TRUE RESIDENTIAL THE TRUE 42 User manual

09/26/2022 TRUE 42/48 INSTALL MANUALTEC_TM_170 REV. A

PRESERVE THE MOMENT®

TRUE RESIDENTIAL®

THE TRUE 42 / 48

INSTALL GUIDE AND USER'S MANUAL

"C" REVISION

848062

848062

TEC_TM_170 REV. A09/26/2022TRUE RESIDENTIAL®

INSTALLATION CHECKLIST

To ensure no part of the installation process has been overlooked, complete the checklist below.

☐Have all packaging materials been removed?

☐Are the anti-tip brackets securely installed and properly engaging the unit?

☐Has the unit been properly leveled? Do all leveling legs touch the floor?

☐Is the kickplate installed?

☐Is the doorstop being installed (if needed)?

☐Does the customer understand the unit’s operation?

☐Has the customer been given the key and literature package?

☐Have all stainless steel surfaces been inspected for imperfections?*

☐Is the unit operating correctly? If not, is the unit plugged in? Is the control turned on?

*To be completed by either an installer with the customer or an authorized True dealer upon

completion of installation. Stainless steel doors, handles, and shelves are covered by a

limited 30-day warranty for cosmetic defects.

THANK YOU

FOR YOUR PURCHASE

TEC_TM_170 REV. A 09/26/2022 Page 3 of 60TRUE 42/48 INSTALL MANUAL

CONTENTS

SAFETY INFORMATION & OWNERSHIP

REFRIGERANT SAFETY & WARNING

INFORMATION 6

BASIC SAFETY & WARNING PRECAUTIONS 6

CABINET DISPOSAL WARNING 7

OWNERSHIP 8

NOTICE TO CUSTOMER 8

REGISTER YOUR PRODUCT 8

SERIAL LABEL LOCATION 8

CONTACT INFORMATION 8

PRIOR TO INSTALLATION

SITE PREPARATION 10

ANTI-SWEAT FOAM END PANELS 13

ELECTRICAL SAFETY 14

ICEMAKER REQUIREMENTS 16

INSTALLATION PLAN VIEWS

PLAN VIEWS 20

INSTALLATION

UNCRATING 26

ANTI-TIP BRACKET INSTALLATION 29

LEVELING THE UNIT 31

KICKPLATE INSTALLATION 32

JOINING KIT INSTALLATION 33

CABINET SETUP

SHELVING, DOOR BINS & DRAWERS 38

REFIRGERATOR STORAGE 38

FREEZER STORAGE 41

ICEMAKER 42

REFRIGERATOR / FREEZER OPERATION

BASIC ELECTRONIC CONTROL OPERATIONS 44

TEMPERATURE ADJUSTMENT 45

(ZONE NAVIGATION)

MODE NAVIGATION 46

ACCENT LIGHTING SYSTEM 47

ALARM NAVIGATION 48

(DOOR AJAR ALARM FEATURE ON/OFF)

NOTIFICATION ALERTS 49

SHOWROOM MODE 50

ICE MENU NAVIGATION 51

MAINTENANCE, CARE & CLEANING

DOOR REMOVAL 53

DOOR HANDLE TIGHTENING 53

CONDENSER COIL CLEANING 54

CONDENSATION 54

WATER FILTER REPLACEMENT 55

STAINLESS STEEL EQUIPMENT

CARE & CLEANING 56

SERIAL LABEL LOCATION 58

CONTACT US 58

NOTE: AS WE STRIVE FOR CONTINUOUS IMPROVEMENTS, FEATURES AND SPECIFICATIONS

ARE SUBJECT TO CHANGE WITHOUT NOTICE.

NOTE: YOUR APPLICANCE MAY NOT EXACTLY MATCH THE FIGURES SHOWN IN THIS MANUAL.

TEC_TM_170 REV. A09/26/2022Page 4 of 60 TRUE RESIDENTIAL®P#848062

THE TRUE 42 / 48

TR-42SBS-SS-C

STAINLESS SOLID DOOR

TR-48SBS-SG-SS-C

STAINLESS SOLID DOOR

LUXURY REFRIGERATION WITH COMMERCIAL DNA.

PRESERVE THE MOMENT®

TEC_TM_170 REV. A 09/26/2022 Page 5 of 60TRUE 42/48 INSTALL MANUAL

SAFETY INFORMATION & OWNERSHIP

REFRIGERANT SAFETY & WARNING INFORMATION

BASIC SAFETY & WARNING PRECAUTIONS

CABINET DISPOSAL WARNING

OWNERSHIP

NOTICE TO CUSTOMER

REGISTER YOUR PRODUCT

SERIAL LABEL LOCATION

CONTACT INFORMATION

TEC_TM_170 REV. A09/26/2022 P# 848062Page 6 of 60 TRUE RESIDENTIAL®

SAFETY INFORMATION & OWNERSHIP

BASIC SAFETY & WARNING

PRECAUTIONS

• Take care during operation, maintenance or repairs

to avoid cuts or pinching from any part/component

of the cabinet.

• Units may pose a tipping hazard while uncrating,

during installation, or when moving the unit.

• Ensure the unit is properly installed and located in

accordance with the Installation Instructions before

use.

• This appliance is not to be used, cleaned or

maintained by persons (including children) with

reduced physical, sensory or mental capabilities or

lack of experience and knowledge, unless they have

been given supervision or instruction.

• DO NOT allow children to play with the appliance

or climb, stand, or hang on the unit’s shelves to

prevent damage to the refrigerator and personal

injury.

• DO NOT touch the cold surfaces in the freezer

compartment when hands are damp or wet. Skin

may stick to these extremely cold surfaces.

• Unplug the refrigerator before cleaning and making

repairs.

• Setting temperature controls to the 0 position or

powering off an electronic control may not remove

power from all components (e.g., light circuits,

perimeter heaters, and evaporator fans).

• DO NOT store or use gasoline, or other flammable

vapors and liquids, in the vicinity of this or any

other appliance.

WARNING! Use this appliance for its

intended purpose as described in this

Installation Manual.

REFRIGERANT SAFETY & WARNING

INFORMATION

See the serial label inside the cabinet for the units

refrigeration type. For Hydrocarbon Refrigeration

(R290 only), see below:

DANGER! Risk of fire or explosion.

Flammable refrigerant used. DO NOT

use mechanical devices to defrost

refrigerator. DO NOT puncture refrigerant

tubing; follow handling instructions

carefully. To be repaired only by trained

service personnel.

DANGER! Risk of fire or explosion

(flammable refrigerant used), consult

repair manual/owner’s guide before

attempting to service this product. All

safety precautions must be followed.

Dispose of properly in accordance with

local and federal regulations. Follow all

safety precautions.

CAUTION! Keep all ventilation openings

clear of obstruction in the appliance

enclosure or in the structure housing the

appliance.

TEC_TM_170 REV. A 09/26/2022 Page 7 of 60TRUE 42/48 INSTALL MANUAL

PAGE TITLESAFETY INFORMATION & OWNERSHIP

CABINET DISPOSAL WARNING

DANGER! RISK OF

CHILD ENTRAPMENT

PROPER DISPOSAL OF THE CABINET

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous, even if they will sit for "just a few days." If

you are getting rid of your old refrigerator, please follow

the instructions below to help prevent accidents.

Before throwing away your old refrigerator or freezer:

• Take off the doors.

• Leave the shelves in place so that children may not

easily climb inside.

DANGER! Risk of fire or explosion.

Flammable insulation and/or refrigerant

used. Dispose of all in accordance with

local and federal regulations. Follow all

safety precautions.

• DO NOT store explosive substances such as aerosol

cans with a flammable propellant in this appliance.

