Trox Qlci User manual

v1.1 – Issue Date: 02/2023

© 2022 Carson Solutions. All rights reserved.

QLCI with REAR FIN TUBE HEATER ELEMENTS INSTALLATION,

OPERATION, & MAINTENANCE (IOM) MANUAL

2

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

TABLE OF CONTENTS

General Information

1.1 Introduction 3

1.2 Safety 3

1.3 Symbols used in this Manual 3

1.4 Receiving, Inspection and Storage 3

Product Description and Installation Preparation

2.1 Product Overview 4

2.2 Construction Description 4

2.3 Application Precautions 4

2.4 Preparation for Installation 4

2.4.1 Items Provided by Installer 4

2.4.2 Unit Weights 4

Installation

3.1 General Procedure 5

3.2 Installation Considerations 5

3.3 Installing the QLCI with Rear Fin Tube

Elements 5-8

3.4 Water Connections 9

3.4.1 Water Connections Identification 9

3.5 Condensate Drain Connection 9

3.6 Air Connection 10

3.7 Flushing the Water Piping System 10

3.8 Filling and Venting the Water System 10

Commissioning

4.1 Waterside Commissioning 11

4.2 Airside Commissioning 11

4.2.1 Airside Commissioning and K-Factor Table 11-12

Maintenance

5.1 Cleaning Instructions 13

5.2 Replacement Parts 13

Troubleshooting

6.1 Symptoms & Solutions 14

Terms and Conditions

7.1 Manufacturer’s Representations

& Warranties 15-16

3

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

General Information

Important!

Designation of a danger that can cause personal

injury or damage to property

Warning!

Indicates a potentially dangerous situation for the

product and the environment

Note!

Indicates important notices or information

Carson Solution products should not be removed

from its individual carton for storage. Do not unpack

units until they havebeen moved to the installation

location and just before installation is to begin.

1.1 INTRODUCTION

The QLCI displacement induction ventilation diffusers are designed

to provide air quality and acoustical performance similar to

conventional displacement systems but are designed specifically for

the North American climate. Units are fitted with a series of air

induction nozzles that allow the supply of conventional air (50° to

55°F) to the terminal. These nozzles induce room air through a

cooling and/or reheat hydronic coil to pre-condition the air prior to

mixing with the primary nozzles. The result is a constant volume

(variable temperature) displacement type supply of air to the space.

The QLCI displacement induction ventilation diffusers, when applied

with optional rear fin tube heating elements, delivers warm air to the

space along the exterior wall or large window exposures. Room air

migrates through air pathways to the fin tube elements and the

heated air travels upward due to radiation or buoyant heat

forces. No primary air is used to drive air upward across the fin tube

heating elements. Ventilation air from the central station air handler,

coupled with induced room air provides the necessary ventilation

requirements and total airflow to the space via the lower face diffuser

panel outlets.

The integral hydronic coil within the unit is sized to allow the QLCI

terminal to condition the room while the central system air handler

supplies air at (or near) the mandated space ventilation rate.

Therefore, the central station air handler can supply 100% outside

air while all of the return air from the space is exhausted.

The diffuser uses the primary air energy to induce air through the

hydronic coil and does not contain any moving parts such as, fans,

motors, or compressors to be maintained.

1.2 SAFETY

The customer must use qualified personnel and follow all applicable

building codes and safety regulations when installing, commissioning

and performing maintenance of this product. Eye protection and

gloves should be worn at all times when handling the product.

Consult all local building, occupational safety and other codes

applicable to the installation.

Please pay particular attention to the symbols used throughout the

manual that indicate safety related issues, warnings and important

notices or information; read the complete manual before installation

and be familiar with the meaning of the safety symbols in the next

section 1.3.

1.3 SYMBOLS USED IN THIS MANUAL

When reading this manual, particular attention must be given to the

parts marked with the following symbols:

1.4 RECEIVING, INSPECTION AND STORAGE

All Carson Solutions products are inspected and tested prior to

shipment to ensure the highest quality. Carson Solutions

products are packed and labeled in individual cardboard cartons.

Upon receipt of the product shipment, conduct a thorough

inspection of the outer packaging and pallets for possible

damage. If damage has occurred during shipping, indicate the

damaged items on the delivery papers immediately and inspect

the product contained in those containers for damage.

If damage has occurred during shipping, immediately file a claim

with the carrier.

Refer to the Manufacturer’s Representations and Warranties on

pages 15-16 of this manual for detailed handling instructions

and damage reporting procedures.

Carson Solutions products should be stored in a clean and dry

location. If products remain packaged as delivered (strapped and

wrapped on pallet), they can be stored as delivered (do not stack

pallets). If the packaged products are removed from pallet, they

should not be stacked more than four high.

Packaging is not suitable for outside storage

!

!

F

r

agile!

Handle with care. The diffusor should not be

handled using the water pipes which may cause

damage to the unit.

Important!

You must read all instructions prior to the installation,

operation, or maintenance of this product!

4

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Product Description and Installation Preparation

!

Caution!

Machinery recommended for movement and instal-

lation of QLCI’s. Refer to table below for unit weights

and use caution when removing from packaging.

2.1 PRODUCT OVERVIEW

The QLCI displacement induction ventilation diffusers are designed

specifically for classroom applications. Units can operate in cooling,

heating, and or ventilation modes. In standard cooling or heating

modes, primary air is delivered through a series of induction

nozzles. As ventilation or primary air is fed to the round OA plenum,

the air passes through a series of nozzles, producing both a

relatively high velocity airstream and an area of low pressure

thereby inducing room air through the assembly’s return grill and

across its integral hydronic coil. The air is reconditioned and then

mixed with the primary air prior to being discharged back into the

space via a grill mounted on the lower face of the QLCI unit. In

certain circumstances designers have elected to apply optional rear

fin tube heating elements for either primary or supplemental heating

in the space. Please consult your local Representative or Carson

Solutions directly to evaluate what heating approach is best suited

for your application.

The QLCI displacement induction ventilation diffusers should be

installed in the quantities, sizes and configurations shown on the

project plans and performance schedules.

