Trumpf TruArc Weld 1000 User manual

Chapter 1

Safety

1 Safety concept 1‐3

2 Regulations and guidelines 1‐5

3 Terms 1‐6

4 Operational safety 1‐7

4.1 Intended use 1‐7

4.2 Significant change to the machine 1‐8

4.3 Authorized personnel 1‐8

5 Hazards 1‐9

5.1 Mechanical dangers 1‐9

Dangers of slipping, tripping or falling 1‐9

Moving robot axes 1‐9

Tilting and falling workpieces 1‐10

B1154en 2020-09-01 Safety 1‐1

Sharp-edged workpieces 1‐10

Wire feed from the welding torch 1‐10

5.2 Dangers from electricity 1‐10

Dangers due to the open electrical cabinet 1‐11

Electrical voltage on the welding wire 1‐11

5.3 Thermal dangers 1‐11

Fire hazard 1‐11

Dangers due to fire 1‐12

Danger due to flying sparks 1‐12

Hot surfaces and workpieces 1‐12

5.4 Danger due to materials and substances 1‐12

Hazardous materials 1‐12

5.5 Noise hazards 1‐14

Increased sound pressure level through

pneumatics

1‐14

5.6 Combination of dangers 1‐14

Dangers when using the welding torch 1‐14

Dangers in the event of a network con-

nection

1‐15

6 Measures to be taken by the manufacturer 1‐16

6.1 Noise protection 1‐16

6.2 Danger zones and safeguarding 1‐16

6.3 Safety-relevant signs on the machine 1‐23

7 Organizational measures to be taken by

the user

1‐25

7.1 Training and instructing operators 1‐25

7.2 Due diligence when operating the machine 1‐25

7.3 Water protection 1‐26

7.4 Spare parts, accessories, software, operating

materials

1‐27

8 Disassembly and disposal 1‐28

1‐2Safety 2020-09-01 B1154en

1. Safety concept

The "Safety" chapter describes the safety concept of the

machine. It specifies the guards and the manufacturer's design

measures for safe operation of the machine.

It points out dangers when handling the machine and specifies

measures taken by the user to avoid possible dangers.

The "Hazards" section is based on the manufacturer's risk

assessment and describes the residual risk. The user must take

measures to prevent the hazards. The measures must comply

with the national safety and accident prevention regulations of

the country in which the machine is operated.

Dangerous points on the machine are marked with warning

signs and information plates.

The operator's manual contains warnings, which warn of dan-

gers and specify measures to avoid these dangers.

Warnings have the following structure:

■The signaling word designates the degree of a danger.

■The danger description specifies the danger and possible

consequences if attention is not paid to the danger.

■The measures for prevention of the danger are planned.

Example of a warning:

Risk of fatal injury due to falling load!

ØObserve safety regulations for the handling of heavy loads.

ØNever walk under a suspended load.

ØUse certified tackle and means of transportation of sufficient

size.

ØEmploy qualified technicians to transport the machine.

ØCarry out transport in accordance with the transport regula-

tions.

A warning contains signaling words that are explained in the fol-

lowing table:

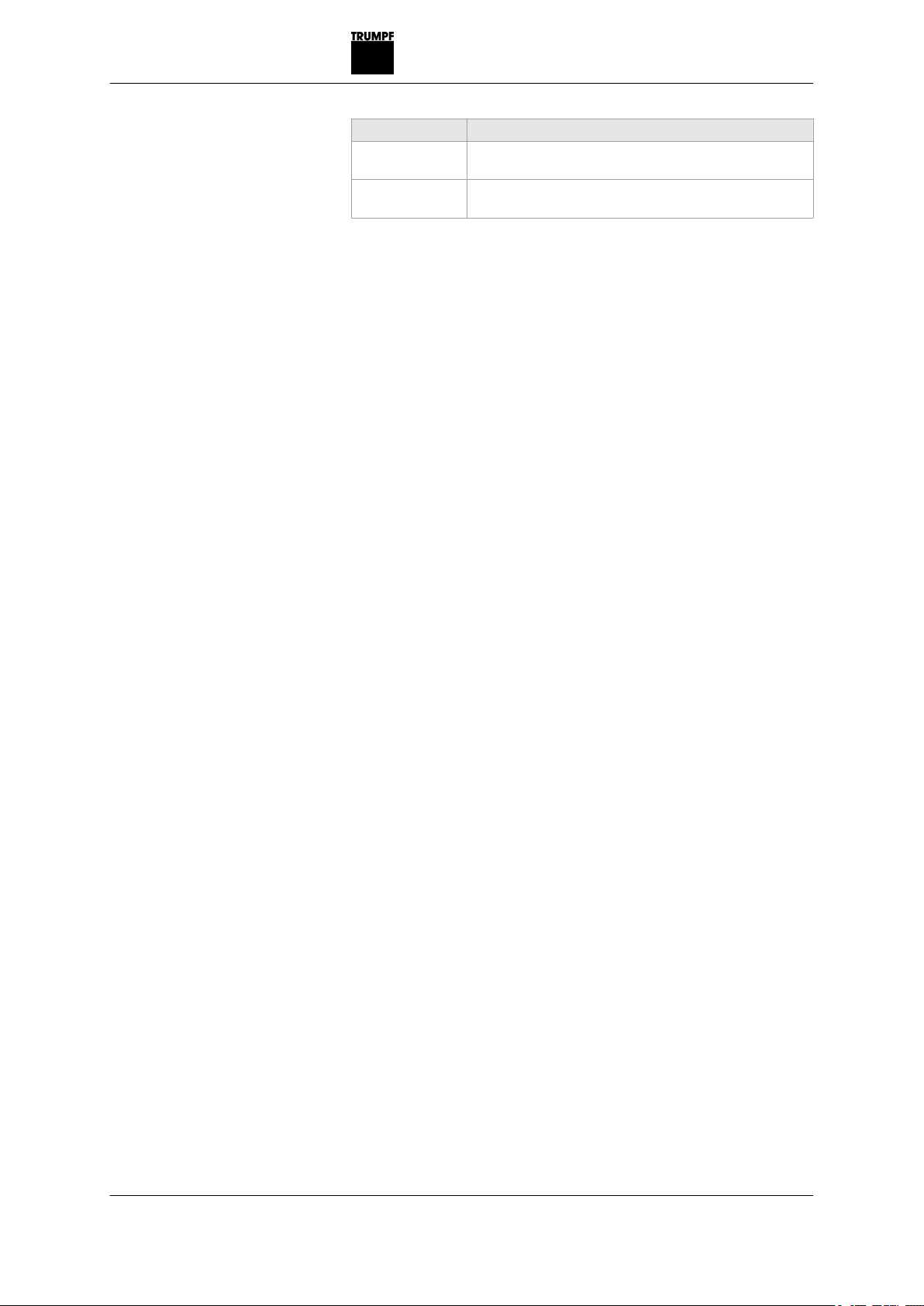

Signaling word Description

DANGER If the dangerous situation is not prevented, death or

serious injuries will result.

WARNING If the dangerous situation is not prevented, death or

serious injuries could result.

B1154en 2020-09-01 Safety concept 1‐3

Chapter Safety

Warning sign and

information plates

Warnings

DANGER

Signaling word Description

CAUTION If the dangerous situation is not prevented, light inju-

ries could result.

NOTICE If the situation is not prevented, damage to property

could result.

Signaling words Tab. 1-1

1‐4Safety concept 2020-09-01 B1154en

2. Regulations and guidelines

TRUMPF issues an EU declaration of conformity for the auto-

mated welding cell in accordance with EC Machinery Directive

2006/42/EC. The automated welding cell is a complete machine.

The standards applied by TRUMPF are stated in the EU declara-

tion of conformity supplied.

With the CE marking, TRUMPF confirms compliance with the fol-

lowing EU directives:

■EC Machinery directive 2006/42/EC.

■Directive about electromagnetic compatibility 2014/30/EU.

The CE marking is on the nameplate.

B1154en 2020-09-01 Regulations and guidelines 1‐5

Laws and guidelines in the

EU

3. Terms

Term Description

User The user is the person who is responsible for the operation of the machine or system

and has the authority to issue orders to employees.

Machine A machine (complete machine) according to the definition in the EC Machinery Direc-

tive is the entirety of interconnected assemblies and components, of which at least

one component is movable. A machine is intended for a specific application.

Personal safety equip-

ment (PPE)

Equipment intended to be used or worn by persons in order to protect themselves

against hazards to their safety and health.

Components of personal protective equipment:

■ Protective clothing (flame retardant, insulating, covers the whole body).

■ Closed safety shoes.