• Keep fingers out of the "pinch point" areas;

clearances between the doors and cabinet are

necessarily small; be careful closing doors when

children are in the area.

• DO NOT use electrical appliances inside the food

storage compartments of the units unless the

appliances are of the type recommended by the

manufacturer.

NOTE: ALL SERVICING MUST BE PERFORMED BY A

QUALIFIED TECHNICIAN.

TEC_TM_170 REV. A09/26/2022 P# 848062Page 8 of 60 TRUE RESIDENTIAL®

SAFETY INFORMATION & OWNERSHIP

OWNERSHIP

To ensure that your unit works properly from the

first day, it must be installed properly. We highly

recommend a trained refrigeration mechanic and

electrician install your True equipment. The cost of a

professional installation is money well spent.

Before you start to install your TRUE unit,

carefully inspect it for freight damage. IF DAMAGE IS

DISCOVERED, DO NOT INSTALL OR PUT IN SERVICE. NOTIFY

TRUE CUSTOMER SERVICE, AND IMMEDIATELY FILE A CLAIM

WITH THE DELIVERY FREIGHT CARRIER.

Notify True customer service and immediately file a

claim with the delivery freight carrier.

TRUE is not responsible for damage incurred during

shipment.

For any questions about installation, please contact

your True dealer or True Residential Technical

Service at 844-746-9423 or TrueResidentialService@

TrueMfg.com. Please have your model and serial

number available.

NOTICE TO CUSTOMER

Loss or spoilage of products in your refrigerator/

freezer is not covered by warranty. In addition to

following recommended installation procedures, run

the refrigerator/freezer for 24 hours prior to usage to

verify its proper operation.

REGISTER YOUR PRODUCT

To qualify for TRUE’s extended

7–12 year parts-only sealed system

warranty, you must register your

product* within 12 months of the

unit’s installation date. To register

your unit, complete and submit the

form at https://www.true-residential.

com/product-registration. For warranty details, please

see page 59.

SERIAL LABEL LOCATION

The serial label is located on the left wall near the

freezer wire basket or the refrigerator upper drawer.

See fig. 1.

This label contains important information such as

your model name and serial number. Please have this

information on hand when contacting True so we can

better assist you with your service- or parts-related

inquiries.

FIG. 1.

Serial label location.

CONTACT INFORMATION

WARRANTY DEPARTMENT

Phone: 844-849-6179

TrueResidentialWarranty@truemfg.com

CUSTOMER SERVICE

Phone: 888-616-8783

info@true-residential.com

SERVICE DEPARTMENT

Phone: 844-746-9423

TrueResidentialService@truemfg.com

* Please note that ice machines do not qualify for this extended

warranty.

PRESERVE THE MOMENT®

TEC_TM_170 REV. A 09/26/2022 Page 9 of 60TRUE 42/48 INSTALL MANUAL

PRIOR TO INSTALLATION

SITE PREPARATION

ANTI-SWEAT FOAM END PANELS

ELECTRICAL SAFETY

POWER CORD

ICEMAKER REQUIREMENTS

TEC_TM_170 REV. A09/26/2022 P# 848062Page 10 of 60 TRUE RESIDENTIAL®

PRIOR TO INSTALLATION

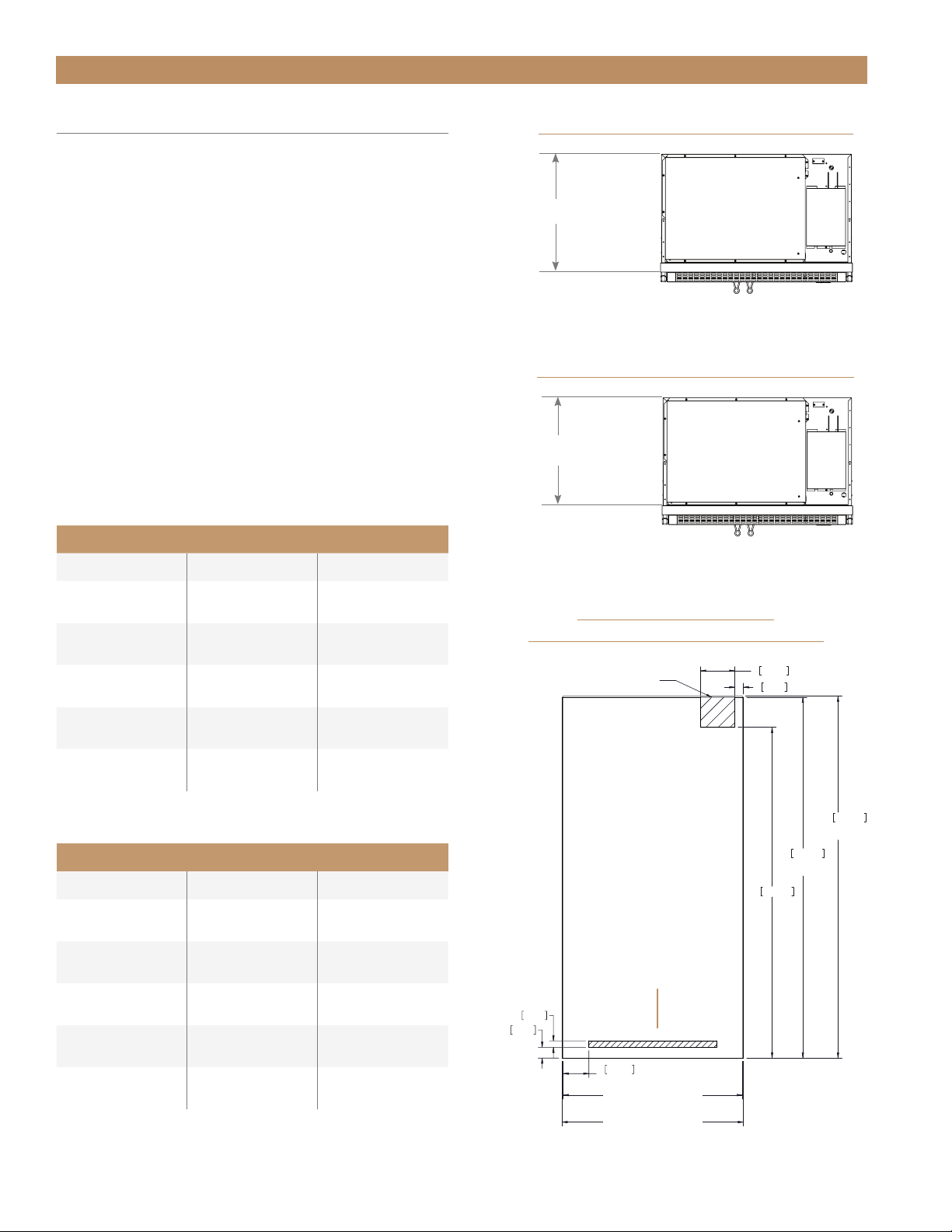

26" (660 mm) MINIMUM

FLUSH INSTALL

TR-42/48 – TOP VIEW FLUSH INSTALL

24" (609 mm) MINIMUM

PROUD INSTALL

TR-42/48 – TOP VIEW PROUD INSTALL

Dimensions may vary by ± 1/8" (3.2 mm)

TR

-42/48

FRONT VIEW

ROUGH OPENING & ELECTRIC AREA

ROUGH OPENINGS & PLAN VIEWS

NOTE: DUE TO THE WEIGHT OF THIS UNIT,

TRUE RECOMMENDS CONSULTING A FLOORING

EXPERT PRIOR TO INSTALLATION. THE

FLOORING BENEATH THE UNIT SHOULD BE

RATED TO SUPPORT ≥150 LBS/FT2( 73 2.36

KG/M2)

NOTE: IT IS NOT RECOMMENDED TO INSTALL

UNITS SIDE BY SIDE WITH HINGES TOUCHING

EACH OTHER. IF YOU PLAN TO INSTALL

UNITS HINGE TO HINGE, CALL TECH SUPPORT

AT 844-746-9423 FOR INSTALLATION

INSTRUCTIONS.