2.2 CONSTRUCTION DESCRIPTION

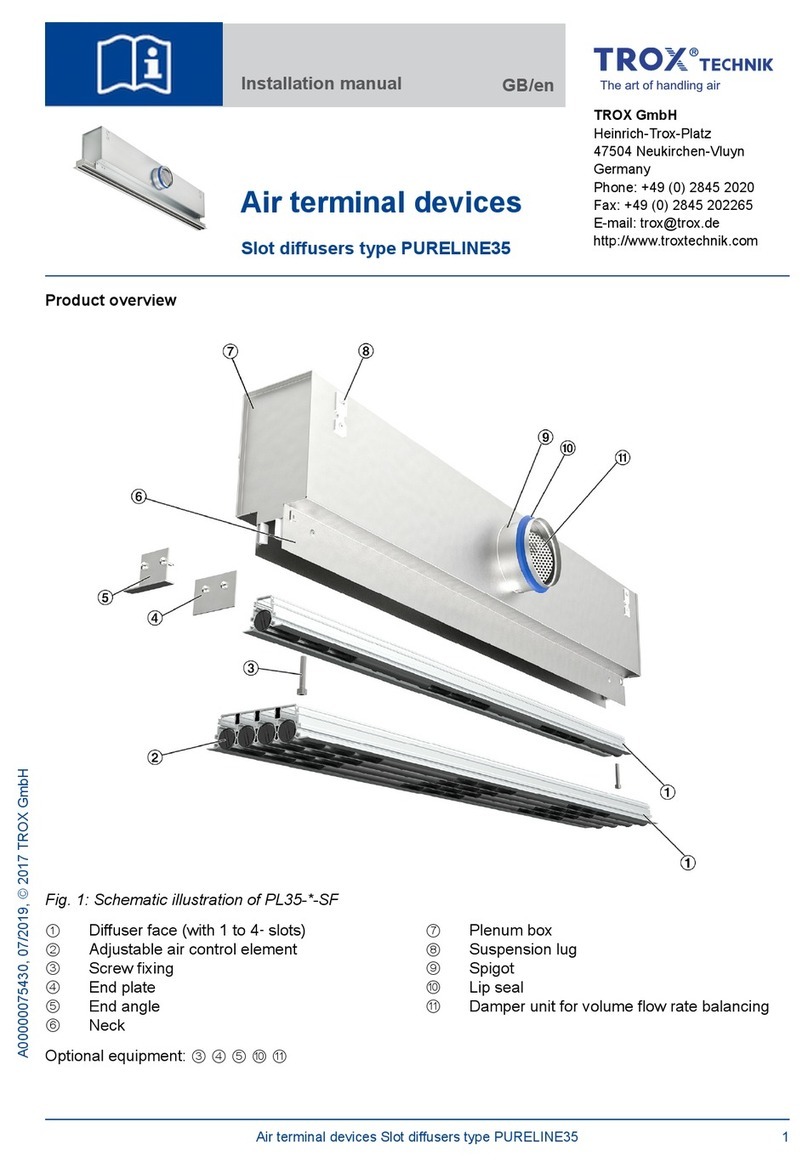

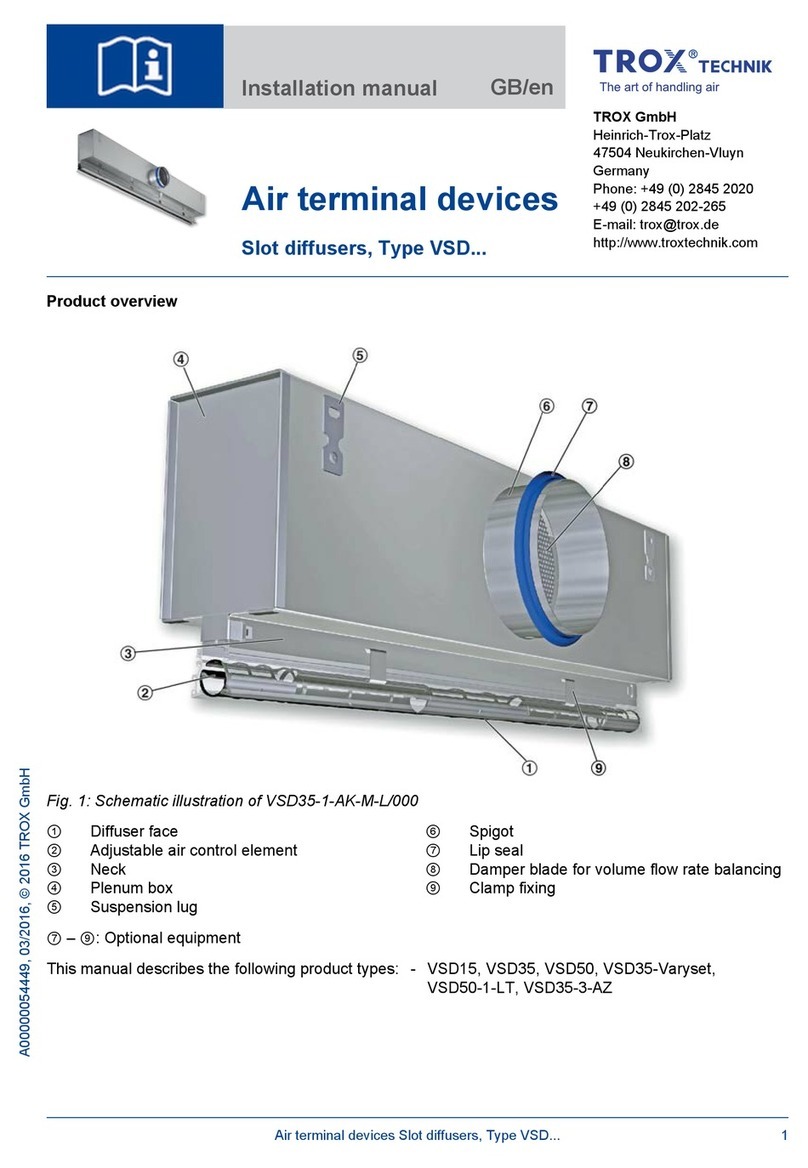

The assembly (figure 1) of the QLCI consists of a heat transfer coil

(2- or 4-pipe), primary air inlet (top or side), induction nozzles,

transition connecting duct and sloped condensate tray with

connection. Cabinet structure is constructed of heavy gauge steel

and powdercoated with a fingerprint proof texture paint. Optional

accessories such as bookshelves, utility cabinets, and OA duct

covers may also be supplied by Carson Solutions.

2.3 APPLICATION PRECAUTIONS

When in cooling mode, the entering water temperature to the

QLCI displacement induction ventilation diffuser coil should

be maintained warmer than the space dew point temperature in

order to prevent condensation.

Extreme latent load applications may, however, require lower

chilled water temperatures be used to condense moisture from the

recirculated air during the reconditioning process.Please consult

with a local Representative or Carson Solutions directly for review

of design approaches.

