............ www.truemfg.com ............

True Food Service Equipment, Inc.

8 8

REMOTE UNITS (This section applies to remotes only!)

• Remote cabinets must be ordered as remote.

We do not recommend converting from a

standard self contained to remote system.

• All remote cabinets must be hard wired.

• No castors available.

• All remote cabinets come standard using 404A

refrigerant.

• All remote units come standard with expansion

valve, liquid line solenoid, heated condensate

pan, and defrost timer when applicable.

• Contact True Technical Service for BTU

requirements.

• No wiring necessary between cabinet and

condensing unit.

• All remote condensing units purchased from

True are 208/230 volts single phase.

If you have any questions regarding this section,

please call True at 1-(800)-325-6152.

INSTALLATION / OPERATION INSTRUCTIONS

SEALING CABINET TO FLOOR

Optional

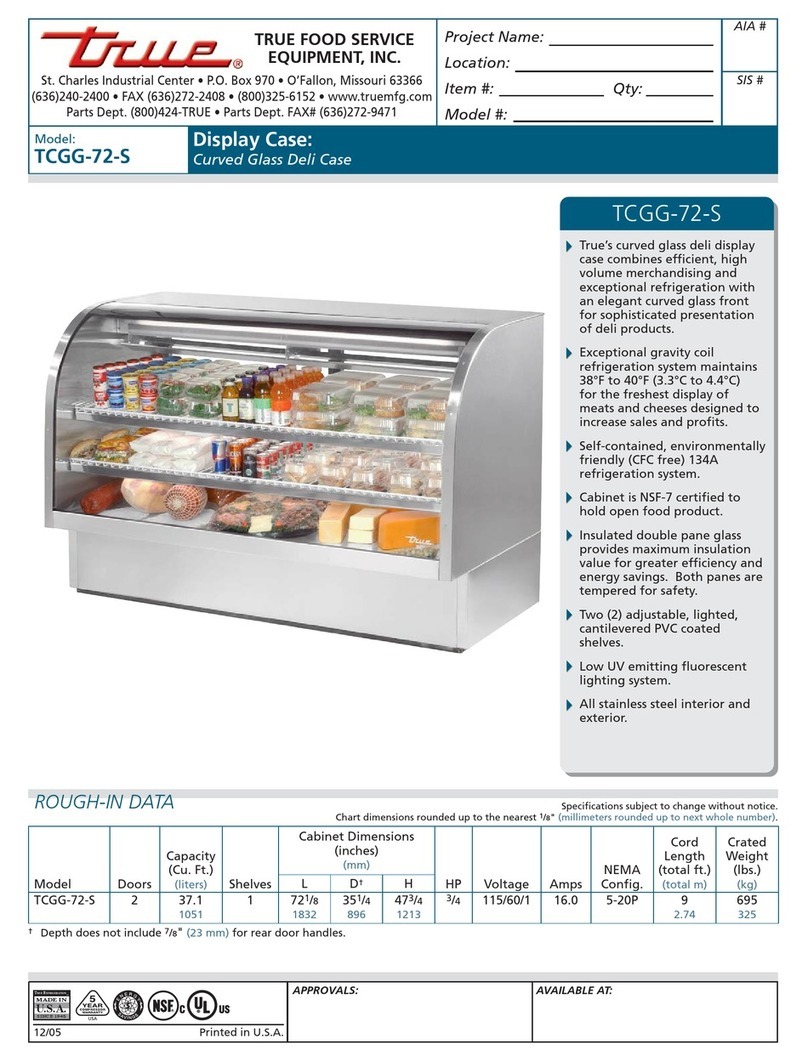

A. It may be necessary to seal the deli case to the

floor for local sanitary codes or if the customer

so desires. TRUE recommends either of the

following methods.