Flush installation: The front face of the unit is flush

with the surrounding cabinets

Proud (standard) Installation: The front face of the

unit extends beyond the surrounding cabinets

TR-42 Rough Opening Dimensions

Flush Install Proud Install

Width 42-1/4"

(1047mm)

41-3/4"

(1060 mm)

Depth 26"

(660 mm)

24"

(609 mm)

Height 84-1/4"

(2139 mm)

84"

(2,134 mm)

Weight 720 Lb

(327 Kg)

720 Lb

(327 Kg)

Cord Length 96"

(2438 mm)

96"

(2438 mm)

TR-48 Rough Opening Dimensions

Flush Install Proud Install

Width 48-1/4"

(1225 mm)

47-3/4"

(1212 mm)

Depth 26"

(660 mm)

24"

(609 mm)

Height 8 4-1/4"

(2,139.95 mm)

84"

(2,133 mm)

Weight 820 Lb

(372 Kg)

820 Lb

(372 Kg)

Cord Length 96"

(2438 mm)

96"

(2438 mm)

84 1/4"

2140mm

FLUSH

INSTALL

42 1/4"

1073mm

FLUSH INSTALL

41 3/4"

1060mm

STANDARD INSTALL

77"

1956mm

8"

203mm

2"

51mm

84"

2134mm

STANDARD

INSTALL

1 1/2"

38mm

2 1/2"

64mm

6"

152mm

TYP

ELECTRICAL LOCATED

IN THIS AREA

25 25/32"

655mm

FLUSH INSTALL

23 25/32"

604mm

STANDARD INSTALL

WATER AREA

PROUD INSTALL

TR-42 – 41 3/4"(1060 mm)

TR-48 – 47 3/4"(1212 mm)

FLUSH INSTALL

TR-42 – 42 1/4"(1047 mm)

TR-48 – 48 1/4"(1225 mm)

TEC_TM_170 REV. A 09/26/2022 Page 11 of 60TRUE 42/48 INSTALL MANUAL

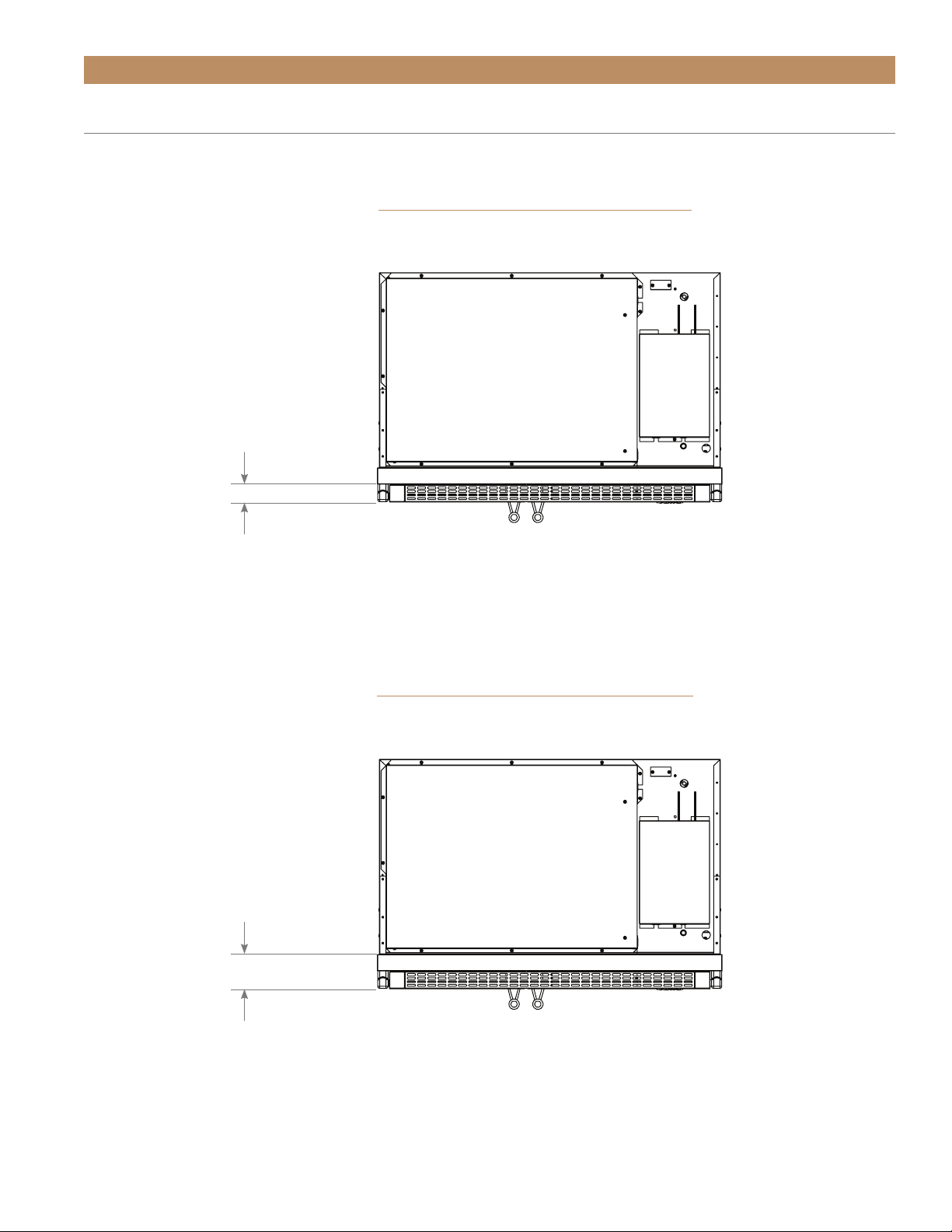

PRIOR TO INSTALLATION

2

-3/16

" (55.56 mm)

4-3/16" (101 mm)

TR-42/48

TR 42/48 – TOP VIEW FLUSH INSTALL

TR 42/48 – TOP VIEW PROUD INSTALL

Dimensions may vary by ± 1/8" (3.2 mm)

Dimensions may vary by ± 1/8" (3.2 mm)

TEC_TM_170 REV. A09/26/2022 P# 848062Page 12 of 60 TRUE RESIDENTIAL®

PRIOR TO INSTALLATION

ANTI-SWEAT FOAM END PANELS

When installing two or more True units side-by-side, be

sure to leave at least a 5/8” (15.88 mm) gap between

the cabinets, or install foam pads between the

cabinets and on any side without this gap, to prevent

moisture from developing on applications.

If installing anti-sweat foam end panels, True

recommends applying a panel to each of the

units being joined together. To order foam pads,

contact our parts department at 844-849-6226 or

TrueResidentialParts@TrueMfg.com.

TEC_TM_170 REV. A 09/26/2022 Page 13 of 60TRUE 42/48 INSTALL MANUAL

PAGE TITLEPRIOR TO INSTALLATION

• NEVER USE AN ADAPTER PLUG!

An adapter plug alters the original

equipment manufacturer (OEM)

plug configuration when connecting

it to a power source. True will not warranty any

refrigerator/freezer that has been connected to an

adapter plug.

• NEVER USE AN EXTENSION CORD! An

extension cord is any component that

adds length to the OEM power cord

when connecting it to a power source.

True will not warranty any refrigerator/

freezer that has been connected to an extension

cord.

• Before your new unit is connected to a power

supply, check the incoming voltage. If the recorded

voltage is less than the rated voltage for operation

(+/-5%) and amp rating, correct immediately. Refer

to the serial label for this voltage requirement.

