Table of Contents

Warnings and Cautions for Safe Operation…………………1

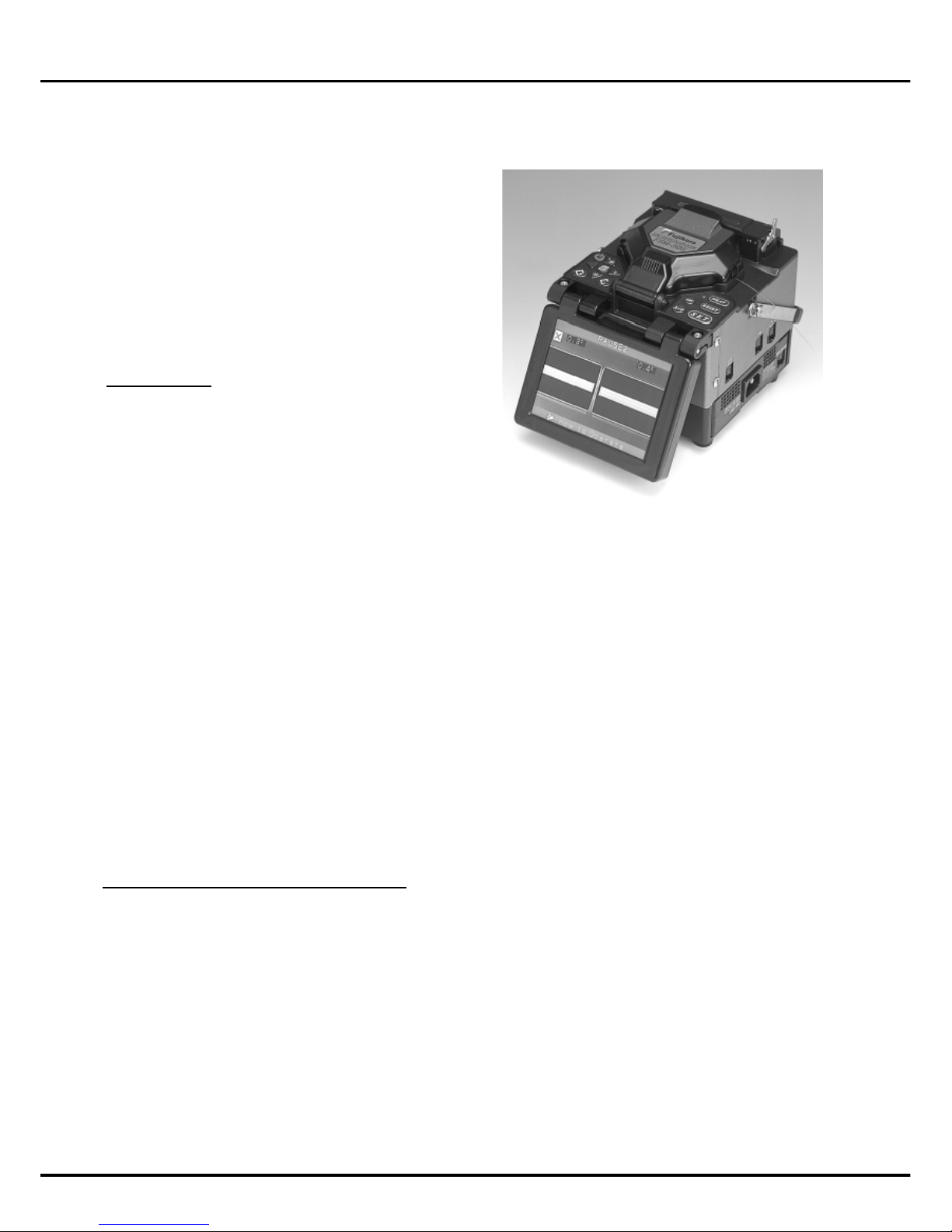

Introduction.............................................................................6

Description of Products...........................................................8

1. Components of Splicer .............................................................................................. 8

