page 2

Document no. 909.0340.1-05

Issue date: 10.03.2021

Contents

Machine........................................................................... 3

Safety precautions........................................................... 4

Common Logic functions................................................. 5

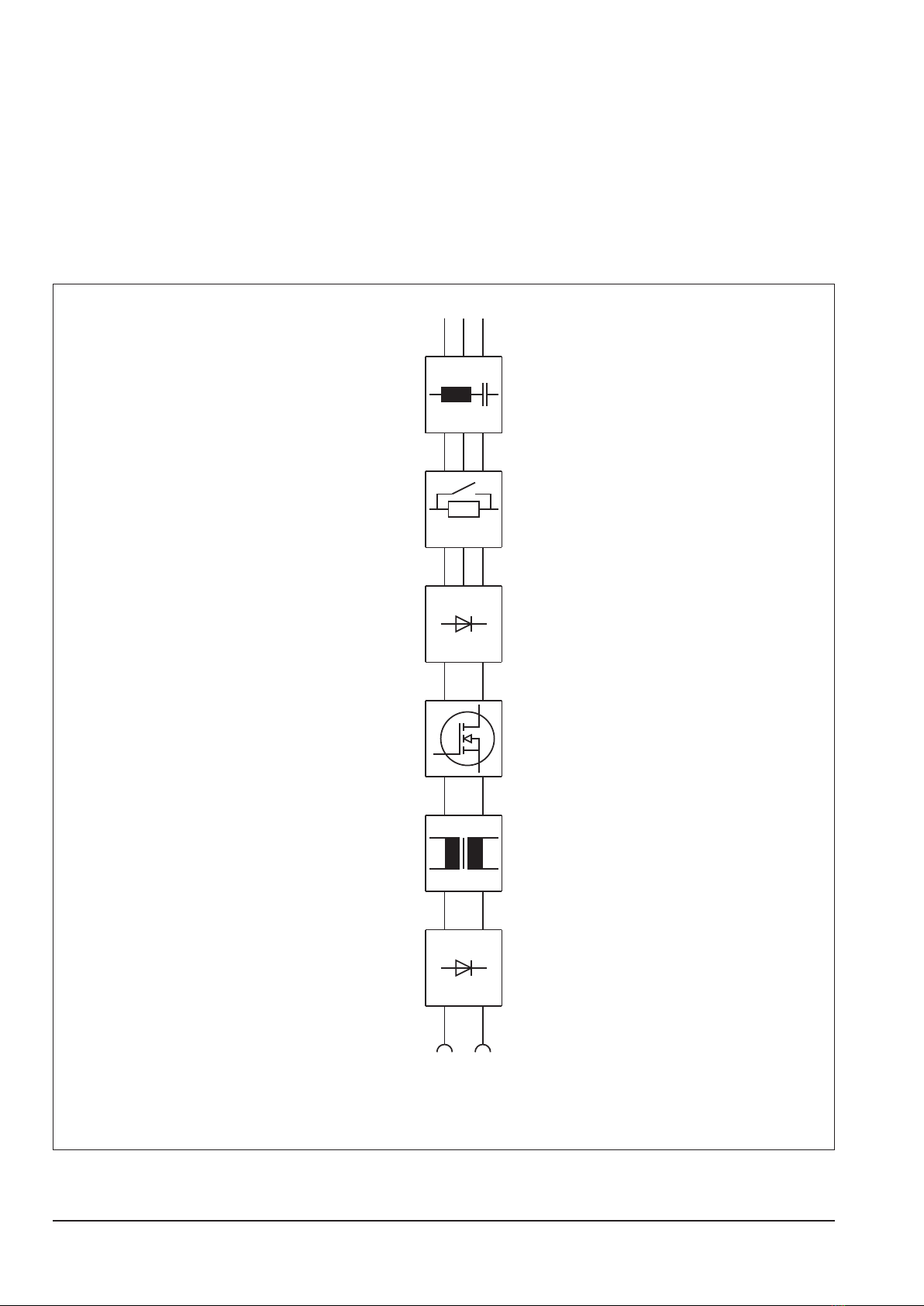

Inverter Principle.............................................................. 6