2.4 PREPARATION FOR INSTALLATON

The QLCI displacement induction ventilation diffuser is

manufactured by Carson Solutions with the following

details:

•Single or dual duct connections

•A series of induction nozzles

•Integral heat exchange coil

•Rear wall mounted fin tube elements

•Perforated discharge baffle plate

•Mounting brackets with a ⅜” x 1” slot

•Sloped condensate trays with capped ½” drain

•Architectural cabinets

2.4.1 ITEMS PROVIDED BY INSTALLER

Installer to provide (according to all applicable local

building codes):

•Proper PPE should be used by the installer

•Level and measure equipment

•Tools such as wrenches, plyers, screw drivers, and drills

•A mounting system including 2x4’s and all mounting

hardware for installation

•Hydronic piping system with NPT fittings

•Water flow regulators and strainers if applicable

•Manual shut-off valve for each pipe run

(recommended) supply and return water circuits

(unless factory furnished flexible hoses are included

with product order) or hard connections

•Air-side balancing and/or control devices as specified in

the project plans and specifications

•Recommended hardware to attach each unit to each

other is (4) 5/16-18 x 1” Phillips head truss screws and

(4) 5/16” serrated nuts per QLCI. End wall units only

require 2 of each per QLCI

2.4.2 UNIT WEIGHTS

Add 7% for to values below for water weight

Fin Tube Length Weight with Packaging

3ft

2.25 lbs

4ft

3.00 lbs

5ft

3.75 lbs

6ft

4.50 lbs

7ft

5.25 lbs

8ft

6.00 lbs

QLCI Unit

Size

Weight without

Cabinet

Weight with

Cabinet

4ft

68 lbs 128 lbs

5ft 84 lbs 160 lbs

1500 95 lbs 180 lbs

6ft 101 lbs 192 lbs

2000 122 lbs 232 lbs

8ft 135 lbs 255 lbs

Important!

Installation must be performed by properly trained

and authorized personnel only! Read all

instructions before beginning installation.

5

Installation

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

3.1 GENERAL PROCEDURE

The QLCI displacement induction ventilation diffusers should be

installed in quantities, sizes and configurations shown on the project

plans, schedules, and submittals. Deviation from the designed plan

should be avoided as the QLCI unit locations and configurations is

critical to the comfort of the conditioned space. Units are designed

for easy installation and access for maintenance.

3.2 INSTALLATION CONSIDERATIONS

Most classrooms will require the QLCI units are installed along 75%

to 80% of the exterior exposure to provide adequate space

conditioning at noise levels that are compliant with ANSI S12.60.

The supply air duct and vertical pipe runs can be housed in the

class- room walls or may be covered using optional architectural

duct covers and can be accessed through the utility cabinets

provided by Carson Solutions.

3.3 INSTALLING THE QLCI WITH REAR FIN-TUBE

ELEMENTS

STEP 1: INSTALL 2X4’S MOUNTING BOARDS

a.) Secure two 2x4 Mounting Boards to the perimeter wall

making sure they are securely mounted to wall framework

as shown below. (Fasteners supplied by others).

b.) The 2x4 Mounting Boards should run the length of the

QLCI installation (not individual units). The 2x4 Mounting

Boards should stop 1.5” from edge of wall to allow end unit

side panel to set flush against the wall.

STEP 3: INSTALLING REAR FIN TUBE ELEMENTS

a.) Attached Fin Tube Mounting Bracketsto the wall using

wall anchors (Supplied by others). Position each Fin Tube

Mounting Bracket 6”-12” inwards from the Fin Tube

Element pipe ends. Example: A 6ft Fin Tube Element

would have the first bracket at 6”-12” and the second bracket

would be located at 60”-66” from the other end. 3ft to 4ft Fin

Tube Elements require 2 mounting brackets and 5ft to 8ft

Fin Tube Elementsrequire 3 mounting brackets. A bracket

for 5ft-8ft the Fin Tube Elements should be mounted in the

middle of the lengths for support. The Fin Tube Mounting

Brackets should rest directly on top of the 2x4 Mounting

Boards before securing to wall. Refer to project plans for the

appropriate fin tube elements installation lengths and

locations.

b.) Hang the lower Fin Tube Elementsby placing it gently onto

the Fin Tube Mounting Brackets. The tubes of the Fin

Tube Elements will rest in the V-Groove of the Fin Tube

Mounting Brackets. The Fin Tube Elements are 2.75” fin

width and 2.50” fin height. Make sure the Fin Tube

Elements are positioned in the correct orientation.

Note:

The locations of the 2x4’s is very important to

install in the locations provided in the

dimensions in Section 3.3.

6

Installation

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

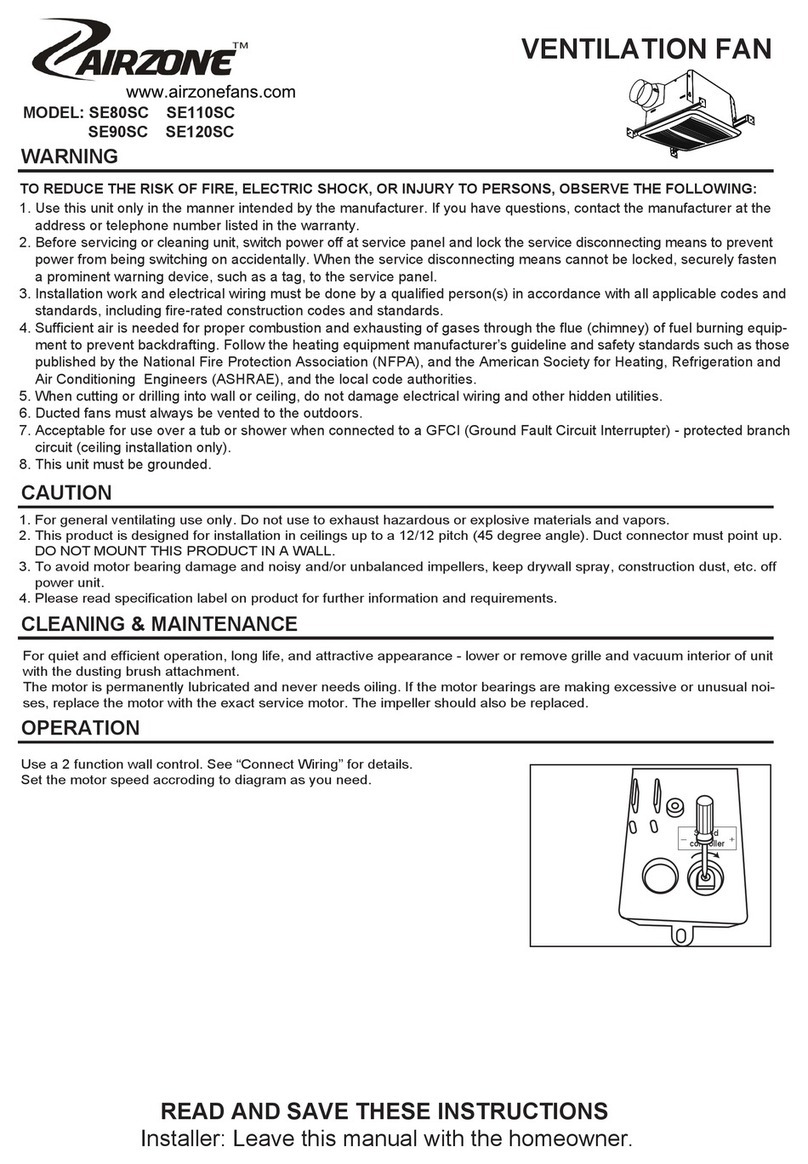

c.) Hang the upper Fin Tube Elementsby placing it gently

onto the Fin Tube Mounting Brackets. The tubes of the

Fin Tube Elements will rest in the V-Groove of the Fin

Tube Mounting Brackets. The Fin Tube Elements are

2.75” fin width and 2.50” fin height. Make sure the Fin Tube

Elements are positioned in the correct orientation.

d.) Repeat Steps (a-c) for additional Fin Tube Elements

according to the room layout of the project plans. Note:

There may be plastic clips on the Fin Tube Elements from

the manufacture, these can be discarded.

e.) Once all Fin Tube Elements are installed, begin joining all

piping together (Straight pipe and fittings supplied by others).