B. Using a vinyl cover base trim as produced by

Armstrong, Johnson, or Kentile (available at floor

covering suppliers) or

C. Using mastics available at hardware stores.

D. When applying the cove base trim, thoroughly

clean both the cabinet and floor of dirt and

grease. Apply a recommended contact cement

to the cove base trim. After cove base trim has

dried, fill in cracks and joints with a caulking

material.

E. When applying a mastic, draw an outline of the

cabinet on the floor. Raise and block the front

side of the cabinet. Apply a bead of mastic to

the floor 1/2” inside the outline drawn. Lower

the cabinet. Raise and block the rear side of the

cabinet. Apply the bead of mastic, lower the

cabinet.

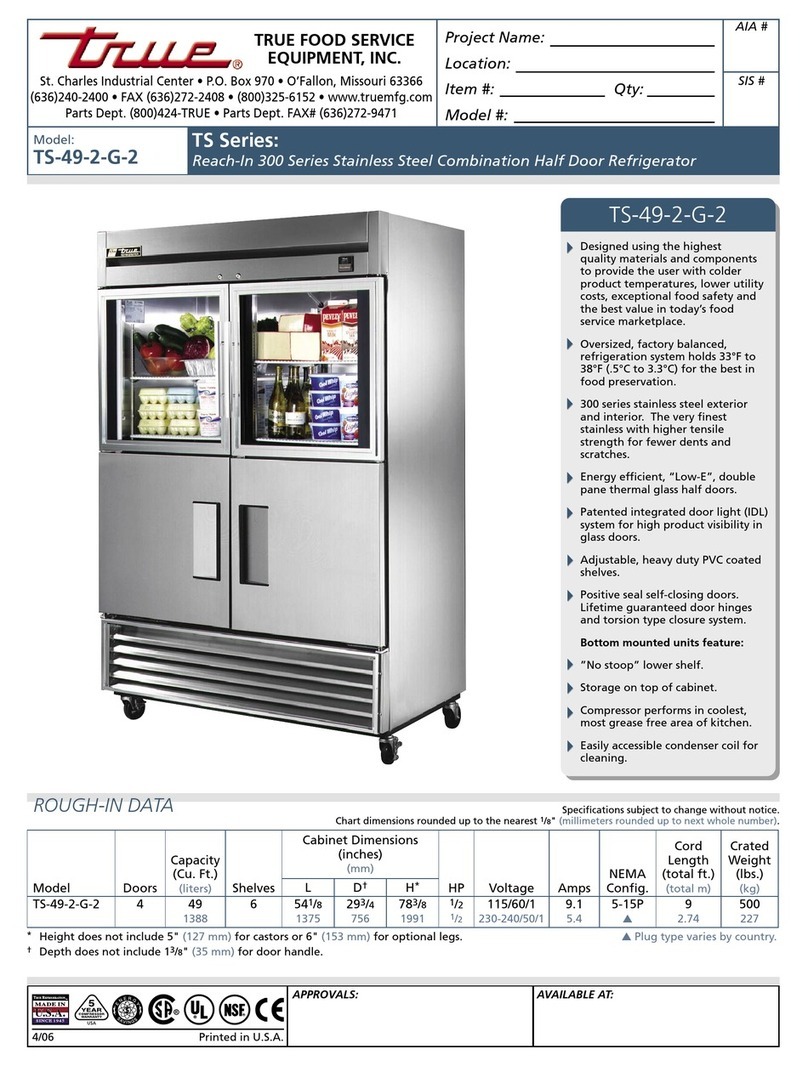

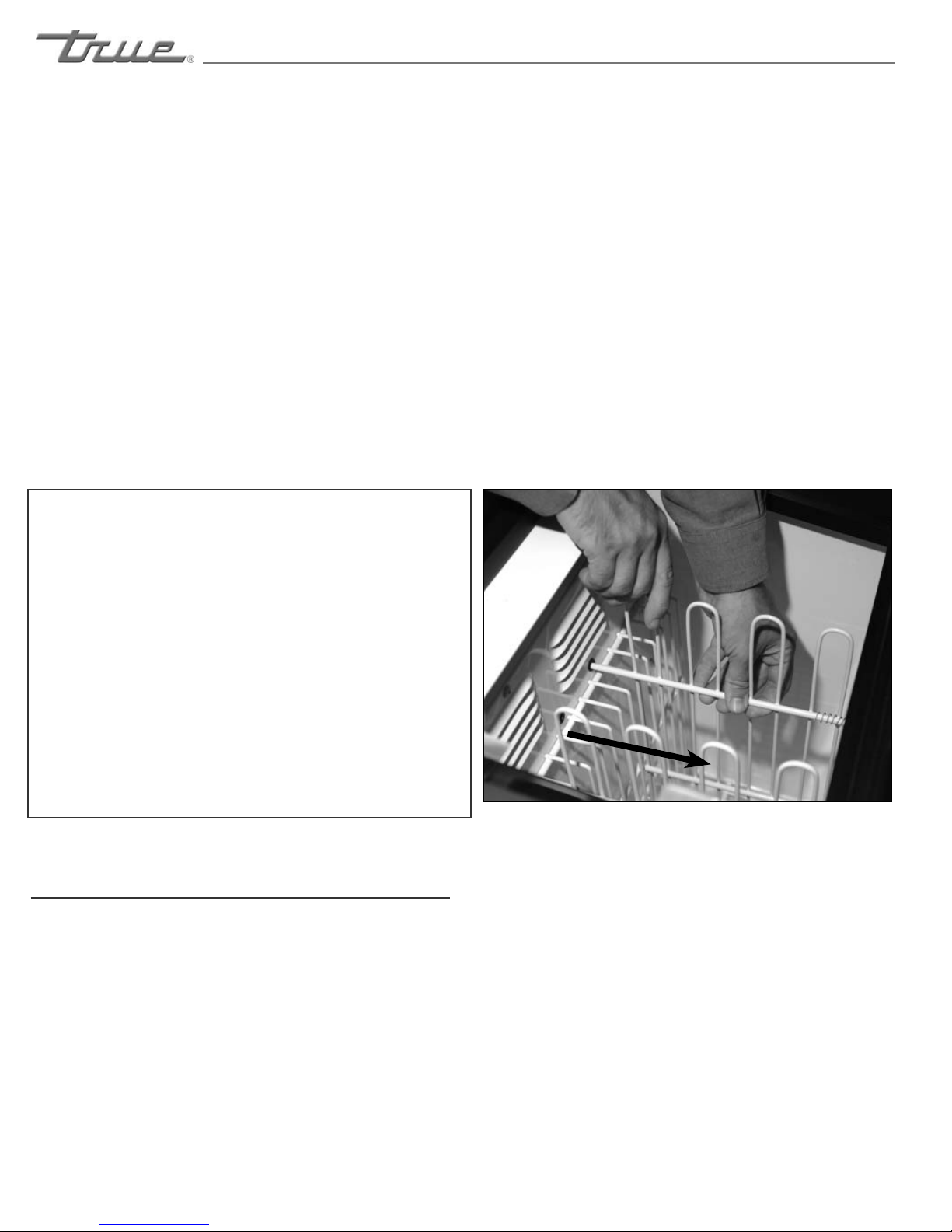

BIN DIVIDER INSTALLATION

STAINLESS STEEL

SHELF INSTALLATION

NOTE

Convenience merchandisers

are shipped with bin dividers

in place. If it is necessary to

adjust spacing the following

procedure is recommended.

