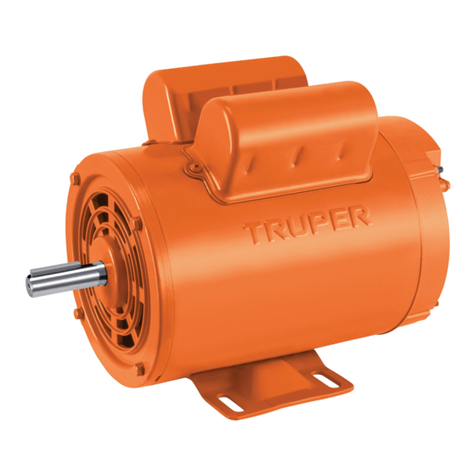

Truper MOE-1/2B User manual

ModelsCodes

MOE-1/2B

MOE-1/4B

Applies for:

102303

102301

LOW SPEED

1 725 RPM

Manual

CAUTION

ENGLISH

ESPAÑOL

Read this manual thoroughly

before using the tool.

1-capacitor

Single-phase

Motor

2

MOE-1/2B

MOE-1/4B

Contents

ENGLISH

CAUTION

Keep this manual for future references.

The illustrations in this manual are for reference

only. They might be different from the real tool.

To gain the best performance of

the tool, prolong the duty life,

make the Warranty valid if

necessary, and to avoid hazards

of fatal injuries please read and

understand this Manual before

using the tool.

Technical Data

Dimensions

Electric requirements

General safety warnings for power tools

Safety warnings for electric motors

Parts

Mounting

Connections

Troubleshooting

Notes

Authorized Service Centers

Warranty Policy

3

3

4

5

6

6

7

8

9

12

13

14

3

Technical Data

56 (NEMA)

IP 21

104 °F

Class F

Speed

1.15

Service factor

Maximum temperature

Insulation class

IP Grade

Frame

Open drip-proof

Type of enclosure

1725 RPM

Voltage

60 Hz

Frequency

115 V / 230 V

MOE-1/2B MOE-1/4B

102301102303

0.372 kW (1/2 Hp) 0.186 kW (1/4 Hp)

Low speed single phase electric motor with 1 capacitor

Code

Description

Rated power

5.2 A / 2.6 A8.8 A / 4.4 A

Current

9 kg 7 kg

Weight

5.6 A / 2.8 A9.4 A / 4.7 A

Current operating

at service factor

Capacitor with centrifugal switch

Start type

Shaft diameter

Shaft wedge 1 3/8” x 3/16” (3.5 cm x 0.5 cm)

5/8” (16 mm)

10.6” 11.4”

Length (A)

A

4.8”

6.2”

8.4”

1.1”

0.65”

r: 0.16”

3”

1.8”

3.5”

Dimensions

Base

ENGLISH

4ENGLISH

From 0 A up to 10 A

From 10 A up to 13 A

From 13 A up to 15 A

From 15 A up to 20 A

18 AWG (**)

16 AWG

14 AWG

8 AWG

16 AWG

14 AWG

12 AWG

6 AWG

3

(one grounded)

from 5.9’ to 49.2’ | higher than 49.2’

Ampere

capacity Number of

conductors (*)

Extension gauge

From 0 A up to 11 A

From 11 A up to 15 A

From 15 A up to 17 A

From 17 A up to 23 A

18 AWG (**)

16 AWG

14 AWG

10 AWG

16 AWG

14 AWG

12 AWG

8 AWG

3

(one grounded)

from 5.9’ to 49.2’ | higher than 49.2’

Ampere

capacity Number of

conductors (*)

Extension gauge

The equipment must be grounded to

prevent electric shock.

• Connect the plug into a properly grounded outlet. Not all

outlets are properly grounded, if you are not sure, check

with a qualified electrician.

• If the outlet available for the equipment is a 2-pole

(2-hole) outlet, DO NOT REMOVE OR ALTER THE

GROUND CONDUCTOR OF YOUR PLUG FOR ANY

REASON.

• Connection to the power source must

be made by an electrical professional, following one of the

diagrams on page 8.