■ Safety glasses

Additional personal safety equipment when welding:

■ Safety shield for eyes and face with filter insert according to regulations to protect

against UV rays, heat and flying sparks.

■ Welding gloves.

Terms Tab. 1-2

1‐6Terms 2020-09-01 B1154en

4. Operational safety

The machine can result in the following dangers if it is used

inappropriately or for purposes other than those intended, or

else if it is not safe to operate:

■Dangers to the safety of the personnel.

■Damage to the machine and other material assets of the

user.

4.1 Intended use

The user may use the machine in the industrial and commercial

sector.

Installation, operating and transport conditions defined by

TRUMPF must be adhered to and maintenance work must be

carried out in accordance with the Operator's manual. The user

must observe the specifications of the country in which the

machine is being operated as well as national and regional

safety and accident prevention regulations.

The user may use the machine to weld mild steel, aluminum

and stainless steel. MAG/MIG welding and CMT welding are

authorized welding processes.

The following is not permitted:

■Any working procedure that impairs the safety.

■Operation of the machine with a welding device that was not

delivered with the machine. Operation of the machine with

another welding device is only permitted after consultation

with TRUMPF.

■Operation of the machine in explosive or corrosive atmos-

phere.

■The processing of materials that do not comply with the

defined specifications.

Any use going beyond this is considered to be unauthorized

use. TRUMPF is not liable for any damage, especially personal

injury and damage to property as well as production failures

resulting from this. The risk is borne solely by the user. The war-

ranty will be voided.

If the user changes or modifies the machine, then the user

rather than TRUMPF is responsible for the safety of the

machine.

B1154en 2020-09-01 Operational safety 1‐7

Machine

Disclaimer

4.2 Significant change to the machine

The machine is delivered as a complete machine, as defined by

the EC Machinery Directive, with a EU declaration of conformity.

The machine is operationally safe at the time of commissioning.

The user can produce goods with the machine as intended.

After commissioning, the responsibility for the safety of the

machine is transferred from the manufacturer to the customer.

4.3 Authorized personnel

■Operation in automatic mode may only be carried out by

authorized and instructed personnel.

■Installation work, connection, setting and maintenance work

may only be carried out by authorized, trained and

instructed personnel.

■Qualified personnel may do the following:

− Transporting the machine and its components to the

installation site.

− Carry out work at the pneumatic and electrical modules.

− Perform work on the shielding gas system.

− Disassemble the machine and its components.

■Program creation and testing in the manual and program

test operating mode may only be carried out by an

instructed welding specialist.

1‐8Operational safety 2020-09-01 B1154en

Delivery condition

5. Hazards

The "Hazards" section is based on the manufacturer's risk

assessment and describes the residual risk. The user must take

measures to prevent the hazards.

5.1 Mechanical dangers

Dangers of slipping, tripping or falling

Slipping, tripping or falling!

Risk of injury.

ØDo not climb or climb over the components in the safety

cabin.

ØWhen entering the safety cabin, pay attention to section

tube on the safety doors.

ØDo not climb onto the welding table.

ØPay attention to cables on the foot switch.

ØRemove leaking cooling fluid immediately.

Moving robot axes

During teaching and setup work there is a risk of crushing and

risk of impact through the movement of the robot axes.

Risk of injury due to movements of the robot axes!

ØKeep an adequate distance from the robot.

ØOnly carry out teaching and setup work at a reduced speed.

ØDo not step between the robot, moving components and

other obstacles.

ØBefore initiating a robot movement ensure that no one is

within reach of the robot.

B1154en 2020-09-01 Hazards 1‐9

CAUTION

WARNING

Tilting and falling workpieces

Tilting or falling workpieces!

Head and hand injuries.

ØOnly process workpieces up to a max. size of 2000 x 600 x

600 mm (78.7 x 23.6 x 23.6 in).

ØPlace workpieces statically with clamping fixtures (e.g. col-

lets, etc.) and bring them into a position with a secure

center of gravity.

ØPeople who are not involved may not stay in the danger

area.

Sharp-edged workpieces

Workpieces have sharp edges!

Cutting injuries of the hands.

ØWear protective gloves.

Wire feed from the welding torch

After opening the anti-glare protection or one of the safety

doors, the robot remains in its current position.

If the robot is not in home position, there is a risk of stab inju-

ries when working on the wire of the welding torch, e.g. when

cutting the wire at the feed.

Wire tip in working area!