The lower Fin Tube Elements are to be the Supply run, and

the upper Fin Tube Elements are to be the Return run. A

Loop should be used to connect the last lower Fin Tube

Element to the upper return row of Fin Tube Elements.

f.) Connect the Supply and Return piping to complete the

circuit. If using a BUC, it will be necessary to install the

BUC first before the main Supply and Return piping is ran

and connected.

STEP 2: Example install QLCI hydronic water piping

a.) Typically, a BUC is used where the water pipes are dropped

from the ceiling along a wall perpendicular to the exposure

and are secured to the wall between the mounting boards as

shown below. Additional valves, regulators, and strainer

may be required. See project plans and specifications

for more information.

7

Installation

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

b.) Install threaded ½˝ NPT connections (provided by others)

on each pipe or solder straight end connections 2˝ to 3˝ from

the point where the QLCI units connect to each other along

the wall as shown below.

c.) Once all the piping is connected, test for leaks and

insulate piping. Refer to project plans for insulation

specifications. Use standard plumbing practices and test for

leaks once the piping is complete. See Section 4.1 for

pressure ratings.

STEP 3: Attaching the QLCI units to the wall

a.) Locate the (2) socket head screws on the face of each upper

face panel. Loosen the locking screws using an 5/32” Allen

Wrench and remove the units upper face panels (as shown

below). Do not use a power driver to loosen or tighten

latches. Do not allow the upper face panels to fall as this

could cause damage to the panel surface. Remove lower

panel as needed by removing the (2) TEK screw.

b.) Position the first QLCI unit (nearest the supply air duct)

against the wall. Secure units to the 2x4 Mounting Boards

by driving ⅜” lag bolts and ⅜”flat washers through the unit’s

four (4) Mounting Brackets as shown below.

STEP 4: Positioning and connecting the remaining units

a.) Repeat Step 3 to mount the remaining units to the wall and to

make water connections.

b.) Connect the QLCI units together by sliding the connector

sleeve from the adjacent QLCI unit onto the entry spigot and

seal the connection as described below in Section 3.5.

8

Installation

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

c.) Attached each QLCI to another using (4) 5/16-18 x 1”

Phillips head truss screws and (4) 5/16” Serrated nuts per

QLCI. End wall units only require 2 of each per QLCI. Locate

the upper and lower holes as shown. Insert hardware and

tighten the units together.

d.) If inspection of the Fin Tube Elements is needed, remove

the Rear Fin Tube Element Grill on the back of the QLCI.

Locate the (2) socket head screws on the top of each Rear

Fin Tube Element Grill. Loosen the locking screws using

an 5/32” Allen Wrench and remove the QLCI Rear Fin Tube

Element Grill as shown below. Make sure when placing the

QLCI Rear Fin Tube Element Grill back in place that the

side tabs interlock with the metal flanges.

e.) Alternative piping method 1: Units can be placed on roller

carts and connected to each other first. The pipework can be

connected to the back of the QLCI’s, and piping connections

can be connected to each other before mounting the entire run

of QLCI’s to the wall mounted 2x4’s as shown below.

f.) Alternative piping method 2: QLCI units can allow the piping

runs to be in the front of the units above the hydronic coil. This

allows the QLCI to be mounted to the 2x4’s first, then connect

the ductwork before making the piping connections. The

feeding pipework can be routed through the side wall

knockouts. QLCI’s and piping connections can be connected in

the front as shown below.

STEP 5: Connecting to water supply

a.) Connect the unit’s hydronic coil to

the water piping using flexible

braided stainless-steel hoses (½˝

female NPT’s to connect to coil).

In most applications, flexible

braided stainless-steel hoses

require 90° elbows. Hard copper

piping may also be used. Proper

sealing techniques should be

applied. Refer to Division 23

Section 23 21 13 “Hydronic

Piping”, connect coils to supply

with shutoff valve, strainer, control

valve, and union or flange, and to

return with balancing valve and

union or flange.

b.) The vertical chilled/hot water pipes

are connected via flexible hoses

run through a pipe work knockout

on the top or side of the unit.

c.) Piping should be insulated and properly labeled in

accordance with local building codes as shown below.

It is recommended to use

these holes on the QLCI

top and bottom panels to

attach each unit together.

9

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Installation

Extreme Caution!

Do NOT over-tighten NPT fittings.

Applying excessive force on the water pipes may

damage the hydronic coil and is not covered under

warranty.

3.4 WATER CONNECTIONS

The QLCI unit is fitted with four water pipes which terminate in

½” NPT threaded male connections. Each coil is factory tested

for leakage and provided clean and capped. Caps shall not be

removed unit piping installation is in process.

Note:

When installing a two-pipe design, connect only the

outside pipes if four-pipe coil was supplied.

STEP 1:

Identify the warm and/or

chilled water supply

connections on the QLCI

unit. See Section 3.4.1.

STEP 2:

Remove the plastic caps

before making the final

water connections.

STEP 3:

Make the water connections to the hydronic coil piping using

flexible braided stainless-steel hoses (½˝ female NPT’s to

connect to coil). Hard copper piping may also be used. Proper

sealing techniques should be applied. Refer to Division 23

Section 23 21 13 “Hydronic Piping”, connect coils to supply

with shutoff valve, strainer, control valve, and union or flange,

and to return with balancing valve and union or flange.

Carson Solutions optional Stainless Steel Flexible Hoses

(contact your factory rep to purchase).

3.4.1 WATER CONNECTIONS IDENTIFICATION

Piping connections for standard 2-pipe and 4-pipe QLCI

displacement induction ventilation diffusers to be operated

and connected as shown below.

3.5 CONDENSATE DRAIN CONNECTION

The QLCI unit is fitted with a sloped condensate drain tray with

an anti-clogging ½” plastic drainpipe fitting (½” OD). Each

drainpipe is located on the right side of the QLCI when looking

at the unit from the front. The drainpipe fitting should be

connected to a condensate line or pumping system as specified

in project documents. Each drain comes capped from the

factory. Remove cap prior to pumping each drainpipe fitting.

10

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Installation

There should be no high points to create

air pockets within the system.