• Use a separate electrical circuit for the

motor. This circuit must not have conductors with a gauge

smaller than 12 AWG, and must be protected with a 20 A

to 30 A time delay fuse depending on the current of each

model.

• Before connecting the motor to the power line, make

sure that the voltage is equal to that indicated on the

motor nameplate. Operating with a lower voltage will

damage the motor.

• The ground wire gauge must not be

smaller than the power supply wire gauge.

• It is recommended that the motor be supplied with a

circuit that includes a residual current circuit breaker with

a rated current of no more than 30 mA

• The motors have a built-in thermal protector to protect

them against overheating.

When using an

extension cord, make sure the

gauge is sufficient for the current

the equipment will draw.

Under-gauging will result in line

voltage drops, loss of power and

motor overheating. The following

tables show the correct gauges to

use depending on the length of the

cable and the ampere rating

indicated on the tool's nameplate.

If in doubt use the next higher

gauge.

All wiring, electrical connections and grounding of the system must comply with MEXICAN

OFFICIAL NOM-001-SEDE, ELECTRICAL INSTALLATIONS (UTILIZATION) or local codes and ordinances.

A qualified electrician must be employed.

230 Volts

115 Volts

* One of the conductors must be a grounding conductor. All conductors are of the same designation (gauge) including the grounding conductor.

** It is allowed to use it as long as the extensions themselves are provided with an overcurrent protection device.

AWG = American Wire Gauge. Reference: NMX-J-195-ANCE

Electric requirements

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

5

ENGLISH

General power tool

safety warnings

Work area

Keep your work area clean, and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Sparks generated by power tools may ignite the flammable material.

Keep children and bystanders at a safe distance while operating

the tool.

Distractions may cause loosing control.

Electrical Safety

The tool plug must match the power outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools.

Modified plugs and different power outlets increase the risk of electric shock.

Avoid body contact with grounded surfaces, such as pipes,

radiators, electric ranges and refrigerators.

The risk of electric shock increases if your body is grounded.

Do not expose the tool to rain or wet conditions.

Water entering into the tool increases the risk of electric shock.

Do not force the cord. Never use the cord to carry, lift or unplug

the tool. Keep the cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a tool outdoors, use an extension cord suitable

for outdoor use.

Using an adequate outdoor extension cord reduces the risk of electric shock.

If operating the tool in a damp location cannot be avoided, use

a ground fault circuit interrupter (GFCI) protected supply.

Using a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense

when operating a tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication.

A moment of distraction while operating the tool may result in personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as safety glasses, anti-dust mask, non-skid shoes,

hard hats and hearing protection used in the right conditions significantly

reduce personal injury.

Prevent unintentional starting up. Ensure the switch is in the

“OFF” position before connecting into the power source and /

or battery as well as when carrying the tool.

Transporting power tools with the finger on the switch or connecting power

tools with the switch in the “ON” position may cause accidents.

Remove any wrench or vice before turning the power tool on.

Wrenches or vices left attached to rotating parts of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at all times.

This enables a better control on the tool during unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep

hair, clothes and gloves away from the moving parts.

Loose clothes or long hair may get caught in moving parts.

If you have dust extraction and recollection devices connected

onto the tool, inspect their connections and use them correctly.

Using these devices reduce dust-related risks.

Power Tools Use and Care

Do not force the tool. Use the adequate tool for your

application.

The correct tool delivers a better and safer job at the rate for which it was designed.

Do not use the tool if the switch is not working properly.

Any power tool that cannot be turned ON or OFF is dangerous and should be

repaired before operating.

Disconnect the tool from the power source and / or battery

before making any adjustments, changing accessories or

storing.

These measures reduce the risk of accidentally starting the tool.

Store tools out of the reach of children. Do not allow persons

that are not familiar with the tool or its instructions to

operate the tool.

Power tools are dangerous in the hands of untrained users.

Service the tool. Check the mobile parts are not misaligned or

stuck. There should not be broken parts or other conditions that

may affect its operation. Repair any damage before using the

tool.

Most accidents are caused due to poor maintenance to the tools.

Keep the cutting accessories sharp and clean.

Cutting accessories in good working conditions are less likely to bind and are

easier to control.