2. Other Necessary Items for Splicing Operation....................................................... 9

3. Description and Function of Splicer...................................................................... 10

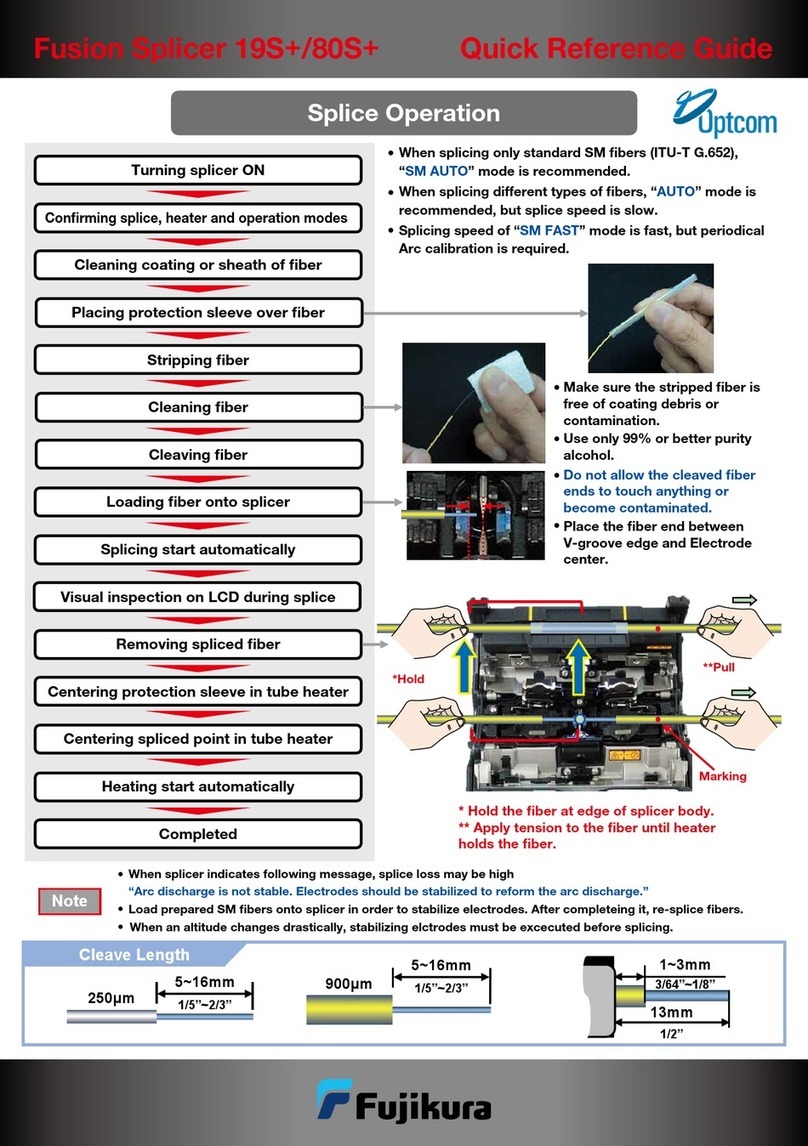

Basic Operation.....................................................................12

1. Inserting Power Supply into Splicer......................................................................12

2.Turning splicer "ON".............................................................................................. 16

3. Setting sleeve centering device ...............................................................................17

4. Cleaning optical fiber.............................................................................................. 17

5. Placing protection sleeve over fiber .......................................................................17

6. Stripping and cleaning fiber................................................................................... 17

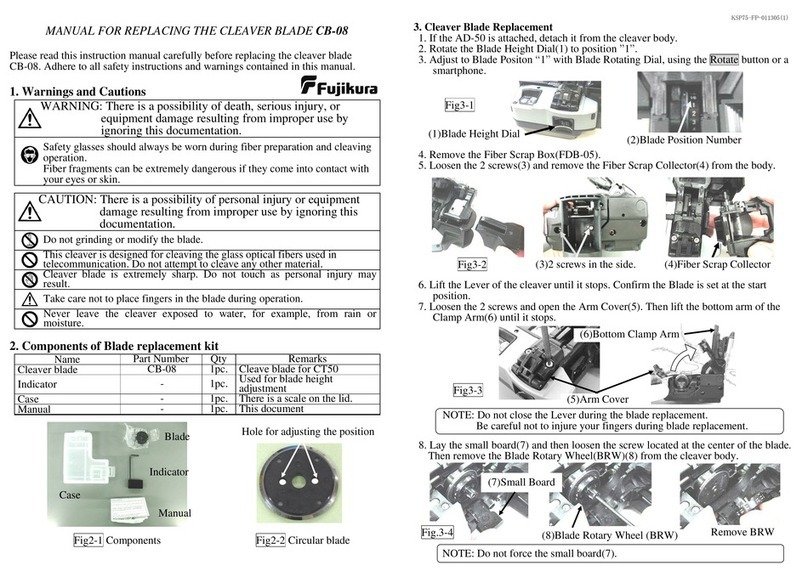

7. Fiber Cleaving.......................................................................................................... 18

8. Loading fiber to splicer........................................................................................... 19

9. Splicing procedure................................................................................................... 20

10. Removing spliced fiber.......................................................................................... 26

11. Hold left fiber with left hand here........................................................................26

12. Heating protection sleeve...................................................................................... 26

Maintenance of Splicing Quality..........................................28

1. Cleaning and Checking before Splicing ................................................................ 28

2. Periodical Checking and Cleaning.........................................................................30

Splice Menu...........................................................................34

1. Splice Mode..............................................................................................................34

2. Heater Mode............................................................................................................. 48

3. Arc Calibration ........................................................................................................ 52

4. Splice Option............................................................................................................ 54

5. Splice Result............................................................................................................. 56

Management Menu...............................................................60

1. Change of Operating Direction.............................................................................. 62

2. Power Save ............................................................................................................... 63

3. Menu Lock / Power On Option / Other Option.................................................... 64