• NEVER unplug your refrigerator/freezer by pulling

on the power cord. Always grip the plug firmly and

pull straight from the outlet.

• When moving the refrigerator/freezer for any reason,

take care to no roll over or damage the power cord.

• Immediately repair or replace all power cords

that have become frayed or otherwise damaged.

DO NOT use a power cord that shows cracks or

abrasion damage along its length or at either end.

• If the supply power cord is damaged, replace it

with OEM components. To avoid hazard, this should

be done by a licensed service provider or similarly

qualified person.

ELECTRICAL SAFETY

Power Supply: 115VAC, 60hz

Circuit Breaker: 15 Amp

Receptacle: 3-Prong Grounding-Type

• For all built-in models, the electrical supply should

be located within the indicated shaded area shown

in the figure below.

• Be sure to follow the National Electrical Code, as

well as local codes and ordinances, when installing

the receptacle.

• A ground fault circuit interrupter (GFCI) is not

recommended and may cause interruption of

operation.

• The power cord from this appliance is equipped

with a grounding plug which minimizes the

possibility of electric shock hazard.

• The wall outlet and circuit should be checked by a

licensed electrician to be sure the outlet is wired

with the correct polarity and properly grounded.

• If the outlet is a standard 2-prong outlet, it is your

personal responsibility and obligation to have it

replaced with a properly grounded wall outlet.

• DO NOT, under any circumstances, cut or remove

the ground prong from the power cord. For personal

safety, this appliance must be properly grounded.

• The refrigerator/freezer should always be plugged

into a dedicated electrical circuit. This provides

the best performance and prevents building wiring

circuits from overloaded, which could cause a fire

hazard from overheated wires.

TEC_TM_170 REV. A09/26/2022 P# 848062Page 14 of 60 TRUE RESIDENTIAL®

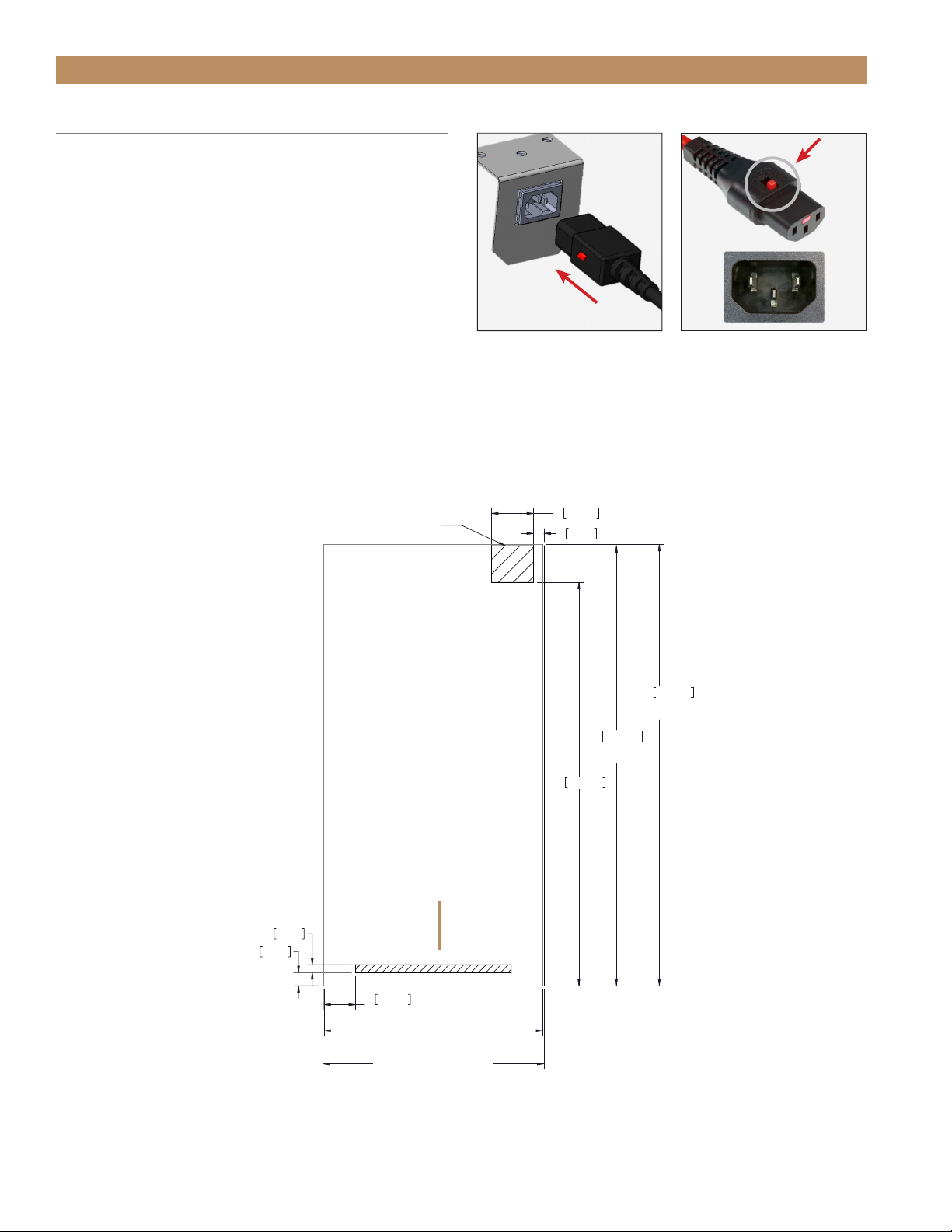

SITE PREPARATION

POWER CORD

INSTALLATION

Fully seat the power cord into the cabinet receptacle

until it locks in position. See fig. 1.

REMOVAL

Depress the red button. See fig. 2.

FIG. 1.

Fully insert the power

cord into the receptacle.

FIG. 2.

Push the red button to

remove the plug.

TR-42/48

FRONT VIEW ROUGH OPENING & ELECTRICAL AREA

NOTE: DIMENSIONS MAY VARY BY ± 1/8” (3.175 mm)

84 1/4"

2140mm

FLUSH

INSTALL

42 1/4"

1073mm

FLUSH INSTALL

41 3/4"

1060mm

STANDARD INSTALL

77"

1956mm

8"

203mm

2"

51mm

84"

2134mm

STANDARD

INSTALL

1 1/2"

38mm

2 1/2"

64mm

6"

152mm

TYP

ELECTRICAL LOCATED

IN THIS AREA

25 25/32"

655mm

FLUSH INSTALL

23 25/32"

604mm

STANDARD INSTALL

WATER AREA

PROUD INSTALL

TR-42 – 41 3/4"(1060 mm)

TR-48 – 47 3/4"(1212 mm)

FLUSH INSTALL

TR-42 – 42 1/4"(1047 mm)

TR-48 – 48 1/4"(1225 mm)