Use the tool, components and accessories in accordance with

these instructions and the projected way to use it for the type of

tool when in adequate working conditions.

Using the tool for applications different from those it was designed for, could

result in a hazardous situation.

Service

Repair the tool in a Authorized Service Center

using only identical spare parts.

This will ensure that the safety of the power tool is maintained.

Children or people with reduced physical; sensory or mental

capabilities shall not operate the tool, neither inexperienced

people or without knowledge in the use of the tool, unless

supervised by a person responsible of their safety or if receiving

previous instructions about the tool operation.

Children shall be kept under supervision to double-check they will not play

with the tool. Tight supervision shall be used with children or disabled

persons to prevent from using or being close to any household tool.

WARNING! Read carefully all safety warnings and instruction listed below. Failure to comply with any of

these warnings may result in electric shock, fire and / or severe damage. Save all warnings and instructions for

future references.

This tool is in compliance with

the Official Mexican Standard

(NOM - Norma Oficial Mexicana).

6

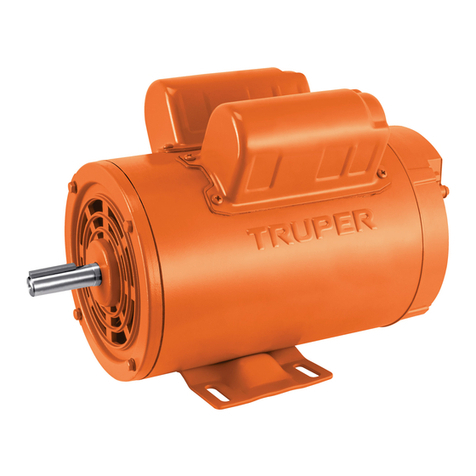

Ventilation

slots

Shaft

Name

plate

Starting

capacitor

Ventilation

slots

Power cord

inlet

Cable outlet

to ground

Connection

panel cover

Base with

fixing holes

Shaft

key

ENGLISH

Safety warnings

for electric motors

Parts

• Before installing or operating the

equipment, disconnect from any power source to avoid

electric shock and/or burns due to short circuits.

• Do not touch the bare (unprotected)

terminal. An electric shock will result.

• Do not touch any live lines simultaneously,

an electric shock will result.

• Do not install or handle equipment without

proper protective equipment or with wet hands.

• Do not install, connect, disconnect or handle the equipment

under load. With the exception of socket outlets, never

connect pluggable equipment when it is energized.

• If you do not have or doubt that you have the appropriate

technical knowledge, never install or handle the equipment.

• Before installation, be sure to read these operating

instructions carefully to ensure correct operation.

• Installation, maintenance and inspection of

electrical equipment must be carried out by qualified

technicians with special knowledge.

• Do not install the equipment in an environment with shock,

high temperature, humidity, dust, corrosive gases, excessive

vibration, etc. to avoid fire accidents and/or equipment

malfunction.

• Use electrical equipment with the voltage and current ratings

shown on the nameplate, otherwise it may cause

malfunctions and even dangerous situations.

• Tighten the terminal screws to the proper torque to prevent

overheating.

• Make sure that the equipment and the connection cables

are securely fastened.

• Always use terminals on the cables to which the equipment

is connected, these must be suitable for the load to be

supported.

• If there are several terminals in close proximity, each

terminal or conductor pole must be connected in parallel.

• If the equipment is equipped with grounding terminals,

make sure they are grounded.

• Always connect the equipment according to the indications

and diagrams provided by the manufacturer.

• Never exceed the operating ranges indicated by the

manufacturer.

• Do not modify the equipment.

• When the equipment is to be disposed of, it should be

disposed of as industrial waste.

• Do not connect aluminum terminals and conductors to the

switch directly.

• Always comply with the regulations in force at the place of

installation.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

7

A

1 2

3

B

ENGLISH

Mounting

• Before mounting the motor remove

the plastic cover from the shaft and rotate it by hand.

The motor shaft must rotate freely.

• The motor is mounted by means of its rigid base,

which must be fixed on a flat surface prepared for

installation according to the dimension table shown on

page 3, using four 5/16” (8 mm) diameter screws or

threaded bolts.

