True Professional 15 Series Installation Guide

1

OWNERSHIP

SAFETY PRECAUTIONS

DANGER!

RISK OF CHILDREN

ENTRAPMENT

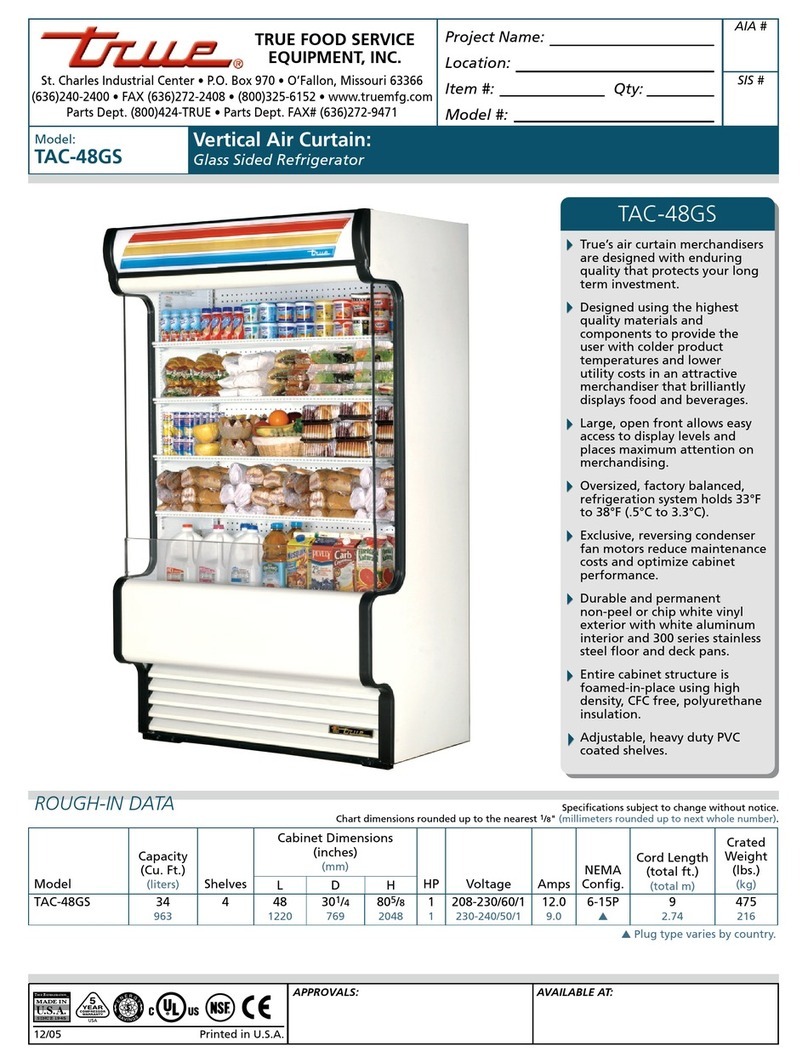

To insure that your unit works properly from the

first day, it must be installed properly. (We highly

recommend a trained refrigeration mechanic and

electrician install your True Professional Cabinet.) The

cost of a professional installation is money well spent.

Before you start to install your True Professional

Cabinet, carefully inspect it for freight damage. If

damage is discovered, immediately file a claim with

the delivery freight carrier. True is not responsible for

damage incurred during shipment.

Any questions about the installation please contact

yourTrue dealer or True Technical Service Department

at 1-800-325-6152 (Please have your model and

serial numbers available when you call our Service

Department).

• This refrigerator must be properly installed

and located in accordance with the installation

instructions before it is used.

• Do not allow children to climb, stand or hang on

the shelves in the refrigerator. They could damage

the refrigerator and seriously injure themselves.

• Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

• Keep hands away from the “pinch point” areas

(gaps between the doors and between the doors

and cabinet) small areas are not necessarily safe.

• Unplug the refrigerator before cleaning and

making repairs.

NOTE: We strongly recommend that any

servicing be performed by a qualified individual.

• Setting temperature control to OFF only removes

power from the refrigeration system, it does not

remove power from other circuits. For example,

temperature control and lights.

NOTE: WE STRONGLY RECOMMEND THAT ANY

SERVICING BE PERFORMED BY A QUALIFIED

INDIVIDUAL

PROPER DISPOSAL OF THE OLD

REFRIGERATOR

Child entrapment and suffocation are not problems

of the past. Junked or abandoned refrigerators are

still dangerous... even if they will sit for “just a few

days”. If you are getting rid of your old refrigerator,

please follow the instructions below to help prevent

accidents.

BeforeYou Throw AwayYour Old Refrigerator or

Freezer:

• Take off the doors.

• Leave the shelves in place so that children may not

easily climb inside.

CFC DISPOSAL

Your old refrigerator may have a cooling system that

used CFC’s (chlorouorocarbons). CFCs are believed

to harm stratospheric ozone. If you are throwing away

your old refrigerator, make sure the CFC refrigerant is

removed for proper disposal by a qualified service. If

you intentionally release this CFC refrigerant you can

be subject to fines and imprisonment under provisions

of the environment legislation.