Note:

Use ONLY non-chilled water when filling up the

system! Cold water can cause immediate

condensation on the pipes. Warm water contains

less oxygen which can limit venting to some extent.

3.6 AIR CONNECTION

STEP 1:

Note:

QLCI displacement induction ventilation diffusers

operate at higher terminal pressures than diffusers in

standard VAV systems therefore the ductwork and

connections feeding the diffuser must be thoroughly

sealed to prevent excessive leakage.

The air connections should include a minimum of three duct

diameter lengths of straight ductwork upstream of the QLCI

connection to ensure laminar flow and prevent noise generation.

Straight ductwork connections will yield a reliable pressure port

measurement.

Air connections can be made with either hard-pipe (most common)

or with flexible duct. If using flexible duct, limit duct length to a

maximum of 5ft.

Using the supplied transition collar to connect each QLCI together.

Properly seal ductwork with either foil HVAC aluminum tape or with

duct sealant mastic. The inner duct connection must be fully sealed

to prevent leakage and loss of performance.

Ensure there is an airtight connection between the supply duct and

each QLCI duct interconnections. Duct connections should meet

SMACNA class B standard up to 2 in. W.G. Refer to Division 23 –

Heating, Ventilation and Air Conditioning (HVAC) Section 23 31

13.01 “Metal Ducts” and or Section 23 07 13 “Duct Insulation” for

additional information.

3.7 FLUSHING THE WATER PIPING SYSTEM

Before flushing the water system, close all valves that isolate the

QLCI units and flush the main piping system first. Refer to

Division 23 Section 23 25 00 “Pipe Cleaning, Flushing, and

Chemical Treatment”.

3.8 FILLING AND VENTING THE WATER SYSTEM

To ensure easy venting, the main pipes should be installed at a

higher level than the QLCI units. The horizontal pipes should be

installed rising slightly towards the venting points.

Before filling, all shut-off and control valves must be in the fully

open position. The pumps should not be running during the

filling processes (static filling). Continuous venting is necessary

during this process. The installation of both manual and

automatic venting systems is recommended. The pump should

only be started when filling is complete. To remove all air from

the system, the majority (>75%) of the system should be closed

so that the water can circulate at a sufficient rate. When each

section is full, it should be closed, and the procedure repeated

throughout the system.

11

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Commissioning

Important:

Commissioning is to be performed by properly

trained and authorized personnel only!

!

Note:

Do not attempt to read the total discharge airflow rate

using ahood or any other device that adds down-

stream pressure to the unit, as it will reduce the

amount of induction and give false readings.

The total supply air flow (primary +induced) cannot

be measured.

The constraints detailed in the tables below are for

standard QLCI. For QLCI’s with non-standard

nozzle configurations, contact Carson Solutions

directly.

4.1 WATERSIDE COMMISSIONING

•Fully purge the complete hydronic system of air prior to

commissioning.

•Carefully inspect the system for leaks, paying particular

attention to the connections.

•Carefully inspect flexible hose for leaks, if applicable.

•For the face coils normal operating pressure is rated at 250 psig

max up to 300°F. The maximum working pressure should not

exceed 360 psi.

•If equipped, the fin-tube elements the minimum flow rate of

1GPM ranging from 110°F to 220°F at a pressure drop of 47

Millinches per foot. Maximum flowrate at 4GPM at the same

operation temperature ranges at a pressure drop of 525

Millinches per foot. The maximum working pressure is 200

psig.

4.2 AIRSIDE COMMISSIONING

NOTE: Using a traverse duct calculation of the supply duct before

the QLCI will not guarantee that the diffuser is properly balanced

because performance is based on internal plenum pressure.

4.2.1 AIRSIDE COMMISSIONING AND K-FACTOR TABLE

STEP 1

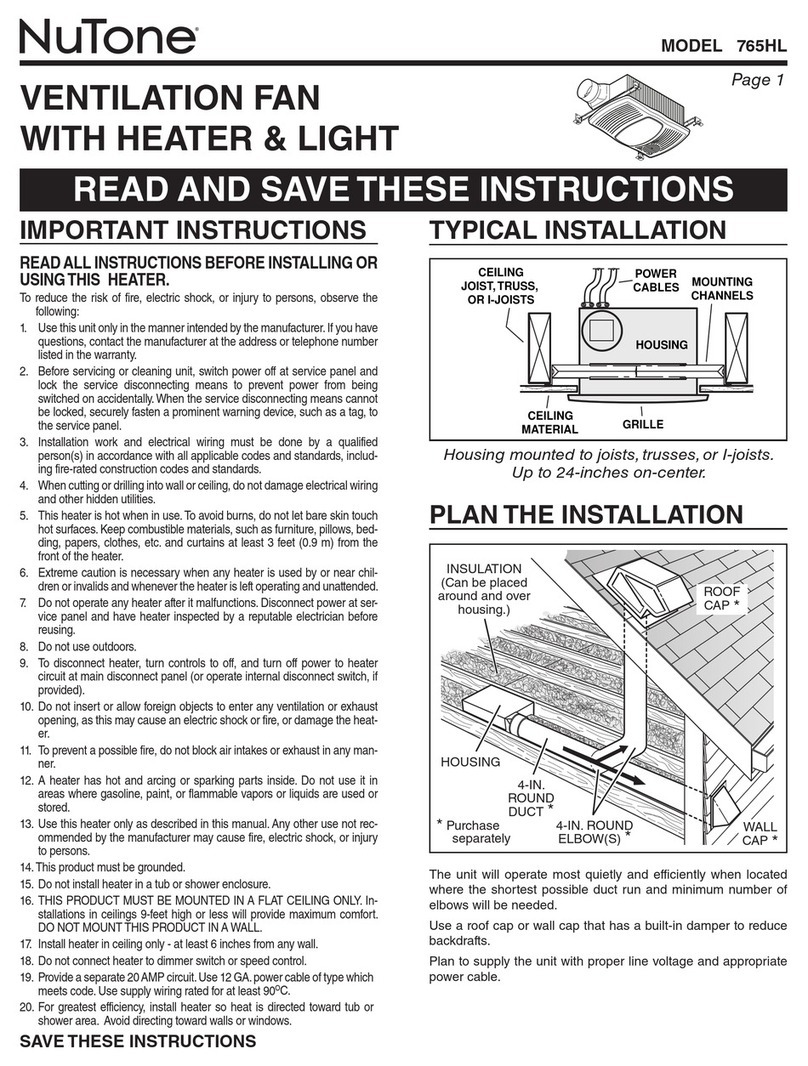

Locate the (2) socket head screws on the top of the upper left

face panel. Loosen the locking screws using an 5/32”Allen

Wrench and remove the units upper face panels (as shown

below). Do not use a power driver to loosen or tighten latches.

Do not allow the upper face panels to fall as this could cause

damage to the panel surface.

STEP 2

Use the commissioning tube to measure the internal pressure

of the plenum.