• If mounting on steel plate (A) it is recommended that

the thickness of the steel plate be no less than the bolt

diameter.

• For mounting on concrete or concrete slab (B), a free

bolt thread length of not less than 7/16” (11 mm) is

recommended.

• Use a drop level or laser to validate motor levelness.

If the motor is not level, use calibrated adjustment

blades to shim the motor base and correct any

deviations in flatness between surfaces.

Motor mounting

• The motor shaft includes a 3/16” (0.5 cm) x 1-3/8”

(3.5 cm) key to transmit motion to the coupling.

• Depending on the application, the shaft can be coupled

to the machine in three ways:

1. Gear or sprocket coupling.

2. Coupling by pulleys or flywheel.

3. Coupling by connecting joint.

• In any of the cases, a correct alignment of the couplings

must be ensured to reduce the vibration of the assembly

between the motor and the driven machine and to

extend the life of the bearings and avoid damage to the

motor shaft.

• The use of flexible couplings, capable of absorbing

small alignment deviations inherent to the installation

during operation of the equipment, is recommended.

• In applications of coupling by means of connecting

joints, the motor must be aligned both axially and radially

as shown in the image.

Shaft joint

CAUTION

Ground

8

Voltage configuration

Direction of rotation configuration

Connections

• To perform the wiring, make sure

that the lines are not energized.

• Remove the rear cover (A) to access the connection

panel.

• Make the connections according to the voltage

configuration that best suits your needs.

• When using any of the configurations shown above,

the motor shaft rotates clockwise as viewed from the

connection panel. To reverse counterclockwise rotation:

interchange the red and brown wires.

Ground

Black

Blue

Red

Orange

Brown

White

Line 1

Line 2

230 Volts115 Volts

1

2

3

4

Line 1

Line 2

1

2

3

4

Black

Blue

Red

Orange

Brown

White

A

ENGLISH

Mounting

• For belt and chain drive applications, verify that the

centers of the drive and driven pulleys and/or sprockets

are aligned with each other as shown.

• Proper alignment and mounting will reduce motor

noise and workload vibration.

CAUTION

9

Troubleshooting

ENGLISH

The engine takes a

long time to

accelerate.

Motor does not start

after initial

installation.

The shaft rotates in

the opposite

direction.

The overload

protector trips

continuously.

Engine has been

running and then will

not start.

• Defective bearings.

• Defective capacitor.

• Faulty stationary switch.

• Voltage too low.

• The fan guard is bent and in contact with

the fan.

• The motor is damaged and the rotor is

hitting the stator.

• The motor has bad wiring.

• Wiring configured to rotate in the

opposite direction.

• Ambient temperature too high.

• The winding is shorted or grounded.

• Protector may be defective.

• Excessive load.

• The motor or its capacitor may have

failed.

• The stator is shorted or has gone to

ground. The motor will hum and the circuit

breaker or fuse will trip.

• The starter switch has failed.

• The fuse or circuit breaker has tripped.

• Motor overloaded or load stuck.

• The bearing must be replaced.

• Refer to a Authorized Service

Center for repair.

• Inspect and repair the switch contacts and connections.

• Make sure the voltage is within 10% of the motor

rating. If not, contact the power company or check to see

if other equipment is drawing power away from the

motor.

• Refer to a Authorized Service

Center for repair.

• Check that the motor is correctly wired according to the

information supplied with the motor.

• Rewire the motor according to the configuration

diagram on page 8.

• Check that the motor receives sufficient air for proper

cooling. The motor is designed to operate below 104 °F

Note: A properly running motor may be hot to the touch.

• Inspect the stator for defects or loose or cut wires that

may cause it to ground.

• Refer to a Authorized Service

Center for repair.

• Verify that the load is not jammed. If the motor is a

a replacement, verify that the rating is the same as the

old motor. If the old motor was a special design, a stock

motor may not be able to match the performance.

Remove the load from the motor and inspect the

amperage draw of the motor under load. It should be

less than the full load rating stamped on the nameplate.