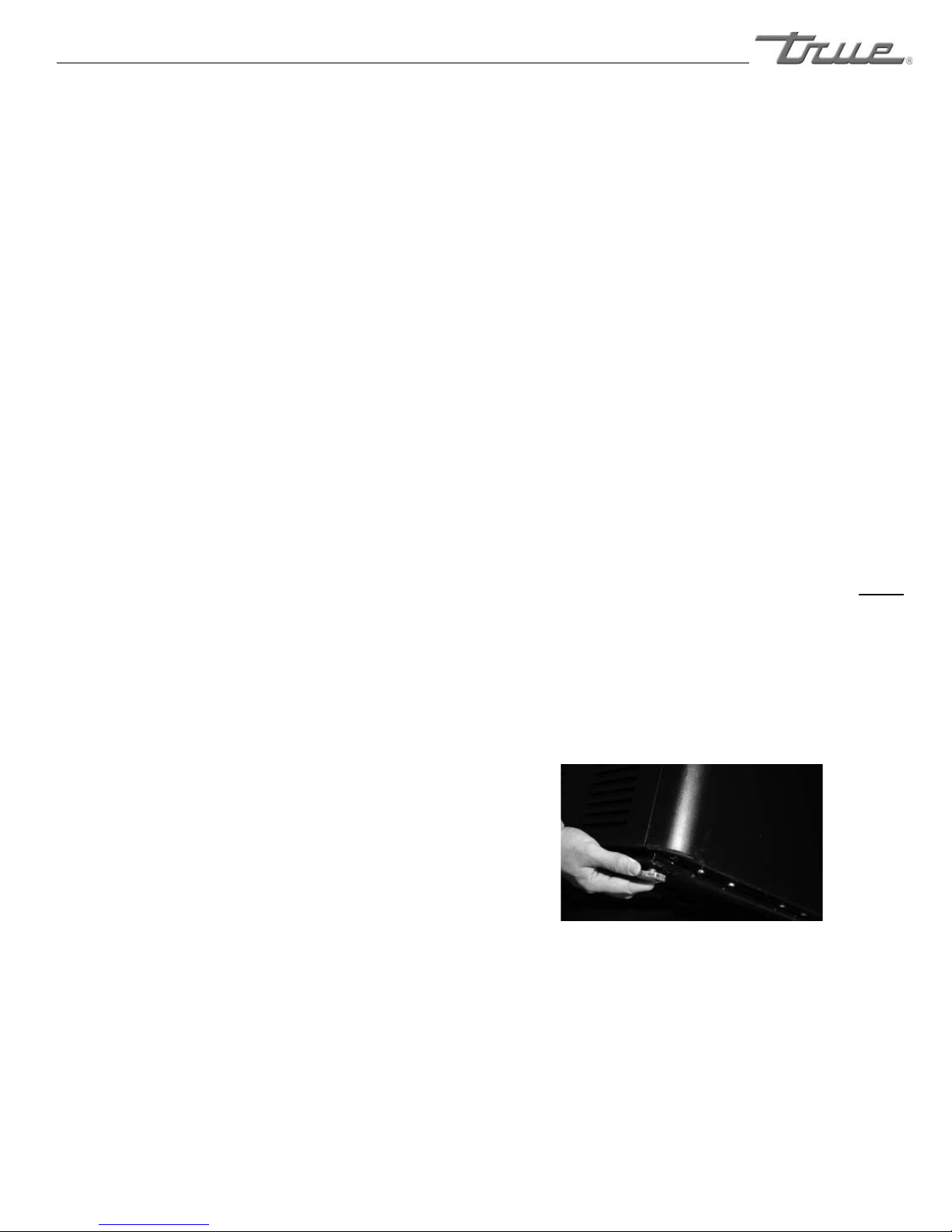

Step 1

A. Dividers are spring loaded

- push divider towards front

of the cooler to release from

rear grommeted holes.

B. Lineup divider front pegs

with desired holes and punch

through interior tape lining

of both top and bottom holes

- bottom peg first (front holes

are taped over to improve

insulation values).

Remove divider from the

front holes and line up

regular and spring loaded

rear pegs with holes in line

with those desired in front.

Insert as far as possible and

maneuver front pegs in place.

Figure 1