Stab injuries to hands and eyes!

ØWear protective gloves.

ØWear safety goggles.

5.2 Dangers from electricity

Work on electrical equipment and live parts is only allowed to

be carried out by trained qualified personnel.

1‐10 Hazards 2020-09-01 B1154en

CAUTION

CAUTION

CAUTION

Dangers due to the open electrical cabinet

The electrical cabinet may be opened only by an electrician.

Electrical voltage!

Electric shock!

ØKeep the electrical cabinet closed.

ØBefore opening the electrical cabinet: turn off the MAIN

SWITCH and secure it against being switched back on

again. Wait for the discharging time (at least 5 minutes).

Electrical voltage on the welding wire

The welding wire and drive parts are under welding voltage dur-

ing operation.

Danger due to electric voltage on the welding wire!

ØWear dry, insulating gloves.

ØUse insulating surface against floor and working area.

ØDo not touch wire electrode with bare hands.

ØWait until the welding wire has cooled down.

ØNever immerse in fluids to cool it down.

5.3 Thermal dangers

Fire hazard

Firefighting must be performed only by personnel who are

trained to do so and who are using appropriate protective equip-

ment. If there is a risk of self-endangerment, or if the fire threat-

ens to escalate, the fire department must be called.

The following fire extinguishers should be kept ready for fire pro-

tection:

■CO2 hand-held fire extinguisher (fire classification B) with 6

extinguishing units for fires in the compact dust extractor

and for fires at the machine (except for metal fires).

■Hand-held fire extinguisher (fire classification D) for metal

fires.

■Metal bucket (at least 20 l) with dry sand.

B1154en 2020-09-01 Hazards 1‐11

DANGER

WARNING

Dangers due to fire

Fire!

Serious injuries.

ØIn the event of fire, leave the danger zone and take fire pro-

tection measures.

Danger due to flying sparks

Severe injuries due to fires and explosions.

ØDo not place any flammable materials on the welding table.

ØPlace flammable materials at least 11m (36ft) away from the

electric arc or cover with a verified cover.

ØKeep suitable and verified fire extinguishers ready at hand.

ØDo not weld on gas, fuel or mineral oil tanks.

Hot surfaces and workpieces

After welding, the welding table and workpieces, as well as the

welding torch and other equipment components become very

hot. There is a risk of burns during removal of the workpieces

and maintenance work.

Risk of burns from hot workpieces, hot surfaces, welding

torch and other equipment components after welding!

ØWear personal protective equipment.

ØWait for the cooling phase to pass (at least 5 minutes).

5.4 Danger due to materials and

substances

Hazardous materials

Processing generates smoke and particles. Heavy metal vapors

can arise if metals are processed. They can damage body tis-

sues and organs.

1‐12 Hazards 2020-09-01 B1154en

WARNING

WARNING

WARNING

In the case of hazardous substances, TRUMPF only indicates

the sources of danger. The user must estimate the dangers

caused by a raw material. The user must check and estimate

the required measures.

When the machine is switched off the valve for the main gas

supply must be closed.

During welding, gas and particles that are hazardous to

health can escape.

Gas and particles can get into the airways.

ØOnly use the machine with an exhaust system that works

properly.

During welding and processing of stainless steels gas and

particles are produced that are hazardous to health, and

which cannot be filtered via the integrated exhaust system.

Gas and particles can get into the airways.

ØDo not suction any stainless steels, such as V2A, V4A, etc.,

with the integrated exhaust system of the mobile welding

cell.

ØWeld stainless steels exclusively with a separate exhaust

system to outside.

ØObserve the national provisions for processing stainless

steels.

During maintenance work, gas and particles that are

hazardous to health can escape.

Irritation and diseases of the airways may occur.

ØWear a breathing mask when performing maintenance oper-

ations on the integrated exhaust system.

Shielding gas escaping uncontrollably

Danger of suffocation

ØMake sure there is a sufficient fresh air supply.

ØCheck the main gas supply of the shielding gas for uncon-

trolled gas leakage prior to every start-up.

ØClose gas tap when not in operation.

B1154en 2020-09-01 Hazards 1‐13

WARNING

WARNING

WARNING

WARNING

5.5 Noise hazards

Increased sound pressure level through

pneumatics

For certain processes, the A-weighted sound pressure level of

the system may exceed 71 dB. In this case, persons in the area

surrounding the machine will be exposed to increased noise pol-

lution.