TEC_TM_170 REV. A 09/26/2022 Page 15 of 60TRUE 42/48 INSTALL MANUAL

PAGE TITLEINSTALLATION

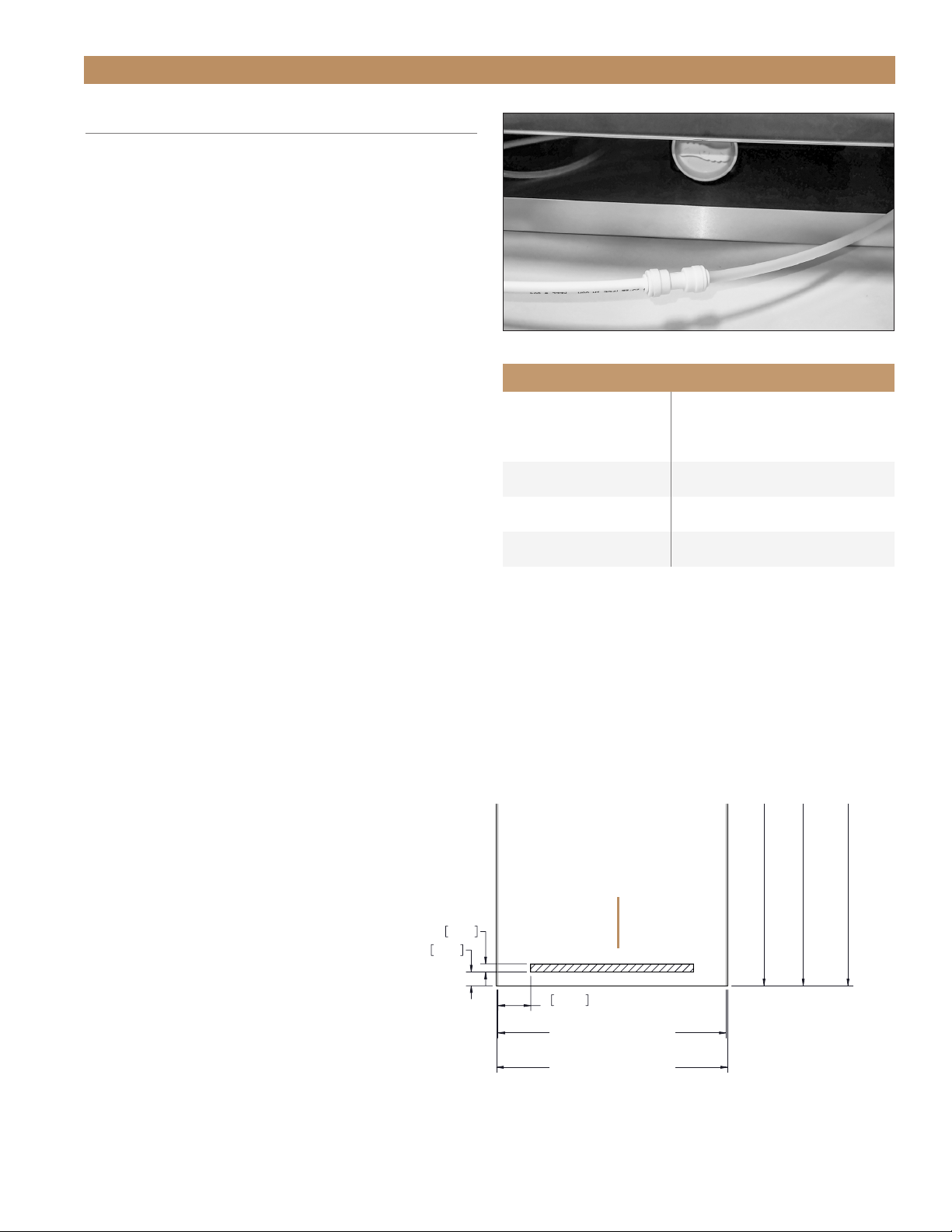

FIG. 1.

Water line connection. Fitting included, PEX not included

Plumbing Requirements

Water Supply

1/4" PEX tubing (1/4" O.D. lines

and fittings not included

NOTE: Copper line is not

recommended

Flow Rate 0.5 gpm / 1.89 lpm

Operating Pressure 30-100 psi (207-689 kPa)

Incoming Water Temperature 33-100°F (0.6 -38°C)

NOTE: DIMENSIONS MAY VARY BY ± 1/8” (3.175 mm)

ICEMAKER REQUIREMENTS

WATER SUPPLY REQUIREMENTS

Units with ice-makers come with 20” (508 mm) of

polyethylene tubing with a 1/4” O.D. push connector

for customer attachment.

Before installing your unit, prepare the water supply

line. Please see plumbing requirements in the

plumbing requirements table.

• Purge the water line prior to final connection to the

unit. This removes any debris present in the line.

• Only connect to a potable water supply!

• Do not connect to a hot water supply!

• Install the water filter before turning on the

water supply to the icemaker. See “Water Filter

Installation” (page 16).

• A copper line is not recommended for this

application.

• Check all water line fittings for leaks.

• Tape the supply line to the floor before moving the

unit into its final installation location.

• In the water connection area (see the rough opening

illustration), tape the water line to the floor.

84 1/4"

2140mm

FLUSH

INSTALL

42 1/4"

1073mm

FLUSH INSTALL

41 3/4"

1060mm

STANDARD INSTALL

77"

1956mm

8"

203mm

2"

51mm

84"

2134mm

STANDARD

INSTALL

1 1/2"

38mm

2 1/2"

64mm

6"

152mm

TYP

ELECTRICAL LOCATED

IN THIS AREA

25 25/32"

655mm

FLUSH INSTALL

23 25/32"

604mm

STANDARD INSTALL

WATER AREA

PROUD INSTALL

TR-42 – 41 3/4"(1060 mm)

TR-48 – 47 3/4"(1212 mm)

FLUSH INSTALL

TR-42 – 42 1/4"(1047 mm)

TR-48 – 48 1/4"(1225 mm)