Note:

The QLCI unit is not provided with any water flow

control or measuring devices, therefore the pipe

work system should be fitted with sufficient

balancing aids to enable adjustment of the flow rate.

12

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Commissioning

STEP 3

The primary air volume in CFM can be calculated with this

formula and the K-Factor value in the charts below: Data on the

charts below are given at Standard Atmosphere at sea level.

The primary air volume in CFM can be calculated with this formula:

CFM = K x √ΔP

CFM = primary airflow (CFM)

K = constant - read from Table below

ΔP = static pressure measured in primary air

chamber (in. W.G.)

Example: Size 1500mm QLCI, 2R-nozzle

measured static pressure of 0.295 in. W.G.

K = 221 (from Table 2)

CFM = 213 x √0.295

= 120.0 CFM

STEP 4

Make necessary adjustments to the balancing damper for the

desired scheduled static pressure to the measured result.

Adjusting the balancing damper should be used for trimming only.

Re-installed front face panels.

Refer to Division 23 Section 23 05 93 “Testing, Adjusting, and

Balancing” for additional procedures for displacement unit,

adjusting and balancing.

Volume Flow Controller (optional) general information:

If a volume flow rate control is required, a volume flow

controller (supplied by others) may be installed in a constant

volume system. See manufactures information specifications

for further details.

Carson Solutions offers a range of volume flow rate

controllers. Please contact Carson Solutions for more

information.

13

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Maintenance

Important!

Maintenance is to be performed by properly trained

and authorized personnel only!

!

Important!

Wear eye protection and gloves.

Product includes sharp edges and burrs.

!

Strong or abrasive chemical detergents should not

be used as they may cause damage to the paint

finish.

5.1 CLEANING INSTRUCTIONS

QLCI units contain no moving or consumable parts, therefore the

maintenance requirements are limited to periodic inspection for leak-

age and occasional cleaning of the hydronic coil, front face panel

and the condensate tray.

The accumulation of dust on the hydronic coil will eventually restrict

the airflow through the coil, reducing cooling and heating

performance.

The inspection frequency is subject to the environmental conditions

and occupancy levels. It is recommended that the QLCI units be

inspected on an annual basis until a scheduled maintenance pattern

is established.

Properly maintain water conditions which prevent corrosion of

copper tubing If included in the system design, check the

condensate sensors or humidity sensors according to sensor

manufacturer’s methods and schedule.

To clean the hydronic coil:

STEP 1

Locate the (2) socket head screws on the top of each upper face

panel. Loosen the locking screws using an 5/32” Allen Wrench

and remove the units upper face panels (as shown below). Do

not use a power driver to loosen or tighten latches. Do not allow

the upper face panels to fall as this could cause damage to the

panel surface.

STEP 2

Using a soft nozzle brush attachment, gently vacuum in the

direction of the coil fin to remove any accumulated dust. Be

careful not to bend or damage any fins. A fin comb can be

used to straighten any bent fins.

STEP 3

After cleaning the coils, replace the unit face panels by

tightening locking screws with 5/32” Allen Wrench.

To clean the QLCI unit:

When necessary, the cabinet can be cleaned using a mild

detergent diluted with warm water. Apply with a soft cloth,

rinse, and wipe dry.

To clean the condensate tray:

If necessary, the condensate drip tray can be cleaned

using a small amount of disinfectant applied with a soft

cloth. Wipe dry.

5.2 REPLACEMENT PARTS

The QLCI displacement induction ventilation diffuser

contains no serviceable or consumable parts. Contact

Carson Solutions for more information.

14

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Troubleshooting

6.1 SYMPTOMS & SOLUTIONS

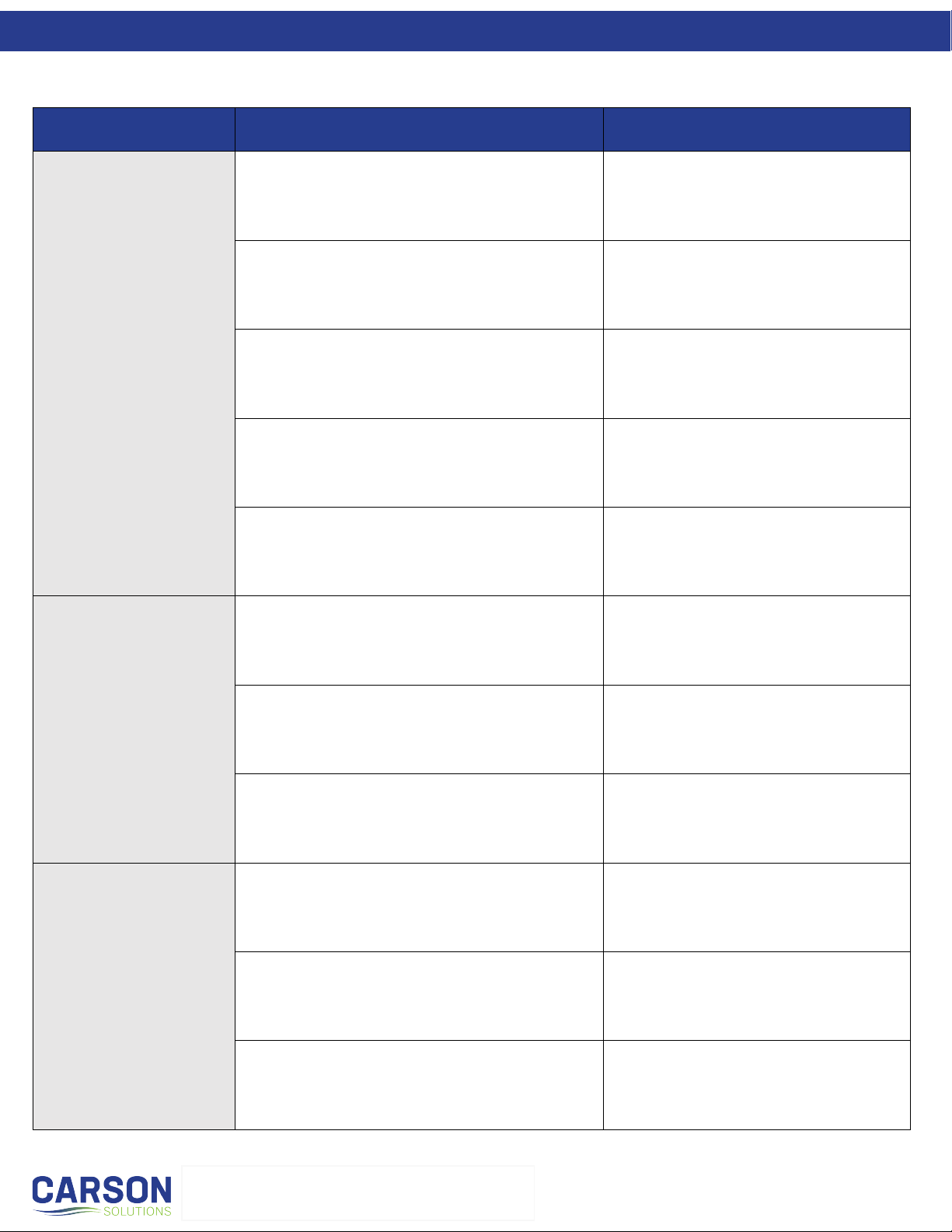

SYMPTOM PROBABLE CAUSE SOLUTION

LOSS OF AIRFLOW

Obstruction on front face panel or

hydronic coil

Remove front face panel and inspect/clean grill

and hydronic coil as necessary

Air connection detached from diffuser Inspect attachment hardware and

reconnect ductwork

Obstruction in primary air plenum Remove primary air connection and

check for debris

Air dampers incorrectly set Inspect and adjust air damper as necessary

Faulty or incorrectly set air handling unit Inspect and re-commission air

handling unit (by certified contractor)