• First discharge the capacitor. To check the capacitor, set

the voltmeter to the RX100 scale and touch its probes to

the capacitor terminals. If the capacitor is OK, the needle

will jump to zero ohms and back up again. A steady zero

ohms indicates a short circuit; a steady high ohm

indicates an open circuit.

• Disassemble the motor and inspect the winding and

internal connections. A burned stator will show a burn

mark. The motor must be replaced or the stator

rewound.

• Disassemble the motor and inspect the centrifugal and

stationary switches. The centrifugal switch weights should

move freely in and out. Make sure the switch is not loose

on the shaft. Inspect the contacts and connections of the

stationary switch. Replace the switch if the contacts are

burned or pitted

• Replace the fuse or reset the circuit breaker.

• Inspect to see that the load is free. Check motor amp

draw against nameplate rating.

Problem Cause Solution

Troubleshooting

10 ENGLISH

Motor runs, but shuts

off.

The motor vibrates.

Run capacitor failure.

Starting capacitors

are constantly failing.

A loud rubbing or

squeaking noise is

produced at start-up.

• Voltage drops.

• Load increase.

• Unbalanced load.

• Unbalanced rotor.

• Defective motor bearings.

• Motor misaligned with load.

• Too much backlash at motor ends.

• Defective windings.

• Possible power surge in the motor caused

by lightning or other high transient voltage.

• Ambient temperature is too high.

• The motor starts too often.

• Motor is not coming up to speed fast

enough.

• The starter switch may be defective,

preventing the motor from coming out of

the starter winding.

• Motor voltage is too low.

• The rotor may be hitting the stator.

• If the voltage is less than 10% of the motor rating,

contact the power company.

• Check to see if any other equipment is drawing

power from the motor and if the motor is running on

an extension cord. Verify that the extension cord is the

proper gauge for the motor current.

• Remove the load from the motor for inspection.

Verify that the shaft is not bent. Rule of thumb:

0.001”deflection per inch of shaft length.

• Remove the load from the motor to inspect it. If it

feels rough and vibrates but the bearings are OK, the

rotor may have been improperly balanced at the

factory. Refer to a Authorized

Service Center for repair.

• If the bearings are bad, you will hear a noise or feel a

roughness. Go to a Authorized

Service Center to replace the bearings. Add grease if

the bearings have fittings.

• Realign the load.

• With the motor disconnected from power, rotate the

shaft. It should move, but with some resistance. If the

shaft moves in and out freely, this indicates a preload

problem and the bearings may need additional shims.

• Check to see if the winding is shorted or open. Amps

may also be high. Refer to a Au-

thorized Service Center for repair.

• This is a common problem. Install an over voltage

protector or motor protector relay.

• Verify that the ambient temperature does not exceed

the motor nameplate.

• Check the duty cycle. Capacitor manufacturers

recommend no more than 20 starts of three-second.

Install a capacitor with a higher voltage rating or add a

bleeder resistor to the capacitor.

• The motor may not be properly sized. Check the time

it takes for the motor to reach speed. Most

single-phase motors with starting capacitors should

reach speed in three seconds. If not, the capacitors

may be failing.

• Replace the switch.

• Verify that the motor voltage is within 10% of the

nameplate value.

• Make sure that the motor has not been damaged

during transport.

• Damage to the frame may not be repairable. If you

cannot see physical damage, inspect the motor rotor

and stator for scuff marks. If there are signs of scuffing,

the motor should be replaced. Sometimes, simply

disassembling and reassembling the motor will

eliminate the scuffing.

Sometimes end bells become misaligned during

shipping.

Problem Cause Solution

11

Troubleshooting

ENGLISH

Bearings fail

continuously.

Elevated or

abnormal noise.

• High ambient temperature.

• Motor load may be excessive or

unbalanced.

• Defect of the components of the driven

machine.

• Misaligned base or unlevel motor.

• Incorrect motor rotation direction.

• Loose fixing screws.

• Deteriorated bearings.

• If the engine is operated in a warm environment, a

different type of bearing grease may be required. Contact

a Authorized Service Center

for a recommendation of the proper type of grease.

• In addition to checking the load, also inspect the drive

belt tension to make sure it is not tight or perhaps too

high. An unbalanced tip will also cause the bearings to

fail.