TEC_TM_170 REV. A09/26/2022 P# 848062Page 16 of 60 TRUE RESIDENTIAL®

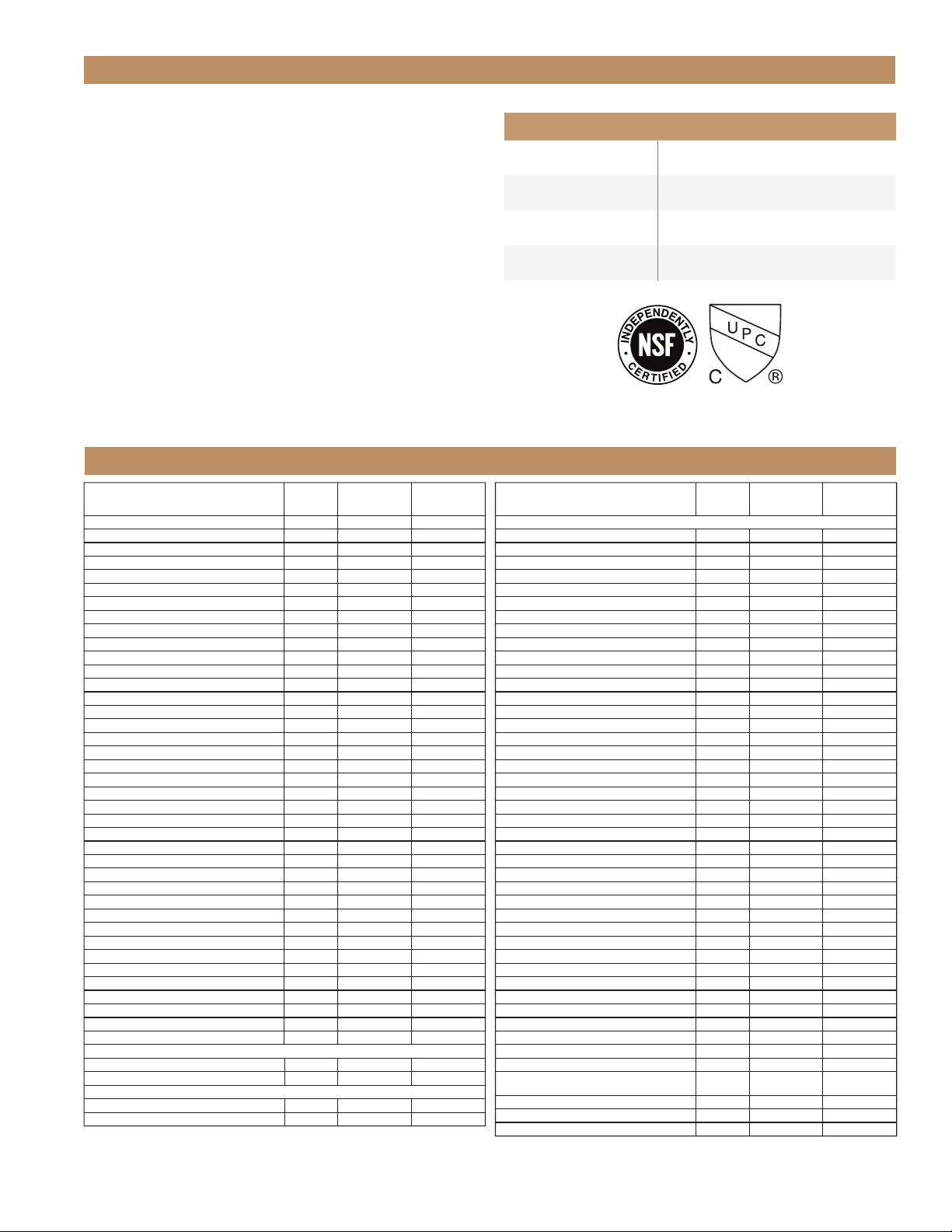

INSTALLATION

WATER FILTER INSTALLATION &

PERFORMANCE DATA

The water filter filters sediment and removes

unpleasant taste and odor. Install the provided water

filter before using the icemaker. The unit will not make

ice until the water filter is installed.

PROCEDURE

1. Remove the kickplate. See fig. 1.

2. Insert the provided water filter (see fig. 2) and

rotate the filter clockwise. (See figs. 3 and 4).

3. Reinstall the kickplate.

WATER FILTER PERFORMANCE DATA

• This system has been tested according to NSF/ANSI

Standard 42, 53, 372, 401, P473 and CSA B483.1

for reduction of the substances listed below. The

concentration of the indicated substances in water

entering the system was reduced to a concentration

less than or equal to the permissible limit for

water leaving the system, as specified in NSF/

ANSI Standards 42, 53, 372, 401, P473 and CSA

B483.1.

• Systems certified for cyst reduction may be used

on disinfected waters that may contain filterable

cysts. The system conforms to NSF/ANSI 42, 53,

372, 401,P473 and CSA B483.1 for the specific

performance claims as verified and substantiated

by test data. Conforms to NSF/ANSI 53 for VOC

reduction. See below for individual contaminants

and reduction performance.

NOTE: TESTING WAS PERFORMED UNDER

STANDARD LABORATORY CONDITIONS,

ACTUAL PERFORMANCE MAY VARY.

FIG. 4.

Installed water filter.

FIG. 3.

Insert the water filter and rotate it clockwise.

FIG. 2.

Locate the provided water filter shipped in the ice bucket.

FIG. 1.

Pull the kickplate from the cabinet.

TEC_TM_170 REV. A 09/26/2022 Page 17 of 60TRUE 42/48 INSTALL MANUAL

INSTALLATION

A-1, G-1, G-2, G-3, G-4, L-1, L-2, L-3, L-4, L-5,

M-1, M-2, S-1, S-2, S-4, W-2, W-3, W-4

Performance Data Sheet

Aquamor • 42188 Rio Nedo • Temecula, California 92590 • www.aquamorusa.com • 866-218-8473

Flow Rate: 0.5 gpm / 1.89 lpm

Operating Temperature: 33 - 100°F (0.6°C - 38°C)

Operating Pressure: 30 psi (207 kPa) - 100 psi (689 kPa)

Capacity: 300 gallons (1,136 L) or six months

Filter Specifications

This system has been tested according to NSF/ANSI Standard 42, 53, 372, 401, P473 and CSA B483.1 for reduction of the substances listed

below. The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the system, as specified in NSF/ANSI Standards 42, 53, 372, 401, P473 and CSA B483.1.

Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts. The system conforms to NSF/ANSI 42, 53, 372, 401,

P473 and CSA B483.1 for the specific performance claims as verified and substantiated by test data. Conforms to NSF/ANSI 53 for VOC reduction. See above

for individual contaminants and reduction performance. Note: Testing was performed under standard laboratory conditions, actual performance may vary.

System to be used with municipal or well water sources treated and tested on regular basis to ensure bacteriological safe quality. Do not use with water that

is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

It is essential that the manufacturer’s recommended installation, maintenance and filter replacement requirements be carried out for the product to perform

as advertised. Manufactured by Aquamor, LLC, Temecula, CA.

CHLORINE >97% 2.0 mg/L 1.0 mg/L

ALACHLOR* >98% 0.050 0.001

Asbestos 99.98% 189 MFL 99%

ATRAZINE* >97% 0.100 0.003

BENZENE* >99% 0.081 0.001

BISPHENOL 99.1% 2.058 mg/L <0.300ng/L

BROMODICHLOROMETHANE (TTHM)* >99.8% 0.300 0.015

BROMOFORM (TTHM)* >99.8% 0.300 0.015

CARBOFURAN (Furadan)* >99% 0.19 0.001

Carbon Tetrachloride >95% 0.014 0.005

CHLORDANE >99.5% 0.04 +/-10% 0.002

CHLOROBENZENE (Monochlorobenzene)* >99% 0.077 0.001

CHLOROPICRIN* 99% 0.015 0.0002

CHLOROFORM (TTHM)* (surrogate chemical) >99.8% 0.300 0.015

2, 4-D* 98% 0.110 0.0017

CYST

(Giardi; Cryptosporidium; Entamoeba; Toxoplasma)

>99.95%

MINIMUM 50,000/L

Cryptosporidium (see CYST)