REDUCED

COOLING OR HEATING

Reduced cooling or heating performance Confirm primary airflow is at designed

CFM or above

Obstruction on front face panel or hydronic coil Remove front face panel and inspect/clean grill

and hydronic coil as necessary

Loss of water circulation through hydronic coil Inspect control valves and check flow using

system test points

CONDENSATION ON

PIPE-WORK OR

HYDRONIC COIL

Chilled water temperature too low Measure chilled water temperature and reset

to design value

Incorrect primary air temperature or condition

Measure room humidity level. If humidity

is higher than design condition, the primary air

is failing to control room humidity. The air

handling unit must be set so the primary air is

dry enough to offset the latent gains.

Primary air volume too low

Measure primary air volume using procedure

described in section 4.2.1 Increase air volume

design figure.

15

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Warranties

7.1 MANUFACTURER’S REPRESENTATIONS &

WARRANTIES

CARSON DESIGN MANUFACTURING (CDM), INC. DBA (CARSON

SOLUTIONS) TERMS & CONDITIONS OF SALE Version 01-01-22 ALL

SALES ARE SUBJECT TO THESE TERMS AND CONDITIONS OF SALES

(“TERMS”) AND AS CONTAINED IN CDM’S INVOICE AND ARE ALSO

SUBJECT TO CDM’S CREDIT AND OTHER POLICIES AND

PROCEDURES, WHICH ARE HEREBY INCORPORATED BY REFERENCE

AND SUBJECT TO CHANGE.

1. TERMS TO GOVERN: These Terms shall be binding upon CDM Inc, and

its subsidiaries and affiliates ("Seller") and the buyer (“Buyer”). No

modification, amendment or change, whether in Buyer’s purchase order,

shipping release forms or otherwise shall obligate Seller, unless authorized in

writing by Seller. Any different or inconsistent terms and conditions contained

in Buyer’s forms whether issued before or after Seller’s quotation are hereby

expressly superseded by these Terms.

2. ACCEPTANCE & PRICES: Any proposal offered by Seller to Buyer is valid

for sixty (60) days from Seller’s issuance. Upon the expiration of sixty (60)

days or sooner if revoked by Seller, the proposal shall expire. Pricing shall

remain valid for Seller’s products shipped within 90 days from the date of

Seller’s acceptance. Thereafter, prices are subject to change. Prices include

transportation charges predicated on a single shipment and any partial

shipments may result in additional cost to Buyer. Seller reserves the right, at

any time, to withdraw a bid, quote or a price that contains an error.

3. PAYMENT & TAXES: Upon credit approval, payment terms for Products

shipped hereunder or labor performed will be thirty (30) days net with no

retainages unless contrary

terms appear on the face hereof or otherwise expressly agreed to in writing by

Seller. Should Buyer default in the timely payment to Seller of sums due on an

order, Seller is entitled to any remedies provided in these Terms or by law. If

Buyer fails to pay any amounts when due, Buyer shall pay Seller interest

thereon at a periodic rate of the lesser of one and one- half percent (1.5%) per

month or the maximum allowable legal interest rate, along with all costs and

expenses (including without limitation mechanics lien or bond, collection

expenses, reasonable attorneys' fees, filing and service fees and

disbursements and Court costs) incurred by Seller. Buyer is responsible for all

sales, customs, or use tax imposed by any governmental agency, including,

but not limited to, Federal, State, Local or international authorities, payable on

the transaction under any applicable statute, except those taxes due as a

result of Seller’s gross profits. If Seller is not timely paid or Buyer is otherwise

in default, Seller reserves the right to pause or terminate any work or services

in process and/or reschedule any delivery at any time.

4. PERFORMANCE: Seller shall be obligated to furnish only the Products or

labor described in the applicable purchase order or acknowledgement and

agreed to in writing. The duty to perform under any order on the part of Seller

and the price thereof is subject to the approval of its Credit Department, and is

contingent upon the absence of strikes, accidents, floods, act(s) of terrorism,

war, fires, fuel shortages, the inability to procure materials from the usual

sources of supply, the requirements of the US Government (through the use

of priorities or preference or any other manner) that Seller divert either the

material or the furnished Product to the direct or indirect benefit of the US

Government, or upon any like or unlike cause beyond the reasonable control

of Seller. Upon disapproval of the Credit Department or upon the occurrence

of any such event, Seller may delay performance or, at its option, renegotiate

prices and terms and conditions of sale with Buyer. If Seller elects to

renegotiate and Seller and Buyer are unable to agree on revised prices or

terms, Seller may cancel without any liability.

5. SHIPMENT & RISK OF LOSS: Shipment dates are estimates only, FOB

factory. Title and risk of loss shall pass to Buyer upon Seller’s delivery to

carrier. Customers may only

make their own shipping arrangements with Seller’s agreement. Seller shall

advise when the Products have been completed and send an invoice at that

time. All Product must be picked up by Buyer within 30 days of Seller’s

completion of manufacture. Seller specifically rejects any order containing a

time is of the essence clause or liquidated damage penalties for late

shipments. Seller is not responsible for loss of goods from shortages,

damages or transit delays. Any claims for damage in shipment, mis-delivery,

loss of the Products or other damage shall be the responsibility of and filed by

Buyer.

6. CHANGES, CANCELLATION & RETURNS: Changes requested by Buyer

following Seller’s acceptance of order must be approved by Seller in writing

and may result in an increase in price by Seller to recover all labor and

material costs, including normal overhead and profit. If any portion of a Seller

accepted order is cancelled by Buyer without default on the part of Seller or

without Seller's written consent, Buyer shall be liable to Seller for cancellation

charges including, but not limited to, Seller's incurred costs and the profit

Seller would have realized from the transaction had the agreement not been

breached by Buyer. Products shall not be returned except by written

permission of Seller pursuant to Seller’s return policy.