• Check the power transmission of the applied load.

• Align and level the motor and load.

• Reverse the direction of rotation of the load.

• Tighten the fixing bolts.

• Replace bearings.

Problem Cause Solution

If problems persist despite performing the recommended corrective actions,

contact a Authorized Service Center.

12

Notes

ENGLISH

13

ENGLISH

Authorized Service Centers

In the event of any problem contacting a Truper Authorized Service Center, please see our webpage www.truper.com

to get an updated list, or call our toll-free numbers 800 690-6990 or 800-018-7873 to get information about the

nearest Service Center.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

CIUDAD DE

MÉXICO

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

14 www.truper.com

06-2022

MOE-1/2B

MOE-1/4B

102303

102301

ENGLISH

1

YEAR

Warranty

policy

Stamp of the business. Delivery date:

Code Model Brand

Warranty. Duration: 1 year. Coverage: parts, components and workmanship against manufacturing or

operating defects, except if used under conditions other than normal; when it was not operated in accordance

with the instructive; was altered or repaired by personnel not authorized by Truper®. To make the warranty

valid, present the product, stamped policy or invoice or receipt or voucher, in the establishment where you

bought it or in Corregidora 22, Centro, Cuauhtémoc, CDMX, 06060, where you can also purchase parts,

components, consumables and accessories. It includes the costs of transportation of the product that derive

from its fulfillment of its service network. . Phone number 800-018-7873. Made in China. Imported by Truper,

S.A. de C.V. Parque Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257, Phone number

761 782 9100.

14 ESPAÑOL

1

AÑO

Póliza de

Garantía

www.truper.com

06-2022

Códigos Modelos Marca

Sello del establecimiento comercial. Fecha de entrega:

MOE-1/2B

MOE-1/4B

102303

102301

Garantía. Duración: 1 año. Cobertura: piezas, componentes y mano de obra contra defectos de fabricación o

funcionamiento, excepto si se usó en condiciones distintas a las normales; cuando no fue operado conforme

instructivo; fue alterado o reparado por personal no autorizado por Truper®. Para hacer efectiva la garantía

presente el producto, póliza sellada o factura o recibo o comprobante, en el establecimiento donde lo compró

o en Corregidora 22, Centro, Cuauhtémoc, CDMX, 06060, donde también podrá adquirir partes, componentes,

consumibles y accesorios. Incluye los gastos de transportación del producto que deriven de su cumplimiento de

su red de servicio. Tel. 800-018-7873. Made in/Hecho en China. Importador Truper, S.A. de C.V. Parque

Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257, Tel. 761 782 9100.

13

Centros de Servicio Autorizados

ESPAÑOL

En caso de tener algún problema para contactar un Centro de Servicio Autorizado Truper

®

consulte nuestra página

www.truper.com donde obtendrá un listado actualizado, o llame al: 800 690 6990 u800-018-7873 donde le

informarán cuál es el Centro de Servicio más cercano.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

CIUDAD DE

MÉXICO

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

12

Notas

ESPAÑOL

11

ESPAÑOL

Solución de problemas

Los rodamientos

fallan continuamente.

Ruido elevado o

anormal.

• Temperatura ambiente elevada.

• La carga del motor puede ser excesiva o

estar desequilibrada.

• Defecto de los componentes de la

maquina accionada.

• Base desalineada o motor desnivelado.

• Sentido de rotación del motor incorrecto.

• Tornillos de fijación sueltos.

• Rodamientos deteriorados.

• Si el motor se utiliza en un ambiente cálido, puede ser

necesario un tipo diferente de grasa para los rodamien-

tos. Acuda a un Centro de Servicio Autorizado

para que le recomienden el tipo de

grasa adecuada.

• Además de comprobar la carga, inspeccione también la

tensión de la correa de transmisión para asegurarse de

que no está tensa o tal vez demasiado alta. Una punta

desequilibrada también hará que los cojinetes fallen.

• Verifique la transmisión de fuerza de la carga aplicada.

• Alinee y nivele el motor y la carga.

• Invierta el sentido de rotación de la carga.