>99.95% MINIMUM 50,000/L

DBCP (see Dibromochloropropane)* >99% 0.052 0.00002

1,2-DCA (see 1,2-DICHLOROETHANE)* 95% 0.088 0.0048

1,1-DCE (see 1,1-DICHLOROETHYLENE)* >99% 0.083 0.001

DIBROMOCHLOROMETHANE

(TTHM; Chlorodibromomethane)*

>99.8% 0.300 0.015

DIBROMOCHLOROPROPANE (DBCP)* >99% 0.052 0.00002

o-DICHLOROBENZENE (1,2 Dichlorobenzene)* >99% 0.080 0.001

p-DICHLOROBENZENE (para-Dichlorobenzene) >98% 0.040 0.001

1,2-DICHLOROETHANE (1,2-DCA)* 95% 0.088 0.0048

1,1-DICHLOROETHYLENE (1,1-DCE)* >99% 0.083 0.001

CIS-1,2-DICHLOROETHYLENE* >99% 0.170 0.0005

TRANS-1,2- DICHLOROETHYLENE* >99% 0.086 0.001

1,2-DICHLOROPROPANE (Propylene Dichloride)* >99% 0.080 0.001

CIS-1,3- DICHLOROPROPYLENE* >99% 0.079 0.001

DINOSEB* 99% 0.170 0.0002

EDB (see ETHYLENE DIBROMIDE)* >99% 0.044 0.00002

ENDRIN 99% 0.053 0.00059

Entamoeba (see CYSTS) 99.95%

MINIMUM 50,000/L

ESTRONE 96.9% 0.1388 mg/L <0.020 mg/L

ETHYLBENZENE* >99% 0.088 0.001

ETHYLENE DIBROMIDE (EDB)* >99% 0.044 0.00002

Furadan (see CARBOFURAN)* >99% 0.19 0.001

Giardia Lamblia (see CYST) >99.95%

MINIMUM 50,000/L

HALOACETONITRILES (HAN)*

BROMOCHLOROACETONITRILE 98% 0.022 0.0005

DIBROMOACETONITRILE 98% 0.024 0.0006

HALOACETONITRILES (HAN)*

DICHLOROACETONITRILE 98% 0.0096 0.0002

TRICHLOROACETONITRILE 98% 0.015 0.0003

% of Influent Max

Contaminant reduction Concentration Allowable

99.95% REDUCTION

REQUIREMENT

99.95% REDUCTION

REQUIREMENT

99.95% REDUCTION

REQUIREMENT

99.95% REDUCTION

REQUIREMENT

HALOKETONES (HK):*

1,1-DICHLORO-2-PROPANONE 99% 0.0072 0.0001

1,1,1-TRICHLORO-2-PROPANONE 96% 0.0082 0.0003

HEPTACHLOR* >99% 0.25 0.00001

HEPTACHLOR EPOXIDE* 98% 0.0107 0.0002

HEXACHLOROBUTADIENE (Perchlorobutadiene)* >98% 0.044 0.001

HEXACHLOROCYCLOPENTADIENE* >99% 0.060 0.000002

IBUPROFEN 96.7% 0.432 mg/L <0.060 mg/L

LEAD (pH 6.5) >99.3% 0.15 +/- 10% 0.010

LEAD (pH 8.5) >99.3% 0.15 +/- 10% 0.010

LINDANE* >99% 0.055 0.00001

METHOXYCHLOR* >99% 0.050 0.0001

Methylbenzene (see TOLUENE)* >99% 0.078 0.001

Mercury (pH 6.5) 74.9% 0.0059 0.002

Mercury (pH 8.5) 97.8% 0.0061 0.002

Monochlorobenzene (see CHLOROBENZENE)* >99% 0.077 0.001

NAPROXEN 95.3% 0.130 mg/L <0.020 mg/L

NONYLPHENOL 97.1% 2.058 mg/L <0.200 mg/L

POLYCHLORINATED BIPHENYLS

(PCBs, Aroclor 1260)

>99.9% 0.01 +/- 10% 0.0005

PCE (see Tetrachloroethylene) >96% 0.014 0.005

PENTACHLOROPHENOL* >99% 0.096 0.001

Perchlorobutadiene

(see HEXACHLOROBUTADIENE)*

>98% 0.044 0.001

PFOA 98.0% 0.0005 mg/L <0.00007 mg/L

PFOS 98.0% 0.001 mg/L <0.00007 mg/L

Phenytoin 94.7% 0.2173 mg/L <.030 mg/L

Propylene Dichloride

(see 1,2 -DICHLOROPROPANE)*

>99% 0.080 0.001

SIMAZINE* >97% 0.120 0.004

STYRENE (Vinylbenzene)* >99% 0.150 0.0005

1,1,1-TCA (see 1,1,1 - TRICHLOROETHANE)* 95% 0.084 0.0046

1,2,4-Trichlorobenze >99% 0.215 0.07

TCE (see TRICHLOROETHYLENE)* >99% 0.180 0.0010

1,1,2,2- TETRACHLOROETHANE* >99% 0.081 0.001

TETRACHLOROETHYLENE* >99% 0.081 0.001

TOLUENE (Methylbenzene)* >99% 0.078 0.001

TOXAPHENE >92.9% 0.015 +/- 10% 0.003

2,4,5-TP (Silvex)* 99% 0.270 0.0016

Toxoplasma (see CYST) >99.95%

MINIMUM 50,000/L

TRIBROMOACETIC ACID* 0.042 0.001

1,1,1-TRICHLOROETHANE (1,1,1-TCA)* 95% 0.084 0.0046

1,1,2-TRICHLOROETHANE* >99% 0.150 0.0005

TRICHLOROETHYLENE (TCE)* >99% 0.180 0.0010

TRIHALOMETHANES (TTHM)

(Chloroform; Bromoform;

Bromodichloromethane; Dibromochloromethane)

>99.8% 0.300 0.015

Unsym-Trichlorobenzene

(see 1,2,4-TRICHLOROBENZENE)

* >99% 0.160 0.0005

Vinylbenzene (see STYRENE)* >99% 0.150 0.0005

XYLENES (TOTAL)* >99% 0.070 0.001

% of Influent Max

Contaminant reduction Concentration Allowable

99.95% REDUCTION

REQUIREMENT

A-1, G-1, G-2, G-3, G-4, L-1, L-2, L-3, L-4, L-5,

M-1, M-2, S-1, S-2, S-4, W-2, W-3, W-4

Performance Data Sheet

Aquamor • 42188 Rio Nedo • Temecula, California 92590 • www.aquamorusa.com • 866-218-8473

Flow Rate: 0.5 gpm / 1.89 lpm

Operating Temperature: 33 - 100°F (0.6°C - 38°C)

Operating Pressure: 30 psi (207 kPa) - 100 psi (689 kPa)

Capacity: 300 gallons (1,136 L) or six months

Filter Specifications

This system has been tested according to NSF/ANSI Standard 42, 53, 372, 401, P473 and CSA B483.1 for reduction of the substances listed

below. The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the system, as specified in NSF/ANSI Standards 42, 53, 372, 401, P473 and CSA B483.1.

Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts. The system conforms to NSF/ANSI 42, 53, 372, 401,

P473 and CSA B483.1 for the specific performance claims as verified and substantiated by test data. Conforms to NSF/ANSI 53 for VOC reduction. See above

for individual contaminants and reduction performance. Note: Testing was performed under standard laboratory conditions, actual performance may vary.

System to be used with municipal or well water sources treated and tested on regular basis to ensure bacteriological safe quality. Do not use with water that

is microbiologically unsafe or of unknown quality without adequate disinfection before or after the system.

It is essential that the manufacturer’s recommended installation, maintenance and filter replacement requirements be carried out for the product to perform

as advertised. Manufactured by Aquamor, LLC, Temecula, CA.

CHLORINE >97% 2.0 mg/L 1.0 mg/L

ALACHLOR* >98% 0.050 0.001

Asbestos 99.98% 189 MFL 99%

ATRAZINE* >97% 0.100 0.003

BENZENE* >99% 0.081 0.001

BISPHENOL 99.1% 2.058 mg/L <0.300ng/L

BROMODICHLOROMETHANE (TTHM)* >99.8% 0.300 0.015

BROMOFORM (TTHM)* >99.8% 0.300 0.015

CARBOFURAN (Furadan)* >99% 0.19 0.001

Carbon Tetrachloride >95% 0.014 0.005

CHLORDANE >99.5% 0.04 +/-10% 0.002

CHLOROBENZENE (Monochlorobenzene)* >99% 0.077 0.001

CHLOROPICRIN* 99% 0.015 0.0002

CHLOROFORM (TTHM)* (surrogate chemical) >99.8% 0.300 0.015

2, 4-D* 98% 0.110 0.0017

CYST

(Giardi; Cryptosporidium; Entamoeba; Toxoplasma)

>99.95%

MINIMUM 50,000/L

Cryptosporidium (see CYST)