7. AUTHORITY OF AGENTS: No agent, employee or representative of Seller

has the authority to bind Seller to any affirmation, representation or warranty

concerning the Product or labor sold, except for Seller’s authorized agents,

employees or representatives.

8. INDEMNITY: Seller shall protect and indemnify Buyer from and against all

claims, damages, judgments and loss solely arising from Seller’s infringement

or alleged infringement of any United States patent by any of the articles or

material delivered hereunder, provided that in the event of suit or threat of suit

for patent infringement, Seller shall promptly be notified and given full

opportunity to negotiate a settlement. Seller does not warrant against

infringement by reason of Buyer's design of the articles or the use thereof in

combination with other materials, or in the operation of any process. In the

event of litigation, Buyer agrees reasonably to cooperate with Seller. All

parties concerned shall be entitled, in connection with any proceeding under

the provisions of this Article, to be represented by counsel at their own

expense. Buyer shall defend, indemnify and hold Seller harmless from any

personal injury, wrongful death or property damage caused in whole or in part

by Buyer’s breach, negligent or intentional act(s).

9. LIMITED WARRANTY: Seller warrants that at the time of delivery and for a

period of twelve (12) months from the initial startup (“Start-Up”), or eighteen

(18) months from date of shipment, whichever is less, Products will be free

from defects in material and manufacture provided that Products have been

installed with proper Start-Up, maintained and operated under normal

conditions for service in accordance with the instructions of Seller, and that

Products have the capacities and ratings set forth in Seller's design

specifications. No warranty is made against corrosion, erosion or deterioration.

At Seller’s option, Seller's obligations and liabilities under this warranty are

limited to repair of Products or replacement of components for Products not

conforming to this warranty. This Limited warranty does not cover labor for

component repair or replacement. Once Seller’s service department has been

notified and approved any warranty related service work, Seller will repair or

replace components as needed and ship FOB factory. Seller shall not be

obligated to pay for the cost of lost refrigerant or Glycol. Consumable parts

and Products that are consumable in nature are explicitly excluded from this

warranty. Consumables include, but are not limited to, filters, glycol and

refrigerant. No warranty or liability whatever shall attach to Seller until full

payment has been received. No warranty herein extended shall apply to repair

or correction of conditions arising from improper or incorrectly connected air

duct, piping, wiring, power supply, blown fuses, freezing, improper Product

control when programmed by non-Seller controls, or personnel, or by anyone

other than Seller employee or its representative. Operation of Products for

temporary conditioning of a building during construction without the written

consent of an officer of the Seller immediately voids any warranty coverage. If

the Product is replaced, the replacement may not be new, but will be in good

working order and at least functionally equivalent to the item or Product

replaced. The replacement assumes the warranty status of the replaced

Product. The warranty period does not restart. THIS LIMITED WARRANTY IS

VOIDED BY MISUSE, NEGLECT, FAILURE TO FOLLOW INSTRUCTIONS

OR SELLER’S MANUALS OR TAMPERING WITH, THE PRODUCTS

PERFORMED BY ANY PERSON OR ENTITY OTHER THAN SELLER

WITHOUT SELLER’S PRIOR WRITTEN APPROVAL OR ANY USE OF

REPLACEMENT PARTS NOT SUPPLIED BY SELLER. THE WARRANTY

AND LIABILITY SET FORTH HEREIN REPRESENT BUYER’S EXCLUSIVE

REMEDY AND ARE IN LIEU OF ALL OTHER WARRANTIES AND

LIABILITIES WHETHER IN CONTRACT, TORT, WARRANTY OR IN

NEGLIGENCE, EXPRESSED OR IMPLIED, IN LAW OR IN FACT,

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR USE. SELLER PROVIDES NO

INDEPENDENT WARRANTY FOR THIRD PARTY PRODUCTS OR

COMPONENTS SOLD TOGETHER OR INCORPORATED WITH SELLER’S

PRODUCT(S).

16

952.525.2050

www.carsonsolutions.com

info@carsonsolutions.com

Warranties

10. LIABILITY DISCLAIMER: TO THE MAXIMUM EXTENT PERMITTED BY

LAW, SELLER’S TOTAL LIABILITY FOR CLAIMS, REGARDLESS

OF THE FORM OF ACTION OR THEORY OF LIABILITY (INCLUDING

CONTRACT, TORT OR WARRANTY), SHALL BE LIMITED TO THE FEES

PAID TO SELLER BY BUYER FOR THE PRODUCTS OR LABOR THAT

WAS THE PROXIMATE CAUSE OF THE DAMAGE. IN NO EVENT SHALL

SELLER BE LIABLE TO BUYER FOR ANY INCIDENTAL,

CONSEQUENTIAL, SPECIAL, PUNITIVE, OR INDIRECT DAMAGES OF

ANY KIND (INCLUDING, WITHOUT LIMITATION, LOST PROFITS, LOSS

OF USE, OR CLAIMS OF THIRD PARTIES) THAT MIGHT OCCUR AS A

RESULT OF THE PERFORMANCE OR BREACH OF THE AGREEMENT OR

IN ANY WAY ARISING OUT OF OR IN CONNECTION WITH THE

AGREEMENT WHETHER BY CONTRACT, TORT, WARRANTY OR

OTHERWISE. SELLER SHALL NOT BE LIABLE OR RESPONSIBLE FOR

ANY CRANE, RIGGING, LABOR OR OTHER CHARGES OR DAMAGES OF

ANY KIND OR NATURE CAUSED IN WHOLE OR IN PART BY DELAYS IN

SHIPMENT OR SELLER’S BREACH.

11. ASSIGNMENT: Buyer may not assign or transfer this agreement. Seller

may assign its rights or obligations under this Agreement in the event of a

merger or change of control of Seller.

12. GOVERNING LAW: This Agreement shall be governed and construed in

accordance with the laws State of Minnesota. Buyer consents to jurisdiction in

the Circuit Court of

Hennepin County, Minnesota. Each party consents to that choice of law and

jurisdiction and irrevocably waives any objection to same.

13. EXPORT CONTROLS: Buyer shall comply with the export laws and

regulations of the United States. Buyer agrees it shall not export or enter into

an agreement for the export any goods from Seller to any prohibited or

embargoed country or to any denied, blocked or restricted person or entity.

14. MISCELLANEOUS: Seller’s waiver or failure to enforce the terms of this

Agreement shall not constitute a waiver of Seller’s rights. The prevailing party

may recover their reasonable attorney fees and reasonable out-of-pocket

expenses.

Table of contents

Other Trox Fan manuals

Popular Fan manuals by other brands

Challenge

Challenge FF-450A instruction manual

NuTone

NuTone QTRE090FL Specification sheet

Inspire

Inspire Ana LM JB36301 Assembly manual

Fanimation

Fanimation Air Shadow FP810 Series owner's manual

Trisa electronics

Trisa electronics Star Line 9326.47 Instructions for use

Vortice

Vortice NORDIK HVLS SUPER BLADE E instruction manual