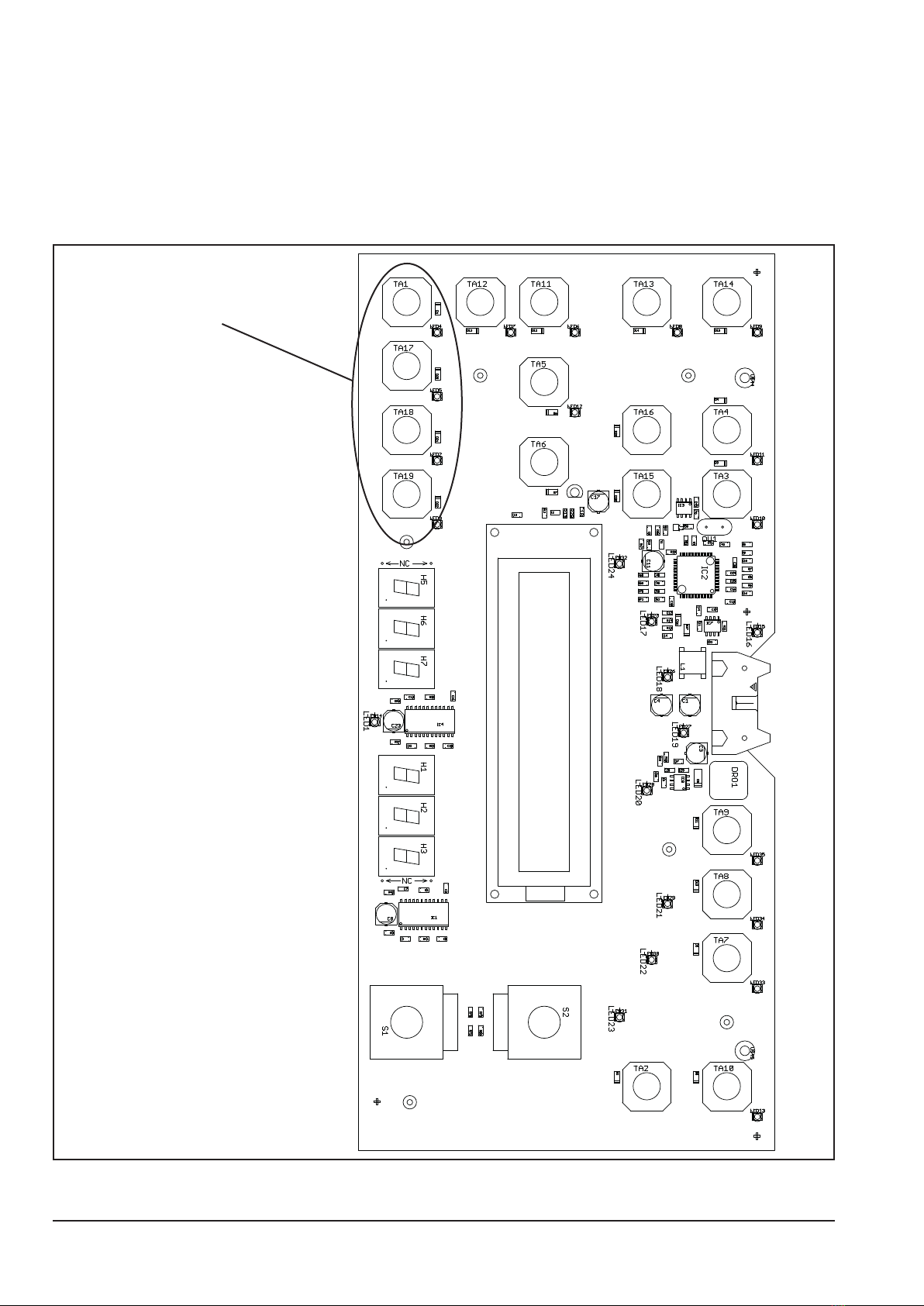

Pc-board DK-MAPRO...................................................... 7

Pc-board DK-DCI40 / DK-ACI40 ................................... 10

Pc-board DK-DCI45 / DK-ACI45 ....................................11

Pc-board DK-DCDRV .................................................... 13

Pc-board DK-ACDRV .................................................... 18

Pc-board DK-PWRUP ................................................... 20

Pc-board DP-S3NEFI .................................................... 21

Pc-board NEFI3x32....................................................... 22

Pc-board DK-GLCL3 ..................................................... 24

Pc-board DK-KSDC / DK-KSDCD / DK-KSDCN ........... 25

Pc-board DK-HFDC / DK-HFDC HV.............................. 27

Pc-board DK-UFI........................................................... 29

Pc-board DK-EMV......................................................... 29

Pc-board LSW ............................................................... 30

Current sensor VAC....................................................... 30

Control transformer........................................................ 31

Temperature monitoring................................................. 32

Supply voltages ............................................................. 33

Monitoring welding current ............................................ 34

Monitoring welding voltage............................................ 35

Cooling unit.................................................................... 36

Torch control.................................................................. 38

Remote control interface ............................................... 39

Monitoring primary current............................................. 40

Power-up cycle.............................................................. 41

Monitoring bus voltage .................................................. 42

Identication power units............................................... 43

Checking MOSFETs ...................................................... 44

Inside diagram diodes ................................................... 45

PE protection (optional)................................................. 45

List of error codes.......................................................... 46