• Apriete los tornillos de fijación.

• Reemplace los rodamientos.

Problema Causa Solución

Si los problemas persisten a pesar de realizar las acciones correctivas recomendadas,

contacte a un Centro de Servicio Autorizado .

Solución de problemas

10 ESPAÑOL

El motor funciona,

pero se apaga.

El motor vibra.

Fallo del capacitor de

marcha.

Los capacitores de

arranque fallan

constantemente.

Al arrancar se

produce un fuerte

ruido de rozamiento

o chirrido.

• Caída de voltaje.

• Aumento de la carga.

• Carga desequilibrada.

• Rotor desbalanceado.

• Rodamientos del motor defectuosos.

• Motor desalineado con la carga.

• Demasiado juego en los extremos del

motor.

• Bobinado defectuoso.

• Posible sobrecarga de energía en el

motor causada por un rayo u otra tensión

transitoria elevada.

• La temperatura ambiente es demasiado

elevada.

• El motor se pone en marcha con

demasiada frecuencia.

• El motor no está llegando a la velocidad

suficientemente rápido.

• El interruptor de arranque puede estar

defectuoso, impidiendo que el motor

salga del devanado de arranque.

• La tensión del motor es demasiado

baja.

• Si la tensión es inferior al 10% de la potencia nominal

del motor, póngase en contacto con la compañía de

electricidad.

• Compruebe si algún otro equipo está tomando energía

del motor y si éste está funcionando con un cable de

extensión. Verifique que el cable de extensión sea del

calibre adecuado para la corriente del motor.

• Retire la carga del motor para inspeccionarlo. Verifique

que el eje no esté doblado. Regla de oro: 0.001”(0.02

mm) de desviación por cada pulgada de longitud del eje.

• Retire la carga del motor para inspeccionarlo. Si se

siente áspero y vibra pero los cojinetes están bien, puede

ser que el rotor haya sido mal balanceado en la fábrica.

Acuda a un Centro de Servicio Autorizado

para su reparación.

• Si los cojinetes están mal, se escuchará un ruido o se

sentirá una aspereza. Acuda a un Centro de Servicio

Autorizado para sustituir los

rodamientos. Añada grasa si los rodamientos tienen

accesorios.

• Vuelva a alinear la carga.

• Con el motor desconectado de la corriente, gire el eje.

Debería moverse, pero con cierta resistencia. Si el eje se

mueve hacia adentro y hacia afuera libremente, esto

indica un problema de precarga y los cojinetes pueden

necesitar calzos adicionales.

• Compruebe si el devanado está en cortocircuito o

abierto. Los amperios también pueden ser altos. Acuda

a un Centro de Servicio Autorizado

para su reparación.

• Es un problema común. Instale un protector de sobre

tensión o un guarda motores.

• Verifique que la temperatura ambiente no exceda la

placa de datos del motor.

• Verificar el ciclo de trabajo. Los fabricantes de

condensadores recomiendan no más de 20 arranques de

tres segundos por hora. Instale un condensador con una

tensión nominal más alta o añada una resistencia de

purga al condensador.

• Es posible que el motor no esté bien dimensionado.

Verifique el tiempo que tarda el motor en alcanzar la

velocidad. La mayoría de los motores monofásicos con

condensadores de arranque deberían alcanzar la

velocidad en tres segundos. De lo contrario, los

condensadores pueden estar fallando.

• Cambie el interruptor.

• Verifique que la tensión del motor esté dentro del 10%

del valor de la placa de datos.

• Asegúrese de que el motor no haya sufrido daños

durante el transporte.

• Los daños en el bastidor pueden no ser reparables. Si

no puede ver el daño físico, inspeccione el rotor y el

estator del motor para ver si hay marcas de golpe. Si hay

signos de rozamiento, el motor debe ser sustituido. A

veces, el simple hecho de desmontar y volver a montar

el motor elimina las rozaduras.

A veces, las campanas finales se desajustan durante el

transporte.

Problema Causa Solución

9

ESPAÑOL

Solución de problemas

El motor tarda

mucho en acelerar.

El motor no arranca

tras la instalación

inicial.