Exceeding noise level.

Hearing damage

ØWear hearing protection from noise level > 80 dB (A).

ØSet pneumatic pressure to max. 6 bar.

5.6 Combination of dangers

Dangers when using the welding torch

High temperatures on welding torch and other equipment

components.

Severe burns to skin!

ØWait for the cooling phase to pass (at least 5 minutes)

before carrying out work on welding torch or other equip-

ment components.

ØWear protective gloves.

Electric arc in case of MIG and MAG welding.

Risk of severe skin burns and damage to the eyes.

Impairment or even loss of eyesight possible!

ØWelding with anti-glare protection open only with safety

glasses.

ØDo not climb on the machine during the welding process.

ØDo not look into the safety cabin from above.

1‐14 Hazards 2020-09-01 B1154en

CAUTION

WARNING

WARNING

Dangers in the event of a network

connection

The electrical cabinet may be opened only by an authorized spe-

cialist.

Note

It is possible to connect to the customer network using the FAB

interface option.

B1154en 2020-09-01 Hazards 1‐15

6. Measures to be taken by the

manufacturer

6.1 Noise protection

The A-weighted emission sound pressure level at the worksta-

tion of the personnel is between 70 dB(A) and 80 dB(A). The

operating conditions of the machine during the measurement,

the measuring method and the exact measurement results of

the A-weighted emission sound pressure level can be taken

from the noise measurement report.