>99.95% MINIMUM 50,000/L

DBCP (see Dibromochloropropane)* >99% 0.052 0.00002

1,2-DCA (see 1,2-DICHLOROETHANE)* 95% 0.088 0.0048

1,1-DCE (see 1,1-DICHLOROETHYLENE)* >99% 0.083 0.001

DIBROMOCHLOROMETHANE

(TTHM; Chlorodibromomethane)*

>99.8% 0.300 0.015

DIBROMOCHLOROPROPANE (DBCP)* >99% 0.052 0.00002

o-DICHLOROBENZENE (1,2 Dichlorobenzene)* >99% 0.080 0.001

p-DICHLOROBENZENE (para-Dichlorobenzene) >98% 0.040 0.001

1,2-DICHLOROETHANE (1,2-DCA)* 95% 0.088 0.0048

1,1-DICHLOROETHYLENE (1,1-DCE)* >99% 0.083 0.001

CIS-1,2-DICHLOROETHYLENE* >99% 0.170 0.0005

TRANS-1,2- DICHLOROETHYLENE* >99% 0.086 0.001

1,2-DICHLOROPROPANE (Propylene Dichloride)* >99% 0.080 0.001

CIS-1,3- DICHLOROPROPYLENE* >99% 0.079 0.001

DINOSEB* 99% 0.170 0.0002

EDB (see ETHYLENE DIBROMIDE)* >99% 0.044 0.00002

ENDRIN 99% 0.053 0.00059

Entamoeba (see CYSTS) 99.95%

MINIMUM 50,000/L

ESTRONE 96.9% 0.1388 mg/L <0.020 mg/L

ETHYLBENZENE* >99% 0.088 0.001

ETHYLENE DIBROMIDE (EDB)* >99% 0.044 0.00002

Furadan (see CARBOFURAN)* >99% 0.19 0.001

Giardia Lamblia (see CYST) >99.95%

MINIMUM 50,000/L

HALOACETONITRILES (HAN)*

BROMOCHLOROACETONITRILE 98% 0.022 0.0005

DIBROMOACETONITRILE 98% 0.024 0.0006

HALOACETONITRILES (HAN)*

DICHLOROACETONITRILE 98% 0.0096 0.0002

TRICHLOROACETONITRILE 98% 0.015 0.0003

% of Influent Max

Contaminant reduction Concentration Allowable

99.95% REDUCTION

REQUIREMENT

99.95% REDUCTION

REQUIREMENT

99.95% REDUCTION

REQUIREMENT

99.95% REDUCTION

REQUIREMENT

HALOKETONES (HK):*

1,1-DICHLORO-2-PROPANONE 99% 0.0072 0.0001

1,1,1-TRICHLORO-2-PROPANONE 96% 0.0082 0.0003

HEPTACHLOR* >99% 0.25 0.00001

HEPTACHLOR EPOXIDE* 98% 0.0107 0.0002

HEXACHLOROBUTADIENE (Perchlorobutadiene)* >98% 0.044 0.001

HEXACHLOROCYCLOPENTADIENE* >99% 0.060 0.000002

IBUPROFEN 96.7% 0.432 mg/L <0.060 mg/L

LEAD (pH 6.5) >99.3% 0.15 +/- 10% 0.010

LEAD (pH 8.5) >99.3% 0.15 +/- 10% 0.010

LINDANE* >99% 0.055 0.00001

METHOXYCHLOR* >99% 0.050 0.0001

Methylbenzene (see TOLUENE)* >99% 0.078 0.001

Mercury (pH 6.5) 74.9% 0.0059 0.002

Mercury (pH 8.5) 97.8% 0.0061 0.002

Monochlorobenzene (see CHLOROBENZENE)* >99% 0.077 0.001

NAPROXEN 95.3% 0.130 mg/L <0.020 mg/L

NONYLPHENOL 97.1% 2.058 mg/L <0.200 mg/L

POLYCHLORINATED BIPHENYLS

(PCBs, Aroclor 1260)

>99.9% 0.01 +/- 10% 0.0005

PCE (see Tetrachloroethylene) >96% 0.014 0.005

PENTACHLOROPHENOL* >99% 0.096 0.001

Perchlorobutadiene

(see HEXACHLOROBUTADIENE)*

>98% 0.044 0.001

PFOA 98.0% 0.0005 mg/L <0.00007 mg/L

PFOS 98.0% 0.001 mg/L <0.00007 mg/L

Phenytoin 94.7% 0.2173 mg/L <.030 mg/L

Propylene Dichloride

(see 1,2 -DICHLOROPROPANE)*

>99% 0.080 0.001

SIMAZINE* >97% 0.120 0.004

STYRENE (Vinylbenzene)* >99% 0.150 0.0005

1,1,1-TCA (see 1,1,1 - TRICHLOROETHANE)* 95% 0.084 0.0046

1,2,4-Trichlorobenze >99% 0.215 0.07

TCE (see TRICHLOROETHYLENE)* >99% 0.180 0.0010

1,1,2,2- TETRACHLOROETHANE* >99% 0.081 0.001

TETRACHLOROETHYLENE* >99% 0.081 0.001

TOLUENE (Methylbenzene)* >99% 0.078 0.001

TOXAPHENE >92.9% 0.015 +/- 10% 0.003

2,4,5-TP (Silvex)* 99% 0.270 0.0016

Toxoplasma (see CYST) >99.95%

MINIMUM 50,000/L

TRIBROMOACETIC ACID* 0.042 0.001

1,1,1-TRICHLOROETHANE (1,1,1-TCA)* 95% 0.084 0.0046

1,1,2-TRICHLOROETHANE* >99% 0.150 0.0005

TRICHLOROETHYLENE (TCE)* >99% 0.180 0.0010

TRIHALOMETHANES (TTHM)

(Chloroform; Bromoform;

Bromodichloromethane; Dibromochloromethane)

>99.8% 0.300 0.015

Unsym-Trichlorobenzene

(see 1,2,4-TRICHLOROBENZENE)

* >99% 0.160 0.0005

Vinylbenzene (see STYRENE)* >99% 0.150 0.0005

XYLENES (TOTAL)* >99% 0.070 0.001

% of Influent Max

Contaminant reduction Concentration Allowable

99.95% REDUCTION

REQUIREMENT

Filter Specifications

Flow Rate 0.5 gpm / 1.89 lpm

Operating Temperature 33-100°F (0.6-38°C)

Operating Pressure 30-100 psi (kPa)

Capacity 300 gal. (1,136 L) or six months

Contaminant and Reduction Performance

WATER FILTER INSTALLATION &

PERFORMANCE DATA (CONT.)

• System to be used with municipal or well water

sources treated and tested on regular basis to

ensure bacteriological safe quality. Do not use with

water that is microbiologically unsafe or of unknown

quality without adequate disinfection before or after

the system.

• It is essential that the manufacturer’s recommended

installation, maintenance and filter replacement

requirements be carried out for the product to

perform as advertised. Manufactured by Aquamor,

LLC, Temecula, CA.

TEC_TM_170 REV. A09/26/2022 P# 848062Page 18 of 60 TRUE RESIDENTIAL®

PAGE TITLENOTES

TEC_TM_170 REV. A 09/26/2022 Page 19 of 60TRUE 42/48 INSTALL MANUAL

INSTALLATION PLAN VIEWS

TR-42SBS-SS-C

TR-48SBS-SG-SS-C

TEC_TM_170 REV. A09/26/2022 P# 848062Page 20 of 60 TRUE RESIDENTIAL®

INSTALLATION PLAN VIEWS

OVERALL DIMENSIONS – TR-42

26-5/8"

(676 mm)

20-13/16"

(529 mm)

DOORS OPEN 90º

23-25/32"

(604 mm)

41-9/16" (10556 mm)

CABINET WIDTH

2-1/2" (546mm)

DOORS OPEN 135º

13-1/32" (331 mm)

17-5/32" (436 mm)

TOP VIEW

Dimensions may vary by ± 1/8" (3.2 mm)

This manual suits for next models

3

Table of contents

Other TRUE RESIDENTIAL Refrigerator manuals

Popular Refrigerator manuals by other brands

DAEWOO ELECTRONICS

DAEWOO ELECTRONICS RN-325PW Service manual

Bosch

Bosch CTC29BT3NI user manual

Tricity Bendix

Tricity Bendix TB 55 R Operating & installation instructions

Zanussi

Zanussi CBI750 Instruction booklet

Viking

Viking Undercounter/Freestanding Refrigerated... Use & installation guide

Dometic

Dometic CLASSIC RM 2620 Installation and operating instructions