El eje gira en

dirección contraria.

El protector de

sobrecarga se dispara

continuamente.

El motor ha estado

en marcha y luego

no arranca.

• Rodamientos defectuosos.

• Condensador defectuoso.

• Interruptor estacionario defectuoso.

• Tensión demasiado baja.

• El protector del ventilador se ha doblado

y está en contacto con el ventilador.

• El motor está dañado y el rotor golpea el

estator.

• El motor tiene mal el cableado.

• Cableado configurado para girar en la

dirección contraria.

• Temperatura ambiente demasiado alta.

• El devanado está en cortocircuito o

conectado a tierra.

• El protector puede estar defectuoso.

• Carga excesiva.

• El motor o su condensador pueden haber

fallado.

• El estator está en cortocircuito o se ha ido

a tierra. El motor emitirá un zumbido y el

disyuntor o el fusible se dispararán.

• El interruptor de arranque ha fallado.

• Se ha disparado el fusible o el disyuntor.

• Motor sobrecargado o carga atascada.

• El rodamiento debe ser reemplazado.

• Acuda a un Centro de Servicio Autorizado

para su reparación.

• Inspeccione y repare los contactos y las conexiones del

interruptor.

• Asegúrese de que la tensión está dentro del 10% de la

capacidad nominal del motor. Si no es así, póngase en

contacto con la compañía eléctrica o compruebe si otros

equipos están consumiendo energía fuera del motor.

• Acuda a un Centro de Servicio Autorizado

para su reparación.

• Compruebe que el motor está correctamente cableado

según la información suministrada con el motor.

• Volver a cablear el motor según el diagrama de

configuración de la página 8.

• Compruebe que el motor recibe suficiente aire para

una correcta refrigeración. El motor está diseñado para

funcionar a menos de 40 °C Nota: Un motor que

funciona correctamente puede estar caliente al tacto.

• Inspeccione el estator en busca de defectos o de cables

sueltos o cortados que puedan hacer que se vaya a tierra.

• Acuda a un Centro de Servicio Autorizado

para su reparación.

• Verifique que la carga no está atascada. Si el motor es

de reemplazo, verifique que el valor nominal sea el

mismo que el del motor antiguo. Si el motor anterior era

un diseño especial, es posible que un motor de serie no

pueda igualar el rendimiento. Retire la carga del motor e

inspeccione el consumo de amperios del motor con

carga. Debe ser menor que el valor nominal a plena

carga estampado en la placa de datos.

• Primero descargue el condensador. Para comprobar el

condensador, ponga el voltímetro en la escala RX100 y

toque con sus sondas los terminales del condensador. Si

el condensador está bien, la aguja saltará a cero ohmios

y volverá a subir. Un valor constante de cero ohmios

indica un cortocircuito; un valor constante de altos

ohmios indica un circuito abierto.

• Desmonte el motor e inspeccione el bobinado y las

conexiones internas. Un estator quemado mostrará una

marca de quemadura. El motor debe ser reemplazado o

el estator rebobinado.

• Desmonte el motor e inspeccione los interruptores

centrífugos y estacionarios. Los pesos del interruptor

centrífugo deben moverse libremente hacia dentro y

hacia fuera. Asegúrese de que el interruptor no está

suelto en el eje. Inspeccione los contactos y las

conexiones del interruptor estacionario. Sustituya el

interruptor si los contactos están quemados o picados.

• Sustituir el fusible o reajustar el disyuntor.

• Inspeccione para ver que la carga está libre. Verificar el

consumo de amperios del motor en comparación con el

valor nominal de la placa de datos.

Problema Causa Solución

This manual suits for next models

3

Table of contents

Other Truper Engine manuals

Popular Engine manuals by other brands

LZ design

LZ design FES-LS8-M100 manual

Siemens

Siemens Simotics HV C 1NA14544WA600AG0-Z Operating instructions and installation instructions

Harbor Freight Tools

Harbor Freight Tools Predicator 212cc owner's manual

Man

Man D 0824 LE 201 operating instructions

Wartsila

Wartsila ?31DF Series Product guide

Fiamma

Fiamma 98655Z111 Installation and usage instructions