6.2 Danger zones and safeguarding

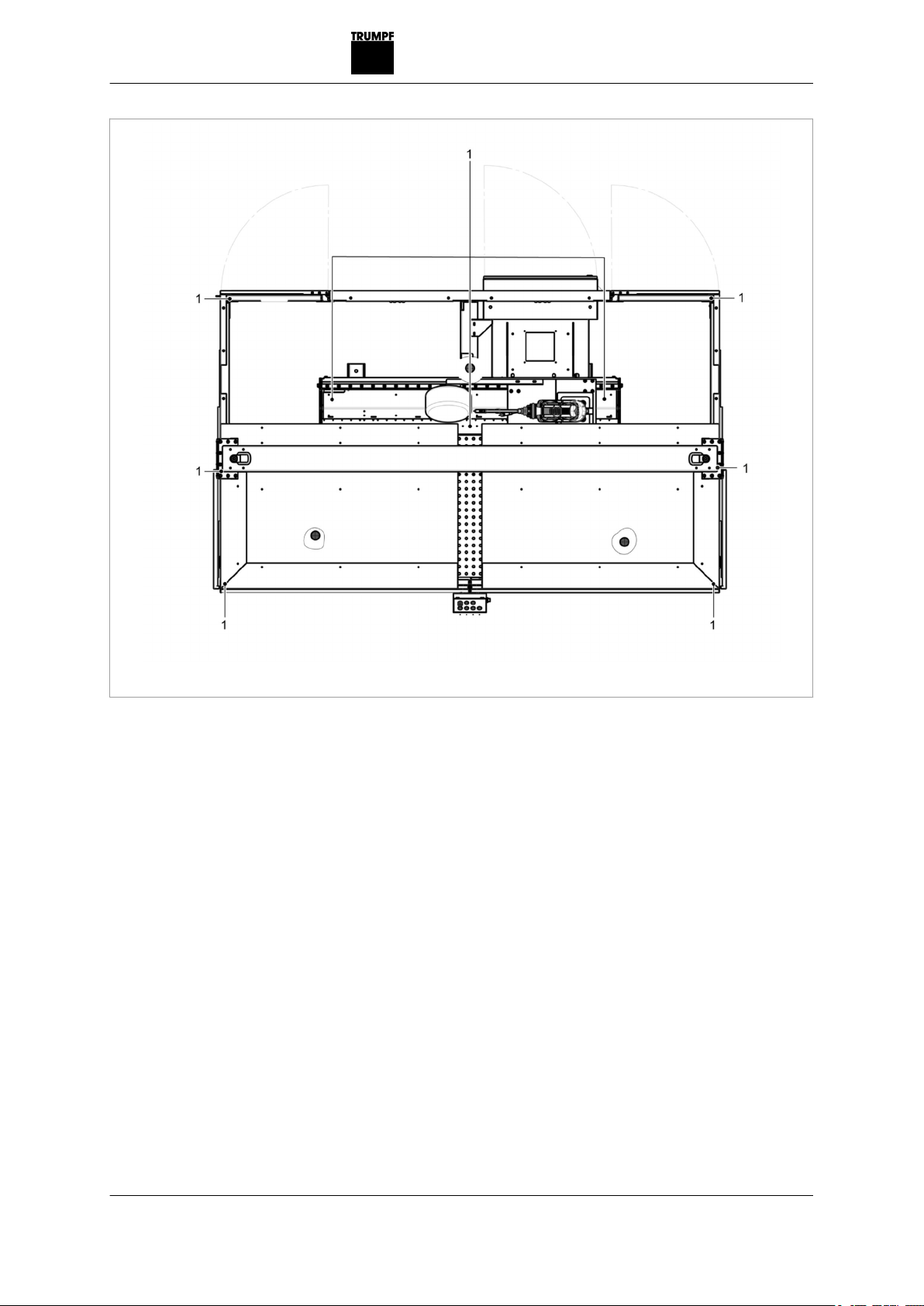

The danger zone of the machine is protected by guards. The

machine may only be operated with an active guard.

1‐16 Measures to be taken by the manufacturer 2020-09-01 B1154en

1 Rear safety doors (hinged

doors)

2 Lateral safety doors (sliding

doors)

3 Anti-glare protection

4 EMERGENCY STOP push-but-

ton

5 Operating unit with foot switches

6 Operating-mode key switch

7 Upper cover with exhaust hood

8 Operating elements on the

robot welding arm

9 Power source

10 Exhaust system

11 Extendible partition wall

Danger zones and safeguarding device Fig. 105422

The operating-mode key switch is located laterally on the central

operating unit.

Unauthorized operation of the machine in the operating

modes "Manual mode" and "Program test" by operating

personnel!

Injuries due to unintended use of the machine.

ØRemove the key in automatic mode and store it safely.

ØHave setting and test work performed by instructed welding

specialists.

B1154en 2020-09-01 Measures to be taken by the manufacturer 1‐17

Operating-mode key switch

WARNING

1 Manual mode

2 Program test

3 Automatic mode

Key switch positions Fig. 105430

The main switch is used to switch the machine on and off. The

main switch can be secured with a padlock against being

switched back on again.

The main switch has two switch settings:

Switch setting 0The machine is switched off and the voltage

supply of the machine is interrupted .

Switch setting 1The machine is switched on.

Tab. 1-3

The main switches prevent the machine from starting unintention-

ally:

■Pneumatic: main valve with stop

■Shielding gas: main valve (ball valve) with stop

■Electric: lockable main switch

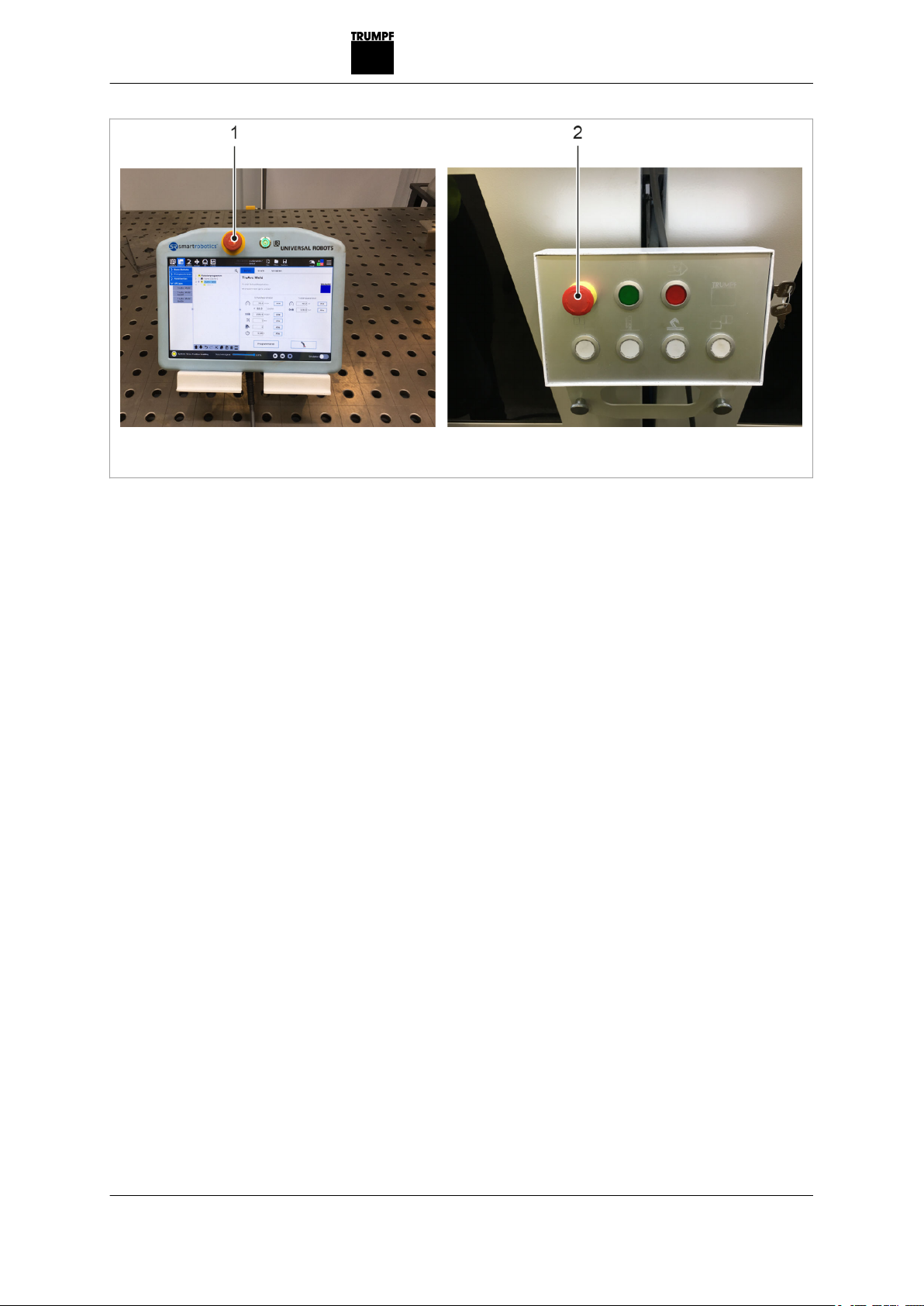

EMERGENCY STOP push-buttons are located at the following

points on the machine:

■On the central operating unit.

■On the mobile operating unit.

1‐18 Measures to be taken by the manufacturer 2020-09-01 B1154en

Main switch

Power isolation switches on

the machine

EMERGENCY STOP push-

button

1 EMERGENCY STOP push-button, mobile operating

unit

2 EMERGENCY STOP push-button, central operating

unit

EMERGENCY STOP push-button Fig. 105429

EMERGENCY STOP has the following effect:

■All axis motions stop.

■All drives are switched off electrically.

■The power supply of the power source is interrupted.

■The 24 V control voltage is maintained.

■The shielding gas supply valves are closed.

■The anti-glare protection movements and extendible partition

wall stop.

Lateral and rear safety doors prevent entry into the danger zone

in automatic mode.

The safety doors are electronically monitored by safety contacts.

B1154en 2020-09-01 Measures to be taken by the manufacturer 1‐19

Safety doors

1 Safety contacts for door monitoring

Safety contacts Fig. 105427

If one or several of the safety doors are opened during opera-

tion, the robot is stopped and transferred into a safe state.

A restart of the machine has to be acknowledged again.

A two-part anti-glare protection at the front of the machine pro-

tects the operator from optical radiation and prevents access to

the danger zone in automatic mode.

The anti-glare protection must be manually closed in automatic

mode before a welding process is started. For program tests, a

program can be started and be welded with the glare protection

open. In manual mode, only the robot can be moved with the

anti-glare protection open.

To reduce the risk of people in the machine being overseen and

becoming trapped, the anti-glare protection opens automatically

when a safety door is opened. The robot is stopped and trans-

ferred into a safe state. Acknowledgement with the START /

RESET button must be carried out.

1‐20 Measures to be taken by the manufacturer 2020-09-01 B1154en

Anti-glare protection

Table of contents

Popular Welding System manuals by other brands

EWM

EWM MT221-301G F2 operating instructions

Elektra Beckum

Elektra Beckum 170 - 230 Amp Models Operating instruction

Strata

Strata ADVANCECUT 45 operating instructions

Luna

Luna WI 1505 manual

Lincoln Electric

Lincoln Electric K3924-1 Operator's manual

Miller Electric

Miller Electric Tandem Systems owner's manual