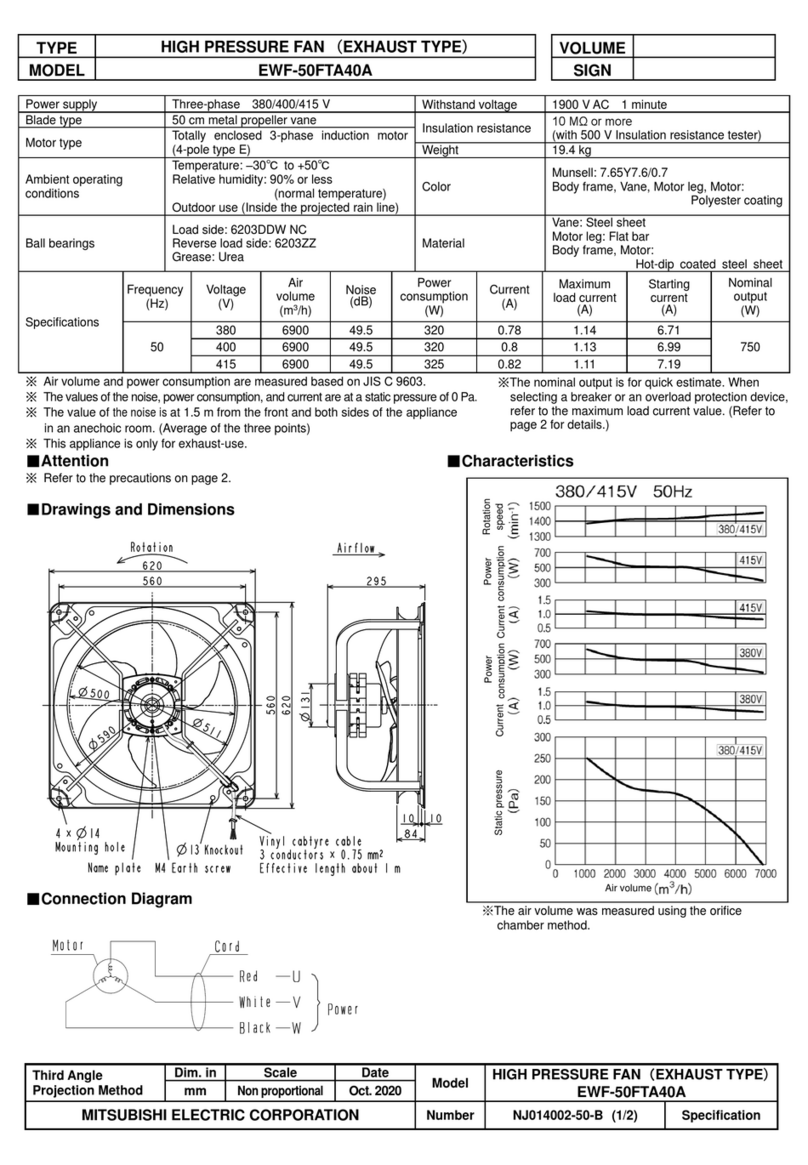

Mitsubishi Electric

Mitsubishi Electric EWF-50FTA40A quick start guide

CellarPro

CellarPro 3000Scmr-EC owner's manual

Maico

Maico ECA 150 ipro Installation and operating instructions

MOBAIR

MOBAIR 2010 owner's manual

Ellington

Ellington E-BFT52ABZ5C installation guide